Oomatshini bokuvuthela iibhotile abakumgangatho ophezulu bawuguqule umhlaba wokwenziwa kwemveliso. Amashishini ngoku axhomekeke kwaba matshini ukuhlangabezana neemfuno ezikhulayo zesantya esiphezulu, imveliso esekwe ngokuchanekileyo. Iimpawu ezifana ne-automation kunye nexesha langempela lokubeka iliso liqinisekisa umgangatho ohambelanayo ngelixa unciphisa iindleko. Iimodeli ezinesantya esiphezulu zinokuvelisa phakathi kwe-500 ukuya kwi-1,000 yeebhotile ngeyure, ukujongana nemfuno ekhulayo yoshishino lwesiselo lwezisombululo ezisebenzayo. Ukongeza, ukutshintshela kwipakethe ekhaphukhaphu kukhokelele abavelisi, kubandakanyaIifektri zoomatshini bokuvuthela ibhotile yePP, ukwamkela obu buchwepheshe ngenxa yokuguquguquka kwabo. Ngaphaya koko, ukudityaniswa kwe-aPVC ibhodi amagwebu umgca extrusionkwandisa amandla emveliso, ngelixa ai-extruder screw enye yengxowa yenkunkumaimveliso izalisekisa usetyenziso olwahlukeneyo lwaba matshini baphambili.

Basebenza njani oomatshini bokuvuthela iibhotile

Ukudalwa kwangaphambili kunye nokufudumeza

Inkqubo yokuvuthela ibhotile iqala ngokudala kunye nokufudumeza kweepreforms. Ezi preforms, ngokwesiqhelo zenziwe ngemathiriyeli efana ne-PET, ziyafudunyezwa ukuze zifezekiseke ngokufanelekileyo ukubumba. Oomatshini bokuvuthela ibhotile abaphezulu basebenzisa imitha ye-infrared okanye ukujikeleza komoya oshushu ukutshisa ngokulinganayo iipreforms. Oku kuqinisekisa ukufana kubushushu bezinto eziphathekayo, okubaluleke kakhulu ukugcina umgangatho ohambelanayo ngexesha lezigaba ezilandelayo.

Inkqubo yokufudumala kumatshini wanamhlanje yenzelwe ukuchaneka. Abasebenzisi bangalawula ubushushu ukuze bacuthe iziphene, ngoseto olucetyiswayo rhoqo malunga ne-45°C (113°F). Eli nqanaba lokulawula linciphisa inkunkuma yezinto kwaye liqinisekisa ukuba i-preforms ilungiselelwe ngokwaneleyo ukunweba kunye nokuvuthela. Emva kokufudumeza, i-preforms iguqulela ngokungenamthungo ukuya kwinqanaba elilandelayo, apho ifakwe kwiibhotile.

Ukubumba kunye nokuBumba

Xa sele ishushu, ii-preforms zifakwa kwiimbumba ezichaza ukumila kokugqibela kunye nobukhulu beebhotile. Inkqubo yokubumba ibandakanya amacandelo amaninzi aphambili asebenza ngokuhambelanayo ukuqinisekisa ukuchaneka nokusebenza kakuhle.

- Iyunithi yokufudumeza: Ithambisa i-preform ukuze ibe lula.

- Inkqubo yokuBamba umngundo: Ikhusela iimolds kwaye ilungelelanise i-preform yokubunjwa okuchanekileyo.

- Ukuzolula nokuvuthelaInkqubo: Wolula i-preform ethambileyo ngelixa umoya ocinezelekileyo uyivuthela kwisingundo, usenza ibhotile.

