Ndiyayibona indlelaIibhareli zeScrew eziNyeukuguqula ukurisayikilishwa kweplastiki. Xa ndisebenzisa umphanda wesijiva omnye ukuphinda kusetyenziswe igranulation, ndibona umgangatho ongcono wokunyibilika, ukuxubana okuzinzileyo, kunye nokunxiba okuncinci. EyamI-Plastic Extruder yePlastiki yokuRecyclingihamba kakuhle. Ngobushushu obuchanekileyo kunye nesantya se-screw, yamI-Extruder yePlastiki yokuRecyclingifezekisa imveliso ephezulu kunye nomgangatho wepellet.

- Ukunyibilika kokunyibilika

- Isantya sokukrazula

- Ubushushu bomphanda

- Ukulawula uxinzelelo lwe-chear

IiNdlela eziPhambili zokuSebenza ngokuSebenzayo

Ukuphuculwa kwe-Melt Homogenization

Xa ndisebenzisa i-extruder yam yokurisayikilisha, ndigxila ekufumaneni inyibiliko efanayo. I-Melt homogenization ithetha ukuxuba iplastiki ngokucokisekileyo njengoko inyibilika, ngoko yonke i-pellet inomgangatho ofanayo. Ndiyifundile loo ntoukulawula ubushushu bokunyibilika kunye nokuhambaibalulekile. Uphononongo kwiiplastiki ezifana nenayiloni kunye ne-polypropylene zibonisa ukuba xa ndigcina iyunifomu enyibilikayo, ndifumana iipellets eziphinda zisetyenziswe. Ukuba ukunyibilika akuhambelani, iplastiki esetyenzisiweyo inokuba buthathaka okanye ibe brittle.

Ndibona umahluko kumgangatho wepellet xa ndisebenzisa umbhobho osijiva omnye owenzelwe ukuxubana okungcono. Umzekelo, uphando malunga ne-melt-state shear homogenization lubonisa ukuba ukuxubana kwe-shear ephezulu kwimibhobho ye-screw enye kuphucula ukufana komzimba kunye ne-thermal yeeplastiki ezisetyenzisiweyo. Le nkqubo inciphisa ungcoliseko kwaye itshintsha ubume bepolymer ngendlela enceda ngamanyathelo angakumbi okuhlaziya. Ndiqaphela ukuba iipellets zam ezisetyenzisiweyo zineziphene ezimbalwa kunye nokusebenza okungcono xa inyibilika ifana.

