I-twin screw extrudersdlala indima ebalulekileyo kwimveliso yale mihla ngokuqinisekisa iinkqubo zemveliso ezisebenzayo nezingabiziyo. Uyilo lwabo oluphambili lwenza abavelisi bafezekise iziphumo eziphezulu ngelixa benciphisa inkcitho kunye nokusetyenziswa kwamandla.

- Imakethi yehlabathi ye-twin screw extruder ifikelele kwi-USD 1,128.1 yezigidi ngo-2022.

- Kuqikelelwa ukuba iya kukhula ibe yi-USD 1,649.5 yezigidi nge-2031.

- Imakethi ikhula kwi-CAGR ezinzileyo ye-4.5%, iqaqambisa imfuno yabo ekhulayo.

Aba matshini, kubandakanywa oomatshini bokudibanisa izikrufu abangamawele kunye nemigca ye-twin screw extrusion, babonelela ngokuqina okungahambelaniyo kunye nokuguquguquka, okubenza babaluleke kakhulu kumashishini kwihlabathi liphela. Ukongeza, oomatshini be-tube extrusion baphucula ngakumbi amandla emveliso, baqinisa ukubaluleka kwetekhnoloji yesikrufu samawele kwicandelo lemveliso.

Ukuqonda Twin Screw Extruders

Yintoni iTwin Screw Extruders?

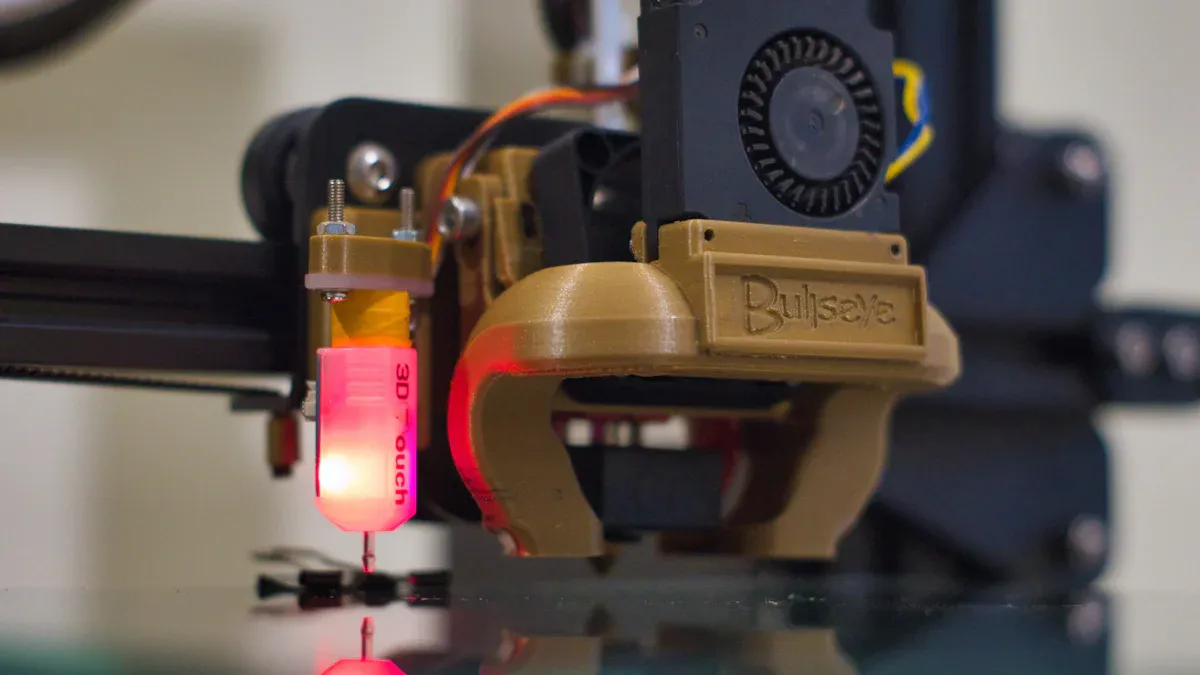

I-Twin screw extruders ngoomatshini abaphambili abayilelwe ukuqhubekekiswa kwemathiriyeli. Ziquka izikrufu ezibini ezidibanisayo ezigcinwe ngaphakathi komphanda. Ezi zikrufu zijikeleza ukuze zigqithise, zixube, kwaye ziqhube imathiriyeli ngokufanelekileyo. Amacandelo olwakhiwo abandakanya i-mainframe, i-gearbox yokuhambisa, inkqubo yokuthambisa, inkqubo yamanzi okupholisa, inkqubo yokufunxa, kunye nenkqubo yokondla. Izikrufu zenziwe ngezinto ezomeleleyo ezifana nentsimbi ye-nitriding, eqinisekisa ukusebenza kwexesha elide. Imigqomo yenzelwe ukutshintshwa nokugcinwa lula, oko kwandisa ukusebenza kakuhle.

