Imigqomo ye-screw ephindwe kabini idlala indima ebalulekileyo kwiiplastiki kunye noomatshini berabha, iqinisekisa ukusetyenzwa kwemathiriyeli egudileyo nesebenzayo. Ukugcinwa ngendlela eyiyo kunye nokufunwa kweendawo ezisecaleni ezithembekileyoiifektri ezimbini zeplastiki zemibhobhoukwandisa ukuqina kunye nokusebenza kakuhle. Ukungahoyi amacandelo afana ne-twin parallel screw barrels okanye i-conical twin screw twin screws kukhokelela ekusebenzeni okucuthiweyo kunye nobomi obufutshane besixhobo.

Ukubaluleka kokuLondolozwa kunye nokuThunyelelwa kweMigqomo ye-Screw yamawele

Iziphumo zoKunxitywa kunye nokuKhawulwa kuMsebenzi

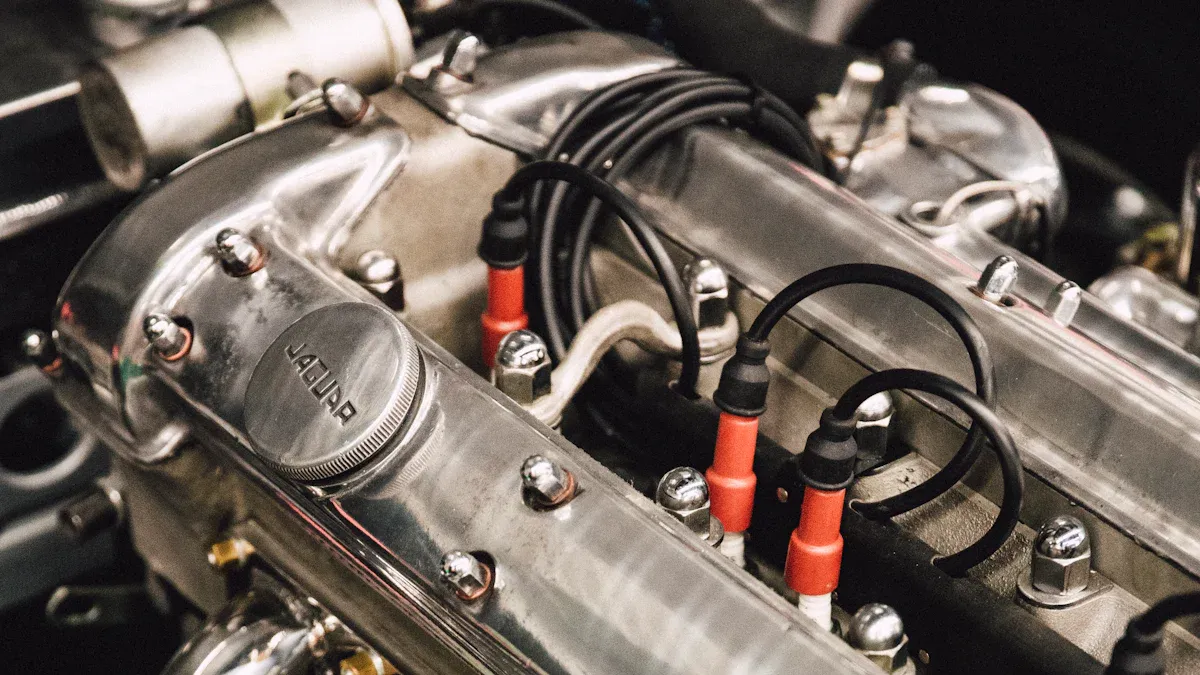

Ukunxiba kunye nokukrazula kunempembelelo enkulu ekusebenzeni kwemibhobho ye-screw. I-Abrasion, ebangelwa ngamasuntswana aqinileyo kwi-polymers, yonakalisa indawo ye-screws kunye nemigqomo. Ukunxitywa kwe-Corrosion, okubangelwa ukuhlaselwa kweekhemikhali ngezongezo kunye namasuntswana e-polymer ethotyiweyo, kukhokelela kwi-pitting kunye nokuchithwa kwezinto. Isenzo sokucheba ngexesha lothutho lwemathiriyeli lukwanegalelo ekugugeni kwe-abrasive kwi-flight flights nakwiindonga zemibhobho. Ukonakala kwakhona kukhawulezisa ukuguga koomatshini njengoko umphezulu wentsimbi uwohloka. Ezi zinto ngokudibeneyo zinciphisa ukusebenza kakuhle, ukwandisa ukusetyenziswa kwamandla, kunye nokunciphisa ixesha lokuphila kwezixhobo.