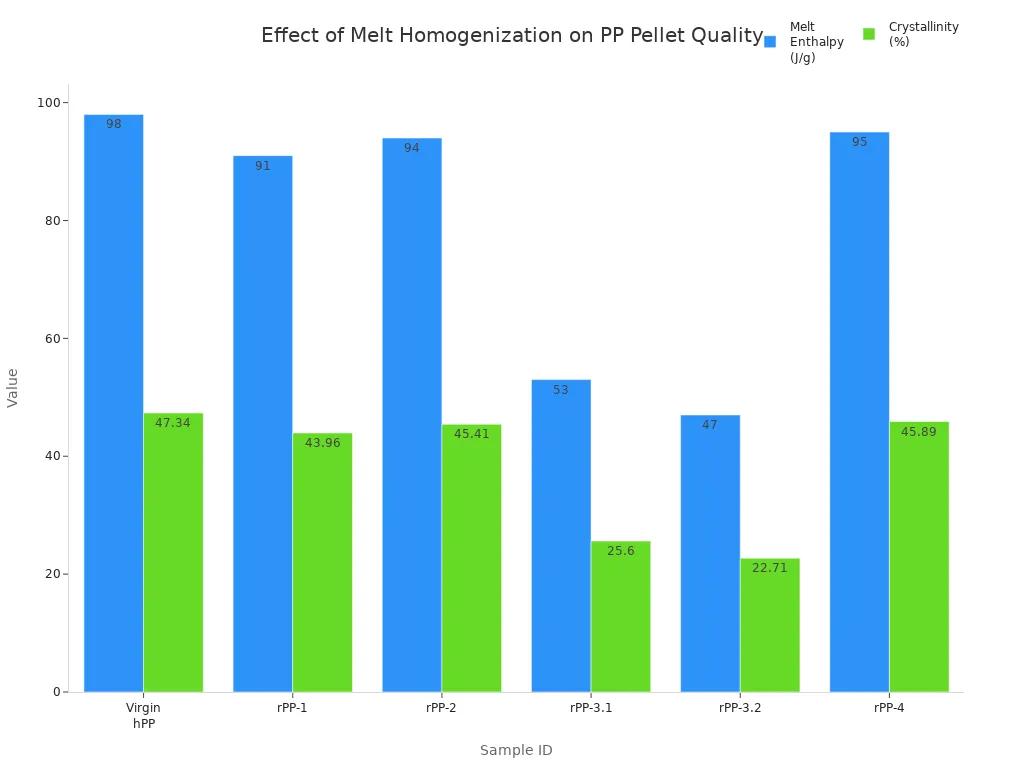

Amanani axhasa oko ndikubona kwivenkile yam. Xa ndithelekisa iisampulu zepolypropylene ezisetyenzisiweyo, ezo zinecrystallinity ephezulu kwaye zinyibilike imbonakalo ye-enthalpy kwaye zenze ngakumbi njengeplastiki enyulu. Nantsi itheyibhile ebonisa indlela iimeko ezahlukeneyo zokucwangcisa ezichaphazela umgangatho wepellet:

| Isampulu yesazisi | Melt Enthalpy (J/g) | Ubukhazikhazi (%) |

|---|---|---|

| I-homopolymer enyulu ye-PP (hPP) | 98 | 47.34 |

| IRecycled PP-1 (rPP-1) | 91 | 43.96 |

| IRecycled PP-2 (rPP-2) | 94 | 45.41 |

| Recycled PP-3.1 (rPP-3.1) | 53 | 25.60 |

| Recycled PP-3.2 (rPP-3.2) | 47 | 22.71 |

| IRecycled PP-4 (rPP-4) | 95 | 45.89 |

Ndihlala ndijolise kwiziphumo ezifana ne-rPP-1, i-rPP-2, kunye ne-rPP-4, ekufutshane ne-virgin PP. Amaxabiso asezantsi, afana ne-rPP-3.1 kunye ne-rPP-3.2, ndixelele ukuba inyibilika ayixutywanga kakuhle okanye inosulelo.

Xa ndilawula ukuhamba kwenyibilika kunye nokuxuba, ndibona kwakhona iipropathi ezingcono zoomatshini kwimveliso yokugqibela. Iipellets zam ezisetyenzisiweyo zolula kwaye zibambe phantse kunye neplastiki entsha, okuthetha ukuba ndingazisebenzisa kwizicelo ezifuna kakhulu.

I-Optimized Screw Geometry

Ubume kunye noyilo lwesikrufu ngaphakathi kwi-extruder yam yenza umahluko omkhulu. Ndizamile iijiyometri zesijija ezahlukeneyo kwaye ndaqaphela ukuba zichaphazela njani ukusetyenziswa kwamandla, umgangatho wokunyibilika, kunye nemveliso. Xa ndisebenzisa isikrufu ngejiyometri echanekileyo, ndifumana ukuxubana okungaguqukiyo kunye nomthamo ophezulu. Ndikwasebenzisa amandla amancinci, okonga imali kunye nokunciphisa ukuguga kwezixhobo zam.

- I-Screw geometry ichaphazela ubungakanani bamandla endiwadingayo kunye nokuba uzinzile kangakanani na ubushushu benyibilika.

- Ukonyusa isantya se-screw kunokwehlisa ukusetyenziswa kwamandla, kodwa uyilo lwe-screw kufuneka luhambelane nemathiriyeli.

- Izikhonkwane zokuthintela kunye nezinto zokuxuba zinceda ukugcina ubushushu obunyibilikayo kunye nokuphucula ukuxuba.

