I-twin screw extruders idlala indima ebalulekileyo kwiinkqubo zokuvelisa, ngakumbi kwiiplastiki kunye nokuveliswa kwerabha. Ukugcinwa rhoqo kwe-twin screw extruder kubalulekile ukugcina aba matshini beqhuba kakuhle. Ukujonga amacandelo afana neiplastiki extruder screwyokunxiba, ukulungelelanisa itwin screw extruder amalungu umphanda, kunye nokulawulwa koxinzelelo lokubeka iliso kuqinisekisa imveliso ehambelanayo. Ezi zenzo zandisa ubomi bezixhobo, kubandakanywaiplastiki extrusion machine screw, kwaye unciphise ixesha lokuphumla, ukonga ixesha kunye nemali kubaqhubi.

IiNdlela eziPhambili zoLondolozo lweeTwin Screw Extruders

Ukucocwa rhoqo kunye nokuTshintsha izinto

Ukugcina i-twin screw extruder icocekile kubalulekile ukugcina ukusebenza kwayo. Izinto ezishiyekileyo zingakhokelela kungcoliseko, okuchaphazela umgangatho wemveliso. Ukuhlanjululwa rhoqo nge-resin ecocekileyo okanye izinto ezikhethekileyo zokucoca kunceda ukususa ukungcola okufana neegels kunye nezongezo. Nazi iindlela zokucoca ezisebenzayo:

- Gubha inkqubo ngentlaka ecocekileyo okanye ucokise imathiriyeli ukususa iintsalela.

- Sebenzisa i-resins yokucoca ukuphelisa ungcoliseko olunenkani.

- Qwalasela ubuchule obuphambili obufana nokucoca idisco ngococa ngokucokisekileyo.

Ukuqonda ukuba izinto zokucoca zisebenza njani kunokwenza inkqubo yokucoca isebenze ngakumbi. I-extruder ecocekileyo ayiqinisekisi imveliso engaguqukiyo kuphela kodwa yandisa ubomi bomatshini.

Ukuthanjiswa okufanelekileyo kweeNdawo ezihambayo

Ukuthambisa kudlala indima ebalulekileyo ekugcineni iindawo ezihambayo ze-twin screw extruder zikwimeko ephezulu. Ngaphandleukuthambisa okufanelekileyo, ukungqubuzana kuyanda, nto leyo ekhokelela ekugugeni. Izithambisi ezikumgangatho ophezulu zinciphisa ukukhuhlana, zandisa ubomi bamalungu, kwaye ziphucula ukusebenza kakuhle ngokupheleleyo.

| Inzuzo | Inkcazo |

|---|---|

| Mtyibilizi | Iziphumo zokukhuhlana okuncinci |

| Ubomi obude | Yandisa ubomi begiya, iibheringi, kunye netywina |

| Ubushushu | Yehlisa ubushushu bokusebenza kunye nengxolo |

| Viscosity | Igcina i-viscosity nangona ucheba ngomatshini |

| Ubushushu obuphezulu | Igcina i-viscosity ephezulu kumaqondo obushushu aphakamileyo |

Ukujonga rhoqo kunye nokuzalisa izithambiso kuqinisekisa ukuba i-extruder isebenza kakuhle, naphantsi kweemeko ezinzima.

Uhlolo lweSiqhelo lokuNxitywa kunye nokukrazula

Ukuhlolwa kwesiqhelo kubalulekile ukuze kuchongwe imiba enokubakho ngaphambi kokuba inyuke. Ukujonga ukuguga kunye nokukrazula kumalungu afana nezikrufu kunye nemigqomo kunokuthintelaukulungiswa okuxabisa kakhulu kunye nexesha lokuphumla. Ukuhlola kwakhona kunceda ukugcina umgangatho wemveliso ongaguqukiyo.

| Inzuzo | Inkcazo |

|---|---|

| Ukujongwa kwe-Wear and Tear | Ukuchongwa kwangethuba kwamanqanaba okunxiba kuthintela imiba yemveliso. |

| UkuNcitshiswa kweendleko | Ukunciphisa ukusetyenziswa kwezinto zokucoca kunye neendleko ngexesha lokutshintsha kombala. |

| Ukusebenza ngokufanelekileyo | Yenza lula ugcino, icuthe ixesha lokuphumla, kwaye icuthe ukuxinana kwabasebenzi. |

Ngokucwangcisa uhlolo rhoqo, abaqhubi banokulungisa imiba emincinci kwangoko, beqinisekisa ukuba i-twin screw extruder ihlala ithembekile kwaye isebenza kakuhle.