Uyilo lwe-twin screw extruders luqinisekisa ukukhutshwa okuchanekileyo kwe-axial kunye ne-radial. Oku kuchanekileyo kuphucula umgangatho wokucubungula kunye nokunciphisa inkunkuma yezinto eziphathekayo. Ukongeza, oomatshini banokuthatha indawo ezininzi zokutya, bebenza bafanelekele ukuphatha izixhobo kumazwe ahlukeneyo. Ukuguquguquka kwabo kunye nokwakhiwa okuqinileyo kubenza ilitye lembombo kwimveliso yanamhlanje.

Zisebenza njani iTwin Screw Extruders?

I-twin screw extruders isebenza ngokudityaniswa kweenkqubo zoomatshini kunye ne-thermal. Izikrufu zijikeleza ngaphakathi kombhobho ukuhambisa, ukuxuba, ukunyibilika, kunye ne-homogenize imathiriyeli. Icandelo ngalinye lidlala indima ebalulekileyo ekufezekiseni inkqubo esebenzayo.

| Icandelo | Umsebenzi |

|---|---|

| Umphanda kunye nezikrufu | Jikelezisa ukuhambisa, ukuxuba, ukunyibilika, kunye ne-homogenize imathiriyeli; yenzelwe iimfuno ezithile zokusetyenzwa. |

| Inkqubo yokuqhuba | Amandla kunye nokulawula ukujikeleza kwe-screw, ukuqinisekisa ukusebenza kakuhle kunye nomgangatho kwinkqubo ye-extrusion. |

| Ibhokisi yegiya | Lungisa ukwahluka kwesantya se-screw, ukucheba okuphembelelayo, ukuxuba, kunye nezenzo zokuxova. |

| Ulawulo kunye nokuBeka iliso | Ivumela ukubeka esweni kunye nohlengahlengiso lweeparamitha ezifana nesantya se-screw kunye neeprofayile zobushushu. |

Iinkqubo zokutya ezilungelelanisiweyo zenza ulawulo oluchanekileyo kwigalelo lezinto eziphathekayo, ukuqinisekisa umgangatho wemveliso ongaguqukiyo. Iisistim zolawulo ezikumgangatho ophezulu esweni iiparameters ezifana nesantya se-screw kunye nobushushu, ezivumela abaqhubi ukuba balungise inkqubo. Eli nqanaba lolawulo liqinisekisa ukusebenza kakuhle kunye nokunciphisa ukusetyenziswa kwamandla.

Usetyenziso olungundoqo kuMveliso

I-twin screw extruders ngoomatshini abaguquguqukayo abasetyenziswa kumashishini ahlukeneyo. Kwiicandelo leplastiki, zibalulekile ekuveliseni iimveliso ezikumgangatho ophezulu njengemibhobho, iifilimu, kunye neeprofayili. Umzi-mveliso wamachiza uxhomekeke kwaba matshini ukuze kuqhubeke igranulation emanzi, ukuxuba ubunzima begelatin emanzi, kunye nokudala i-amorphous dispersions eqinileyo ukuphucula ukunyibilika kweziyobisi. Bakwadlala indima ebalulekileyo ekulayisheni amachiza kwiipholima zezixhobo zokuhambisa iziyobisi.

| Isicelo | Ubungakanani beMarike (2025) | I-CAGR (%) |

|---|---|---|

| Iimveliso zePlastiki | XX yezigidi | XX% |

| Ukutya kunye neFind Extrusion | XX yezigidi | XX% |

| Amachiza | XX yezigidi | XX% |

Ukulungelelaniswa kwe-twin screw extruders ivumela abavelisi ukuba basebenzise izixhobo ezifanayo zophando kunye nemveliso. Oku scalability kubenza babe lolona khetho lufanelekileyo kumashishini afuna ukuguquguquka nokusebenza kakuhle. Ukukwazi kwabo ukuphatha izinto ezahlukeneyo kunye neenkqubo ziqinisekisa ukufaneleka kwazo okuqhubekayo kwimveliso yanamhlanje.