Inzuzo yokufumana iiNdawo eziziGcini ezikumgangatho oPhezulu

Ukusebenzisaiindawo ezisecaleni ezikumgangatho ophezuluiphucula ukusebenza kunye nokuqina kwemibhobho yesikrufu esingamawele. I-metallurgical bonding ephezulu yomeleza uxhulumaniso phakathi kweengubo kunye nemigqomo, ukuphucula ukuchasana nokugqoka kunye nokubola. Ukuqina okuphuculweyo kwandisa ubomi bokusebenza kwesixhobo, ukunciphisa ixesha lokuphumla. Ukongezelela, ukusebenza kakuhle kweendleko kufezekiswa ngokunciphisa ukuphindaphinda kokugcinwa kunye nokutshintshwa.

| Inzuzo | Inkcazo |

|---|---|

| Ukubambisana okuPhezulu kweMetallurgical | Yenza unxibelelwano oluqinileyo phakathi kwengubo kunye nomgqomo, ukuqinisa ukuqina. |

| Ukomelezwa koKuhlala ixesha elide | Inika ukuchasana okukhethekileyo kokunxiba kunye nokubola, ukwandisa ubomi bokusebenza. |

| UkuSebenza kweendleko | Yehlisa ukugcinwa rhoqo, okukhokelela kugcino lweendleko ezibalulekileyo ekuhambeni kwexesha. |

Impembelelo yezeMali yokungahoyi uLondolozo

Ukungahoywa kwesondlo kukhokelela kwimiphumo ebiza kakhulu. Izinto ezigugileyo zandisa ukusetyenziswa kwamandla kwaye zinciphisa ukusebenza kakuhle kwemveliso. Ukonakaliswa rhoqo kubangela ukwehla okungacwangciswanga, ukuphazamisa ukusebenza kunye nokulibazisa ukuhanjiswa. Ekuhambeni kwexesha, iiindleko zokulungisaokanye ukutshintsha iindawo ezonakele kakhulu kuzidlula kude iindleko zokugcinwa rhoqo. Ukhathalelo olusebenzayo luqinisekisa ukusebenza okuhambelanayo kunye nokuthintela ilahleko yemali ebangelwa kukungaphumeleli kwezixhobo.

IiNgcebiso zokuLondoloza okuBalulekileyo kwimigqomo ye-Screw yamawele

Ukucoca Ukuthintela Ukwakhiwa Kwezinto

Ukwakhiwa kwezinto ngaphakathi kwe-twin screw barrels kunokuthintela ukusebenza kwaye kukhokelela ekungaphumeleli. Ukucoca rhoqo kuthintela ukuqokelelwa kwe-residu kwaye kuqinisekisa ukusebenza kakuhle.Iikhompawundi zokucoca zorhwebo(iiCPC) zinika isisombululo esisebenzayo sokucoca.

- Ii-CPCs zisusa i-resin, umbala, ungcoliseko, kunye neediphozithi zekhabhoni kumphezulu wombhobho.

- Ubudlelwane babo obuphantsi bentsimbi buphucula ukusebenza kakuhle kokucoca.

- Ii-CPC ezizinzile ngokwe-Thermally zithintela i-oxidation ngexesha lokuvalwa.

- Ezi khompawundi zanda kwiindawo ekunzima ukufikelela kuzo, zisusa izinto ezishiyekileyo ngokucokisekileyo.

- Ii-CPCs zipholile kwaye ziyancipha, zinceda ekususeni i-buildup enenkani.

