Iplastiki yokubumba umbhobho wesikrufu udlala indima enkulu ekubumbeni umgangatho wokunyibilika kunye nesantya semveliso. Iinjineli zijolise kwiIsitofu sokubumba umphandauyilo lokunyusa ukusebenza. Basebenzisa izixhobo ezahlukeneyoIsikruru esinye sePlastiki yokukhupha umatshinikwayeUmatshini wokuSikrola omnye oNye. Ukhetho ngalunye lunceda oomatshini baqhube iiplastiki ngcono.

I-Plassic Injection Molding Screw Barel Isakhiwo kunye nokuSebenza

Iindidi zemiphanda: Bimetallic vs. Integral

Ukukhetha uhlobo lomphanda oluchanekileyo lungenza umahluko omkhulu kwindlela aIsitofu sePlastiki sokubumba umgqomo wesikrufuyenza. Iibhobho ze-Bimetallic zisebenzisa isiseko esiqinileyo sentsimbi kunye ne-alloy lining eqinile ngaphakathi. Olu yilo lugcina izinto ezixabisekileyo kwaye luvumela abavelisi ukuba bathathe indawo ye-lining egugileyo kuphela, eyenza ukugcinwa kube lula kwaye kungabizi kakhulu. Ukulingana phakathi kwe-lining kunye ne-barrel kufuneka ichaneke ukugcina ubushushu buhamba kakuhle kwaye buthintele ukuhamba. Imigqomo ye-Bimetallic isebenza kakuhle ekuqhubeni iiplastiki ezinqabileyo okanye ezomeleziweyo kuba zixhathisa ukunxiba kwaye zihlala ixesha elide.

Imibhobho edibeneyo yenziwa njengeqhekeza elinye. Oku kubanika ukuchaneka okuphezulu kunye nokusasazwa kobushushu ecaleni komphanda. Benza ukuba kube lula ukufaka nokugcina iinkqubo zokufudumeza kunye nokupholisa. Nangona kunjalo, bafuna ulawulo olungqongqo lwemveliso ukugcina umgangatho uphezulu. Xa uthelekisa ezi zimbini, imigqomo edibeneyo ibonelela ngolondolozo olulula kunye nokufudumeza okufanayo, ngelixa imigqomo ye-bimetallic ibonelela ngokumelana nokunxiba okungcono kunye nokutshintshwa kwenxalenye elula.

| Umba wokuSebenza | Umphanda odibeneyo | Umgqomo weBimetallic |

|---|---|---|

| Ukwakhiwa | Isiqwenga esinye, ukuchaneka okuphezulu kwemveliso | Umgqomo wesiseko kunye ne-alloy steel bushing enokutshintshwa |

| Ukusasazwa koBubushushu | Ukusasazwa kobushushu obulinganayo ecaleni kwe-asis yomphanda | Ukuqhutywa kobushushu kuyagcinwa ukuba i-bushing fit ichanekile |

| Nxiba ukuxhathisa | Ukumelana nokunxiba okusemgangathweni | Ukomelezwa kokumelana nokunxiba ngenxa yentsimbi ye-alloy |

| Isondlo | Ufakelo olulula kunye nokugcinwa kweenkqubo zokufudumeza / zokupholisa | I-bushing enokubuyiselwa ivumela ukutshintshwa kwenxalenye lula |

| Ukusetyenziswa kwezinto eziphathekayo | Ifuna ukuchaneka okuphezulu kunye nomgangatho wezinto eziphathekayo | Ugcina izinto ezixabisekileyo ngokusebenzisa i-alloy iron kuphela kwi-lining |

Imigqomo yeBimetallic ihlala ixesha elide kunemigqomo edibeneyo, ngakumbi xa kusetyenzwa izinto ezinzima. Uyilo lwabo lunciphisa ixesha lokuphumla kunye neendleko zokutshintshwa, ezinceda ukugcina imveliso isebenza kakuhle.

