Ilabhoratri ye-screw extruder isebenzisa isikrufu esijikelezayo ukunyibilika, ukuxuba, kunye nokubumba iipholima ngaphakathi komphanda oshushu. Abaphandi baxhomekeke kwikuphume isikrufu esinye, umatshini wokujija omnye, kwayeumatshini wegranulator ongenamanziukufezekisa ukuxubana okufanelekileyo kunye nokhuseleko olukhuselekileyo, olusebenzayo. Uphando lubonisa ukubaisantya screw kunye lobushushunefuthe ngqo umgangatho imveliso kunye nokhuseleko.

Amacandelo Angundoqo eSikruru Esisodwa

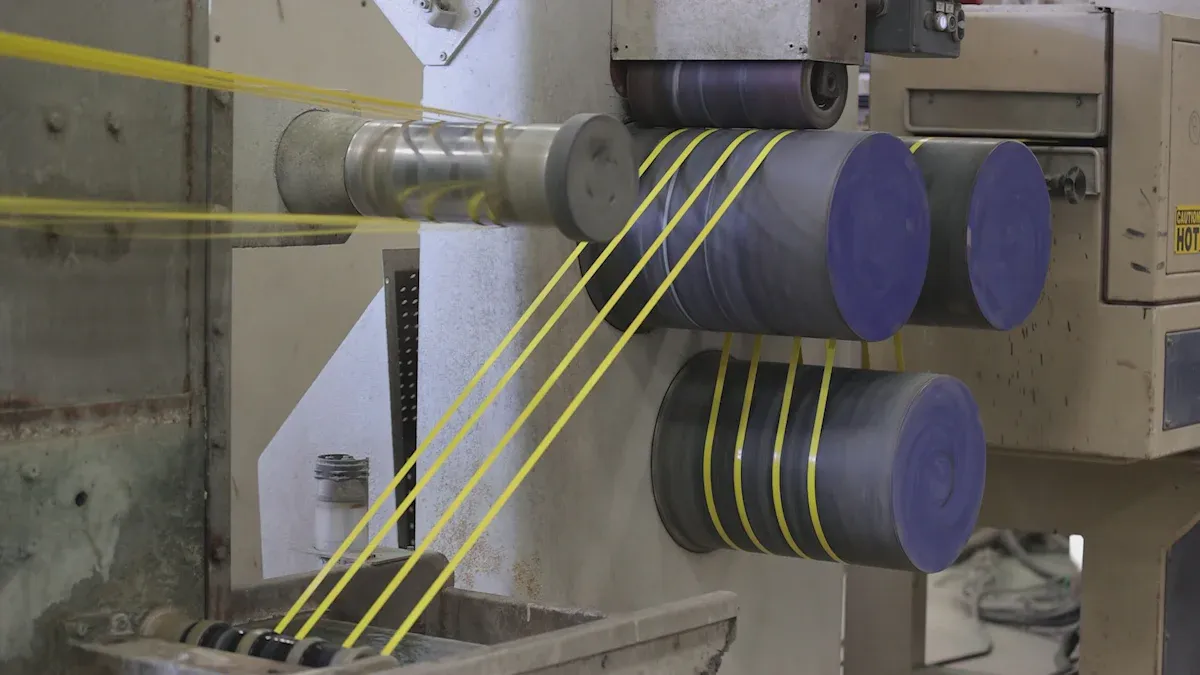

I Screw

Isikrufuyintliziyo yesikrufu esinye. Ijikeleza ngaphakathi kombhobho kwaye ihambisa i-polymer phambili. Isikrufu siyanyibilika, sixube, kwaye sityhalele imathiriyeli kwicala lokufa. Uyilo lwe-Screw, oluquka i-diameter, ubude-to-diameter ratio, kunye ne-compression ratio, ichaphazela indlela i-polymer enyibilika kwaye ixube ngayo. Isikrufu esiyilwe kakuhle siphucula izinga lokunyibilika kunye nokusebenza kakuhle. Iigrooves kwi-screw okanye i-barrel inokunyusa isantya sokunyibilika kwaye incede ukulawula inkqubo. Isantya se-screw siphinde sitshintshe inani lokuxuba kunye nobushushu obuveliswayo.

Ingcebiso: Ukulungelelanisa isantya se-screw kunokunceda ukulawula ubushushu obunyibilikayo kunye nomgangatho wemveliso.