Ukusebenzisa ii-CPCs kuneendleko ezisebenzayo xa kuthelekiswa neendlela zokucoca zendabuko, okwenza kube yinto ekhethiweyo yokugcina imibhobho ye-screw.

Ukuthambisa ukuNciphisa iFriction kunye nokuNxitywa

Ukuthambisa kudlala indima ebalulekileyo ekunciphiseni ukukhuhlana kunye nokunxiba kwimibhobho yesikrufu esingamawele. Ukuthambisa okufanelekileyo kuqinisekisa ukusebenza kakuhle kwaye kunciphisa uxinzelelo lomatshini.Ukukhetha i-lubricant efanelekileyoinokunciphisa kakhulu iindleko zexesha elide ngelixa iphucula ukusebenza kakuhle.

- Ukuthambisa kunciphisa ukunxiba koomatshini, kuthintela ukulahleka kwamandla okuqala.

- Igcina uxinzelelo oluyimfuneko lokupompa, iqinisekisa amanqanaba ahambelanayo emveliso.

- Ukuthambisa okufanelekileyo kuthintela ukunyuka kwe-radial clearance, okunokukhokelela ekuhambeni kokuvuza kunye nokunciphisa ukuphuma.

- Inceda ukuphepha amaqondo aphezulu okunyibilika, ukunciphisa isidingo sokunyuka kwe-RPM kunye nokusetyenziswa kwamandla.

Ngokubeka phambili ukuthambisa, abaqhubi banokwandisa ubomi bemigqomo yesikrufu esingamawele kwaye bagcine ukusebenza kakuhle.

Ukubeka iliso kwimimiselo yoBubushushu

Ulawulo lobushushu lubalulekile ekusebenzeni ngokufanelekileyo kweebhareli ezijijwa ngamawele. Ubushushu obugqithisileyo bunokonakalisa imathiriyeli kwaye kukhawulezise ukunxiba, ngelixa ubushushu obungonelanga bunokuthintela ukusetyenzwa. Abasebenzisi kufuneka babeke iliso kwizicwangciso zobushushu ngokusondeleyo ukugcina uluhlu olufanelekileyo lwezicelo ezithile.

Ukusebenzisa iisistim zokujonga ubushushu obuphezulu kuqinisekisa ukuhanjiswa kobushushu obuhambelanayo kunye nokuthintela ubushushu. Ezi nkqubo zinceda abaqhubi ukuba bachonge izinto ezingahambi kakuhle kwangethuba, zivumela uhlengahlengiso olungexesha ukuthintela umonakalo. Ulawulo olufanelekileyo lobushushu luphucula ukusetyenzwa kwezinto kunye nokunciphisa umngcipheko wokungaphumeleli kwezixhobo.

Ukuqhuba uhlolo lokunxiba rhoqo

Ukuhlolwa kokunxiba rhoqo kubalulekile ukuze kuchongwe imiba enokubakho ngaphambi kokuba inyuke. Abanini-zithuthi kufuneka bahlole iinqwelomoya ezizijija, iindonga zemigqomo, kunye nezinye izinto ezibalulekileyo kwiimpawu zokukrazuka okanye umhlwa.

Ukuhlolwa kokunxiba kunceda ukufumanisa umonakalo owenziwe kwangethuba, okwenza ungenelelo ngexesha elifanelekileyo. Ukusebenzisa izixhobo zokulinganisa ngokuchanekileyo kuqinisekisa uvavanyo oluchanekileyo lwamanqanaba okunxiba. Ukuhlolwa okucwangcisiweyo kunciphisa amathuba okuphuka okungalindelekanga, ukuqinisekisa imveliso engaphazamisekiyo.

Ukutshintshwa kwangexesha kwezixhobo ezigugileyo

Ukutshintshwa kwezinto ezigugileyo ngokukhawuleza kuthintela umonakalo ongakumbi kwaye kugcina ukusebenza kakuhle. Ukulibazisa ukutshintshwa kunokukhokelela ekusetyenzisweni kombane okwandisiweyo kunye nokuncipha kokuhamba komsebenzi. Abanini-zithuthi kufuneka bagcine uluhlu lweendawo ezisecaleni ezibalulekileyo ukulungiselela ukutshintshwa ngokukhawuleza.

