Ukukhetha umgangatho ophezuluizikrufu ze-nitrided kunye nemigqomokubalulekile ukuqinisekisa ukusebenza ngokupheleleyo koomatshini. Izinto ezifana nohlobo lwemathiriyeli, ukuhambelana koyilo, kunye neemfuno zesicelo zinempembelelo kakhulu kolu khetho. Izigqibo ezinolwazi aziphuculi nje ubomi bokusebenza bamacandelo afana neExtrusion Machine Single Screw Barelkwaye iPvc Umbhobho Single Screw umphandakodwa ikwaphucula ukusebenza kakuhle kunye nemveliso.

UKhetho lweMathiriyeli kwizikrufu zeNitrided kunye nemigqomo

Ukukhetha izixhobo ezifanelekileyoizikrufu ze-nitrided kunye nemigqomoibalulekile ekufezekiseni umsebenzi ogqwesileyo kwizicelo ezahlukeneyo. Izinto ezisetyenzisiweyo zinempembelelo kakhulu ekomeleleni, ukusebenza kakuhle, kunye nokusebenza ngokupheleleyo kwala malungu.

Iintlobo zeMathiriyeli

Izinto ezininzi zisetyenziswa ngokuqhelekileyo ekwenzeni izikrufu ze-nitrided kunye nemigqomo. Isixhobo ngasinye sineempawu ezizodwa ezichaphazela ukufaneleka kwayo kwizicelo ezithile. Nazi ezinye zezona mathiriyeli zixhaphakileyo:

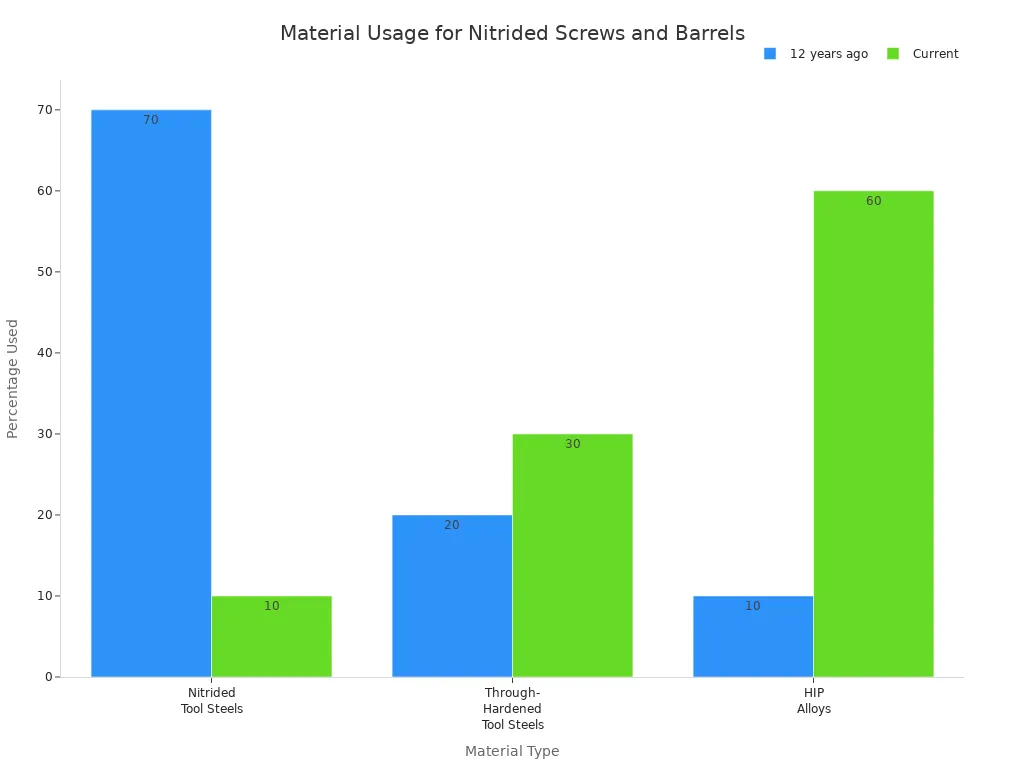

- Nitrided Tool Steels: Ngokwembali, ezi ntsimbi zazibalelwa malunga ne-70% yesabelo semarike kwiminyaka elishumi elinesibini eyadlulayo. Nangona kunjalo, ukusetyenziswa kwazo kwehlile ukuya malunga ne-10% okwangoku.