Umphanda

Umphandaijikeleze isikrufu kwaye ibambe ipholima njengoko ishukuma. Umphanda uneendawo ezahlukeneyo zobushushu. Indawo nganye inokumiselwa kwiqondo lobushushu elithile ukunceda ukunyibilikisa ipholima ngokulinganayo. Umzekelo, indawo yokuqala inokuba pholileyo ukunceda ukuhambisa ipholima eqinileyo, ngelixa imimandla yamva ishushu ngakumbi ukunyibilikisa izinto. Ukulawula ukushisa okufanelekileyo kwi-barrel kubalulekile ukuhamba kakuhle kunye nomgangatho wemveliso.I-Thermocouples ilinganisa ubushushu ngaphakathi kombhobhoukugcina inkqubo izinzile.

- Iisetingi zobushushu bebhareli zixhomekeke kuhlobo lwepolymer kunye noyilo lwe screw.

- Ii-extruders zanamhlanje zihlala zineendawo ezintathu okanye ngaphezulu zobushushu.

- Icandelo lesondlo kufuneka lifudumale kodwa lingatshisi kakhulu ukuphepha izinto ezincamathelayo.

Inkqubo yokufudumala

Inkqubo yokufudumala igcina umgqomo kwiqondo lokushisa elifanelekileyo. Izifudumezi zibekwe ecaleni komgqomo kwaye zilawulwe zinzwa. Inkqubo inokulungelelanisa indawo nganye ukuze ihambelane neemfuno zepolymer. Ulawulo olululo lwesifudumezi lunceda ukunqanda iingxaki ezifana nokutsha kwezinto okanye ukunyibilika okungalinganiyo. Inkqubo yokufudumala isebenza kunye nenkqubo yokulawula ukugcina inkqubo ikhuselekile kwaye isebenza kakuhle.

I-Die

I-die ibumba ipholima enyibilikisiweyo njengoko ishiya i-extruder screw enye. Uyilo lokufa luchaphazela ubume bemveliso yokugqibela, umphezulu, kunye nobukhulu. Ukufa okulungileyo kunika ukuhamba okugudileyo, okulinganayo kwaye kunceda ukwenza iimveliso ezinobungakanani obuchanekileyo. Idayi kufuneka iphathe ubushushu obufanelekileyo kunye noxinzelelo lokuphepha iziphene. Utshintsho kwiqondo lobushushu okanye ukuhamba kungatshintsha umgangatho wemveliso.

- Isantya esifanayo kunye nokuhla koxinzelelo oluncinci kwindawo yokuphuma ibalulekile kumgangatho.

- Die channel geometry kunye flow balance kuchaphazela ukuchaneka imilo imveliso.

Inkqubo yoLawulo

Inkqubo yokulawula ilawula ukusebenza kwe-screw extruder enye. Ibeka iliso kwiqondo lokushisa, uxinzelelo, isantya se-screw, kunye nesantya sokutya. Abaqhubi basebenzisa inkqubo yokulawula ukuseta nokulungelelanisa iiparamitha zenkqubo. Ukubeka iliso ngexesha lokwenyani kunceda ukugcina inkqubo izinzile kwaye ikhuselekile. Inkqubo yokulawula inokugcina iiresiphi zeepolymers ezahlukeneyo, okwenza kube lula ukuphinda ugijime ngempumelelo.

Iintlobo zeSikruru esiNye Extruder sokuSetyenziswa kweLabhoratri

Iisetingi zeLabhoratri zifuna iintlobo ezahlukeneyo ze-extruders ukuhlangabezana neemfuno ezithile zophando. Uhlobo ngalunye lubonelela ngeempawu ezizodwa kunye neenzuzo zokusetyenzwa kwepolymer.