- Olunye uyilo lwe-screw ndivumele ukuba ndiqhube i-extruder ngokukhawuleza ngaphandle kokuphulukana nomgangatho.

- Ijiyometri ejijwayo elungileyo ilinganisa ukusebenza kakuhle kwamandla kunye nemveliso ephezulu kunye nomgangatho olungileyo wokunyibilika.

Ndibonile ukuba izikrufu zomqobo, ezahlula iplastiki eqinileyo kunye nenyibilikayo, zindivumela ukuba ndibaleke ngesantya esiphezulu kwaye ndifumane iziphumo ezingaphezulu. Nangona kunjalo, kufuneka ndijonge i-throughput ukugcina iyunifomu enyibilikayo. Ukuxuba izinto ezifana necandelo le-Maddock shear lindinika i-homogenization engcono, okuthetha iziphene ezimbalwa kwiipellets zam.

Nalu uthelekiso olukhawulezayo lweentlobo zezikrufu kunye neziphumo zazo:

| Ijiyometri ekrwada | Ukuxubana Ukuhambelana (Homogeneity) | Umsebenzi | Amanqaku |

|---|---|---|---|

| Izikrufu Zomqobo | Ilungile kumthamo ophezulu, kufuneka ulawule ngononophelo | Phezulu | Okona kulungileyo kwiibhetshi ezinkulu, jonga ukuxubana okungalinganiyo ngesantya esiphezulu kakhulu |

| Izikrweqe ezinamaCandelo amathathu | Izinzile, kodwa i-output ephantsi | Phakathi | Ilungele imveliso ezinzileyo, iguquguquka kancinci |

| Ukuxuba Elements | I-homogenization egqwesileyo | Iyahluka | IMaddock shear inika owona mxube ulungileyo, ngakumbi kwiiplastiki ezomeleleyo |

Ndihlala ndikhetha ijiyometri ejijwayo ehambelana neplastiki endiyirisayikilisha. Ngale ndlela, ndifumana eyona ibhalansi yesantya, umgangatho, kunye nokusetyenziswa kwamandla.

IiMathiriyeli zeBarel eziPhezulu

Izinto eziphathekayo ze-screw barrel zibalulekile nje ngokuyilwa kwayo. Ndithembele kwimigqomo eyenziwe ngentsimbi ekumgangatho ophezulu we-alloy efana ne-38CrMoAl, enika amandla kunye nokuqina. Xa ndisebenzisa imigqomo enendawo ene-nitrided, ndibona ukutsiba okukhulu kubulukhuni. Oku kuthetha ukuba isixhobo sam sihlala ixesha elide, nokuba ndisenza iiplastiki ezirhabaxa okanye ezingcolisekileyo.

- Iintsimbi ze-alloy ezifana ne-38CrMoAlA kunye ne-AISI 4140 zindinika ukuqina endikufunayo.

- Iintsimbi ze-metallurgy ze-powder zibonelela ngakumbi ukunxiba kunye nokuxhathisa umhlwa.

- Unyango lwe-nitriding kwandisa ubulukhuni bomphezulu, rhoqo ukufikelela kwi-HV900 okanye ngaphezulu.

- Iingubo ze-Bimetallic, njenge-tungsten carbide, zikhusela ngokuchasene nezizalisi ezinqabileyo.

- I-Chromium plating yongeza omnye umaleko wokuzikhusela kumhlwa kunye nokunxiba.

Ndiye ndaphawula ukuba xa ndisebenzisa imigqomo enezi zixhobo ziphucukileyo kunye neecoatings, ndichitha ixesha elincinane nemali ekuyilungiseni. I-extruder yam iqhuba ixesha elide phakathi kwamathuba eenkonzo, kwaye andinaxhala kakhulu malunga nokuqhekeka. Oku kuthembeka kundivumela ukuba ndigxininise ekuveliseni iipelisi ezihlaziyiweyo ezikumgangatho ophezulu.

Ingcebiso:Hlala uhambelana neimpahla yomphandakwiindidi zeplastiki kunye nezongezo ozenzayo. Izinto eziqinileyo kunye neengubo zokugqoka zihlawula xa ubamba inkunkuma edibeneyo okanye edibeneyo yeplastiki.