- Ngokusebenzisa-Hardened Tool Steels: Olu hlobo lubone ukwanda kokuthandwa, ukunyuka ukusuka kwi-20% ukuya kwi-30% ngexesha elifanayo.

- I-HIP Alloys: Ezi ngxube ziye zafumana i-traction ebalulekileyo, zihamba ukusuka kwi-10% ukuya kwi-60% ekusebenziseni kwangoku.

Le theyibhile ilandelayo ishwankathela utshintsho ekusetyenzisweni kwemathiriyeli ekuhambeni kweminyaka:

| Uhlobo lwezinto eziphathekayo | Ipesenti (iminyaka eyi-12 eyadlulayo) | Ipesenti (Yangoku) |

|---|---|---|

| Nitrided Tool Steels | 70% | 10% |

| Ngokusebenzisa-Hardened Tool Steels | 20% | 30% |

| I-HIP Alloys | 10% | 60% |

Iipropati zeMathiriyeli yeNitrided

Izixhobo ze-nitrided zibonisa iipropathi ezininzi ezinenzuzo ezonyusa ukusebenza kwazo kwizicelo zamashishini. Inkqubo ye-nitriding yazisa i-nitrogen kumphezulu wezinto eziphathekayo, yenza umaleko we-nitride oqinileyo. Olu maleko luphucula kakhulu iipropathi ezahlukeneyo zoomatshini, zenza izixhobo ezine-nitridi zibe zinqweneleka kakhulu.

- Nxiba ukuxhathisa: Izinto ze-nitrided zibonisa ukuxhathisa okugqwesileyo ngenxa yomaleko oqinileyo owenziwe ngexesha le-nitriding. Le propati ibaluleke kakhulu kumalungu aphantsi kweemeko ze-abrasive, ezifana neenkqubo ze-extrusion.

- Ukunyangwa kokuMhlwa: Umaleko we-nitride ukwabonelela ngokuphucuka kokuxhathisa ukubola, okubalulekileyo xa ujongana neepholima ezinyibilikisiweyo kunye nezinye izinto ezidlayo.

- Ukuqina: Emva kwe-nitriding, izixhobo zinokufikelela amanqanaba obunzima obudlula i-65 HRC. Oku kwanda kokuqina kunegalelo kumandla onke kunye nokuqina kwezikrufu kunye nemigqomo.

- Iipropati eziBanzi: Intsimbi ye-nitrided kunye ne-alloys ezithile ezifana ne-38CrMoAl ziyaziwa ngeempawu zazo ezigqwesileyo ngokubanzi, ezizenza zilungele izicelo ezahlukeneyo.

Le theyibhile ilandelayo ichaza iimpawu eziphambili zoomatshini bezinto ezinenitridi ezisetyenziswa kwizikrufu kunye nemigqomo:

| Ipropati | Inkcazo |

|---|---|

| Nxiba ukuxhathisa | Izixhobo ze-nitrided zibonisa ukuxhathisa okugqwesileyo ngenxa yenkqubo ye-nitriding. |

| Ukunyangwa kokuMhlwa | Banokumelana ne-corrosion elungileyo, nangona amanye amabakala anokuba nemida. |

| Ukuqina | Ubulukhuni be-Post-nitriding bunokugqithisa i-65 HRC, ukuphucula amandla onke. |

| Iipropati eziBanzi | Intsimbi ye-nitrided kunye ne-38CrMoAl ziphawulwa ngeempawu zazo ezibalaseleyo. |

| Nitriding umaleko ubunzulu | Ngokuqhelekileyo, i-nitriding layer ifikelela kwi-0.4-0.6 mm. |

Izinto ekufuneka ziqwalaselwe ekuKhetheni iNitrided Components

Niniukukhetha izikrufu ze-nitrided kunye nemigqomo, kukho izinto ezimbini ezibalulekileyo: ukuhambelana koyilo kunye neemfuno zesicelo. Ukuqonda le miba kuqinisekisa ukuba amacandelo akhethiweyo asebenza ngokufanelekileyo kwiindawo ekujoliswe kuzo.