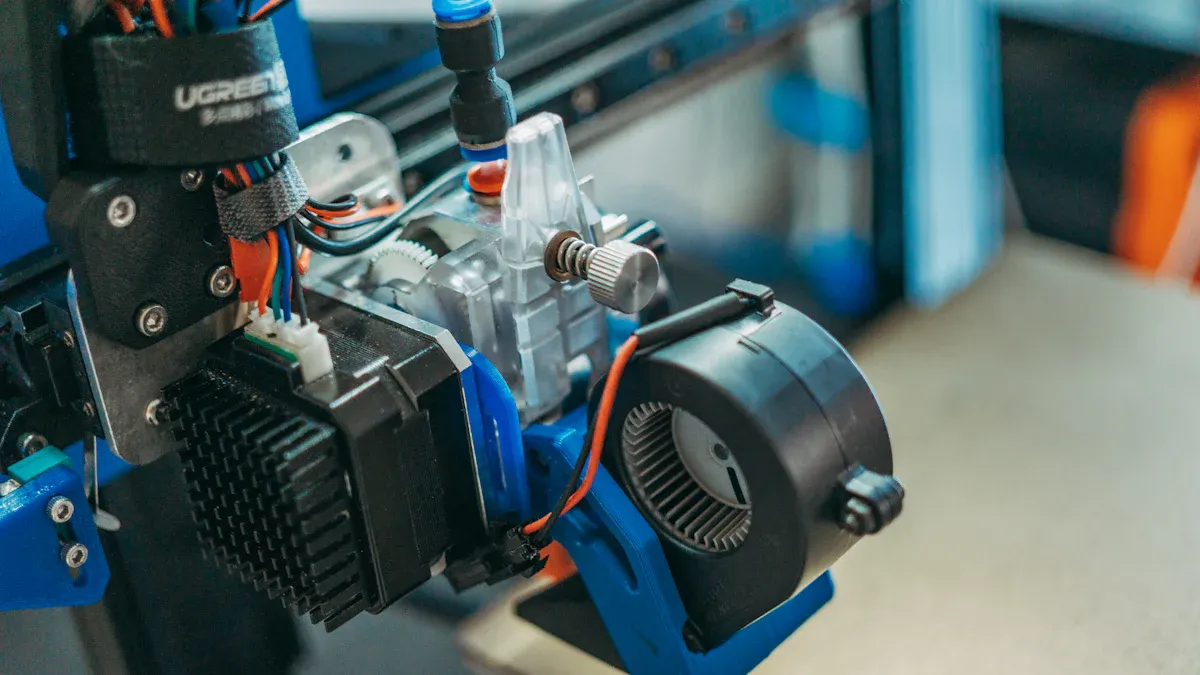

Ukubeka iliso kunye nokutshintshwa kwamatywina kunye neeBearings

Amatywina kunye neebheringi zizinto ezibalulekileyo ezifuna ingqalelo esondeleyo. Iitywina ezigugileyo zinokukhokelela ekuvuzeni, ngelixa iibheringi ezonakeleyo zinokubangela ukukhuhlana kunye nokunciphisa ukusebenza kakuhle. Ukubeka iliso kula macandelo kunye nokutshintshwa xa kuyimfuneko kuqinisekisa ukuba i-extruder isebenza kwintsebenzo ephezulu.

- Ukuhlolwa rhoqo kuthintela ukunxiba kwangaphambi kwexesha kunye nokukhuhlana.

- Ukutshintsha izitywina ezonakalisiweyo kunye neebheringi zigcina ukusebenza kakuhle kunye nomgangatho wemveliso.

- Ukugcinwa okufanelekileyo kwandisa ubomi be-extruder.

Ngokubeka phambili la macandelo, abaqhubi banokukuphepha ukuphuka okungalindelekanga kunye nokugcina umgangatho wemveliso ongaguqukiyo.