Vented Single Screw Extruder

I-extruder yesijija esiphumayo sisebenzisa auyilo lwezikrufu ezimbini. Olu luyilo lunciphisa i-torque kunye neemfuno zamandla ehashe ngelixa ligcina imveliso kunye nesantya se-screw. Inkqubo yokukhupha umoya isusa ukufuma kunye neegesi kwi-polymer melt. Eli nyathelo libalulekile ekwenzeni iiplastiki ezifunxa amanzi. Ukususa oku kuguquguquka kuthintela iziphene ezifana ne-splay kunye neempawu ezibuthathaka zomatshini. Izibuko lokungenisa umoya lihlala lisebenza phantsi kwevacuum, enceda ukukhupha umoya ngokwehlisa uxinzelelo. I-screw enamanqanaba amabini iphinda iphucule ukuxuba ngokucinezela kunye nokunciphisa iplastiki. Le nkqubo idala ukunyibilika okufanayo. Abanini-zithuthi kufuneka balungelelanise imveliso phakathi kwezigaba ezibini ukunqanda ukuvuthuza okanye ukuphuphuma kwamanzi. Ezi mpawu zenza i-extruder ye-screw eyodwa ephumayo isebenze kwaye ithembekile kwizicelo zaselabhu.

Qaphela: Imveliso ezinzileyo kunye nokusetyenziswa kwamandla aphantsi kubeke ii-extruders eziphuma ngaphandle kwiindawo zophando.

Umatshini wokuScrew omnye

Umatshini omnye wokujija ugubungela uluhlu olubanzi lwee-extruders zokunyibilika, ukuxuba, kunye nokubumba iipolymers. Aba matshini banikezela ngoyilo olulula kunye nokusebenza ngokulula. Abaphandi banokulawula ukucheba kunye nobushushu ngokufanelekileyo, okunceda ekuqulunqweni kwesiseko sepolymer kunye nemisebenzi ye-extrusion. Oomatshini be-screw ababodwa basebenza kakuhle ekwenzeni i-tubing, ifilimu, kunye nezinye iimveliso ezilula. Ziza ngobukhulu obahlukeneyo kunye nolungelelwaniso ukuhambelana neemfuno ezahlukeneyo zophando.

| Uhlobo lwe-Extruder | Iimpawu eziphambili kunye nezinto eziluncedo | Izicelo eziqhelekileyo kunye nokufaneleka |

|---|---|---|

| I-Screw Extruders enye | Uyilo olulula, ulawulo oluhle, ukusebenza lula | Iityhubhu, ifilimu, isiseko sepolymer formulations |

| I-Twin Screw Extruders | Ukuxuba okuphezulu, ukuguquguquka, izikrufu ezidibeneyo | Ukudibanisa, izinto ezinzima, amayeza |

| I-Micro Extruders / Miniature | Incinci, ingabizi, ithembekile | I-R&D, iprototyping, iisampulu zemathiriyeli ezincinci |

Umatshini weGranulator ongenaManzi

Umatshini wegranulator ongenamanzi uguqula izinto zeplastiki zibe yigranule ngaphandle kokusebenzisa amanzi. Le teknoloji iphucula ukusebenza kakuhle kwamandla kwaye inciphisa impembelelo yokusingqongileyo. Inkqubo igcina iigranuli zomile kwaye zicocekile, nto leyo enceda amanyathelo okuqhubela phambili. Oomatshini begranulator abangenamanzi baphatha iintlobo ezininzi zeentlaka zeplastiki. Banceda abaphandi ukuba bavelise iigranule ezikumgangatho ophezulu zokuvavanya nophuhliso.

Inyathelo ngeNyathelo Inkqubo yePolymer Extrusion

Ukondla iMathiriyeli yePolymer

Inkqubo ye-extrusion iqala ngokondla imathiriyeli ekrwada yepolymer kwi-hopper yokutya. I-hopper iqinisekisa ukusabalalisa kunye nokuthintela izithintelo, ezinceda ukugcina ukuhamba okuzinzileyo. I-Screw ngaphakathi kwi-barrel iqala ukujikeleza, idonsa iipelisi zepolymer okanye umgubo phambili. Uyilo lwe-screw, kubandakanywa ububanzi bayo kunye nobude-to-diameter ratio, idlala indima ebalulekileyo kwindlela ehamba ngayo ngokufanelekileyo. Inkqubo yokulawula ivumela abaqhubi ukuba bahlengahlengise isantya se-screw kunye nesantya sokutya, esinceda ukulungisa kakuhle inkqubo yeepolymers ezahlukeneyo.

- I-feed hoppers ziyilelwe ukuthintela iiclogs kunye nokuqinisekisa ukutya okugudileyo.

- I-Screw ihambisa, icinezele, kwaye iqala ukutshisa i-polymer.

- Ulawulo lobushushu kumbhobho kunceda ukwandisa inkqubo yokunyibilika.