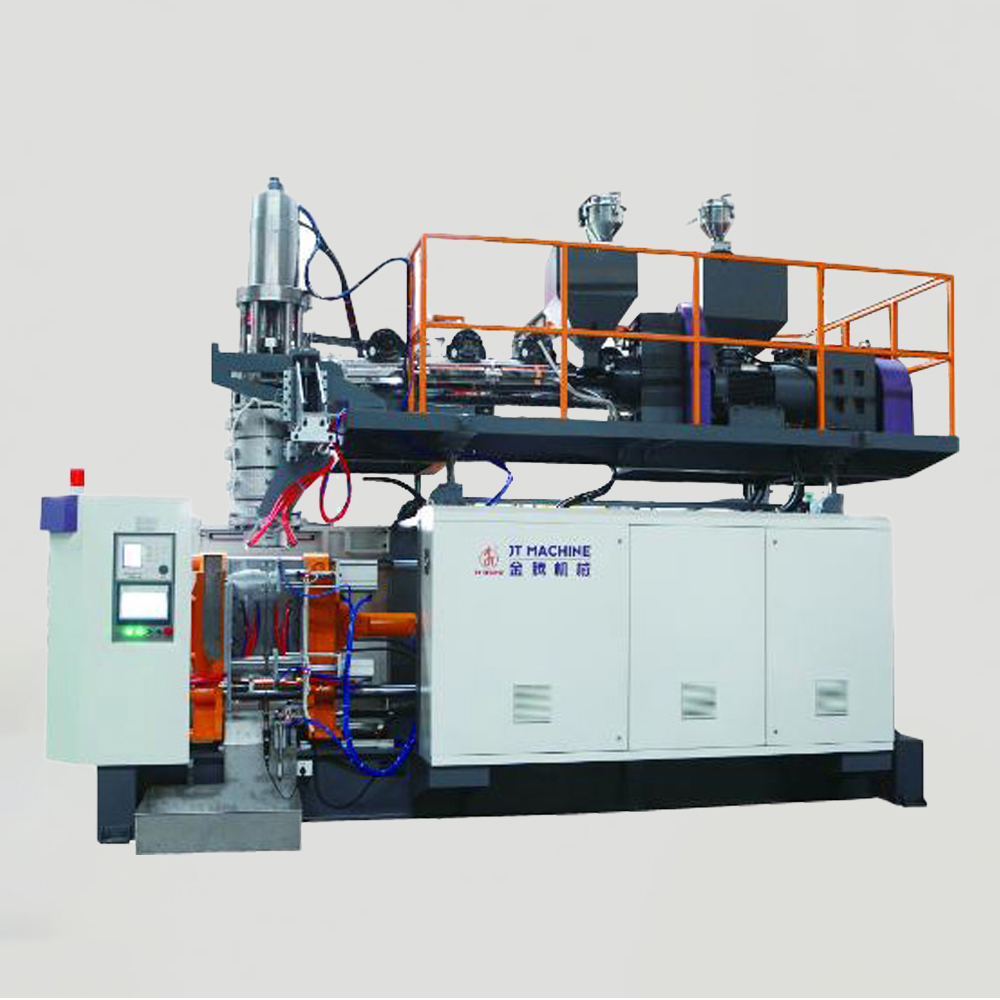

Umatshini wokuvuthela ibhotile we-JT uchungechunge lugqwesa kweli nqanaba ngenxa yeenkqubo zalo zokulawula eziphambili kunye noyilo oluqinileyo. Iimpawu ezinjengomsebenzi wokuphakamisa iqonga zihlala kwiindawo eziphakamileyo ezahlukeneyo, ezivumela ukuveliswa koyilo lweebhotile ezahlukeneyo. Ukongezelela, inkqubo yokulinganisa i-hydraulic yomatshini iqinisekisa izenzo ezigudileyo kunye ezikhawulezayo, ukuphucula imveliso.

| Icandelo | Umsebenzi |

|---|---|

| Iyunithi yokufudumeza | Ithambisa i-preform isebenzisa imitha ye-infrared ukuthobeka ngexesha lokubumba. |

| Inkqubo yokuBamba umngundo | Ikhusela ukubumba kwindawo kwaye ilungelelanise i-preform yokwenziwa kwebhotile echanekileyo. |

| Ukuzolula nokuvuthela | Wolula i-preform ethambileyo kwaye uvuthela umoya kuyo ukubumba ibhotile ngokuchanekileyo. |

| Inkqubo epholileyo ezantsi | Ipholisa ngokukhawuleza ibhotile ukugcina imilo kunye nengqibelelo yesakhiwo emva kokubumba. |

| Inkqubo yokukhupha | Isusa ibhotile egqityiweyo kwi-mold usebenzisa iingalo zomatshini okanye uxinzelelo lomoya ngaphandle komonakalo. |

Eli nqanaba liqaqambisa ukuguquguquka koomatshini bokuvuthela iibhotile, abanokwamkela ubungakanani beebhotile ezahlukeneyo kunye neemilo ukuhlangabezana neemfuno ezahlukeneyo zentengiso.