Ukusombulula iingxaki eziqhelekileyo kwi-Twin Screw Extruders

Ukujongana neMiba yokuFundisa ngokugqithisileyo

Ukutshisa kakhulu kunokuphazamisa ukusebenza kwe-twin screw extruder kwaye kude konakalise izinto ezibuthathaka. Ukulawula ubushushu bomgqomo kunye noxinzelelo ngundoqo ekuthinteleni lo mbandela. Abaqhubi kufuneka babeke iliso rhoqo kwiprofayili yobushushu kwaye baqinisekise ukuba inkqubo yokupholisa isebenza ngokufanelekileyo.

- Ubudlelwane obuthe ngqo bukhona phakathi koxinzelelo kunye nokunyuka kobushushu. Kuwo onke ama-2-bar ukunyuka koxinzelelo, ubushushu bunyuka nge-1 ° C. Ukugcina uxinzelelo luzinzile kunceda ukulawula ukushisa okukhulu.

- Ukufakela izixhobo ezenza uxinzelelo, njengeempompo zegiya, zinokuzinzisa uxinzelelo kunye nokulawula ubushushu obunyibilikayo ngokufanelekileyo.

- Ixesha elifutshane lokuhlala kwi-twin screw extruders linciphisa utyhileko kumaqondo obushushu aphezulu, nto leyo eluncedo kakhulu kwizinto ezingeva bubushushu.

Ngokujongana nokushisa, abaqhubi banokugcina umgangatho wemveliso ohambelanayo kwaye bagweme ixesha lokuphumla elingeyomfuneko.

Ukunqanda i-Screw Wear kunye nomonakalo

Ukunxiba isikrufungumba oqhelekileyo ochaphazela ukusebenza kakuhle kwe-twin screw extruders. Ukuhlolwa rhoqo kunye nokusetyenziswa kwezixhobo zokunxiba kunokunceda ukukhusela le ngxaki. Nanga amanye amacebiso asebenzayo:

- Hlola izikrufu kunye nemigqomo rhoqo ukubona iimpawu zokuqala zokuguga.

- Sebenzisa izinto ezikumgangatho ophezulu, ezinganxibiyo kwizikrufu kunye nemigqomo ukwandisa ubomi bazo.

- Qinisekisa ubungakanani obufanayo bamasuntswana ngexesha lokutyiswa kwemathiriyeli ukunciphisa ukunxitywa kwe-abrasive.

Ukuthintela ukunxitywa kwezikrufu akugcini nje ngokugcina imveliso kodwa ikwaqinisekisa umgangatho wemveliso ongaguqukiyo ekuhambeni kwexesha.

Ukuxazulula iingxaki Ukwakha-Up

Ukwakhiwa kwezinto ngaphakathi kwi-extruder kunokukhokelela ekuphumeni okungahambelaniyo kunye nokunciphisa ukusebenza kakuhle. Ukucombulula ingxaki okusebenzayo kunokuphucula kakhulu iziphumo zokusetyenzwa.

Ukulawula iprofayile yobushushu kubalulekile. Ukulungelelanisa iindawo zokushisa ukushisa kunciphisa i-resin, ukuphucula ukuxutywa kwe-dispersive kunye nokuthintela ukuthotywa kwezinto. Ukongeza, ukwenza uyilo lwesijiva kuvumela ulawulo olungcono kwi-viscosity enyibilikayo, ephucula ukusebenza kakuhle kokuxuba.

Abasebenzisi kufuneka bacoce i-extruder rhoqo ukuze basuse imathiriyeli eshiyekileyo. Esi senzo sinciphisa ukungcoliseka kwaye siqinisekisa ukusebenza kakuhle.

Ukusombulula uMgangatho weMphumo ongangqinelaniyo

Umgangatho wemveliso ongahambelani unokukhokelela kwizinto ezichithwayo kunye neendleko ezongeziweyo. Ukujongana nalo mba kufuna ugxininiso kulawulo lomgangatho kunye nokubeka iliso ngexesha lokwenyani.

- Umenzi odibanise iModel Predictive Control (MPC) inkqubo kunye ne-twin screw extruder yabona ukunyuka kwe-15% kwi-output kunye nokunciphisa i-10% kwizinto ezingaphandle.