Ukuhambelana koyilo

Ukuhambelana koyilo kubalulekile ekudibaniseni ngempumelelo izikrufu ze-nitrided kunye nemigqomo koomatshini abakhoyo. Iimpawu zoyilo ezininzi kufuneka ziqwalaselwe ukuqinisekisa oku kuhambelana:

| Uyilo loyilo | Inkcazo |

|---|---|

| Ukukhethwa kwezinto | Intsimbi ye-nitrided ikhethwa ngenxa yobunzima bayo kunye nokumelana nokubola. |

| Ukugquma umphanda | Iibhobho ze-Bimetallic ezineengubo ezinqabileyo zokunxiba ziyimfuneko kwizicelo eziphezulu zokusebenza. |

| Ijiyometri ekrwada | Iijiyometri ezijijwayo eziyilwe ngokukodwa ziphucula iplastification kunye nemveliso. |

| L/D Umlinganiselo | Umlinganiselo wobude be-screw ukuya kububanzi buchaphazela ukunyibilika kunye neenkqubo zokuxuba. |

| Umlinganiselo woxinzelelo | Imilinganiselo yoxinzelelo oluphezulu luphucula ukusebenza kokuxuba kunye noxinzelelo lwemveliso. |

| Flight Ubunzulu bomlinganiselo | Ilawula umthamo wothutho lwempahla kunye nokusebenza kombhobho. |

Intsimbi ye-nitrided inika ukuqina kunye nokuchasana nokunxiba, okwenza kube lukhetho oludumileyo. Iibhareli zeBimetallic ziphucula ukusebenza kwindawo erhabaxa, ngelixa izikrufu ezinde ziphucula ukusebenza kakuhle kwezinto. Ukunyuka komlinganiselo woxinzelelo kukhokelela kumxube ongcono kunye nemveliso yoxinzelelo, ebalulekileyo ekufezekiseni amanqanaba aphezulu emveliso.

I-HMG Extrusions igxininisa ukubaluleka kokusebenzisa intsimbi ye-nitriding engagugi kakhulu kwizikrufu. Le ngqalelo kwiinkcukacha inceda ukugcina imilinganiselo engqongqo yokunyamezela, iqinisekisa ukuhambelana noomatshini abakhoyo.

IiMfuno zesicelo

Iimfuno zesicelo zidlala indima ebalulekileyo ekuqinisekiseni ukufaneleka kwezikrufu ze-nitrided kunye nemigqomo. Iingqwalasela eziphambili ziquka:

- Iingqwalasela zoyilo: Uyilo kufuneka luphendule ngeempawu eziphathekayo ezifana ne-viscosity, indawo yokunyibilika, kunye nesantya sokuhamba.

- Ukunyibilika okufanayo kunye nokudibanisa: Uyilo olufanelekileyo luqinisekisa ukuba izinto zeplastiki ziyancibilika ngokufanayo kwaye zixutywe, zikhusela ukushisa kunye nokutshisa.

- Umphezulu oGudile: Ukuphucula ukuguda komphezulu kubalulekile ekudibaniseni imathiriyeli, ukucheba, kunye nokuhambisa. Oku kuchaphazela ngokuthe ngqo ukusebenza kwemveliso kunye nomgangatho wemveliso.

Ukunyamezela kwemilinganiselo kuchaphazela nokusebenza. Ukunxiba kwizikrufu kunye nemigqomo kunokuchaphazela kakhulu ukusebenza kakuhle kweplastiki, uxinzelelo lwangasemva, umthamo wokudubula, amaxesha okujikeleza, kunye nokungaguquguquki kwenxalenye. Izinto ezigugileyo zinokucutha ukusebenza kakuhle ukuya kutsho kwi-25%, zandise ukusetyenziswa kwamandla, kwaye zikhokelele kwiziphene kwiindawo ezibunjiweyo. Ukugqithisa imvume phakathi kwe-screw kunye ne-barrel kunokubangela ukuvuza kwe-resin, umgangatho ombi wokunyibilika, kunye noxinzelelo lwenaliti olungaguqukiyo.

Iingcebiso zoLondolozo kuBomi obude

Ukugcinwa ngokufanelekileyo kwezikrufu ze-nitrided kunye nemigqomo kubalulekile ekwandiseni ubomi babo kunye nokuqinisekisa ukusebenza kakuhle. Ukuphumeza inkqubo yogcino oluqinileyo (PM) inokunciphisa kakhulu ukunxiba nokwandisa ubomi bala macandelo.

Ukucoca kunye neNkathalo

Ukucoca rhoqo kunye nokuthambisa kubalulekile ekuthinteleni ukunxiba kwangaphambi kwexesha. Nazi ezinye izenzo ezicetyiswayo:

- Sebenzisa iiCompounds zoRhwebo (CPCs): Ezi khompawundi zomeleza ucoceko olusebenzayo kwaye zinceda ukususa iintsalela kwi-screw kunye nebhere.