I-Screw Geometry: I-L/D Ratio, i-Compression Ratio, kunye noYilo lweFlight

Ijometri yeScrew ngaphakathi kwePlastiki Isitofu sokubumba umbhobho wesikrufuiimilo zeplastiki zinyibilika kwaye zixube. Umlinganiselo we-L / D, othelekisa ubude be-screw kwi-diameter yayo, ichaphazela ukunyibilika okufanayo kunye nokuxuba. I-screw ende (umlinganiselo ophezulu we-L / D) unika iplastiki ixesha elide lokunyibilika kunye nokuxuba, okuphucula umgangatho wemveliso. Nangona kunjalo, ukuba isikrufu side kakhulu, sinokubangela ukuthotywa kobushushu, ngakumbi ngeeplastiki ezingevani nobushushu. Izinto ezifana ne-PVC kunye ne-POM zidinga izikrufu ezimfutshane ukuphepha umonakalo, ngelixa iiplastiki ezizaliswe ngeglasi okanye i-viscosity ephezulu zixhamla kwizikrufu ezinde kunye neendawo zokuxuba eziqinisiweyo.

- Izinto eziphathekayo ezinozinzo oluhle lwe-thermal zisebenzisa izikrufu ezinde zokuxuba okungcono.

- Iiplastiki ezingevani nobushushu zifuna izikrufu ezimfutshane okanye imisonto ekhethekileyo yoyilo.

- Izikrufu zenjongo ngokubanzi (L/D ~20:1) zilungele iiplastiki eziqhelekileyo kodwa zinokubonisa ukuhluka kombala.

- Izikrini zokuthintela (L / D ~ 24: 1) ziphucula ukuxuba iiplastiki eziqinisiweyo.

- Izikrufu zokwahlula (L / D ~ 18: 1) zinceda izinto ezithintela ukushisa ziphephe ukuthotywa.

- Izikrufu zokuxuba (L / D ~ 22: 1) zibonelela ngokunyibilika okufanayo kwiiplastiki ezikhethekileyo.

Umlinganiselo woxinzelelo ulinganisa ukuba isikrufu sicinezela kangakanani iplastiki. Iiplastiki eziphezulu ze-viscosity zifuna umlinganiselo ophezulu woxinzelelo ukuze unyibilike kwaye udibanise kakuhle. Ukulungelelanisa umlinganiselo wokunyanzeliswa kunceda ukulinganisela ukugqithisa kunye nomgangatho wemveliso. Abavelisi bahlala bebeka esweni kwaye banyusele uyilo lwesijiva ukuze lungqinelane neemfuno zemathiriyeli.

Uyilo lwenqwelomoya lubalulekile. Izikrufu eziphuculwe ngokwenzululwazi ziphucula umgangatho wokunyibilika ngokuthelekisa indlela yokuziphatha kwepolima. Iinkqubo eziLawulwayo ze-Melt Delivery zinceda ukulawula ukushisa okunyibilikayo kunye ne-viscosity, ukunciphisa umngcipheko wokuthotywa. Ukuxuba izikrufu kunye nezikrufu eziguquguqukayo zomqobo zibonelela ngokunyibilika okufanayo kunye nokuthintela amabala afileyo, okugcina iplastiki ingatshisi okanye itshintshe umbala.

