Iprofayili ye-PVC ye-Dual-alloy extruders ngoomatshini abaphambili abayilelwe ukuvelisa iiprofayili zePVC ezihlala ixesha elide. Badibanisa izinto ezimbini ezinamandla, ukudala iindawo ezichasayo ukugqoka kunye nomonakalo. Imizi-mveliso efana neyokwakha kunye neyokuvelisa ixhomekeke kwezi zikhuseli ukuze zijongane neemeko ezinzima. Aumbhobho we-pvc umbhobho omnye womzi-mvelisoihlala isebenzisa le teknoloji ukuqinisekisa ukusebenza okuhlala ixesha elide. Iumatshini we-twin screw extrusionyongeza ngakumbi impumelelo ngokunika ulawulo oluchanekileyo ngexesha lemveliso.

Yintoni iDual-Alloy PVC Profile Extruders?

Isishwankathelo seTekhnoloji yeDual-Alloy

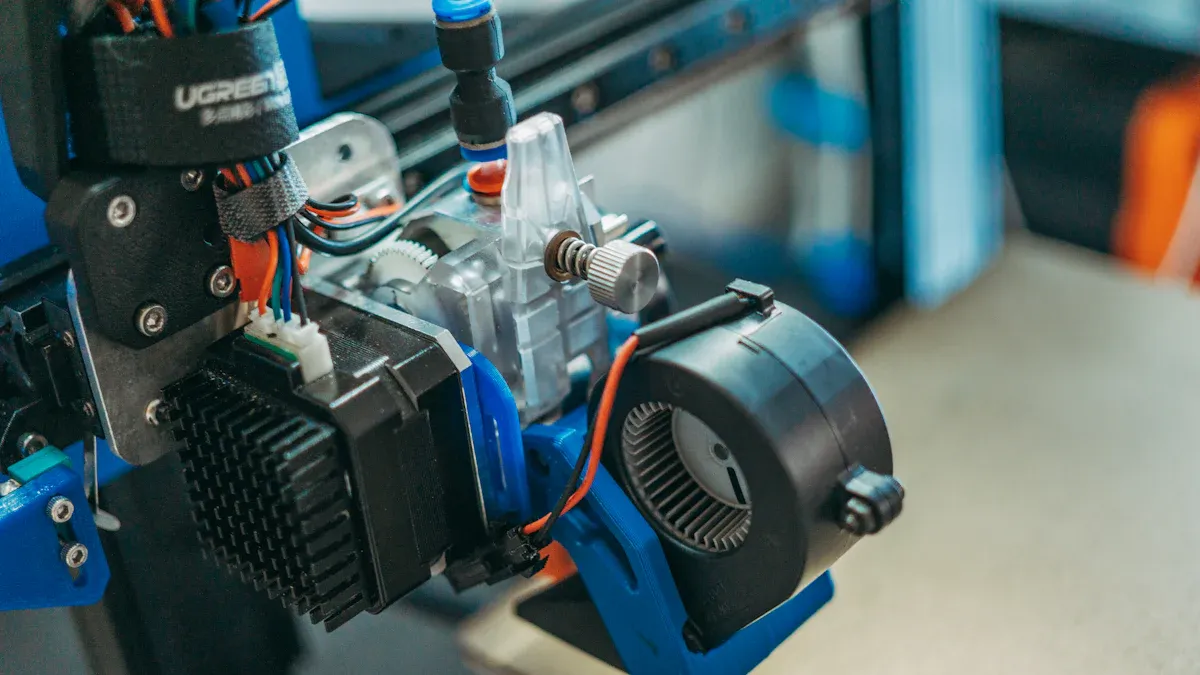

Itekhnoloji ye-Dual-alloy idibanisa izinto ezimbini ezahlukeneyo ukwenza amacandelo anokuqina okuphuculweyo kunye nokusebenza. Le ndlela iphakamisa amandla ezinto zonke, ezifana nokumelana nokunxiba kunye nokuqina, ukuvelisa i-extruders ekwazi ukumelana neemeko ezinzima. Ngokusebenzisa ubuchule bokuvelisa obuphambili, i-dual-alloyPVC profile extrudersukufezekisa ukulingana phakathi kwamandla kunye nokuguquguquka. Oku kubenza balungele amashishini afuna izixhobo ezithembekileyo zokusetyenziswa kwexesha elide.