- Enye inkampani ifake i-rheometer ekwi-line ukujonga ukuguquguquka kwe-viscosity. Ngokulungelelanisa isantya se-screw kunye neeprofayili zeqondo lokushisa ngokusekelwe kwidatha yexesha langempela, banciphisa izinga lokwaliwa kwe-batch ngama-25%.

Le mizekelo igxininisa indlela ukusombulula ukungangqinelani kwemveliso kunokuphucula ukusebenza kwemveliso kunye nokunciphisa inkunkuma.

Iingcebiso zokuSebenzisa kwi-Twin Screw Extruders

Ukulungisa Ulawulo lobushushu

Ulawulo lobushushu ngumtshintshi-mdlalo wokuphucula ukusebenza kwe-twin screw extruder. Ukulungelelanisa ubushushu kwiindawo ezithile kunokuphucula ukunyibilika kwezinto kunye nokunciphisa ukuguga kumacandelo. Njengokuba:

- Ukuseta iizowuni 1 kunye no-2 ukuya kumaqondo obushushu aphezulu kunciphisa ukunxiba kwi-plasticating screw elements. Olu lungelelaniso luvumela izinto ukuba zinyibilike ngokufanelekileyo, ukunciphisa imfuno yamandla omatshini.

- Izifundo ezenziwa nguMaridass kunye noGupta, kunye no-Ulitzsch et al., Ziqaqambise indlelaukwandisa ubushushu bomphandayandisa iimpawu zemathiriyeli kunye neziphumo zenkqubo.

Ukongeza, ukugcina uxinzelelo oluphantsi lokukhutshwa kunokuzinzisa amaqondo obushushu obunyibilikayo. Le ndlela inciphisa ukunxiba kwizikrufu zokukhupha kwaye inyusa uzinzo lwe-thermal, iqinisekisa ukusebenza okuhambelanayo.

Ukuphucula Ukutya nokuPhathwa kwezinto eziphathekayo

Ukutya okusebenzayo kunye nokuphatha kuchaphazela ngokuthe ngqo i-extruder's throughput kunye nokusetyenziswa kwamandla. Iinkampani zifumene iziphumo ezimangalisayo ngokulungiselela ezi nkqubo:

- Iprosesa yeglasi yefiber-reinforced polymers inyuse i-throughput nge-18% ngokudibanisa i-feeder esecaleni kunye nokuguqula uyilo lwe-screw.

- I-Inputput inyuke ukusuka kwi-2000 kg / hr ukuya kwi-2300 kg / hr, ivelisa i-$ 180,000 eyongezelelweyo kwinzuzo yonyaka.

- Ukongiwa kwamandla e-5% (okanye i-138 MWh/yr) kwaphunyezwa ngenxa yeqondo eliphezulu lokuzaliswa kwi-extruder.

Olu phuculo aluphuculi nje ukusebenza kakuhle kodwa lukwanciphisa iindleko, lubenze baphumelele abavelisi.

Ukulungelelanisa ubumbeko lweScrew kwii-Aplikheshini eziKhethekileyo

Ukwenza uqwalaselo lwe-screw ngokwezifiso kunokuphucula kakhulu ukusebenza kwezixhobo ezahlukeneyo kunye nokusetyenziswa. Uhlengahlengiso oluphambili lubandakanya:

- Ukuguqula ubunzulu betshaneli ukuze kuphuculwe umlinganiselo woxinzelelo kwi-thermoplastics.

- Ukwandisa ubude bobude ukuya kwi-diameter (L / D) ukunyusa ukudibanisa kunye nokusebenza kakuhle kokunyibilika.

- Ukubandakanya izinto ezijikelezayo okanye i-Maddock mixers yokudibanisa ngcono kunye nokulawula ubushushu.

- Ukulungelelanisa i-angle ye-helix kunye ne-pitch ukuqinisekisa ukuhamba kwezinto ezifanelekileyo.

- Ukusebenzisa izikrufu zesithintelo ukwahlula izinto ezinyibilikisiweyo nezinganyibilikiyo, ukuphucula ukuhambelana.

Olu hlengahlengiso luvumela abaqhubi ukuba balungelelanise i-extruder kwiimfuno ezithile, ukuqinisekisa iziphumo ezilungileyo.