Iindleko-Ukusebenza kakuhle kweTwin Screw Extruders

UkuSebenza koMbane kunye neNkunkuma eNcitshisiweyo

I-twin screw extruders igqwesa ekusebenzeni kakuhle kwamandla, izenza zibe aisisombululo esingabizi kakhulu kubavelisi. Uyilo lwabo oluphambili lunciphisa ukusetyenziswa kwamandla ngokulungisa iinkqubo zoomatshini kunye ne-thermal ezibandakanyekayo kwi-extrusion yezinto. Izikrufu ze-intermeshing ziqinisekisa ukuhamba kwezinto eziphathekayo, ukunciphisa imfuno yokufaka amandla amaninzi. Ukongeza, iinkqubo ezichanekileyo zolawulo zivumela abaqhubi ukuba bahlengahlengise iiparamitha ezifana nobushushu kunye nesantya se-screw, okomeleza ngakumbi ukonga amandla.

Ukunciphisa inkunkuma lolunye uncedo olubalulekileyo. Ukuxuba okusebenzayo kunye ne-homogenization ye-homogenization ye-twin screw extruders iqinisekisa ukulahleka kwezinto ezincinci ngexesha lokucubungula. Ngokugcina umgangatho wemveliso ongaguqukiyo, aba matshini banciphisa imfuno yokuphinda basebenze kwakhona okanye bachithe, begcina ixesha kunye nezixhobo. Amashishini abeka phambili uzinzo azuza kakhulu kule nkalo, njengoko ihambelana neenjongo zabo zokusingqongileyo ngelixa inciphisa iindleko zokusebenza.

Ingcebiso:Utyalo-mali kwizixhobo ezonga amandla njenge-twin screw extruders ayithobanga amatyala asetyenziswayo kuphela kodwa ikwanegalelo kwinkqubo yokuvelisa eluhlaza.

Ukuqina kwexesha elide kunye ne-ROI

Iulwakhiwo oluqinileyo lwe-twin screw extrudersiqinisekisa ukuqina kwexesha elide, okwenza kube yinto ethembekileyo yokuzikhethela kwimveliso ephezulu. Izinto ezinje ngezikrufu kunye nemigqomo zenziwe ngemathiriyeli yokuqina okuphezulu njengentsimbi ye-nitriding, ekwaziyo ukumelana nokuguga nokukrazuka ixesha elide. Iindlela zokuvelisa eziphucukileyo, ezibandakanya ukucima kunye ne-nitriding, ziphucula ubomi obude bala malungu, ukunciphisa ukuphindaphindeka kokutshintshwa.

Oku kuqina kuguqulela kwimbuyekezo ephezulu kutyalo-mali (ROI). Abavelisi baxhamla kwiindleko zokulungisa ezincitshisiweyo kunye nexesha elincinci lokunciphisa, elichaphazela ngokuthe ngqo imveliso. Ngokuhamba kwexesha, utyalo-mali lokuqala kwi-twin screw extruder ihlawula ngokusebenza okufanayo kunye neendleko zokusebenza eziphantsi. Iinkampani ezifuna ukwandisa i-ROI yazo zihlala zikhetha aba matshini ngenxa yokuthembeka kwabo okuqinisekisiweyo kunye nokusebenza kakuhle kweendleko.

Uyilo lweModyuli yokuNxulumana

Uyilo lweemodyuli lwe-twin screw extruders lubonelela ngezinto ezininzi ezingafaniyo, ezivumela abavelisi ukuba balungelelanise izixhobo kwiimfuno ezahlukeneyo zemveliso. Aba matshini banokwenziwa ngokwezifiso kunye nezikrufu ezitshintshayo, imigqomo, kunye namanye amacandelo okuphatha izinto ezahlukeneyo kunye neenkqubo. Oku kuguquguquka kubenza bafanelekele uluhlu olubanzi lwezicelo, ukusuka kwiiplastiki kunye namachiza ukuya kwimveliso yokutya kunye nokutya.