Ngokudibanisa i-melt homogenization ephuculweyo, ijiyometri yesikrufu esiphuculweyo, kunye nezixhobo zombhobho ophucukileyo, ndifumana impumelelo ephezulu kunye neziphumo ezingcono ekusebenzeni kwam kwakhona kweplastiki. Ezi ndlela zisebenza kunye ukuhambisa umgangatho ongaguqukiyo, imveliso ephezulu, kunye neendleko eziphantsi.

Ukusombulula imingeni eqhelekileyo yokuRisayikilishwa

Ukujongana nokuNgcoliseka kunye ne-Various Feedstock

Xa ndiqhuba umsebenzi wam wokurisayikilishwa, ndijongana nesondlo esingalindelekanga yonke imihla. Ezinye iibhetshi zineeplastiki ezicocekileyo, ezifanayo. Abanye bafika bexutywe nokungcola, isinyithi, okanye ukufuma. Ndiyazi ukuba amasuntswana eregrind amile ngendlela engaqhelekanga anoxinaniso lwesambuku esisezantsi kuneepellets ezinyulu. Oku kunciphisa umthamo kwaye kwenza i-extruder yam isebenze nzima. Ukuba andiyihoxisi le miba, ndibona amaqondo obushushu enyibilikayo aphezulu kunye nomgangatho ophantsi wepellet.

Ndithembele kumbhobho wam wesikrufu omnye ukujongana nale mingeni. Indawo yokutya ephuculweyo yejometri, ngakumbi iipokotho zesondlo ezandisiweyo, iphucula ukutyisa kunye nokuhanjiswa kwezinto eziqinileyo. Olu yilo luthintela ukubola kwezinto kwaye lugcina ukuhamba kakuhle. Ndiqaphela ukuba i-extruder yam igcina umgangatho wokunyibilika naxa ndisenza iiplastiki ezixutywe okanye ezingcolisekileyo.

Nantsi imiceli mngeni engundoqo endidibana nayo ekusetyenzisweni ngokutsha kweplastiki:

- Iimilo ze-regrind ezingaqhelekanga kunye nobuninzi obuphantsi

- Ukucuthwa kokuphuma kunye nokusebenza kakuhle

- Ubushushu obuphezulu bokunyibilika kunye neefestile ezicuthayo zokucutshungulwa

- Ungcoliseko kunye nokuthotywa kwezinto

- Ukucutshungulwa kokuhlukahluka kunye neeplastiki ezixutywe

Ibhere yam yesikrufu enye indinceda ndoyise ezi ngxaki. Ndibona ukusebenza kakuhle kokutyisa, ukuhamba kwezinto ezingaguqukiyo, kunye nokusetyenziswa okuphantsi kwamandla. Ubuchwephesha bundivumela ukuba ndisebenze uluhlu olubanzi lweeplastiki ezisetyenzisiweyo ngaphandle kokuncama umgangatho.

Ndihlala ndithelekisa i-screw extruders kunye ne-twin screw extruders. Oomatshini abangama-twin screw babonelela ngokuxuba okugqwesileyo kunye nokususa umoya, kodwa bayasokola ngoxinzelelo oluphezulu kunye nosulelo. I-screw extruders enye, njengeyam, iphatha ukuhluza-i-recycling enzulu kwaye inyamezela ungcoliseko ngcono. Nalu uthelekiso olukhawulezayo:

| Uphawu | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ukudibanisa Ukusebenza | Ukuxuba okuphakathi, i-homogenization encinci | Ukuxuba okugqwesileyo, ukusabalalisa okunzulu / isenzo sokusabalalisa |

| Ubushushu obufanayo | Uphakathi, uqhelene namabala ashushu/abandayo | Ukuhanjiswa kobushushu obufanayo obuphezulu |

| Uzinzo lweziphumo | Kulungile, inokuba ne-pulsation | Imveliso ehambelanayo, ezinzileyo |

| Ukuguquguquka kwezinto | Eyona nto ingcono kwi-homogeneous, izixhobo ezinyulu | Iphatha izongezo, imixube, izondlo ezingcolisekileyo |

| Ukukhupha amandla | Ilinganiselwe okanye akukho nanye | Phezulu, kunye namazibuko okucoca kunye neendawo zokungena |

| Imeko yokusetyenziswa efanelekileyo | Isikali esincinci, i-ABS enyulu enyulu | Isikali soShishino, i-specialty, imibala, i-ABS ehlaziyiweyo |