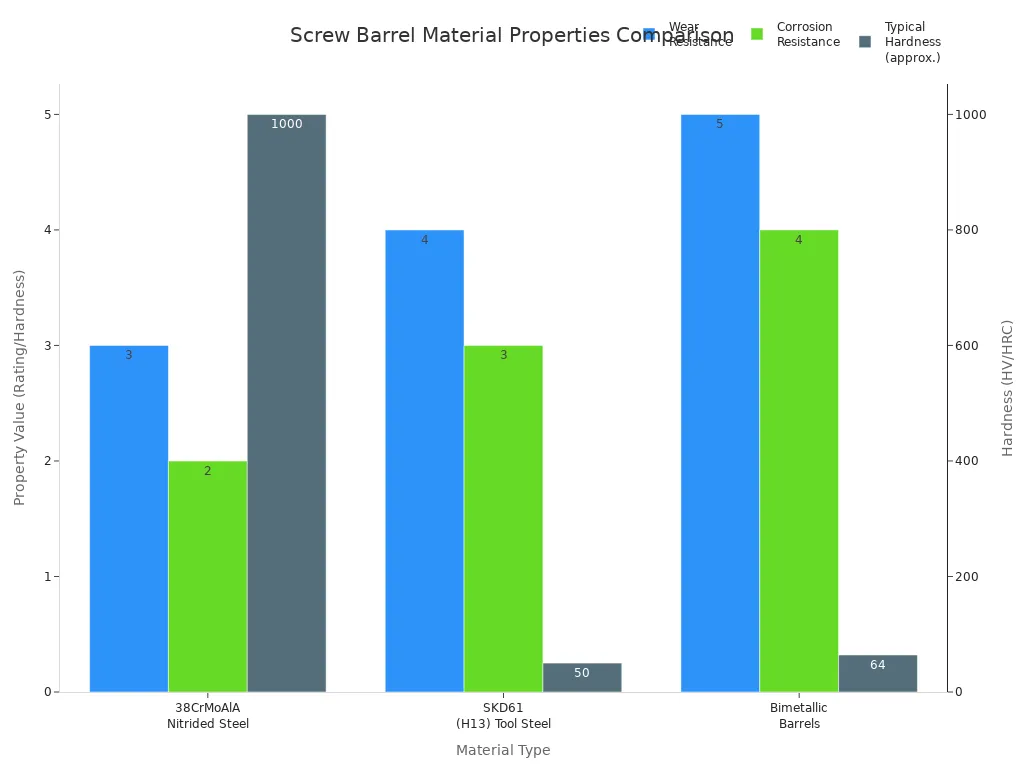

Ukubunjwa kwezinto eziphathekayo kunye noNyango loMphezulu

Izinto ezisetyenziselwa ukwenza i-Plastic Injection molding screw barrel ichaphazela ukuqina kwayo kunye nokusebenza kwayo. Intsimbi ye-nitrided inika ubunzima obuhle kunye nokumelana nokunxiba kwiiplastiki eziqhelekileyo. Imibhobho ye-Bimetallic idibanisa isiseko sentsimbi kunye ne-alloy liner, enika ukugqwesa okugqwesileyo kunye nokuchasana nokugqwala kwiiplastiki ezinzima okanye ezizaliswe. Isixhobo sensimbi sibonelela ngamandla aphezulu kunye nokumelana nokunxiba kweendawo ezigqithisileyo.

| Uhlobo lwezinto eziphathekayo | IiPropati eziPhambili kunye neeNgcebiso | Iingxaki kunye nemida | Ii-Applications ezilungileyo |

|---|---|---|---|

| Nitrided Steel | Ubunzima bomgangatho ophezulu; ukuchasana kakuhle kokunxiba kwiirasi ezingazaliswanga; iyafikeleleka | Ukunganyangeki komhlwa; engafanelekanga kwi-abrasive / ii-chemical resins | Izinto ezithengiswayo ezifana ne-polyethylene, i-polypropylene |

| Iibhareli zeBimetallic | Ukuxhaswa kwentsimbi kunye ne-alloy liner; ukunxiba okugqwesileyo kunye nokumelana nomhlwa; ubomi obude | Ebiza kakhulu; inokuba yi-overkill yokusetyenziswa ngokubanzi | Inayiloni ezaliswe yiglasi, i-ABS engatshiyo lidangatye, iPVC, iipholima ezinobundlobongela |

| I-Nickel-Based Alloys | Ukumelana nomhlwa okungaqhelekanga; ilungile kwi-flame-retardant kunye ne-halogenated resins | Ngaphantsi kobunzima kune-alloys-based alloys; ukumelana nokunxiba okuphantsi | Iipholima ezinobunkunkqele bekhemikhali |

| I-Iron-Based Alloys | Ubulukhuni obuphezulu kunye nokumelana nokunxiba | Ukunganyangeki kwe-corrosion ephantsi kune-alloys esekwe kwi-nickel | I-abrasive, i-resins ezaliswe kakhulu |

| Isixhobo sentsimbi | Ubunzima obukhethekileyo kunye namandla; ukumelana nokunxiba okuphezulu | Iindleko eziphezulu; Iyakwazi ukubola ngaphandle kokutyabeka | Iindawo zokunxiba ezigqithisileyo, izicelo eziphezulu zemveliso |

| Iibhareli eziQithiweyo eziKhethekileyo | Iingubo ezifana ne-tungsten carbide okanye i-chrome plating iphucula ukunxiba kunye nokumelana nokubola | Yongeza iindleko kunye nobunzima; ukunamathela kokugquma kuyahluka | izicelo Custom okanye ndlongondlongo resin |

Unyango oluphezulu olufana ne-nitriding kunye ne-chrome plating yonyusa ukuxhathisa ukunxiba kunye nobomi. I-Nitriding inokuphinda kabini okanye kathathu ubomi benkonzo yezikrufu kunye nemigqomo. I-Chrome plating yonyusa ubulukhuni kunye nokumelana nomhlwa, kodwa i-nitriding ihlala iqhuba ngcono phantsi kweemeko ezirhabaxa. Ukutshiza kwe-molybdenum kudityaniswe ne-nitriding kunika ukhuseleko olungakumbi. Ukusebenza ngokufanelekileyo kunye nokugcinwa kunceda ukwandisa ezi zibonelelo.