Uyilo lwe-alloy ezimbini luqinisekisa ukuba iindawo ezibalulekileyo, njengezikrufu kunye nemigqomo, ziyakwazi ukusingatha amanqanaba aphezulu oxinzelelo ngaphandle kokunciphisa ukusebenza kakuhle. Olu lutsha luguqule ukuveliswa kweeprofayili zePVC, lubonelela ngesisombululo sokunciphisa ukunxiba kunye nokukrazula ngelixa ukhulisa imveliso.

Izixhobo kunye neNkqubo yokuVelisa

Inkqubo yokwenziwa kwe-dual-alloy PVC profile extruders ibandakanya ubunjineli obuchanekileyo kunye nezinto ezikumgangatho ophezulu. Amacandelo afana nezikrufu kunye nemigqomo zifumana unyango oluninzi ukunyusa iipropathi zazo. Ngokomzekelo, ukucima kunyei-nitriding iphucula ubulukhunikunye nokumelana nokunxiba. Le theyibhile ilandelayo iqaqambisa ezinye iimpawu zobugcisa eziphambili zezi extruders:

| Uphawu | Ixabiso |

|---|---|

| Ubunzima emva kokucima | HB280-320 |

| Ukuqina kweNitrided | HV920-1000 |

| Nitrided Case Ubunzulu | 0.50-0.80mm |

| I-Nitrided Brittleness | Ngaphantsi kweBanga lesi-2 |

| Uburhabaxa boMphezulu | Ra 0.4 |

| Screw Ukuthi tye | 0.015mm |

| Umphezulu weChromium-Plating Ukuqina | ≥900HV |

| Ubunzulu beChromium-Plating | 0.025-0.10mm |

| Ukuqina kwengxubevange | HRC55-65 |

| Ubunzulu be-alloy | 2.0-3.0mm |

Ezi nkcukacha ziqinisekisa ukuba i-extruders inokusingatha iimeko ezinzima ngelixa igcina ukuchaneka. Ukusetyenziswa kwezinto ezimbini-i-alloy kunciphisa iimfuno zokugcinwa, ukonga ixesha kunye neendleko kubavelisi.

Indima kwiProfayili yoMveliso wePVC

Iiprofayile ze-PVC ezine-alloy ezimbini zidlala indima ebalulekileyo ekuveliseni iiprofayili ze-PVC ezikumgangatho ophezulu. Uyilo lwabo oluphezulu luvumela ukuxuba okuphezulu kunye nokunyibilika kwezinto, ukuqinisekisa iziphumo ezihambelanayo. I-Twin-screw extruders, ngokukodwa, igqwesa ekudaleni indawo yokuxuba esebenzayo. Oku kuqinisekisa ukusasazwa okungcono kwezongezo, eziyimfuneko ekufezekiseni iipropati ezifunwayo kwiiprofayili zePVC.