Ukusebenzisa iintsimbi ezikumgangatho ophezulu kuqinisekisa ukuhambelana kunye nokuqina. Amalungu e-OEM abonelela ngokusebenza okuthembekileyo kunye nokwandisa ixesha lokuphila lemibhobho yesikrufu. Ukutshintshwa ngexesha elifanelekileyo kunciphisa ixesha lokunciphisa kwaye kuthintele ukulungiswa kweendleko, okunegalelo ekongeni iindleko zexesha elide.

IiNdlela eziGqwesileyo zokuFumana iiNdawo eziSetyenzisiweyo zeMibhobho yeSikruru samawele

Ukuvavanya ukuthembeka koMboneleli

Ukukhetha umthengisi othembekileyo kubalulekile ekuqinisekiseni ubomi obude kunye nokusebenza kweimigqomo yesikrufu esiwele. Ababoneleli abanegama elinamandla bahlala bebonelela ngezixhobo ezikumgangatho ophezulu ezihlangabezana nemigangatho yoshishino. Ukuvavanya ukuthembeka komthengisi kubandakanya izinto ezininzi eziphambili:

- Uphononongo lwabathengi lubonelela ngeembono ezixabisekileyo kwisidima somthengisi. Ingxelo encomekayo ihlala iqaqambisa ukuqina kwemveliso, ukusebenza ngokulula, kunye nenkxaso ephendulayo emva kokuthengisa.

- Ubungqina obuvela kwiingcali zoshishino ziqinisekisa amabango omthengisi malunga nokusebenza kwemveliso kunye nokuthembeka.

- Iwaranti ebanzi ibonisa ukuzithemba komthengisi kwiimveliso zabo, ngelixa inkxaso yobugcisa ethembekileyo inciphisa ixesha lokunciphisa kunye nemingeni yokusebenza.

- Ukufikelela ngokulula kwiindawo ezisecaleni kuqinisekisa ukuqhubeka kwemveliso, kunciphisa ukulibaziseka okubangelwa kukufumana ubunzima.

Ngokuqwalasela ezi zinto, amashishini anokukhetha ababoneleli abahambelana neemfuno zabo zokusebenza kunye nokulindela umgangatho.

Ukubaluleka kwaMacandelo e-OEM

Amacandelo e-Original Equipment Manufacturer (OEM) adlala indima ebalulekileyo ekugcineni ukusebenza kwe-twin screw barrels. Ezi nxalenye zenzelwe ngokukodwa ukuhambelana neenkcukacha zesixhobo, ukuqinisekisa ukuhambelana kunye nokusebenza kakuhle. Uphando lubonisa ukuba ukusebenzisa iinxalenye ze-OEM kunokunciphisa ukunxiba ukuya kuthi ga kwi-50 ukuya kuma-60 ekhulwini, njengoko zilungelelaniswe kwisicelo kwaye zenziwe kwizinto ezifanelekileyo kakhulu.

Amalungu e-OEM nawo aphucula ukuxhathisa ukunxiba kwaye andise ubomi bezikrufu kunye nemigqomo. Uyilo lwabo oluchanekileyo kunye nokuhambelana kwezinto kunciphisa umngcipheko wokungaphumeleli komatshini, ukuqinisekisa ukusebenza okuhambelanayo. Umzekelo, umthengi waseTshayina ugcine i-twin screw extruder phantse iminyaka engama-30 ngokusebenzisa iinxalenye ze-OEM kunye nokugcinwa kwesiqhelo. Eli tyala ligxininisa ukubaluleka kokukhangela umgangatho ophezulu, amacandelo athile kwisicelo ukuphumeza ukuthembeka kwexesha elide.