Ukupholisa kunye neNkqubo yokuKhutshwa

Inqanaba lokugqibela libandakanya ukupholisa kunye nokukhupha iibhotile. Ukupholisa ngokukhawuleza komeleza ubume bebhotile, kuqinisekisa ukuba igcina imilo yayo kwaye ihlangabezana nemigangatho yomgangatho. Oomatshini abakwizinga eliphezulu njenge-JT series basebenzisa indibaniselwano yeenkqubo zokupholisa umoya kunye namanzi ukukhawulezisa le nkqubo. Amaxesha okupholisa angavela kwimizuzwana eyi-1.5 ukuya kwimizuzwana engama-20, kuxhomekeke kubungakanani bebhotile kunye nezinto eziphathekayo.

Emva kokupholisa, iibhotile zikhutshwa kwi-molds usebenzisa iingalo zemishini okanye uxinzelelo lomoya. Eli nyathelo libalulekile ekugcineni isantya semveliso kunye nokuthintela umonakalo kwiimveliso ezigqityiweyo. Uchungechunge lwe-JT lubandakanya inkqubo yokuthambisa ngokuzenzekelayo kunye nenkqubo ye-cylinder drive ejection esebenzayo, ukunciphisa iimfuno zokugcina kunye nexesha lokuphumla lokusebenza.

| Inkqubo | Inkcazo |

|---|---|

| Ukupholisa | Ukupholisa okukhawulezayo kuqinisa isakhiwo sebhotile, ukuqinisekisa ukugcinwa kwemilo kunye nemijikelezo yokuvelisa ngokukhawuleza. |

| Ukukhutshwa | Iibhotile ziyakhutshwa emva kokupholisa kwaye ziphantsi kolawulo lomgangatho ukuhlangabezana nemigangatho yemveliso. |

Ngokudibanisa ezi mpawu ziphambili, oomatshini bokuvuthela iibhotile bongeza isantya semveliso kunye nokuqinisekisa umgangatho ongaguqukiyo, ubenza babaluleke kakhulu kwimveliso yanamhlanje.

IiNzuzo eziPhambili zoomatshini bokuvuthela iibhotile

Ukwandiswa kwesantya seMveliso kunye nokuSebenza

Oomatshini banamhlanje bokuvuthela iibhotile baye baguqula iinkqubo zemveliso ngokwandisa kakhulu isantya kunye nokusebenza kakuhle. Aba matshini basebenzisa iindlela eziphucukileyo, ezinje ngeenkqubo eziqhutywa yi-servo kunye ne-proportional hydraulic technology, ukulungelelanisa imisebenzi. Umatshini wokuvuthela ibhotile we-JT ungumzekelo wolu tshintsho, uvelisa iimveliso zeplastiki ezingenanto ngokuchaneka okumangalisayo kunye nesantya.

Isantya sokuvelisa siyahluka ngokuxhomekeke kwindlela esetyenziswayo. Itekhnoloji yokuvuthela ifikelela kwiibhotile ezingama-200 ngomzuzu, ngelixa iindlela zokucinezela zihamba phakathi kwe-50 kunye ne-100 yeebhotile ngomzuzu. Oku kuguquguquka kuvumela abavelisi ukuba bakhethe eyona ndlela ifanelekileyo kwiimfuno zabo ezithile.

| Indlela | Isantya seMveliso (iibhotile ngomzuzu) |

|---|---|

| Vuthela Vuthela | 200 |

| Cinezela Vuthela | 50-100 |

Ukudityaniswa kwe-automation kwandisa ngakumbi ukusebenza kakuhle. Iimpawu ezifana neenkqubo zokuthambisa ezizenzekelayo kunye nokubeka iliso ngexesha lokwenyani kunciphisa ixesha lokuphumla kunye neemfuno zokugcinwa. Olu phuculo luvumela abavelisi ukuba bahlangabezane neemfuno zomthamo ophezulu ngelixa begcina imveliso engaguqukiyo.

Ingcebiso: Utyalo-mali koomatshini bokuvuthela ibhotile ngesantya esiphezulu kunokunceda amashishini alinganise imveliso ngaphandle kokuthomalalisa umgangatho.