Ukongeza, ezi extruders ziphucula ukusebenza kakuhle kwemveliso ngokunciphisa inkunkuma yezinto kunye nokwenza ukuba izinga eliphezulu lemveliso. Ukukwazi ukulungisa kakuhle iiparameters zenkqubo kuzenza zisebenziseke ngeendlela ezininzi, zivumela abavelisi ukuba baphathe iindlela ezahlukeneyo zePVC. Oku kuziqhelanisa kubaluleke kakhulu kumashishini afana nelokwakha kunye neemoto, apho iinkcukacha ezichanekileyo zibalulekile.

| Inzuzo | Inkcazo |

|---|---|

| Ubuchule bokuxuba obuPhezulu | I-twin-screw extruders yenza indawo yokuxuba esebenza kakhulu, iqinisekisa ukusasazwa okungcono kwezongezo. |

| Uphuculo lweNkqubo yokuSebenza | Bavumela amazinga aphezulu emveliso kwaye banciphise inkcitho yezinto eziphathekayo ngokuhambisa ngcono kunye nokunyibilika. |

| Ukuguquguquka okukhulu | Ukukwazi ukulungisa kakuhle iiparameters zenkqubo kuvumela ukuphatha iifomati ezahlukeneyo zePVC kunye neenkcukacha. |

Ngokudibanisa ukuqina, ukusebenza kakuhle, kunye nokuguquguquka kwezinto ezininzi, iiprofayili zeprofayili ye-PVC yealloyi ezimbini ziye zaba yimfuneko kwimveliso yanamhlanje. Ukukwazi kwabo ukuhambisa ukusebenza okungaguqukiyo phantsi kweemeko ezinzima kubenza babe lolona khetho lukhethwayo kumashishini kwihlabathi liphela.

Iimpawu eziphambili kunye neeNzuzo ze-Dual-Alloy PVC Profile Extruders

Ukuxhathisa kwi-Corrosion kunye nokuNxitywa

Iprofayile ye-PVC ene-alloy ephindwe kabini yakhiwe ukuba ihlale, nakwiindawo ezinzima kakhulu. Ukwakhiwa kwabo okuyingqayizivele kudibanisa izinto ezimbini, nganye ikhethiweyo ngenxa yokukwazi ukumelana nomonakalo. Olu yilo luzenza zikwazi ukumelana nomhlwa ngenxa yokufuma, imichiza okanye ezinye izinto ezirhabaxa. Kuba amashishini afanaukwakhiwa kunye nokwenza, olu phawu luqinisekisa ukuba isixhobo sisebenza ngokuthembekileyo ekuhambeni kwexesha.

Ukumelana nokunxiba yenye inzuzo ebalaseleyo. Izikrufu kunye nemigqomo kwezi extruders zifumana unyango njenge-nitriding kunye nokucima. Ezi nkqubo zenza lukhuni umphezulu, okwenza kube lula ukuguga ngexesha lokusebenza. Ngenxa yoko, abavelisi banokuqhuba oomatshini babo ixesha elide ngaphandle kokukhathazeka ngokulungiswa rhoqo okanye ukutshintshwa. Oku kuqina akugcini nje ixesha kodwa kunciphisa iindleko zokusebenza.

Ukusebenza kobushushu obuphezulu

Ukusebenza kwiindawo ezinobushushu obuphezulu kunokuba ngumngeni koomatshini abaninzi. Nangona kunjalo, ii-extruders zeprofayili ze-PVC ezimbini-alloy zigqwesa phantsi kweemeko ezinjalo. Izinto zabo eziphambili kunye noyilo zivumela ukuba zigcine ukusebenza nangona zibonakaliswe kubushushu obukhulu. Esi sikhundla sibalulekile kumashishini afuna imveliso engaguqukiyo, kungakhathaliseki ukuguquguquka kobushushu.

Uphononongo lubonisa ukuba njengoko amaqondo okushisa enyuka ukusuka kwi-10 ° C ukuya kwi-60 ° C, umthwalo wokungaphumeleli we-tensile we-PVC-based composites uyancipha nge-25.08%. Ngexesha elifanayo, ukufuduka okuphezulu kwe-tensile kunyuka nge-74.56%. Oku kuthetha ukuba amaqondo okushisa aphezulu aphucula i-ductility yezinto eziphathekayo, okwenza kube lula ukucubungula. I-dual-alloy extruders ithatha ithuba le propati, iqinisekisa ukusebenza kakuhle kunyeiziphumo ezikumgangatho ophezulunakumaqondo obushushu aphezulu. Oku kubenza ukhetho oluthembekileyo kwizicelo ezifunayo.