Ukuqinisekisa ukuhambelana kwezinto

Ukuhambelana kwezinto kuthathelwa ingqalelo xa kufunwa iindawo ezisecaleni zemibhobho engamawele. Izikrufu kunye nemigqomo kufuneka zenziwe kwi-alloys kunye nezixhobo ezingagugiyo ezihambelana nesicelo esithile. Izinto ezingahambelaniyo zinokukhokelela ekunxibeni okukhawulezileyo, ukunciphisa ukusebenza kakuhle, kunye nokuqhekeka rhoqo.

Ababoneleli kufuneka banike ulwazi oluneenkcukacha malunga nezinto ezisetyenziswa kwiimveliso zabo. Amashishini kufuneka aqinisekise ukuba iindawo ezikhethiweyo ziyahlangabezana neemfuno zokusebenza koomatshini babo. Ukukhethwa kwezinto ezifanelekileyo akugcini nje ukwandisa ukusebenza kodwa kunciphisa iindleko zokugcinwa kwexesha.

Ukugcina uluhlu lweeNdawo eziBalulekileyo eziSizi

Ukugcina uluhlu lweendawo ezisecaleni ezibalulekileyo sisicwangciso esisebenzayo sokunciphisa ixesha lokuphumla. Izinto ezibalulekileyo, ezifana nezikrufu kunye nemigqomo, kufuneka zihlale zifumaneka lula ukulungisa ukonakala okungalindelekanga. Le ndlela iqinisekisa ukuba iishedyuli zemveliso zihlala zingaphazamiseki, nangexesha likaxakeka.

Amashishini kufuneka abeke phambili ukugcina iinxalenye ze-OEM ukuqinisekisa ukuhambelana kunye nokuqina. Ukuphonononga rhoqo amanqanaba e-inventri kunye nokuzalisa kwakhona isitokhwe njengoko kuyimfuneko kuthintela ukulibaziseka okubangelwa yimingeni yokukhangela. Ngokugcina iindawo ezisecaleni ezibalulekileyo esandleni, abaqhubi banokugcina ukusebenza kakuhle kunye nokuthembeka kwemibhobho yabo yesikrufu.

UQeqesho lomSebenzi kunye noXwebhu lwemigqomo ye-Twin Screw

AbaSebenzi boQeqesho ngokuPhathwa ngendlela eyiyo

Ukuphathwa ngendlela eyiyo kwemibhobho yesikrufu ngamawele kuqalauqeqesho olubanzi lwabaqhubi. Abaqhubi bezakhono banokuthintela ukunxiba okungadingekile kwaye baqinisekise ukusebenza okuhambelanayo. Iiprogram zoqeqesho kufuneka zigxininise kubuchule bokuphatha ngokukhuselekileyo, njengokuphepha amandla amaninzi ngexesha lokuhlanganisa okanye ukuchithwa. Abanini-zithuthi kufuneka bafunde ukuchonga iimpawu zokuqala zokuguga, ezinje ngokungcangcazela okungaqhelekanga okanye ukuguquguquka kobushushu, ukujongana nemiba ngokukhawuleza.

Iiseshoni zoqeqesho, ezidityaniswe nolwazi lwethiyori, ziphucula ubuchule bomsebenzi. Umzekelo, ukuqonda impembelelo yokulungelelaniswa kwesijiva esingafanelekanga ekuhambeni kwezinto kunokunceda abaqhubi baphephe iimpazamo ezibiza kakhulu. Iikhosi zokuhlaziya rhoqo ziqinisekisa ukuba abaqhubi bahlala behlaziywa ngezenzo zogcino lwamva nje kunye nophuculo lwezixhobo.

Ukugcina iiRekhodi zoLondolozo oluneenkcukacha

Ukugcina iirekhodi zogcino oluneenkcukacha sisicwangciso esisebenzayo sokunciphisa ixesha lokuphumla nokuphucula ukuthembeka kwezixhobo. Ezi rekhodi zamaxwebhu okuhlolwa, ukulungiswa, kunye nokutshintshwa, okwenza abaqhubi bakwazi ukuchonga iipateni kunye nokuqikelela iimfuno zolondolozo lwexesha elizayo. Ngokomzekelo, ukulandelela iimvavanyo ze-vibration kunye neziphumo ze-imaging ye-thermal kunokubonisa iimpawu zokuqala zokunxiba, ukuvumela ungenelelo ngexesha elifanelekileyo.