Uphononongo lwakwangoko lusekiwe ukuba ukulawula isantya se-screw kunye nobushushu buchaphazela ngokuthe ngqo indlela ipolymer etyisa ngayo kwaye inyibilika ngayo. Ii-extruders zalebhu zanamhlanje zisebenzisa ulawulo oluphambili ukugcina ukondla ngokufanelekileyo kwaye kuzinzile.

Ukunyibilika kunye nePlastiki

Njengoko i-polymer ihamba ecaleni kombhobho, ingena kwiindawo ezishushu. Iqondo lokushisa kwindawo nganye liyanda ngokuthe ngcembe, libangela ukuba i-polymer ithambe kwaye inyibilike. Ukujikeleziswa kwesikrufu kunye nobushushu bombhobho basebenza kunye ukwenza iplastiki into, ukuyijika ibe bubunzima obutyhidiweyo obufanayo. Izinzwa ezibekwe ecaleni kombhobho zijonga zombini ubushushu kunye noxinzelelo lokuqinisekisa ukuba i-polymer iyanyibilika phakathi koluhlu olufanelekileyo lokusetyenzwa.

| Ipharamitha | Inkcazo |

|---|---|

| Melt Ubushushu | Kufuneka uhlale ngaphakathi koluhlu lokusetyenzwa kwepolymer ukuze ufumane iziphumo ezilungileyo. |

| Uxinzelelo Ngaphezu Kwesikrufu | Ibonisa umgangatho wokunyibilika kunye nokuzinza kwenkqubo. |

| Ukuguquguquka koxinzelelo | Ibekwe esweni ukukhangela nayiphi na imiba ngokunyibilika okanye ukuhamba. |

| Ukuguquguquka kobushushu | Ilandelelwe ukuqinisekisa ukufudumeza kunye nokuphepha iziphene. |

| Iqondo lokunyibilika | Ihlolwe ngokubonakalayo okanye ngokuvavanya ifilimu ekhutshiweyo ukucaca kunye nokufana. |

| Screw Performance Index | Udibanisa le miba ukukala umgangatho wokunyibilika ukusuka kokubi (0) ukuya kokugqwesileyo (1). |

Ulawulo oluchanekileyo lobushushu kunye noxinzelelo lunceda ukukhusela ukuthotywa kunye nokuqinisekisa ukunyibilika okuhambelanayo. Ukubeka iliso ngexesha langempela kunye neenzwa eziphambili kunye nobuchule be-spectroscopy kunika idatha eqhubekayo, evumela abaphandi ukuba bahlengahlengise izicwangciso njengoko kufuneka.

Ukuxuba kunye nokuhambisa

Emva kokuba inyibilikile, i-polymer kufuneka ixutywe kakuhle ukuqinisekisa ukufana. Uyilo lwe-screw, olubandakanya iimpawu ezinje ngamacandelo omqobo okanye iindawo zokuxuba, zinceda ukudibanisa izinto kunye nokususa nawaphi na amaqhekeza asele eqinile. Njengoko i-screw ijikeleza, ityhala i-polymer etyhidiweyo phambili, iyigqithisele kwifa.

Abaphandi basebenzisa iiseti eziphambili ngeiisampulu zezibuko kunye nee-optical detectorsukufunda indlela izinto ezixuba kakuhle ngayo. Ngokufaka i-tracers kunye nokulinganisa indlela ezisasazeka ngayo, banokubona indlela isantya se-screw kunye nejometri ekuchaphazela ngayo ukuxuba. Izantya eziphezulu zokujija ngamanye amaxesha zinokushiya amaqhekeza aqinileyo, kodwa uyilo olukhethekileyo lwe-screw luphucula ukuxuba kwaye luthintele lo mba.Izinzwa zoxinzelelo ecaleni kombhobhojonga ukuba i-polymer ihamba ngokufanelekileyo kangakanani, inceda abaqhubi ukuba baphucule inkqubo.