Ubomi obude kunye nokuSebenza kweendleko

Enye yezona zinto ziluncedo kwiprofayile ye-PVC ye-alloy ephindwe kabini bubomi babo obude. Ukwakhiwa kwazo okuqinileyo kunciphisa ukuguga kunye nokukrazula, ukunciphisa imfuno yokugcinwa rhoqo. Ubomi obude buguqulela kugcino lweendleko ezibalulekileyo kubavelisi. Ngokutyala imali kwizixhobo ezomeleleyo, iinkampani zinokuthoba iindleko zazo zizonke kwaye ziphucule imbuyekezo yazo kutyalo-mali.

I-cost-efficiency yala ma-extruders icaca ngakumbi xa ujonga amanani. Emva kokuphucula kwi-teknoloji ye-alloy-alloy, abavelisi baye babika ukunciphisa i-45.8% kwinkunkuma yezinto eziphathekayo kunye nokuncipha kwe-28.7% ekusebenziseni amandla ngekhilogram yemveliso. Ukongeza, imbuyekezo kwixesha lotyalo-mali lehlile ukusuka kwiminyaka eyi-5.2 ukuya kwiminyaka nje eyi-3.8. Olu phuculo luqaqambisa iingenelo zemali zokusebenzisa ii-extruders zealloy ezimbini, zibenza babe lukhetho olunobulumko kumashishini anenjongo yokuphucula ukusebenza kwawo.

| Metric | Ukuphucula kwangaphambili | Emva kokuPhucula | Uphuculo |

|---|---|---|---|

| Inkunkuma yezinto eziphathekayo | 12% | 6.5% | 45.8% Ukunciphisa |

| Ukusetyenziswa kwamandla/kg | 8.7kWh | 6.2 kWh | 28.7% Ulondolozo |

| Ixesha le-ROI | 5.2 Iminyaka | 3.8 Iminyaka | 26.9% ngokukhawuleza |

Ngokudibanisa ukuqina, ukusebenza kobushushu obuphezulu, kunye nokusebenza kakuhle kweendleko, iiprofayili zeprofayili ze-PVC ezidibeneyo ezimbini zibonelela ngexabiso elingenakuthelekiswa nanto. Aziphuculi imveliso kuphela kodwa zikwanceda amashishini onge imali ekuhambeni kwexesha.

Izicelo kunye naMatyala oSetyenziso lweShishini

Ulwakhiwo kunye neZiseko zoPhuhliso

I-extruders ye-alloy ephindwe kabini ibe yinto etshintsha umdlalo kwiulwakhiwo kunye neziseko zophuhlisoamacandelo. Aba matshini bavelisa iiprofayili zePVC ezisetyenziswa kwiifestile, iingcango, kunye neenkqubo zemibhobho. Ukukwazi kwabo ukuphatha iimeko ezinzima kubenza bafezekiseke kwizicelo zangaphandle. Umzekelo, iiprofayili zePVC ezenziwe ngee-dual-alloy extruders zixhathisa ukubola kwimvula, ukufuma, kunye nezinye izinto zokusingqongileyo. Oku komelela kuqinisekisa ukuba izakhiwo zihlala zomelele kwaye zithembekile iminyaka.

Ukongeza, ukuchaneka kwezi extruders kuvumela abavelisi ukuba benze iiprofayili ezinobungakanani obuchanekileyo. Oku kuchaneka kubalulekile kwiiprojekthi zokwakha apho imilimitha nganye ibala. Abakhi kunye nabakhi bezakhiwo bakhetha ezi profayili kuba zidibanisa amandla kunye nezakhiwo ezilula, ukwenza ukuthutha kunye nokufakwa kube lula.