Ukuphucula iNkqubo yokuSebenza ngokuSebenza

I-Automation iye yatshintsha indlela yokusebenza kwe-twin screw extruders. Iinkqubo eziphezulu ezixhotyiswe ngeenzwa kunye nokubeka iliso ngexesha lokwenyani kunciphisa imfuno yokungenelela ngesandla. Iimpawu zogcino oluqikelelweyo zinciphisa ixesha lokuphumla kunye nokuphucula ukuthembeka.

I-Artificial Intelligence (AI) ithatha i-automation inyathelo eliya phambili ngokulungisa iiparamitha ze-extrusion kunye nokuhamba kwezinto. Oku kukhokelela ekuncitshisweni kwenkunkuma, ulawulo olungcono lomgangatho, kunye nokwandiswa kokusebenza ngempumelelo. Abavelisi abasebenzisa i-automation babona ukuphucuka okubalulekileyo kwimveliso kunye nokonga kweendleko, kuyenza ibe lutyalo-mali oluxabisekileyo.

Amanyathelo oThintelo lweTwin Screw Extruders

Ukuphumeza iiShedyuli zokuGcinwa kweMigaqo

Iishedyuli zogcino lwesiqhelo zingumqolo wokhathalelo lothinteloamawele Scruders extruders. Ukugcinwa rhoqo kuqinisekisa ukuba oomatshini baqhuba kakuhle kwaye banqande ukophuka okungalindelekanga. Abanini-zithuthi banokucwangcisa amaxesha olondolozo ngokusekelwe kwidatha yembali, ukutshintshwa okanye ukuhlaziya amacandelo phambi kokuba basilele.

Ingcebiso: Inkqubo yokugcinwa okucwangcisiweyo ayithinteli kuphela ixesha lokuphumla kodwa yandisa ubomi besixhobo.

Nantsi into etyhilwa luphononongo lweshishini malunga noncedo lolondolozo lwesiqhelo:

| Inzuzo | Inkcazo |

|---|---|

| UPhuculo lokuSebenza | Ukugcinwa rhoqo kuqinisekisa ukusebenza okuphezulu ngolungelelwaniso olufanelekileyo kunye nokuthambisa amacandelo. |

| Ukuthintela Ukuphumla | Ukugcinwa okucwangcisiweyo kunciphisa ukwaphuka okungalindelekanga, okuvumela ukuphazamiseka kwemveliso okucwangcisiweyo. |

| Ugcino lweendleko | Ukuhlolwa kwesiqhelo kunokuthintela imiba encinci ukuba ibe yingxaki enkulu, ukonga kwiindleko zokulungisa. |

| Ukhuseleko | Ukugcinwa kwangexesha kunciphisa iingozi zokhuseleko kubaqhubi boomatshini ngokujongana neendawo ezigugileyo okanye ezonakalisiweyo. |

| Ukwandiswa kwexesha lokuphila | Ukugcinwa okuhambelanayo kunokwandisa kakhulu ubomi bokusebenza kwe-extruder, ukukhusela utyalo-mali. |

| Umgangatho weMveliso | Oomatshini abagcinwe kakuhle bavelisa iimveliso ezikumgangatho ophezulu ngokuthintela ukungcola kwizinto ezicutshungulwayo. |

| Ukusebenza kakuhle kwamandla | Ukuhlolwa rhoqo kwandisa amacandelo ukuze asetyenziswe ngcono amandla, ukunciphisa iindleko zokusebenza. |

Ngokunamathela kwishedyuli yokulungisa, abaqhubi banokukuphepha ukulungiswa okuxabisa kakhulu kwaye bagcine imveliso isebenza ngokufanelekileyo.

AbaSebenzi boQeqesho kwiiNdlela eziGqwesileyo

AbaSebenzisi badlala indima ephambili ekugcineni izikruru ezingamawele. Ukubaqeqesha kwezona zinto zilungileyo kuqinisekisa ukuba bayayiqonda indlela yokuphatha izixhobo ngokufanelekileyo. Abasebenzi abafundileyo banokuchonga iimpawu zokuqala zokuguga kwaye balungise imiba emincinci ngaphambi kokuba inyuke.