Umgangatho ohambelanayo kunye nothembekileyo

Ukuhambelana kumgangatho wemveliso luphawu oluphambili koomatshini bokuvuthela ibhotile.Ubunjineli obuchanekileyoiqinisekisa ukuba ibhotile nganye ihlangabezana nemigangatho engqongqo, inciphisa iziphene kunye nenkunkuma. Uchungechunge lwe-JT lubandakanya itekhnoloji yokuvuthela i-servo, ephucula umgangatho webhotile ngokunciphisa izitenxo.

Iinkqubo zokufudumeza kwe-infrared zidlala indima ebalulekileyo ekugcineni ukufana. Ezi nkqubo zisasaza ubushushu ngokulinganayo kwi-preforms, ukuthintela amanqaku oxinzelelo kunye neendonga ezingalinganiyo. Le ndlela yobuchule ibangela ukuba iibhotile zingabonakali nje kuphela kodwa kunye nesakhiwo esilungileyo.

| Uphawu | Impembelelo kuMgangatho wokuZimba |

|---|---|

| Ubunjineli obuchanekileyo | Iqinisekisa iibhotile ezikumgangatho ophezulu ezinemilinganiselo ehambelanayo |

| Servo Yolula Ukuvuthela | Ukuphucula umgangatho webhotile, ukunciphisa iziphene |

| Ukufudumeza nge-infrared | Ukunciphisa iimpawu zoxinzelelo kunye neendonga ezingalinganiyo |

Abavelisi kumashishini afana nokupakishwa kokutya kunye namachiza baxhomekeke kwaba matshini ukuvelisa iibhotile ezihambelana nemigangatho engqongqo yokulawula. Uluhlu lwe-JT lugqamile ngenxa yokukwazi ukuhambisa iziphumo ezithembekileyo kuzo zonke iintlobo zezicelo.

Phawula: Umgangatho ohambelanayo unciphisa isidingo sokuphinda usebenze, ukonga ixesha kunye nezixhobo.

Ukusebenza kakuhle kwamandla kunye noLondolozo lweendleko

Ukusebenza kakuhle kwamandla yeyona nto ibalulekileyo kwimveliso yanamhlanje. Oomatshini bokuvuthela ibhotile abaphezulu, njengoluhlu lwe-JT, lubandakanya ubugcisa bokugcina amandla obunciphisa iindleko zokusebenza. Iimotor frequency eziguquguqukayo kunye ne-servo-controlled hydraulic systems ziphakamisa ukusetyenziswa kwamandla, okwenza aba matshini babe yi-15% ukuya kwi-30% eyonga amandla ngaphezu kweemodeli eziqhelekileyo.

| Inkcazo yobungqina | Iinkcukacha |

|---|---|

| Impembelelo yokuSetyenziswa kwamandla | Oomatshini bemveli basebenzisa i-25% yamandla ngaphezu kweemodeli ze-hybride, ezikhokelela kwiindleko eziphezulu zokusebenza. |

| Iindleko zoMbane | Iindleko zombane zibalelwa kwi-20% yeendleko zemveliso iyonke, ikhuthaza utyalo-mali koomatshini abonga amandla. |

| Ukunciphisa ukusetyenziswa kwamandla | Oomatshini abatsha banokucutha ukusetyenziswa kwamandla nge-15%, okuchaphazela ngqo iindleko zokusebenza. |

Ukongeza, ukutshintshela kwiindlela ezizinzileyo kuqhuba ukwamkelwa koomatshini abaxhasa iiplastiki ezinokubola. Phantse i-35% yeemodeli ezintsha zenzelwe ukulungiselela izinto ezinokuphinda zisetyenziswe, zihambelane neenjongo zokusingqongileyo.

- Ukusetyenziswa kweiinkqubo ezonga umbanekunciphisa iindleko zombane, ezithatha inxalenye enkulu yeendleko zokuvelisa.

- Abavelisi bamkela inzuzo yokuvelisa ibhotile ezinzileyo kusetyenziso lwamandla oluphantsi kunye nokunciphisa impembelelo yokusingqongileyo.

Ngokubeka phambili ukusebenza kakuhle kwamandla, amashishini anokuphumeza ukonga ixesha elide ngelixa enegalelo kwimizamo yozinzo lwehlabathi.

Biza ngaphandle: Oomatshini bokuvuthela ibhotile abonga amandla abapheleli nje ekunciphiseni iindleko kodwa bakwaxhasa iindlela zokwenziwa kwe-eco-friendly.