- Landela iNgcebiso zabavelisi: Namathela kwizikhokelo ezibonelelwa ngabavelisi be-screw kunye nemigqomo yokugcinwa rhoqo.

Ukugcina amacandelo ngokufanelekileyo, qwalasela la maza alandelayo okugcinwa:

| Ukugcinwa rhoqo | Inkcazo yomsebenzi |

|---|---|

| Rhoqo ngeveki | Guqula i-lubricating oil filter of the reducer kwaye ujonge ukungcola. |

| Ngenyanga | Jonga i-coaxiality ye-motor coupling kwaye uyilinganise. |

| Ngekota | Gqibezela ukuhlolwa kwe-disassembly yesikrufu, umphanda, kunye nokungunda. |

Ukuhlolwa kunye noTshintsho

Ukuhlolwa rhoqo kubalulekile ukuze kubonwe ukuguga okanye umonakalo kwizikrufu ezine-nitrided kunye nemigqomo. Amagcisa kufuneka abandakanye obu buchule bulandelayo kwiinkqubo zabo zokulondoloza:

- Ukuqhuba uhlolo lwesiqhelo lwamacandelo eplastiki.

- Ukulinganisa ukunxiba ngexesha lokuhlolwa okucwangcisiweyo ukwenza iprofayili yokunxiba.

- Ukuchonga ubude bobomi obulindelekileyo bamacandelo okutshintshwa nokulungiswa okucwangcisiweyo.

Ukuhlola rhoqo izikrufu kunye nemigqomo kuvumela ukubonwa kwangethuba kwemiba enokubakho, okwenza ungenelelo olukhawulezileyo. Le theyibhile ilandelayo ichaza ubomi obuqhelekileyo bamacandelo ahlukeneyo:

| Uhlobo lwecandelo | Ubomi (iminyaka) | Amanqaku |

|---|---|---|

| Izikrufu eziqhelekileyo | 1 – 1.5 | Ngeeplastiki zenjongo jikelele (umzekelo, iPP/PE) |

| Izikrufu eziqhelekileyo | 0.5 - 0.67 | Yezihluzi (umzekelo, i-fiberglass) |

| Ubomi bomgqomo | 1.5 - 2 amaxesha | Ngokuqhelekileyo ubude kunobomi be-screw; buyisela ukuba ungaphezulu kweminyaka emi-3 ubudala. |

| Isicwangciso soTshintsho | N / A | Buyisela isikrufu kunye nomphanda njengeseti yeenzuzo zoqoqosho. |

Ngokulandela eziiingcebiso zokugcina, abaqhubi banokuqinisekisa ixesha elide kunye nokuthembeka kwekhwalithi ephezulu ye-nitrided screws kunye nemigqomo.

Ukuqwalaselwa kweendleko kuMgangatho oPhezulu we-Nitrided Screw kunye ne-Barrel

Xa utyala imali kwi-screws ekumgangatho ophezulu we-nitrided kunye nemigqomo, ukuqondaiziphumo zeendlekoibalulekile. Iinkampani kufuneka zilinganise iindleko zokuqala kunye neenzuzo zexesha elide ukwenza izigqibo ezinolwazi.

Uhlahlo lwabiwo-mali loMgangatho

Uhlahlo lwabiwo-mali lwamalungu e-nitrided lufuna uqwalaselo ngononophelo lwemiba eyahlukeneyo. Iinkampani kufuneka zivavanye le miba ilandelayo:

- Uhlobo lweplastiki esetyenzisiweyo: Qinisekisa ukuba isicelo sibandakanya iiplastiki eziqhelekileyo okanye ezomeleziweyo. Olu khetho luchaphazela ukukhethwa kwezinto kunye neendleko ezinxulumene nazo.

- Izongezo ezisetyenzisiweyo: Vavanya ukuba izongezo zichaphazela njani ukunxitywa kunye nokuphila ixesha elide. Ezi zinto zinokuchaphazela kakhulu iindleko zizonke.

- Isikali semveliso: Imisebenzi yevolumu ephezulu kufuneka ibeke phambili ii-alloys ezinamandla. Utyalo-mali kwizinto ezihlala ixesha elide zihlawulela ixesha elide.