Abavelisi banokuphinda balinganise imisebenzi yabo ngokufanelekileyo nge-modular twin screw extruders. Ngokuphucula amacandelo athile okanye ukongeza iinkqubo ezincedisayo, banokunyusa umthamo wokuvelisa ngaphandle kokutshintsha umatshini wonke. Oku kuziqhelanisa akunciphisi nje kuphela inkcitho eyinkunzi kodwa kukwaqinisekisa ukuba izixhobo zihlala zifanelekile njengoko iimfuno zemveliso zikhula.

Phawula:I-Modular twin screw extruders lolona khetho lubalaseleyo kumashishini ajonge kubungqina bexesha elizayo kwiinkqubo zabo zokuvelisa.

Ukuveliswa koMqulu oPhezulu kunye ne-Twin Screw Extruders

Co-Rotating Screw Technology

Itekhnoloji ye-screw ejikelezayo iphucula ukusebenza kakuhle kwe-twin screw extruders ngokulungiselela ukuhamba kwezinto kunye nokuxuba. Olu luyilo luqinisekisa ukucheba okuhambelanayo kunye nokusabalalisa ubushushu, okubaluleke kakhulu kwimveliso ephezulu. Izikrufu zijikeleza kwicala elifanayo, zenze umphumo wokuzisula othintela ukwakhiwa kwezinto kunye nokuphucula ukusebenza kakuhle.

| Umba | Inkcazo |

|---|---|

| Ulawulo loxinzelelo | Uxinzelelo oluphezulu lunokukhokelela ekuvuzeni okuphezulu kwe-overflight, okuchaphazela ubushushu bokunyibilika kunye nokwehla okunokwenzeka. |

| I-Screw Design | Ukukhethwa kwezikrufu kuchaphazela i-gradient yoxinzelelo kunye nokusebenza kakuhle kwenkqubo ye-extrusion. |

| Iiparamitha zokuSebenza | Izinto ezifana nexesha lokuhlala, indawo engaphezulu, kunye namanqanaba evacuum achaphazela kakhulu ukusebenza kwe-devolatilization. |

Le teknoloji ixhasa amazinga emveliso ukuya kuthi ga kwi-1800 kg / hr (4000 lb / hr), iyenze ibe yinto efanelekileyo kumashishini afuna imveliso enkulu. Ukukwazi kwayo ukuphatha izinto ezahlukeneyo ngokuchanekileyo kuqinisekisa umgangatho ohambelanayo kunye nokunciphisa inkunkuma.

IiNkqubo zoLawulo oluPhezulu

Iisistim zolawulo ezikwinqanaba eliphezulu zidlala indima ebalulekileyo ekwandiseni ukusebenza kwe-twin screw extruders. Ezi nkqubo zibeka iliso kwaye zihlengahlengise iiparamitha ezibalulekileyo ezifana nobushushu, isantya se-screw, kunye nokuhamba kwezinto ngexesha langempela. Ukuphunyezwa kwe-algorithms yokulawula i-neuron-PID yokushisa komgqomo kuphuculwe kakhulu ukuchaneka kunye nokunciphisa ukugqithisa.

| Uphawu | I-Extruder yangoku | Uyilo olufanayo |

|---|---|---|

| I-Ink Viscosity | Phezulu | Phantsi |

| Ukukhupha imiqulu | Iyaguquguquka | Ilungisiwe |

| Ulawulo lokurhoxa | Ikwinqanaba eliphezulu | Isiseko |

| Iindleko | Ukhuphiswano | Phezulu |

Umlawuli we-PSO-neuron-PID wongeza ngakumbi ukusebenza kakuhle ngokunciphisa iziphumo zokufudumeza ukudibanisa. Olu tshintsho luqinisekisa umgangatho wemveliso ongaguqukiyo kunye nokonga amandla, okwenza i-twin screw extruders ibe yinto ethembekileyo yokuvelisa umthamo ophezulu.

I-Scalability yokwenziwa kweMveliso eNkulu

I-twin screw extruders ibonelela ngokunyuka okungahambelaniyo, okwenza abavelisi bahlangabezane neemfuno ezikhulayo zemveliso. Uyilo lwabo lweemodyuli luvumela uphuculo olulula kunye nokwenza ngokwezifiso, ukuqinisekisa ukuziqhelanisa ngokungenamthungo kwiimfuno zomthamo owandisiweyo.

- UkuGqwesa kweTubhu yezoNyango:Inkampani yaseYurophu ebonelela ngezinto zonyango isebenzise isikruda esilungiselelweyo sokuphucula ukusebenza kakuhle kunye nokuchaneka kwetyhubhu yonyango ye-PVC.