Izibuko lokutyisa kunye noYilo lokuPhumelela

Uyilo lwezibuko lokutyisa lulawula indlela iplastiki engena ngayo emgqomeni. Ulawulo olulungileyo lobushushu kwizibuko lokutyisa ligcina i-viscosity yezinto ezinzile, nto leyo enceda ukugcina ukuhamba okungaguqukiyo kunye nokutya. Izilayishi zevacuum kunye nabamkeli behopper baqinisekisa ukuba izinto zihamba kakuhle kumatshini, zinciphisa ungcoliseko kunye nokuchitheka. Olu cwangciso lugcina umgangatho wemveliso uphezulu kwaye ukondla kungaguquki.

- Izilayishi zevacuum zikhwela ngokuthe ngqo kumqala womatshini, zinciphisa ukungcoliseka.

- Abamkeli beHopper basebenzisa ubunzima bokutya izinto eziphathekayo, ukwenza lula inkqubo.

Uyilo lokungenisa umoya lukwadlala indima ebalulekileyo. Izikrufu ze-vent zineendawo ezikhethekileyo ezisusa ukufuma kunye nokuguquguquka ngexesha lokucubungula. Oku kubalulekile kwizinto ze-hygroscopic kunye neeplastiki ezihlaziyiweyo. Amazibuko okungenisa umoya avumela iigesi kunye nokufuma ukubaleka, ukuthintela iziphene kunye nokugcina umgangatho we-extrusion uphezulu.

Ingcebiso: Izibuko lokutyisa elichanekileyo kunye noyilo lokungena umoya lunceda ukugcina imveliso ezinzileyo kunye nokuphucula umgangatho wemveliso, ngakumbi xa usebenza ngeeplastiki ezisetyenzisiweyo okanye ezibuthathaka.

Iziphumo zeNtsebenzo yoYilo lwePlastiki yokuSikrola umbhobho wokubumba

Umgangatho onyibilikayo kunye ne-Homogeneity

Umbhobho owenziwe kakuhle wePlastiki Isitofu sokubumba inceda ukwenza igudileyo kwaye inyibilike. Ijiyometri yesikrufu, kubandakanywa nayoumlinganiselo woxinzelelokunye nokumila kwemimandla yayo, ilawula indlela iipellet zeplastiki ezinyibilika ngayo kwaye zixube. Xa umlinganiselo wokunyanzeliswa uhambelana nezinto eziphathekayo, i-melt ihamba ngokulinganayo. Oku kunciphisa iingxaki ezifana namanqaku okudlala okanye ukunyibilika okungagqibekanga. Iindawo yokutyaihambisa kwaye ifudumeze iipellets, indawo yoxinzelelo iyanyibilika kwaye icinezele izinto, kwaye indawo yokulinganisa iqinisekisa ukuba inyibilika ilingana. Iimpawu ezinje ngobunzulu betshaneli kunye namacandelo okuxuba anceda ubushushu be-screw kunye nokudibanisa iplastiki. Izikrufu zezithintelo zinokwahlula iplastiki eyomeleleyo nenyibilikisiweyo, yenze ukunyibilika kusebenze kakuhle kwaye konge amandla.

Xa inyibilika ifana, imveliso yokugqibela ibonakala ingcono kwaye isebenza ngcono. Ukuxuba okungalunganga kunokubangela imivimbo yombala, amabala abuthathaka, okanye utshintsho kwinxalenye yobukhulu. Good melt homogeneity kuthetha iziphene ezimbalwa kunye namalungu athembekileyo. Abasebenzisi banokusebenzisa abenzi boluvo ukujonga umgangatho wokunyibilika kunye nokulungelelanisa useto lweziphumo ezingcono.

- Ukuxuba okungalunganga kwe-melt kubangela imigca yombala kunye neendawo ezibuthathaka.