Ukuphuculwa kwezobuGcisa koomatshini bokuvuthela iibhotile

Ukuzenzekela kunye neSmart Control Systems

I-Automation ibe sisiseko soomatshini banamhlanje bokuvuthela iibhotile, ukuguqula iinkqubo zokuvelisa ngokuchaneka okungenakulinganiswa kunye nokusebenza kakuhle. Iinkqubo zokulawula i-Smart, ezixhaswe ngobukrelekrele bokwenziwa kunye nezinzwa eziphambili, zenza ukuba iliso lexesha langempela kunye nohlengahlengiso oluzenzekelayo. Ezi mpawu ziqinisekisa umgangatho ongaguqukiyo kunye nokunciphisa inkunkuma yezinto eziphathekayo. Umzekelo, ukubek'esweni okuqhubekayo kuphucula ukulandeleka kwedatha, kuvumela abavelisi ukuba bachonge kwaye basombulule imiba ngokukhawuleza.

Iinkqubo ezizenzekelayo zikwanyusa isantya semveliso kunye nokuhamba komsebenzi. Oomatshini abaxhotyiswe ngeerobhothi banokuziqhelanisa neentlobo ezahlukeneyo zeebhotile, ukuphelisa imfuno yokuseta ezininzi. Oku bhetyebhetye kunciphisa ixesha lokuphumla kwaye kwandisa imveliso. Ukongeza, ujongano olusebenziseka lula lwenza lula ukusebenza, lunciphise iimfuno zoqeqesho kunye nokuphucula imveliso ngokubanzi.

| Umba | Inkcazo |

|---|---|

| Ukuchaneka kunye nokungqinelana | I-automation iqinisekisa ukuba ibhotile nganye idibana neenkcukacha ezichanekileyo, ukunciphisa iziphene kunye nenkunkuma. |

| Isantya | Iinkqubo ezizenzekelayo zongeza kakhulu isantya semveliso kunye nokunciphisa ukulibaziseka. |

| Smart Manufacturing | Ukudibanisa kunye neenkqubo zedatha kuvumela ukugcinwa kwangaphambili kunye nokulungiswa komsebenzi. |

Ezi nkqubela phambili zenza i-automation ibe yinto ebalulekileyo kubavelisi abajonge ukuhlala bekhuphisana kwimarike ekhawulezayo.

Ukuguquguquka kuYilo lwebhotile kunye nobukhulu

Oomatshini banamhlanje bokuvuthela iibhotile babonelela ngeendlela ezahlukeneyo ezimangalisayo, ezibonelela auluhlu olubanzi loyilo lweebhotilekunye nobukhulu. Oomatshini abafana nochungechunge lwe-JT bagqwesa ekuveliseni iibhotile zeemilo ezahlukeneyo kunye nomthamo, ukusuka kwizikhongozeli ezincinci ze-100 ml ukuya kwiimveliso ezinkulu ze-50-litre. Iinkqubo zolawulo oluphezulu kunye nezinzwa ziqinisekisa ukuchaneka, ukugcina ingqibelelo yesakhiwo kulo lonke uyilo.

Abavelisi bayazuza kolu lungelelwaniso, njengoko luphelisa imfuno yoomatshini abaninzi bokuphatha iintlobo ezahlukeneyo zeebhotile. Umzekelo, oomatshini bokubumba be-PET Technologies banokuvelisa iibhotile zezicelo ezibuyiswayo ngelixa bexhasa i-100% yezixhobo ze-PET ezisetyenzisiweyo. Esi sixhobo sihambelana neentsingiselo zeshishini ukuya kwizisombululo zokupakishwa ezikhaphukhaphu kunye nezizinzileyo.

- Oomatshini banokuphatha iimilo zeebhotile ezahlukeneyo kunye nobukhulu, beqinisekisa ukuchaneka okuphezulu kunye nokusebenza kakuhle.

- Izinzwa eziphezulu ziphucula iimeko zokuvelisa, ukuphucula ukuguquguquka kwimveliso.

Oku kuguquguquka kuvumela abavelisi ukuba bahlangabezane neemfuno zamashishini ahlukeneyo, ukusuka kwiziselo ukuya kumayeza, ngokulula.