Ndikhetha imigqomo yesikrufu esinye ngenxa yesakhono sazo soxinzelelo oluphezulu kunye nokunyamezelana okungcono kongcoliseko. Esi sigqibo sindinceda ndiphephe ukulungiswa okuxabisa imali eninzi kwaye ndigcine umgca wokurisayikilisha usebenza kakuhle.

Ukunciphisa ukuNxitywa kwizinto eziNxulutywayo

Iiplastiki ze-abrasive kunye nezihluzi, ezifana ne-glass fibers, i-talc, kunye ne-calcium carbonate, zinika umngeni omkhulu kwisityalo sam. Ezi zixhobo zinxiba izikrufu kunye nemigqomo ngokukhawuleza. Ndandidla ngokutshintsha amacandelo rhoqo, nto leyo eyandisa ixesha lokuphumla kunye neendleko.

Ngoku, ndisebenzisa imigqomo ye-screw enye enonyango oluphezulu kunye neengubo. Umphanda wam unendawo ene-nitrided kunye ne-bimetallic alloy layers. Ezi zongezo zongeza ubulukhuni kwaye zixhathise ukukrazuka. Ndibona umahluko omkhulu kukuqina. Isixhobo sam sihlala ixesha elide, naxa ndisenza iiplastiki ezomeleleyo, ezirhabaxa.

Iimpawu eziphambili zoyilo ezindinceda ukuba ndinciphise ukunxiba ziquka:

- Ijiyometri yesikrufu esilungiselelweyo ukunqanda i-spikes yoxinzelelo kunye nokunyibilika kwesiphithiphithi

- Ukukhethwa kwezinto eziphathekayo zokunxiba kunye neengubo ezikhethekileyo

- Uyilo olulungiselelweyo lwemathiriyeli ekrwada ethile kunye nezihluzi

- Umatshini ochanekileyo wokugqiba umphezulu ogudileyo

- Isoftware yokulinganisa ukuqonda ukunyibilika koxinzelelo losasazo

Ndafunda ukubaUkunxitywa okuphezulu kwenzeka kufutshane necandelo lotshintsho, apho izinto eziqinileyo zikhula kunye noxinzelelo. Ngokukhetha izixhobo ezifanelekileyo kunye neengubo, Inciphisa ukunxiba ukuya kuthi ga kwi-60%. Ukuhlolwa rhoqo kunye nokugcinwa kweendawo eziphezulu zokunxiba, ezifana neendawo zokutya kunye nokukhupha, gcina i-extruder yam ikwimo ephezulu.

Ingcebiso:Ndihlala ndithelekisa uyilo lwam lombhobho wesikrufu kwiiplastiki kunye nezihluzi endiziqhubayo. Le ndlela yandisa ubomi bezixhobo kwaye iphucula ukusebenza kakuhle kwemveliso.

Ukwandiswa kozinzo lweNkqubo kunye nokuZinzo kwiziphumo

Ukusetyenzwa okuzinzileyo kubalulekile ekuveliseni iipelisi ezihlaziyiweyo ezikumgangatho ophezulu. Phambi kokuba ndamkele itekhnoloji ye-screw barrel enye, bendisokola ngokuqukuqela, ukunyibilika, kunye nokuhanjiswa kwezinto eziqinileyo. Ezi ngxaki zikhokelele ekuthotyweni kwamazinga emveliso, ukunyuka kwenkunkuma, kunye neendleko eziphezulu zabasebenzi.