- Umgangatho olungileyo wokunyibilika ukhokelela kubungakanani benxalenye engaguqukiyo kunye namandla.

- Umgangatho wokunyibilika uxhomekeke kwiqondo lobushushu lomphanda, isantya sesijija, kunye noxinzelelo lwangasemva.

Qaphela: Ukugcina iqondo lobushushu lokunyibilika lizinzileyo kunye noyilo lwesijiva oluhambelana nohlobo lweplastiki kunceda ukuphepha iziphene kwaye ugcine umgangatho wemveliso uphezulu.

Ukuxuba Ubuchule kunye nexesha le-Cycle

Ukudibanisa ukusebenza kakuhle kuxhomekeke kwimilo ye-screw kunye neempawu ezikhethekileyo. Njengoko i-screw ijika, ityhala kwaye isonge iplastiki, idala yomeleleukucheba amandla. Ukuxuba amacandelo kufuphi nencam, njengezikhonkwane okanye iinqwelomoya zokuthintela, nceda ukudibanisa ukunyibilika. Esi senzo sisasaza umbala kunye nezongezo ngokulinganayo, ngoko ke inxalenye yokugqibela ibonakala igudile kwaye ifana. Izikrufu zokuthintela zisebenzisa inqwelomoya yesibini ukwahlula iplastiki enyibilikisiweyo kumasuntswana aqinileyo, ukukhawulezisa ukunyibilika kunye nokuthintela amaqhekeza anganyibilikiyo.

- Ijiyometri ekrwada ilawula ukuba iipellet zihamba, zinyibilike, kwaye zixube njani.

- Amacandelo okuxuba enza intshukumo ejikelezayo,ukudibanisa ngaphezulu kwe 95%wemathiriyeli ngokukhawuleza.

- Izikrini zokuthintela kunye noyilo olukhethekileyo lunceda ukusabalalisa umbala kunye nezongezo.

Ukudibanisa ukusebenza kakuhle kuchaphazela ixesha lomjikelo. Ukukhawuleza nangakumbi ukunyibilika kuthetha ukuba umatshini unokuqhuba imijikelo emininzi ngexesha elincinci. Ukusebenzisa izikrufu zesithintelo, izikrufu ezinkulu zedayamitha, okanye iigrooves ezinzulu zonyusa isantya seplastiki. Ukunyusa isantya se-screw (xa ukhuselekile kwizinto eziphathekayo) kunye nokunciphisa uxinzelelo lwasemva kunokunciphisa amaxesha omjikelezo. Iinkqubo zokufudumeza eziphezulu kunye nokupholisa zigcina umgqomo kwiqondo lokushisa elifanelekileyo, zinceda iindawo zokupholisa ngokukhawuleza kunye nokugcina imveliso ihamba.

- Uyilo lombhobho olungelelanisiweyo luthintela ukuvala kunye nokulibaziseka.

- Ukufudumeza okuchanekileyo kunye neenkqubo zokupholisa zinceda iindawo zokuqina ngokukhawuleza.

- Izinto ezihlala ixesha elide kunye neengubo zokwaleka zinciphisa ixesha lokulungiswa.

Nxiba ukuxhathisa kunye noLondolozo

Ukunxitywa yinkxalabo enkulu kuyo nayiphi na iplastiki yesitofu sokubumba umbhobho wesikrufu. Izihluzi ze-abrasive, iiplastiki ezonakalisayo, kunye nokuveliswa kwexesha elide kunokuphelisa isikrufu kunye nomphanda. Iindidi zokunxiba eziqhelekileyo ziquka ukuncamatheliswa kokuncamathelisa, ukunxitywa kwe-abrasive, kunye ne-corrosion. Umzekelo, ukunxitywa kwe-abrasive kwenzeka xa izigcwalisi eziqinileyo ezifana nefiber yeglasi zikhuhla kwintsimbi. Impahla eyonakalisayo ivela kwiikhemikhali ezikwiiplastiki ezifana nePVC.