Ukudityaniswa neZenzo eziZinzileyo

Ukuzinza kuye kwaba yingqwalasela ebalulekileyo kwimveliso yeebhotile. Oomatshini bokuvuthela iibhotile abakumgangatho ophezulu ngoku babandakanya iinkqubo zokonga amandla kunye nokuxhasa ukusetyenziswa kwezinto ezisetyenzisiweyo. Iimotor frequency eziguquguqukayo kunye ne-servo-controlled hydraulics zinciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-30%, zehlisa iindleko zokusebenza kunye nefuthe lokusingqongileyo.

Imizekelo yophando iqaqambisa impumelelo yala manyathelo. Inkampani yesiselo saseMntla Melika izuze ukucuthwa kokusetyenziswa kwamandla nge-30% kunye nokwanda kwe-20% kwisantya semveliso ngokwamkela izenzo ezizinzileyo. Ngokufanayo, umenzi wemveliso yokhathalelo lomntu waseYurophu unciphise kakhulu inkunkuma ngelixa ephucula ukwaneliseka kwabathengi.

| Igama leKhampani | UkuNcitshiswa kwamandla | Ukwandiswa kwesantya soMveliso | UkuNcitshiswa kweNkunkuma | Ukwaneliseka koMthengi |

|---|---|---|---|---|

| Inkampani yaseMntla Melika yesiselo | 30% | 20% | N / A | N / A |

| Umvelisi weMveliso yoLondolozo lwaseYurophu | 25% | N / A | Kubalulekile | Iphuculwe |

Ngokudibanisa izenzo ezizinzileyo, abavelisi abagcini nje ukunciphisa iindleko kodwa baphinde bahambelane neenjongo zokusingqongileyo zehlabathi, ukuphucula idumela labo lemarike.

Usetyenziso lweLizwe lokwenyani loomatshini bokuvuthela iibhotile

Imizi-mveliso yeziselo kunye nokuPakisha ukutya

Amashishini okupakisha iziselo kunye nokutya athembele kakhuluoomatshini bokuvuthela ibhotileukuhlangabezana nemfuno ekhulayo yezisombululo zokupakishwa ezisebenzayo nezikumgangatho ophezulu. Aba matshini bavelisa iibhotile zoluhlu olubanzi lweemveliso, kubandakanya amanzi, iijusi, iziselo ezibandayo, iisosi, kunye neoyile etyiwayo. Ukusetyenziswa kwehlabathi kwamanzi asebhotileni kukodwa kunyuka nge-7.0% ngonyaka, kunye noqikelelo olubonisa ukunyuka ukusuka kwii-232 zeebhiliyoni zeelitha ngo-2011 ukuya kwii-513 zeebhiliyoni zeelitha ngo-2025. Oku kunyuka kugxininisa imfuno yobuchwepheshe bokupakisha obuphambili obunokuhambisana neemfuno zemarike.

Izibonelelo eziphambili zala mashishini ziquka isantya semveliso esikhawulezayo, inkunkuma encitshisiweyo yezinto eziphathekayo, kunye nokukwazi ukudala iibhotile ezikhaphukhaphu kodwa ezihlala ixesha elide. Imfuno yezisombululo zokupakisha ezisebenzayo ziyaqhubeka nokukhula njengoko abavelisi bezama ukuhlangabezana nokulindela kwabathengi ukuzinza kunye nokulula.

Amacandelo amachiza kunye nezokuthambisa

Oomatshini bokuvuthela iibhotile badlala indima ebalulekileyo kumacandelo amayeza kunye nezithambiso, apho ukuchaneka kunye nomgangatho kubaluleke kakhulu. Kumashishini amayeza, aba matshini bavelisa iibhotile ezenzelwe ukugcina ngokukhuselekileyo kunye nokuthutha iisyrups, iipilisi, iipilisi, kunye namayeza angamanzi. Kwizinto zokuthambisa, benza izikhongozeli ezibukekayo zeloshini, iikhrimu, iishampu, kunye neziqholo, ziphucula umboniso wemveliso kunye nokuthengiswa.

| Icandelo | Inkcazo yesicelo |

|---|---|

| Amachiza | Ukuvelisa iibhotile zokupakisha amayeza ukuqinisekisa ukugcinwa okukhuselekileyo kunye nokuthuthwa kwamayeza. |

| Izithambiso | Ukudala iibhotile zokuthambisa ezigqwesileyo zokuphucula umgangatho kunye nomtsalane weemveliso kwintengiso. |

Ukuguquguquka koomatshini bokuvuthela iibhotile kuvumela abavelisi ukuba baziqhelanise neemfuno ezizodwa zala mashishini, baqinisekise ukuthotyelwa kwemigangatho engqongqo yolawulo ngelixa begcina isibheno sobuhle.