Inkqubo yokugcinwa kweerekhodi ecwangciswe kakuhle ikwaququzelela ukuthotyelwaiingcebiso zomenzi. Ngokubhekisela kwimisebenzi yokulondoloza edlulileyo, abaqhubi banokucwangcisa amanyathelo okukhusela, ukunciphisa ukulungiswa kongxamiseko. Le ndlela ayigcini nje ukwandisa ubomi bemigqomo yesikruru kodwa ikwaqinisekisa imveliso engaphazanyiswa.

Ukusebenzisa iziKhokelo zoMvelisi ngokufanelekileyo

Izikhokelo zomenzi zibonelela ngezimvo ezixabisekileyo zokugcina imigqomo yesikrufu esingamawele. Ezi zikhokelo zichaza ezona ndlela zingcono zokucoca, ulondolozo lothintelo, kunye neenkqubo zokuhlola. Umzekelo:

| Ingcebiso yoLondolozo | Inkcazo |

|---|---|

| Ukucoca rhoqo | Isusa iintsalela ezinokuthintela ukusebenza. |

| ULondolozo oluThintelayo | Kubandakanya ukuhlolwa kwesiqhelo ukuthintela ukuguga okugqithisileyo kunye nokugcina ukusebenza kakuhle. |

| Iinkqubo zokuHlola | Uchonga ukunxiba kunye nokukrazula ngaphambi kokuba anyukele kwimiba ebalulekileyo. |

Abasebenzisi kufuneka balandele iingcebiso ezithile, ezinjengokugcina izithuba ezifanelekileyo phakathi kwemisonto yesikrufu kunye nomphezulu wombhobho. Ukuhlolwa rhoqo kuthintela imiba yobulunga ebangelwa ngamaqondo aphezulu okunyibilika. Ukongeza, ukulungelelanisa isantya se-screw kunye noseto lwamandla olusekwe kuvavanyo lokunxiba luqinisekisa ukusebenza kakuhle. Ukuthobela ezi zikhokelo kuphucula ukusebenza kakuhle kwaye kunciphisa iindleko zexesha elide.

Ukusebenzisana nabaBoneleli beNkonzo kwii-Twin Screw Barrels

Izinto eziluncedo kwiiNkonzo zoLondolozo oluKhethekileyo

Ukusebenzisana nabanikezeli benkonzo abakhethekileyo kunika inzuzo ebalulekileyo yokugcinaimigqomo yesikrufu esiwele. Ezi ngcali zinolwazi olunzulu ngezixhobo ezintsonkothileyo, ezibenza bakwazi ukujongana nemiba entsonkothileyo ngokufanelekileyo. Ubuchwephesha babo buqinisekisa ukuchaneka ngexesha lemisebenzi yokulondoloza, ukunciphisa umngcipheko weempazamo ezinokuphazamisa ukusebenza.

Ababoneleli ngeenkonzo nabo bazisa izixhobo eziphambili kunye nobuchule etafileni. Ngokomzekelo, basebenzisa izixhobo zokuxilonga ezikumgangatho ophezulu ukuchonga iipatheni zokunxiba kunye nokusilela okunokwenzeka. Le ndlela yokusebenza inciphisa ixesha lokuphumla kwaye yandisa ubomi besixhobo. Amashishini asebenzisana nababoneleli abakhethekileyo ahlala efumana impumelelo ephuculweyo yokusebenza kunye nokuncipha kweendleko zokugcina.