| Nxiba iMechanism | Inkcazo | Uyilo lwezicwangciso-qhinga zokuNciphisa |

|---|---|---|

| I-Adhesive Wear | Imiphezulu yesinyithi yoqhagamshelwano kunye nemathiriyeli yokudlulisa. | Sebenzisa i-alloys ye-hardfacing, khangela ukuba amanqaku, uqinisekise ukuhambelana kwezinto eziphathekayo. |

| I-Abrasive Wear | Isenzo sokucheba kwiipellets okanye kwizihluzi. | Sebenzisa i-alloys eqinile, uthintele izizalisi ezi-abrasive, gcina i-feedstock icocekile. |

| Impahla Eyonakalisayo | Ukuhlaselwa kweekhemikhali kwiiplastiki ezithile. | Sebenzisa izinto ezinganyangekiyo kwi-corrosion, ziphephe iikhemikhali ezibukhali. |

| Imiba yokulungelelanisa | Ukungalungelelanisi kubangela ukukhuhla kunye nokunxiba okungalinganiyo. | Qinisekisa ukuba tye kunye nokulungelelaniswa okufanelekileyo. |

Ukukhetha izinto eziphathekayo kunye nonyango lomphezulu kwenza umahluko omkhulu. I-nitriding yolwelo yonyusa ubulukhuni bomphezulu kunye nokumelana nokunxiba. Iibhobho ze-Bimetallic ezineentsimbi ezikhethekileyo zihlala ixesha elide, ngakumbi ngeeplastiki ezinzima. Ukuhlolwa rhoqo kunye nokugcinwa kothintelo, njengokucoca kunye nokujonga ulungelelwaniso, kunceda ukubamba iingxaki kwangoko. Iingubo eziphuculweyo kunye nezixhobo ezitsha zinokwandisa ubomi bomgqomo ukuya kuthi ga kwi-40%, ukunciphisa iindleko zokugcinwa kunye nokunciphisa ixesha lokuphumla.

- Ukugcinwa rhoqo kuxhomekeke kwizinto eziphathekayo zebhari kunye neengubo.

- Ukugcinwa kothintelo kunye nokuhlolwa rhoqo kwandisa ubomi bomphanda.

- Unyango lomphezulu oluphezulu lunciphisa ukulungiswa kunye nokutshintshwa.

Ukuziqhelanisa neeMathiriyeli ezahlukeneyo kunye nezicelo

Uyilo lwebhareli ethambileyo lwenza abavelisi baqhube iintlobo ezininzi zeeplastiki. Ijiyometri ekrwada, efana nobude, inowuthi, nobunzulu betshaneli, inokutshintshwa ukuze ilungele imathiriyeli eyahlukeneyo. Injongo ngokubanzi, isithintelo, kunye nezikrufu zokuxuba nganye isebenza ngcono ngeeplastiki ezithile. Iinkqubo zokupholisa, njengemijelo yamanzi, gcina umgqomo kwiqondo lokushisa elifanelekileyo kwisixhobo ngasinye.

- Ukuyila isikrufu kunye nejometriTshatisa iiplastiki ezahlukeneyo.

- Iinkqubo zokupholisa zithintela ukushisa.

- I-alloys yamandla aphezulu kunye neengubo zibamba iimeko ezinzima.

Uyilo oluguquguqukayo lukwakwenza kube lula ukutshintsha phakathi kwemisebenzi. Iimpawu ezifana neeadaptha zokuqhawula ngokukhawuleza kunye nezityhuli ezizijija zinceda abaqhubi batshintshe izikrufu ngokukhawuleza. Ulawulo lwenkqubo yokuguquguquka lusebenzisa izinzwa kunye nokufunda koomatshini ukulungisa useto ngexesha lokwenyani. Oku kunciphisa utshintsho lwezandla kunye nokukhawulezisa utshintsho, ngoko ke imveliso inokutshintsha ukusuka kwenye into okanye imveliso ukuya kwenye kunye nexesha elincinci lokunciphisa.

Ingcebiso: Uyilo oluguquguqukayo lombhobho we-screw lunceda iifektri zibambe iintlobo ezininzi zeeplastiki kunye nokutshintsha imisebenzi ngokukhawuleza, ukugcina imveliso ibhetyebhetye kwaye isebenza kakuhle.