Ngombhobho wam we-JT one screw, ndifumana ukuhamba okuzinzileyo kwenyibiliko kunye nemveliso engaguqukiyo. Iisistim zolawulo oluphezulu, kubandakanywa izinzwa kunye nezilawuli zengqiqo, ndincede ndigcine ubushushu obuzinzileyo kunye noxinzelelo. Ndibeka iliso kwiimeko zenkqubo ngokusondeleyo ukuthintela ukuguquguquka okunokuthi kuphazamise umsebenzi.

ndisebenziseialloys bimetallic kunye neengubo eziphambiliukomeleza ukuguga kunye nokumelana nomhlwa. Ezi mpawu zibaluleke kakhulu ekusetyenzweni kweeplastiki ezibolileyo okanye ezisetyenzisiweyo. Iimeko zenkqubo ezinzileyo zithintela ukuhluka kwiipropati zemveliso kunye nokunciphisa inkunkuma.

Nanga amanyathelo endiwathathayo ukugcina uzinzo lwenkqubo:

- Ukugcinwa rhoqo kunye nokutshintshwa kwangethuba kwezikrufu ezigugileyo kunye nemigqomo

- Ukubeka iliso kwiqondo lokushisa kunye noxinzelelo kunye neenkqubo zokulawula eziphambili

- Ukusebenzisa iiprofayili zesiko lokujija ukwenza ngcono i-homogeneity kunye nokuxuba

- Ukuhlola iindawo zokunxiba okuphezulu ukunciphisa ixesha lokuphumla elingalindelekanga

Uphononongo lubonisa ukuba ukwenza ngcono isantya se-screw kunye neendawo zobushushu kwandisa umthamo kunye nokuphucula ukusetyenzwa kwakhona. Izantya ze-screw ezisezantsi zonyusa i-torque kunye nokunciphisa amandla oomatshini, okukhokelela ekusebenzeni kakuhle kunye nemveliso engaguqukiyo. Ndibhale ireyithi yokunyuka kwe-18% ukuya kwi-36% emva kokuphucula uyilo lwam lombhobho wesikrufu.

Phawula:Uhlolo olungaguquguqukiyo kunye nolungiso oluqikelelweyo longeza ubomi besixhobo kunye nokuphucula uzinzo lwenkqubo ngokubanzi kumsebenzi wam wokurisayikilisha.

Ngokujongana nongcoliseko, ukunxitywa, kunye nozinzo lwenkqubo, umphanda wam omnye wokujija uyandinceda ndihambise iipellets ezithembekileyo, ezikumgangatho ophezulu. Ndihlangabezana neemfuno zokurisayikilisha kwale mihla ngokuzithemba nangempumelelo.

I-Screw Barrel enye yokuRecycling iGranulation: Iziphumo zeLizwe lokwenyani

Ukunyuka koMsebenzi kunye noMgangatho

Xa nditshintshela kumbhobho osijiva omnye wokuphinda kusetyenziswe igranulation, ndabona ukomelela okucacileyo kokubini kokuphuma kunye nomgangatho wepellet. Iipellets zam ezisetyenzisiweyo ngoku zibonisa amandla angcono oomatshini kunye nokuphucuka kokungafihli. Ndiyakwazi ukulawula ubungakanani bepellet ngokuchanekileyo ngakumbi, nto leyo endinceda ukuba ndihlangabezane neemfuno ezingqongqo zomthengi. Ulawulo oluphezulu lobushushu lugcina ukuhamba kwenyibilika kuzinzile, ngoko ke ndifumana iziphene ezimbalwa kunye neepeliti ezifanayo.