- Ukuxhobisa abangeneli abatsha ngeTurnkey Solutions:Umenzi omtsha uye wasebenzisa izixhobo ezilungiselelwe ukulinganisa ukusebenza ngokufanelekileyo, ukuhlangabezana neemfuno zemarike ngokulula.

La mabali empumelelo aqaqambisa ukuguquguquka kunye nokuthembeka kwe-twin screw extruder kwimveliso enkulu. Ukukwazi kwabo ukuhambisa ukusebenza okuhambelanayo kuzo zonke izicelo ezahlukeneyo kuqinisekisa ixabiso lexesha elide kumashishini.

Ukukhetha kunye nokugcina iTwin Screw Extruders

Izinto ekufuneka ziqwalaselwe xa ukhetha i-Extruder

Ukukhetha i-twin screw extruder echanekileyo kufuna uphononongo ngononophelo lwemiba emininzi. Abavelisi kufuneka baqale bavavanye uhlobo lwemathiriyeli kunye neemfuno zokusetyenzwa. Umzekelo, izinto ezirhabaxa okanye ezingeva bubushushu zinokufuna uyilo oluthile lwezikrufu okanye imibhobho yokugquma. Umthamo wemveliso yenye inkangeleko ebalulekileyo. Oomatshini abanamandla okuphumelela aphezulu bafanele imisebenzi emikhulu, ngelixa iimodeli ezincinci zinokwanela uphando okanye izicelo ze-niche.

I-modularity ye-extruder nayo idlala indima ebalulekileyo. Izinto ezinokwenziwa ngokwezifiso, ezifana nezikrufu kunye nemigqomo, zivumela abavelisi ukuba balungelelanise umatshini kwiinkqubo ezahlukeneyo. Iisistim zolawulo ezikwinqanaba eliphezulu ziphucula ukuchaneka nokusebenza kakuhle, zizenza zibe yimfuneko kumashishini afuna umgangatho ongaguqukiyo. Ukongezelela, udumo lomenzi kunye nokufumaneka kwenkxaso emva kokuthengisa akufanele kuhoywe. Iinkampani ezifana neZhejiang Jinteng Machinery Manufacturing Co., Ltd. zibonelela ngoyilo olomeleleyo kunye nenkonzo ethembekileyo yabathengi, eqinisekisa ixabiso lexesha elide.

IiNdlela zokuGcinwa kweSiqhelo

Ukugcinwa kwesiqhelo kuqinisekisa ixesha elide kunye nokusebenza kakuhle kwe-twin screw extruders. Iinkqubo eziphambili ziquka:

- Ukuqhuba uvavanyo lokungcangcazela kwiibhokisi zegiya rhoqo emva kweenyanga ezintandathu ukuya kwezili-12 ukubona imiba enokubakho.

- Ukusebenzisa iikhamera zokucinga nge-thermal ukujonga ukufudumeza kunye neenkqubo zokupholisa kwizitenxo.

- Ukuhlola imigqomo kunye nezikrufu ukuba zigugile kwaye zitshintshwe okanye zakhiwe kwakhona njengoko kufuneka.

- Ukutshintsha ioyile yebhokisi yegiya rhoqo kwaye uyihlalutye ukunqanda ukusilela okuyintlekele.

Ezi zenzo zinciphisa ukulungiswa okungxamisekileyo kunye nokunciphisa ixesha lokunciphisa. Ukugcina iirekhodi ezineenkcukacha zokuhlolwa nokulungiswa kunceda ukuchonga iipateni kunye nokuqikelela iimfuno zogcino lwexesha elizayo. Ukhathalelo olusebenzayo alugcini nje ukwandisa ubomi bomatshini kodwa luqinisekisa umgangatho wemveliso ongaguqukiyo.

Ukusombulula imiba eqhelekileyo

Imingeni yokusebenza inokuvela nangona i-extruders egcinwe kakuhle. Ukubeka iliso kwimveliso ethile kunceda ukwandisa iqondo lokuzaliswa, ukuqinisekisa ukusebenza ngokufanelekileyo kweemveliso ezintsha. Imilinganiselo ethile yamandla ityhila ukusetyenziswa kwamandla ngekhilogram nganye yezinto, inceda ekuchongeni ukungasebenzi kakuhle kwamandla.