Imizekelo yeeNkampani eziSebenzisa oomatshini abakwinqanaba eliphezulu

Iinkampani ezininzi zamkele ngempumelelo oomatshini bokuvuthela iibhotile ukunyusa amandla abo okuvelisa. I-Beermaster, inkampani yesiselo eMoldova, isebenzise umatshini wokubumba uthotho lwe-APF-Max ukufezekisa uphuculo olubalulekileyo. Lo matshini wandise imveliso yemveliso ukuya kwiibhotile ze-8,000 ngeyure kwiibhotile ze-500 ml, ukugqithisa amandla angaphambili. Utshintsho lokungunda olukhawulezayo, olugqitywe kwimizuzu nje engama-20, lubonelele ngokuguquguquka ukuvelisa ubukhulu bebhotile ezintlanu ezahlukeneyo. Ukongezelela, ukuphuculwa kokusebenza kwamandla okuhambelana nezenzo ezizinzileyo, ukunciphisa ukusetyenziswa kwamandla ngokubanzi. Iinketho zokwenziwa ngokwezifiso zoyilo lweebhotile zomeleze ngakumbi ukuqondwa kwebrendi kunye nokunomtsalane okubonakalayo.

Le mizekelo ibonisa indlela oomatshini bokuvuthela ibhotile abaphambili benza ukuba amashishini ahlale ekhuphisana ngokuphucula ukusebenza kakuhle, ukunciphisa iindleko, kunye nokuhlangabezana neemfuno ezahlukeneyo zemarike.

Oomatshini bokuvuthela ibhotile abaphezulu, njengoluhlu lwe-JT, chaza ngokutsha ukuveliswa ngokunyusa isantya sokuvelisa, ukuqinisekisa umgangatho ohambelanayo, kunye nokunciphisa ukusetyenziswa kwamandla. Uyilo lwabo oludityanisiweyo, oluyimodyuli lulungelelanisa imijikelo yemveliso, ngelixa izinto ezomeleleyo zikhulisa ukuthembeka. Iinkqubo ezonga amandla zithoba iindleko kunye neempembelelo zokusingqongileyo, nto leyo eyenza aba matshini babaluleke kakhulu kwiinkampani ezizamela ukuhlala zikhuphisana kwiimarike eziguqukayo.

| Umba | Inkcazo |

|---|---|

| Isantya seMveliso | Uyilo olubambeneyo, oluyimodyuli ludityaniswa ngokungenamthungo kwimigca yemveliso, ukukhawulezisa imijikelo. |

| Umgangatho | Izinto ezihlala ixesha elide kunye nobuchule obuphambili buqinisekisa ukuthembeka, umgangatho ophezulu wemveliso. |

| Ukusebenza kakuhle kwamandla | Uyilo lokulondoloza amandla lunciphisa iindleko zokusebenza kunye nokuxhasa izenzo ezizinzileyo zokuvelisa. |

FAQ

Ziziphi izinto ezinokuthi inkqubo yomatshini wokuvuthela ibhotile ye-JT?

Uluhlu lwe-JT lubambaizixhobo ezifana PE, PP, kunye ne-K, iyenza isebenze ngeendlela ezininzi ekuveliseni iimveliso zeplastiki ezingenanto kumashishini ahlukeneyo.

Uluhlu lwe-JT luqinisekisa njani ukusebenza kakuhle kwamandla?

Umatshini usebenzisa iimotor frequency frequency kunye ne-servo-controlled hydraulics, ukunciphisa ukusetyenziswa kwamandla nge-15% ukuya kwi-30% xa kuthelekiswa neemodeli zemveli.

Ngaba uchungechunge lwe-JT lunokuthatha ubungakanani beebhotile ezahlukeneyo?

Ewe, umsebenzi wokuphakamisa iqonga kunye neenkqubo zokulawula eziphambili zivumela uchungechunge lwe-JT ukuba luvelise iibhotile ukusuka kwi-20 ukuya kwi-50 ilitha ngokuchanekileyo.

Ingcebiso: Ukuze ufumane iziphumo ezilungileyo, lungisa izicwangciso zomatshini ngokusekelwe kwizinto eziphathekayo kunye neemfuno zebhotile.

Ixesha lokuposa: May-23-2025