Ukubumba NgeDie

I-polymer etyhidiweyo ifikelela kwi-die, eyibumba ibe yifom efunwayo. Uyilo lwedayizi lumisela ubungakanani bemveliso yokugqibela kunye nomgangatho womphezulu. Iinjineli zisebenzisa ukulinganisa kwekhompyuter kunye nohlalutyo lwezinto ezinomda ukuyila ukufa okuvelisa iimilo ezichanekileyo kunye nokunciphisa iziphene. Bakwanyusa ijometri yejeyometri yomjelo wokuqukuqela ukulinganisa isantya kunye nokunciphisa umahluko wemolekyuli, onokuchaphazela imilinganiselo yemveliso.

| Inkalo yobungqina | Inkcazo |

|---|---|

| Finite Element Analysis | Isetyenziselwa ukufunda ukuhamba kunye nokubumba ukuchaneka kwidayiri. |

| Uyilo loPhuculo | Ukunciphisa iimpazamo kunye nokuphucula ukuchaneka kwejometri. |

| Ukuqinisekiswa koMvavanyo | Iqinisekisa ulawulo oluluqilima lwemilinganiselo yemveliso. |

| Ukulinganisa kwamanani | Uqikelelo lufa ludumba kunye nentshukumo yojongano lweziphumo ezingcono. |

| Ulawulo lokuJongene neMolekyuli | Iibhalansi ziyahamba ukuthintela ukolula okungalinganiyo kunye notshintsho lwemilo. |

Ulawulo oluchanekileyo lokufa kunye nezixhobo ezisezantsi ziqinisekisa ukuba imveliso ishiyaIsikruru esiNye Extruderenemilo kunye nobukhulu obuchanekileyo.

Ukupholisa kunye nokuqinisa

Emva kokubumba, i-polymer eshushu iphuma kwi-die kwaye ingene kwisigaba sokupholisa. Ukupholisa kuqinisa i-polymer, ukuvala kwimo yayo yokugqibela kunye neempawu. Izinga lokupholisa lixhomekeke kwiqondo lokushisa le-extrusion, iimeko ze-ambient, kunye nesantya apho imveliso ihamba ngayo kwindawo yokupholisa.

| IParameter/Inkalo | Ukuqwalaselwa/isiphumo |

|---|---|

| Extrusion lobushushu | Ipolymer ikhutshwe kwi-100 °C |

| Ubushushu obugciniwe | Igcinwe malunga ne-20 °C ngexesha lovavanyo |

| Iqondo lokupholisa lobushushu obuphezulu | Malunga nama-72 °C |

| Isiphumo sesantya | Izantya ezisezantsi zicotha ukupholisa kwaye zandisa ixesha lokuqina |

| Izinga lokupholisa lokuziphatha | Isantya esiphezulu siyehla njengoko isantya sincipha; i-peak shifts ukuya kwixesha elide |

| Isiphumo se-Multi-layer | Iileyile zamva zinokuphinda zifudumeze ezo zangaphambili, ziphucule ukuncamathela |

Ukugcina iizowuni zokupholisa ngaphakathi koluhlu olumxinwa lobushushu, rhoqo ngaphakathi ±2°C, kunceda ukuqinisekisa umgangatho wemveliso ongaguqukiyo. Ukupholisa okufanelekileyo kuthintela ukulwa kwaye kuqinisekisa ukuba i-polymer iyaqina ngokulinganayo.

Usetyenziso lweSikruru esiNye Extruder kuPhando lwePolymer

Ukuqulunqwa kwezinto kunye noVavanyo

Abaphandi basebenzisa ii-extruders zaselabhoratri ukuphuhlisa kunye nokuvavanya imixube emitsha yepolymer. Izifundo ezisisiseko kunye namalungelo awodwa omenzi wechiza achaza ukuba njaniuyilo Screwkunye nokulawula ubushushu kuphucula ukunyibilika kunye nokuxuba. Olu phuculo lunceda izazinzulu zenze izinto ezintsha ezineempawu ezithile. Ngokomzekelo, i-extruder ephantsi yomthamo owenziwe ngezixhobo zasekhaya ibonise ukusebenza okuqinileyo kwimveliso ye-lab-scale. Icutshungulwe ukuya kuthi ga kwi-13 kg ngeyure kwaye yanciphisa iikhompawundi ezingafunwayo kwimveliso yokugqibela. Ezi ziphumo ziqinisekisa ukuba i-laboratory extruders ixhasa zombini izinto ezintsha kunye nokulawula umgangatho ekuqulunqweni kwezinto.