Ukunxiba kwizikrufu kunye nemigqomo ngumba oqhelekileyo obangelwa zizinto ezirhabaxa, ulungelelwaniso olubi, okanye ukwandiswa kwe-thermal. Ukulinganisa rhoqo i-diameter yangaphakathi yomphanda kunye nokuqinisekisa ukulungelelaniswa okufanelekileyo kunokunciphisa ezi ngxaki. Ukugcina isikrufu esisecaleni esandleni kunciphisa ixesha lokuphumla ngexesha lokutshintshwa. Ukujongana nale miba ngokukhawuleza kuthintela umonakalo ongakumbi kunye nokugcina ukusebenza kakuhle.

Ingcebiso:Ukubeka iliso okusebenzayo kunye nokungenelela kwangethuba kubalulekile ukuze kuthintelwe ukulungiswa okuneendleko eziphezulu kunye nokuqinisekisa imveliso engaphazamisekiyo.

I-twin screw extrudersukuhambisa izibonelelo ezingenakuthelekiswa namaxabiso asebenzayo, imveliso ephezulu. Uyilo lwabo oluphambili luqinisekisa ukuxubana okuphuculweyo, umthamo ophezulu, kunye nokusetyenzwa kwezinto ngokubanzi. Aba matshini bakwanyusa umgangatho wemveliso kunye nokusebenza kakuhle kwamandla ngelixa begcina ulawulo lwenkqubo oluchanekileyo.

| Inzuzo | Inkcazo |

|---|---|

| UkuPhuculwa koKuxutywa | Ukwandisa ukufana kokuhanjiswa kwezinto kunye nokulawula inkqubo yokuxuba. |

| Umthamo weMveliso oPhezulu | Iphunyeleliswa ugqithiso oluphezulu xa kuthelekiswa ne-screw extruder, iluncedo kwizicelo ezinkulu. |

| Uluhlu olubanzi lokuLungiselela | Iyakwazi ukucubungula izinto ezahlukeneyo, kubandakanywa ne-viscosity ephezulu kunye nonyango olukhethekileyo. |

| Umgangatho weMveliso owomeleziweyo | Ukuxubana okuzinzileyo kunye nokukhutshwa kwemveliso kuphucula umgangatho wemveliso, kubalulekile ekuhlanganiseni kunye nemveliso ye-masterbatch. |

| Ukuphuculwa kokuSebenza kwamandla | Ukwandisa ukusetyenziswa kwamandla kunye nokunciphisa uxinzelelo lwe-chear, okukhokelela kugcino lweendleko zexesha elide. |

| Ukuphuculwa koLawulo lweNkqubo | Igcina iiparameters zenkqubo ngaphakathi kwamanqanaba amiselweyo kwiziphumo ezizezona zilungileyo kwiindawo ezikhutshiweyo. |

Ukukhethwa ngokufanelekileyo kunye nokugcinwa kwe-twin screw extruder kuqinisekisa ukuthembeka kwexesha elide kunye nokusebenza kakuhle. Utyalo-mali kwizisombululo ezikumgangatho ophezulu uqinisekisa ukusebenza okungaguqukiyo, oko kuyenza ibe yi-asethi exabisekileyo kwimveliso yanamhlanje.

FAQ

Zeziphi izixhobo ezinokusebenza ngokujija amawele?

I-twin screw extruders iphatha iiplastiki, irabha, amayeza, ukutya, kunye nezixhobo zokutya. Uyilo lwabo lweemodyuli luvumela ukwenziwa ngokwezifiso kweempawu ezithile zezinto kunye neemfuno zokusetyenzwa.

Kufuneka kwenziwe kangaphi ulondolozo?

Ulondolozo lwesiqhelo kufuneka lwenziwe ngenyanga, kunye nohlolo olucacileyo rhoqo emva kweenyanga ezintandathu. Utshintsho lweoyile rhoqo kunye nokuhlolwa kokunxiba kuqinisekisa ukusebenza kakuhle kunye nokuphila ixesha elide.

Yintoni eyenza i-twin screw extruders isebenzise amandla?

Izikrufu zabo ze-intermeshing zandisa ukuhamba kwezinto kunye nokunciphisa igalelo lamandla. Iinkqubo zolawulo oluphezulu lweparameters, ukunciphisa inkunkuma kunye nokwandisa ukusebenza kakuhle.

Ixesha lokuposa: Apr-27-2025