Uncedo ngoHlolo kunye noLungiso

Ababoneleli ngenkonzo badlala indima ebalulekileyo ekuqhubeni uhlolo olucokisekileyo kunye nokulungiswa kweebhareli ezijijwa ngamawele. Iindlela zabo zibandakanya ubuchwephesha obuphambili obunje nge-barrel relining, ukuhlolwa kwe-endoscope, kunye nemilinganiselo yokunxiba. Ezi nkonzo ziqinisekisa iimvavanyo ezichanekileyo kunye nokungenelela ngexesha elifanelekileyo.

| Uhlobo lweNkonzo | Inkcazo |

|---|---|

| I-Barel Relining | Inika enye indlela engabizi kakhulu yokutshintsha ngokupheleleyo, iqinisekisa ukuchaneka kunye nokhathalelo ekunxibelelaneni. |

| Ukuhlolwa kwe-Endoscope | Ibonelela ngohlalutyo oluneenkcukacha lwemeko yomphanda, okwenza ukuba kubonwe kwangethuba imiba enokwenzeka. |

| Umlinganiselo wokuGxilwa komphanda | Ifumanisa ukuguga kunye nokukrazula ukukhusela ixesha lokunciphisa iindleko, ukubonelela ngedatha yezigqibo zolondolozo ezinolwazi. |

Ngokusebenzisa ezi nkonzo, amashishini anokugcina umgangatho wemveliso ongaguqukiyo kwaye aphephe ukuwohloka okungalindelekanga. Ukubona kwangaphambili ukunxiba okanye umonakalo kuvumela abaqhubi ukuba bajongane nemiba ngaphambi kokuba banyuke, baqinisekise ukusebenza okungaphazanyiswa.

IiNgcebiso zeNgcali zokufumana iiNdawo eziSpare

Ababoneleli ngeenkonzo banika isikhokelo esixabisekileyo xaukufumana iindawo ezisecaleniiibhareli ezijijwa ngamawele. Amava abo kwishishini anceda amashishini achonge amacandelo akumgangatho ophezulu ahambelana neemfuno ezithile zokusebenza. Ababoneleli bahlala bencoma iinxalenye ze-OEM, ukuqinisekisa ukuhambelana kunye nokuqina.

Ukongezelela, ababoneleli ngeenkonzo bancedisa ekuqinisekiseni ukuhambelana kwezinto eziphathekayo, okubaluleke kakhulu ekusebenzeni kwexesha elide. Ukuqonda kwabo kunceda amashishini aphephe iimpazamo ezibiza kakhulu, ezinjengokusebenzisa izinto ezingahambelaniyo ezikhawuleza ukunxiba. Ngokuthembela kwiingcebiso zeengcali, abaqhubi banokwenza izigqibo ezinolwazi, ukuphucula ukuthembeka kwezixhobo kunye nokusebenza kakuhle.

Ukugcinwa rhoqo kunye nomgangatho wokukhangela iindawo ezisetyenzisiweyo zibalulekile ekuqinisekiseni ukusebenza ngokugqibeleleyo kwemibhobho yesikrufu esingamawele. Ukhathalelo olukhawulezileyo lunciphisa ixesha lokuphumla kwaye lwandisa ubomi besixhobo. Ukuphumeza ezi zenzo kuphucula ukusebenza kakuhle kwaye kunciphisa iindleko zexesha elide. Amashishini kufuneka abeke phambili ezi zicwangciso zokugcina imveliso ehambelanayo kunye nokufezekisa ukuthembeka kwexesha elide.

FAQ

Zeziphi iimpawu zokuguga kwimibhobho yesikrufu esingamawele?

Abanini-zithuthi kufuneka bajonge umthamo ocuthiweyo, ukusetyenziswa kwamandla okwandisiweyo, ukungcangcazela okungaqhelekanga, okanye umonakalo obonakalayo wokujija iinqwelomoya kunye neendonga zemigqomo.

Kukangaphi kufuneka imigqomo yezikrufu ezimbini igcinwe?

Ukugcinwa rhoqo kufuneka kwenzeke rhoqo kwi-1,000 ukuya kwi-2,000 yeeyure zokusebenza, ngokuxhomekeke kubukhulu bokusetyenziswa kunye nokunyanzeliswa kwezinto.

Ngaba iindawo ezingezizo eze-OEM zingasetyenziselwa ukutshintshwa?

Amalungu angengawo awe-OEM anokungena kodwa ahlala engachanekanga kunye nokuqina kwamalungu e-OEM, okukhokelela ekusebenzeni okucuthiweyo kunye nokunxiba okwandileyo.

Ixesha lokuposa: May-24-2025