- Iingqwalasela zohlahlo lwabiwo-mali: Ukukhetha i-bimetallic okanye i-coated options ingakhokelela ekugcinweni kwexesha elide. Olu khetho luhlala lunciphisa iindleko zokugcina kunye nokubuyisela.

Iindleko zokuqala eziphezulu ze-bimetallic components, ezifana nezikrufu ze-nitrided kunye nemigqomo, zivela kwiinkqubo zokuvelisa eziyinkimbinkimbi kunye nezixhobo ezizodwa. Olu bunzima lukhokelela ekunyukeni kweendleko zemveliso, ezichaphazela kakhulu ixabiso lokugqibela la macandelo. Kumacandelo afana neemoto, imfuno ye-nitriding steel feed screw barrels ivela kubulukhuni bayo obuphezulu kunye nokunganyangeki kokunxiba. Ezi propati zithethelela izinto eziphakamileyo kunye neendleko zokuvelisa.

Ixabiso lexesha elide vs. Iindleko zokuqala

Utyalo-mali kwizinto ezikumgangatho ophezulu ezine-nitrided zinokuzisa ukonga ixesha elide. La macandelo ahlala ehlala amaxesha ama-2 ukuya kwe-5 ubude kunezinye iindlela ezingenayo i-nitrided. Oku kuphila ixesha elide kunciphisa ukuphindaphindeka kokutshintshwa kunye nokugcinwa, okukhokelela kwixabiso eliphantsi lilonke lobunini koomatshini kunye neenkqubo ezisebenzisa izakhi ze-nitrided.

Le theyibhile ilandelayo ibonisa indlela izinto ezahlukeneyo ezichaphazela ngayo iindleko zobunini:

| Umba | Impembelelo kwiindleko zobunini |

|---|---|

| Nxiba ukuxhathisa | Ukutshintshwa okumbalwa, iindleko eziphantsi |

| Ukugcinwa rhoqo | Ixesha eliphantsi lokuphumla, ukuncitshiswa kweendleko zabasebenzi |

| Ukusebenza kakuhle kwamandla | Amatyala aphantsi asetyenziswayo |

| Ukubeka iliso kwangaphambili | Ukufunyanwa kwangethuba, kuncitshiswe ukulungiswa |

Ngokuqwalasela zombini iindleko zokuqala kunye nexabiso lexesha elide, iinkampani zinokwenza izigqibo ezicwangcisiweyo zokuphucula ukusebenza kakuhle kunye nokunciphisa iindleko zizonke. Utyalo-mali kwi-screws ekumgangatho ophezulu we-nitrided kunye nemigqomo ayiphuculi nje kuphela ukusebenza kodwa inegalelo kwimbonakalo yemali ezinzileyo.

Ukukhetha izikrufu ze-nitrided ezifanelekileyo kunye nemigqomo kubandakanya ukuqwalaselwa ngononopheloukuhambelana kwezintokunye neendlela zokulondoloza. Imiba ephambili ibandakanya ukukhetha izinto ezinxitywayo ezifana nentsimbi ye-nitrided kunye nokuhlola rhoqo. Ngokwenza ukhetho olunolwazi, abaqhubi banokuphucula ukusebenza kwaye bandise ubomi bamacandelo abo oomatshini.

Izinto eziphambili zokuThatha:

- Ukuhambelana kwezinto kuchaphazela ukunxiba kunye nokumelana nokubola.

- Ukugcinwa rhoqo kunciphisa ixesha lokuphumla kwaye kwandisa ukusebenza kakuhle.

FAQ

Yintoni inkqubo ye-nitriding?

I-Nitriding lunyango lokuqina komphezulu olusasaza initrogen kwizinto, yenze umaleko oqinileyo we-nitride.

I-nitriding iphucula njani ukusebenza kwesikrufu kunye nomgqomo?

I-Nitriding yongeza ukuxhathisa ukunxiba, ukuxhathisa umhlwa, kwaye inciphisa ukukhuhlana, okukhokelela kubomi obude benkonzo kunye nokuphucula ukusebenza kakuhle.

Zeziphi iindlela zokulondoloza ezandisa ubomi bamalungu e-nitrided?

Ukucocwa rhoqo, ukuthambisa, kunye nokuhlolwa kunceda ukufumanisa ukuguga kwangethuba, ukuqinisekisa ukusebenza ngokugqibeleleyo kunye nobomi obude bezikrufu ze-nitrided kunye nemigqomo.

Ixesha lokuposa: Sep-16-2025