Izicelo zeMichiza kunye nezoShishino

Imizi-mveliso ejongene neekhemikhali kunye nezinto ezirhabaxa zixhomekeke kakhulu kwii-dual-alloy extruders. Aba matshini bavelisa iiprofayili zePVC ezinokumelana nokuvezwa kwiiasidi, iialkali, kunye nezinye izinto ezidlekayo. Ngokomzekelo, izityalo zemichiza zisebenzisa ezi nkcukacha kwiitanki zokugcina, iipayipi kunye nezithintelo zokukhusela. Ukuchasana nokunxiba kunye nokubola kuqinisekisa ukuba izixhobo zihlala ixesha elide, nakwiindawo ezinzima.

Ngaphaya koko, ii-extruders ezine-alloy-alloy ziphucula ukusebenza kakuhle kwiseto zemizi-mveliso. Bonaukunciphisa inkunkuma yezintokunye nokusetyenziswa kwamandla, okunceda iinkampani zonge imali. Oku kubenza babe lolona khetho lufanelekileyo kumashishini ajonge ukwandisa ukusebenza kwawo ngelixa egcina imigangatho ekumgangatho ophezulu.

Imizi-mveliso yeemoto kunye ne-Aerospace

Imizi-mveliso yeemoto kunye ne-aerospace ifuna imathiriyeli ekhaphukhaphu kwaye ehlala ixesha elide. I-extruders ye-alloy ephindwe kabini ihlangabezana nale mfuno ngokuvelisa iiprofayili ze-PVC ezinomlinganiselo okhethekileyo wamandla ukuya kubunzima. Ezi profayili zisetyenziswa ngaphakathi kwesithuthi, kwiinkqubo zeengcingo, kunye namacandelo esakhiwo. Ukuchasana kwabo nokushisa kunye nokugqoka kuqinisekisa ukuba baqhuba kakuhle phantsi kweemeko ezinzima, ezifana nesantya esiphezulu okanye ukuguquka kweqondo lokushisa.

Kwi-aerospace, ukuchaneka kuyo yonke into. I-extruders ye-alloy ephindwe kabini ivumela abavelisi ukuba benze iiprofayili ezinokunyamezela okuqinileyo, ukuqinisekisa ukhuseleko kunye nokuthembeka. Ubuchwephesha buvule amathuba amatsha okuyila izinto ezinobunzima benqwelomoya, ukunciphisa ukusetyenziswa kwamafutha, kunye nokuphucula ukusebenza kakuhle.

Iprofayili ye-PVC ye-Dual-alloy extruders inika ukuqina kunye nokusebenza okungahambelaniyo. Ukukwazi kwabo ukumelana nokunxiba kunye nokusingatha iimeko ezinzima kunciphisa iimfuno zokugcinwa kunye nokwandisa ubomi benkonzo.

Amashishini afuna izisombululo ezithembekileyo, zexesha elide ze-extrusion kufuneka ziqwalasele ukwamkela obu buchwepheshe. Lutyalo-mali oluphucukileyo olunyusa ukusebenza kakuhle kwaye luthobe iindleko zokusebenza.

FAQ

Yintoni eyenza iprofayile ye-PVC ye-alloy ephindwe kabini yahluke kwii-extruders eziqhelekileyo?

I-extruders ye-alloy ephindwe kabini idibanisa izinto ezimbini zokuqina okuphuculweyo. Ziyaxhathisa ukuguga, ukubola, kunye namaqondo obushushu aphezulu, nto leyo ezenza zilungele indawo ezingqongileyo.

Ngaba ii-extruders ezine-alloy zinciphisa iindleko zokugcinwa?

Ewe! Uyilo lwabo olomeleleyo lunciphisa ukunxiba kunye nokukrazula, ukunciphisa ukuphindaphindeka kokulungisa. Abavelisi bonga ixesha kunye nemali ngokutshintshwa okumbalwa.

Ixesha lokuposa: May-19-2025