Phawula: Iinkqubo zoqeqesho kufuneka zibandakanye uhlolo lwesiqhelo, iindlela zokuthambisa, kunye nokusombulula iingxaki eziqhelekileyo.

Xa abaqhubi bekwazi ukungena kunye nokuphuma komatshini, banokwenza ukulungiswa ngexesha elifanelekileyo kunye nokutshintshwa, ukunciphisa ixesha lokunciphisa kunye nokuphucula imveliso.

Ukugcina i-Spare Parts Inventory ilungile

Ukuba neendawo ezisecaleni kusindisa ubomi ngexesha leemeko ebezingalindelekanga. Izitywini ezigugileyo, iibheringi, okanye izikrufu zingayimisa imveliso ukuba ezinye azifumaneki lula. Ukugcina uluhlu lwamacandelo abalulekileyo kuqinisekisa izilungiso ezikhawulezayo kunye nokunciphisa ixesha lokuphumla.

- Iindawo ezibalulekileyo zesitokhwe njengezikrufu, imigqomo, kunye netywina.

- Beka iliso kumanqanaba okunxiba ukuze uqikelele iimfuno zokutshintshwa.

- Sebenzisana nabanikezeli abathembekileyo ukuqinisekisa umgangatho kunye nokufumaneka.

Uluhlu lweempahla olugcinwe kakuhle lugcina imisebenzi iqhuba kakuhle kwaye ithintela ukulibaziseka okuneendleko eziphezulu.

Ukusebenzisa iMathiriyeli yoMgangatho oPhezulu kunye neMixholo

Izinto ezikumgangatho ophezulu zisisiseko se-twin screw extruders ethembekileyo. Izinto ezenziwe ngezinto ezihlala ixesha elide njengentsimbi ye-nitriding ziphucula ukusebenza kunye nokunciphisa iimfuno zogcino. Ubuchule bokuvelisa obuphezulu, obufana nokucima kunye ne-nitriding, buphucula ngakumbi ubomi obude bamalungu.

Utyalo-mali kwizinto ze-premium zihlawula ixesha elide. Abavelisi bafumana ukonakaliswa okumbalwa, iindleko ezisezantsi zokulondolozwa, kunye nokusebenza okungaguqukiyo.

Ngokubeka phambili umgangatho, abaqhubi bakhusela utyalo-mali lwabo kwaye banandipha i-ROI engcono ngokunciphisa iindleko zokusebenza kunye nexesha lokuphumla.

Ukugcinwa rhoqo kugcina i-twin screw extruders isebenza kakuhle. Ukhathalelo olusebenzayo lunciphisa ixesha lokuphumla, lwandisa ubomi besixhobo, kwaye luqinisekisa umgangatho wemveliso ongaguqukiyo. Abaqhubi abalandela ezi ngcebiso banokwandisa ukusebenza kwaye baphephe ukulungiswa kweendleko.

Ingcebiso: Qala kancinci. Yenza ishedyuli yokulungisa kwaye uqeqeshe iqela lakho. La manyathelo enza umahluko omkhulu ekuhambeni kwexesha!

FAQ

Yeyiphi eyona ndlela yokucoca i-twin screw extruder?

Ukucoca nge-resin efanelekileyo okanye ukucoca izinto kusebenza kakuhle. Isusa intsalela kwaye ithintele ukungcoliseka, iqinisekisa ukusebenza okuhambelanayo kunye nomgangatho wemveliso.

Kufuneka kwenziwe kangaphi ulondolozo lwesiqhelo?

Abaqhubi kufuneka balandele iingcebiso zomenzi. Ngokuqhelekileyo, ukugcinwa kwesiqhelo kwe-twin screw extruder kufuneka kwenzeke rhoqo kwiiyure zokusebenza ezingama-500-1,000.

Yintoni ebangela ukunxitywa kwe-screw kwi-twin screw extruder?

Ukunxitywa kwezikrwesi kudla ngokuphuma kwizinto ezirhawuzelayo, amaqondo obushushu aphezulu okusebenza, okanye ukuthambisa okungafanelekanga. Ukuhlolwa rhoqo kunye nokusetyenziswa kwezixhobo zokunxiba kunganceda ukunciphisa lo mbandela.

Ixesha lokuposa: May-29-2025