| Ipharamitha | Ixabiso/Isiphumo |

|---|---|

| Umsebenzi | 13.0 kg/h |

| Isantya seScrew | 200 rpm |

| Umphanda Ububanzi | 40 mm |

| Ukwandiswa komlinganiselo | 1.82–2.98 |

| Ukunciphisa i-Trypsin Inhibitor | 61.07%–87.93% |

Inkqubo yokuPhucula

Ii-extruders zaselabhoratri zinceda izazinzulu ukuba zifumane ezona zicwangciso zenkqubo zingcono kwiipolymers ezahlukeneyo. Idatha yovavanyo ibonisa ukubaUkusetyenziswa kwamandla kuxhomekeke kwisantya sesijija kunye neempawu zezinto eziphathekayo. Ngokurekhoda amandla eemoto kunye nokulungelelanisa izicwangciso, abaphandi banokuphucula ukusebenza kakuhle kwamandla kunye nomgangatho wemveliso. Uphononongo lukwabonisa ukuba utshintshoisantya sokujijakwaye ukongeza izithako ezithile kunokuphucula indlela iipolymers ezixuba ngayo kunye nokuhamba. Ezi ziphumo zinceda amaqela ukuseka iinkqubo ezikhuselekileyo, ezisebenzayo, neziphindaphindwayo kuzo zombini uphando kunye nemveliso.

Ingcebiso: Ukulungelelanisa isantya se-screw kunye nobushushu kunokulinganisa ukusetyenziswa kwamandla kunye nokuphucula umgangatho wemveliso.

Iprototyping yeeMveliso eziNcinci

I-Lab extruders yenza kube lula ukwenza iibhetshi ezincinci zeemveliso ezintsha. Amaqela anokulawula ubushushu, uxinzelelo, kunye nesantya se-screw ngeziphumo ezithembekileyo. Le ndlela yonga imali kwaye ikhawulezisa uphuhliso. Abaphandi banokukhawuleza bavavanye imibono emitsha kwaye banyuse abo baphumeleleyo. I-compact extruders ikwavumela utshintsho oluguquguqukayo kwizinto okanye kuyilo. Inkqubela phambili kwi-automation kunye nokubeka iliso ngexesha lokwenyani liphucula ngakumbi ulawulo lwenkqubo kunye nokunciphisa inkunkuma.

- Ulawulo oluchanekileyo kwiiparamitha zenkqubo

- Iprototyping enexabiso kunye nekhawulezayo

- Ukulungelelaniswa lula kwizinto ezahlukeneyo

- Umgangatho wemveliso ophuculweyo kunye nokufana

Iingcebiso zokuSebenza kunye nokuJonga iNgxaki kwiSikruru esiNye Extruder

Ukumisela i-Extruder

Ukuseta ngokufanelekileyo kuqinisekisa ukusebenza okuthembekileyo kunye nokwandisa ubomi besixhobo. Amagcisa alandela eziamanyathelo okusebenza kakuhle:

- Faka izikrufukwizikhundla zabo zokuqala kwaye uvavanye izikrufu ezitsha ngesantya esiphantsi ngaphambi kokuba zisebenze ngokupheleleyo.

- Ukulinganisaulawulo lobushushuizixhobo rhoqo uhlengahlengiso oluchanekileyo.

- Sebenzisa amanzi adibeneyo kwitanki yokupholisa ukuthintela ukunyuswa kunye nokukhangela amanqanaba amanzi rhoqo.

- Hlola iivalvu ze-solenoid kunye neekhoyili, utshintshe naziphi na iindawo ezingalunganga.

- Khusela ii-couplers yonke imihla kwaye uqinisekise ukuba ii-relay zone zokufudumeza kunye neevalvu ze-solenoid zisebenza ngokuchanekileyo.

- Amatanki acocekileyo acocekileyo kunye namagumbi okukhupha; buyisela amakhonkco okutywina agugileyo njengoko kufuneka.

- Jonga iibrashi zeemoto zeDC kwaye ukhusele kumhlwa.

- Ukutshisa kancinci kancinci ngexesha lokuqalisa kwaye unyuse isantya se-screw kancinci.

- Lubricate iindawo ezihambayo kwaye uqinise i-fasteners rhoqo.

- Ukugcina ixesha elide, sebenzisa igrisi echasene nomhlwa kwaye ugcine izikrufu ngokufanelekileyo.

Ingcebiso: Ukulandela la manyathelo kunceda ukugcina umgangatho wemveliso kunye nexesha elide lesixhobo.