Ukucombulula iingxaki kwiMiba yokuSebenza eqhelekileyo

Nangona uyilo olugqwesileyo, iingxaki zinokwenzeka. Imiba eqhelekileyo ibandakanyaukunxiba ngokugqithisileyo, iingxaki zobushushu, ukuvaleka, ingxolo, neempazamo zokuxuba imibala. Ingxaki nganye inonobangela kunye nezisombululo zayo.

| Umba wokuSebenza | Inkcazo kunye neempawu | Oonobangela kunye nezisombululo |

|---|---|---|

| Ukunxiba Ngokugqithisileyo | Ukuvuza kwezinto, umgangatho ombi, amaqondo obushushu aphezulu, ingxolo | Sebenzisa imibhobho ye-bimetallic, i-hardfacing alloys, ukucoca rhoqo, ukulungelelaniswa okufanelekileyo |

| Ulawulo lobushushu | Ukutshintsha kombala, ukurhawuzelela, amaqamza, ukujikajika | Yahlula umgqomo ube ziindawo, sebenzisa izinzwa, ukufudumeza kancinci kancinci, iibhatyi zokugquma |

| Ukuvala kunye noKwakha-Up | Uxinzelelo oluphezulu, ukuhamba kakubi, amabala amnyama | Coca ngeekhompawundi zokucoca, isantya esifanelekileyo sokujija, umgqomo wokutywina ngexesha lokuphumla |

| Ingxolo okanye Ukungcangcazela | Izandi eziphakamileyo, ukungcangcazela, ukushukuma | Hlola ulungelelwaniso, iibheringi, sebenzisa i-vibration damping, amacandelo ahlukeneyo |

| Ukuxuba Umbala / Usulelo | Imivimbo yombala, i-shades engahambelaniyo, ukungcola | Sebenzisa iikhompawundi zokucoca, ukucoca rhoqo, ukongeza uyilo lwesijija, oomatshini bokutywina ngexesha lokuvalwa |

Abaqhubi banokucombulula iingxaki ezininzi ngokulandela amanyathelo aphambili ambalwa:

- Lungiselela uqwalaselo lwesijivu kunye neendawo zobushushu bomgqomo.

- Gada kwaye uhlengahlengise amaqondo obushushu kunye nesantya se-screw.

- Ukulungelelanisa izinto ezixhasayo kwaye uthintele ukudityaniswa kwezinto.

- Hlola izikrufu kunye nemigqomo yokunxiba, ngakumbi kwiindawo ezinoxinzelelo oluphezulu.

- Sebenzisa ulondolozo oluqikelelweyo ukucwangcisa ukulungiswa kunye nokunciphisa ixesha lokuphumla.

- Gcina isikrufu esisecalenikwaye uhlaziye amaxesha ambalwa kuphela.

- Qeqesha abasebenzi ukuba babone iimpawu ezilumkisayo kwangethuba.

Phawula:Ukucoca rhoqo, ukuthambisa okufanelekileyo, kunye nokubeka iliso ngononophelonceda ukugcina iPlastiki yokubumba i-screw barrel isebenza kakuhle kwaye yandise ubomi bayo.

Ukuphucula ubume bePlastiki Isitofu sokubumba umbhobho kunyusa umgangatho wokunyibilika kunye nobomi besixhobo. Xa abavelisi bekhetha iuhlobo lombhobho wasekunene, ijiyometri ejijwayo, kunye nemathiriyeli, babona ukuhamba kakuhle, ukuxuba okungcono, kunye neziphene ezimbalwa. Ukugcinwa rhoqo, kuquka ukucocwa nokuhlolwa, kugcina oomatshini besebenza kakuhle kuze kuthobe iindleko.

FAQ

Yintoni eyona nzuzo iphambili ye-bimetallic screw barrel?

Imigqomo yeBimetallic ixhathisa ukunxiba kwiiplastiki ezinzima. Zihlala ixesha elide kwaye zinciphisa ixesha lokugcinwa.

Kufuneka abasebenzi bawuhlole kangaphi umbhobho wokujija?

Abasebenzisi kufuneka bajonge umgqomo wesikrufu rhoqo ngenyanga. Ukuhlolwa rhoqo kunceda ukubamba ukuguga kwangoko kwaye ugcine oomatshini besebenza kakuhle.

Ngaba umphanda omnye ojijwayo ungasebenza ngeentlobo ezininzi zeeplastiki?

| Uhlobo lomphanda | Ukuguquguquka |

|---|---|

| Iinjongo jikelele | Kulungile |

| Umqobo | Egqwesileyo |

| Ukuxuba | Kakuhle kakhulu |

Umgqomo owenziwe kakuhle unokuphatha iiplastiki ezininzi, kodwa ezinye izinto zifuna iimpawu ezikhethekileyo.

Ixesha lokuposa: Aug-25-2025