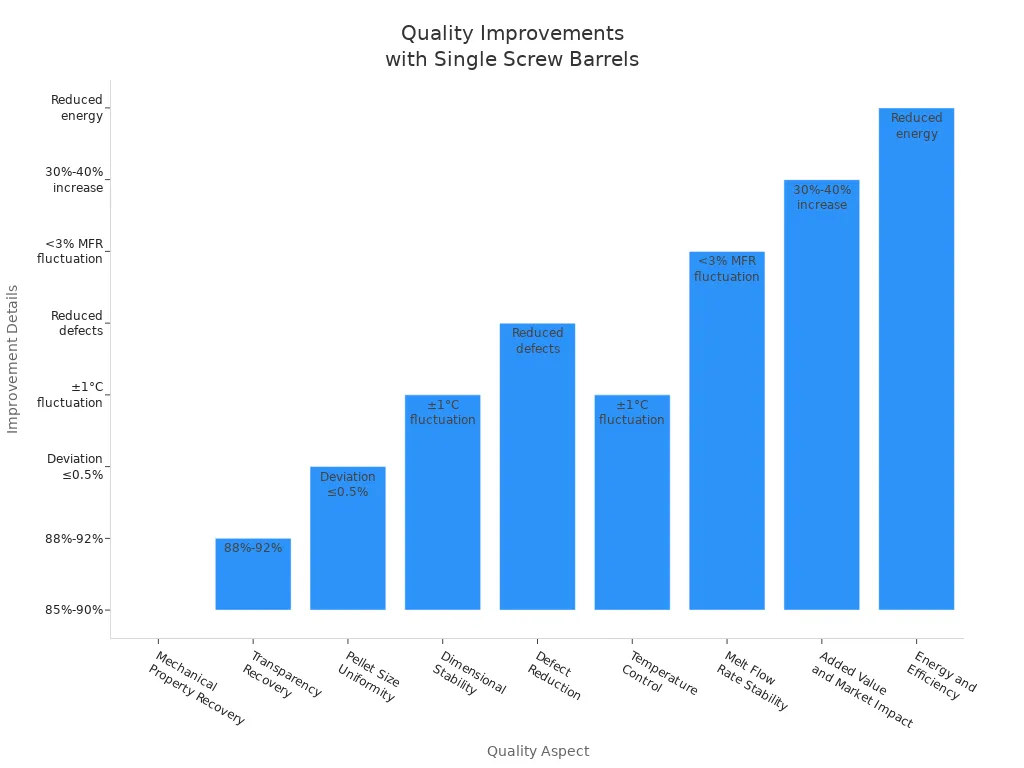

| Umgangatho Womgangatho | IiNkcukacha zoPhuculo |

|---|---|

| UkuBuyiselwa kwakhona kwePropati yoomatshini | I-85% -90% izinga lokubuyisela, liphezulu kakhulu kunezixhobo eziqhelekileyo |

| UkuBuyisa ekuhleni | I-88% -92% izinga lokubuyisela |

| Ubungakanani bePellet Uniformity | Ubungakanani bokutenxa phakathi kwe-0.5% |

| Uzinzo lweDimensional | Ubushushu obufanayo (± 1°C ukuguquguquka) buqinisekisa uzinzo |

| UkuNcitshiswa kwesiphene | Ukungcola okumbalwa kunye neziphene |

| Ulawulo lobushushu | Ulawulo olunamanqanaba amahlanu, ±1°C ukuguquguquka |

| Melt Flow Rate Uzinzo | Ukuguquguquka kwe-MFR ngaphantsi kwe-3% |

| Ixabiso elongeziweyo kunye neMpembelelo yeMarike | I-30% -40% ukunyuka kwexabiso elongezelelweyo |

| Amandla kunye nokusebenza ngokufanelekileyo | Ukusetyenziswa kwamandla aphantsi, ukusebenza kakuhle okuphezulu |

ULondolozo olusezantsi kunye nexesha lokuPhula

Ndifundile ukuba ukhathalelo oluqhelekileyo lugcina umphanda wam wesikrufu omnye wokuphinda usetyenziswe igranulation isebenza kakuhle. Ndilandela ishedyuli engqongqo yokugcinwa kwaye ndihlola umgqomo rhoqo ngeveki. Ndihlala ndigcina iqondo lobushushu kunye nesantya se-screw sizinzile ukuphepha uxinzelelo kumatshini. Impahla yeplastiki ecocekileyo, ehleliweyo inceda ukuthintela umonakalo kwizinto ezingcolisayo. Ndicoca kwaye ndithambisa iindawo ezihambayo ukunqanda umhlwa kunye nokukhuhlana. Xa ndibona iindawo ezigugileyo, ndizibuyisela ngoko nangoko. Ndikhetha imigqomo eyenziwe kwi-alloys eqinile kunye neengubo ezikhethekileyo, njenge-nitriding, ukwandisa ubomi babo.