Imiba eqhelekileyo kunye nezisombululo

Abaqhubi banokudibana nemiba emininzi ngexesha lokusebenza. Le theyibhile ingezantsi ichaza iingxaki eziqhelekileyo kunye nezisombululo:

| Uluhlu loMba | Imiba eqhelekileyo | Oonobangela | Iimpawu | Izisombululo |

|---|---|---|---|---|

| Ukusilela koomatshini | Isikrufu sixingile | Ukwakhiwa kwezinto, i-lube embi | Ukugcwala kweMotor, ingxolo | Coca, thambisa, uhlole |

| Ukusilela koMbane | Ukungaphumeleli kweemoto | Ukushisa, isiphaluka esifutshane | Akukho siqalo, ukufudumeza | Hlola inkqubo, kunqande ukugcwala |

| Ukusilela kweNkqubo | Iplastiki engalunganga | Isantya esiphantsi, isantya esingalunganga | Umphezulu orhabaxa, amaqamza | Lungisa isantya, isantya, imathiriyeli |

| Amanyathelo othintelo | Isondlo | Ukunqongophala kokucoca, ukuhlolwa | N / A | Ukucoca ishedyuli, ukuhlolwa |

Ukuhlolwa nokugcinwa rhoqo kuthintela imiba emininzi. Abaqhubi kufuneka balandele imiyalelo yesandla xa belungisa ukufa kwe-extrusion ukuphepha iimpazamo.

Iingqwalasela zoKhuseleko

Ukusebenza kweLabhoratri ye-extruder kubandakanya iingozi ezininzi. Amanyathelo okhuseleko aquka:

- Ukunxiba izixhobo zokuzikhusela ezifana nezihlangu zokhuseleko kunye neendondo.

- Ukuphepha impahla exegayo kufutshane neendawo ezihambayo.

- Ukuthoba zonke izixhobo zombane ngabasebenzi abaqeqeshiweyo.

- Ukugcina imigangatho yomile kunye nokusebenzisa amaqonga okanye iidreyini ukuthintela ukutyibilika.

- Ukufaka oonogada kwiindawo ezihambayo ukukhusela izandla.

- Ukusebenzisa imigca yokuqalisa ukuthunga endaweni yokutyisa ngesandla.

Qaphela: Ukhuseleko olungqongqo lunciphisa umngcipheko wokutsha, ukothuka kombane kunye nokwenzakala koomatshini.

Ii-extruders zaseLabhoratri zixhasa ukhuseleko, ukusebenza ngokufanelekileyo kwepolymer ngokusebenzisaulawulo oluchanekileyo lobushushu, uxinzelelo, kunye nesantya sokujija. Abaphandi baxhamla kwimveliso yeebhetshi ezincinci, ukunciphisa inkunkuma, kunye neprototyping ngokukhawuleza. Uyilo lwemodyuli luvumela utshintsho olukhawulezayo kunye nokwenza ngokwezifiso. Ukuziqhelanisa kunye nokuqwalaselwa kweenkcukacha kunceda ukufezekisa iziphumo ezithembekileyo kunye nokukhuthaza ukusungula izinto ezintsha kuphando lwepolymer.

FAQ

Zeziphi iipholima ezinokuthi inkqubo yelabhoratri enye Screw extruder?

A elebhu enye Scruder extruderinokusebenza uninzi lwe-thermoplastics, kubandakanya i-polyethylene, i-polypropylene, i-polystyrene, kunye ne-PVC. Abaphandi bahlala bekhetha izinto ezisekelwe kwiimfuno zeprojekthi.

Ukukhupha umoya kuphucula njani umgangatho wepolymer?

Ukukhupha umoya kususa ukufumakunye neegesi ezivela kwi-polymer ziyanyibilika. Eli nyathelo lithintela iziphene, ezifana namaqamza okanye amabala abuthathaka, kwaye liphucula iimpawu zomatshini zemveliso yokugqibela.

Abaqhubi bawalawula njani amaqondo obushushu e-extrusion?

Abaqhubi babeka kwaye bajonge amaqondo obushushu emigqomo besebenzisa inkqubo yokulawula. Izinzwa zibonelela ngengxelo yexesha langempela, ukuvumela uhlengahlengiso oluchanekileyo lokunyibilika kwepolymer kunye nokubunjwa.

Ixesha lokuposa: Jul-01-2025