- Ukuhlolwa kwemigqomo ngevekigcina izixhobo zam zikwimo ephezulu.

- Ukushisa okuchanekileyo kunye noxinzelelo loxinzelelo luthintela ukunxiba.

- Isondlo esicocekileyo sinciphisa umonakalo wangaphakathi.

- Ukucocwa rhoqo kunye nokuphazamiseka kokuyeka ukuthambisa.

- Ukutshintshwa kwenxalenye esebenzayo kuthintela ixesha lokuphumla elingalindelekanga.

- Ii-alloys ezinzima kunye neengubo zenza umgqomo uhlale ixesha elide.

Izityalo ezilandela la manyathelo zibika ixesha eliphantsi lokunciphisa kunye neendleko eziphantsi zokulungisa. Umgca wam wokurisayikilisha ngoku usebenza ngokufanelekileyo nangokuthembekileyo.

I-Case Study: i-JT Single Screw Barel kwi-Multi-Plastic Recycling

Ndifake i-JT single screw barrel yokuphinda isetyenziswe kwigranulation kwiplanti yam yokuphatha iiplastiki ezahlukeneyo njengePE, PP, kunye nePVC. Izinto zokunxiba ezixhathisayo, njengeI-38CrMoAl kunye ne-tungsten carbide, bandise ubomi bomphanda. Ngoku ndichitha imali encinane ekulungiseni nasekutshintsheni izinto. Umgca wam wemveliso awufane ume, ngoko ke ndihlangabezana nemihla yam yokuhambisa. Ukusebenza okungaguqukiyo kwe-JT i-screw barrel enye yokuphinda isetyenziswe i-granulation iphucule imveliso yam kwaye yanciphisa iindleko zam. Ndibona iziphazamiso ezimbalwa kwaye ngconoumgangatho wepellet, endincedayo ukuba ndihlale ndikhuphisana kwimarike.

Ndibona indlela imigqomo yesikrufu enye ezisombulula ngayo iingxaki eziphambili zokuphinda isetyenziswe. Amava am abonisa umgangatho ongcono wokunyibilika, ukuxuba, kunye nokuzinza kwenkqubo. Ngombhobho omnye wokujija wokuphinda usebenziseke igranulation, ndifumana ukusebenza kakuhle okuphezulu kunye nokuthembeka. Olu phuculo luxhasa imisebenzi yokucoca, amaxabiso aphantsi, kwaye lundinceda ndihlangabezane neemfuno ezikhulayo zeshishini lokwenziwa ngokutsha kweplastiki ezinzileyo.

FAQ

Zeziphi iiplastiki endinokuzisebenzisa nge-JT single screw barrel?

Ndiyakwazi ukucubungula iiplastiki ezininzi, kuquka i-PE, i-PP, i-PS,I-PVC, PET, PC, kunye ne-PA. Umphanda uqhelana nemathiriyeli eyahlukeneyo ukuze isetyenziswe ngokufanelekileyo.

Ndikunciphisa njani ukuguga kwibhareli yam yesikrufu?

Ndisebenzisa imigqomo eyenziwe kwi-alloys eqinile ene-nitrided okanye i-bimetallic coatings. Ukucoca rhoqo kunye nesetingi ezifanelekileyo zindinceda ndandise ubomi bomgqomo kwaye ndigcine ukusebenza kuphezulu.

Kutheni kubalulekile ukunyibilikisa i-homogenization ekusetyenzisweni kwakhona?

I-Melt homogenization indinika iipellet ezifanayo. Ndibona iziphene ezimbalwa kunye namandla angcono emveliso. Ukuxubana okungaguqukiyo kundinceda ndihlangabezane nemigangatho yomgangatho kunye neemfuno zabathengi.

Ixesha lokuposa: Aug-21-2025