Ukukhetha i-screw echanekileyo ye-plastic extruders iqinisekisa ukusebenza kakuhle kunye nokuchaneka kwiinkqubo zokubumba inaliti. Aba matshini baphucula ukuxubana kwezinto, baphucule umthamo, kwaye bandise amandla okusebenza, babenze babaluleke kakhulu kwimveliso ephezulu.

- Imakethi yehlabathi ye-twin screw extruder, exabisa i-USD 1,128.1 yezigidi ngo-2022, kuqikelelwa ukuba iya kufikelela kwi-USD 1,649.5 yezigidi ngo-2031.

- I-4.5% yezinga lokukhula ngonyaka ligxininisa imfuno yabo ekhulayo kuwo wonke amashishini.

- Uyilo oluphezulu, njengeimigqomo yesikrufu se-twin-screw extruder, ukunyusa ukusebenza kunye nokuthembeka.

Ukuhambelana, ukulungelelaniswa, kunye nokusebenza kakuhle kweendleko kuhlala kuyimiba ebalulekileyo xa ukhetha akabini screw extruderkwizicelo ezithile, ngakumbi xa kuqwalaselwa aumatshini Screw extruder kabiniilungiselelwe ukuhlangabezana neemfuno ezizodwa zemveliso.

Ukubaluleka kweTwin Screw Plastic Extruders

Iinzuzo zokuMbumba ngesitofu

I-twin screw extruders zeplastiki zidlala indima ebalulekileyoindima ekwandiseni impumelelokunye nomgangatho weenkqubo zokubumba inaliti. Uyilo lwabo oluhambele phambili luvumela ulawulo oluchanekileyo malunga nokudibanisa, ukuchithwa, kunye nokuxuba, okuyimfuneko ekuveliseni iindawo ezibunjiweyo eziphezulu. Ngokulawula uxinzelelo ngokufanelekileyo, aba matshini bagcina ubushushu obuphezulu bokunyibilika kunye ne-viscosity, beqinisekisa ukusebenza kwemveliso engaguqukiyo.

Iinzuzo eziphambili ziquka:

- Ukutshintsha amashishini ukusuka kwibhetshi ukuya kuqhubekeko oluqhubekayo, ukuphucula kakhulu ukusebenza kakuhle.

- Ukwenza izinto eziphathekayo ngokwezifiso ngokusebenzisa amandla aphezulu okuxuba, okuchaphazela ngokuthe ngqo umgangatho wemveliso.

- Ukuququzelela ukudilizwa kunye neendawo zokungenisa umoya ezibekwe ngobuchule, ukuthintela izikhukhula kunye nokuqinisekisa ukususwa kwezinto eziguqukayo.

- Ukuvumela ulawulo oluzimeleyo lwemilinganiselo yokutya kunye ne-screw RPMs, ukulungelelanisa ukudibanisa kunye neenkqubo ze-devolatilization.

Uyilo olujikelezayo, oludibanisayo lwe-twin screw extruders zeplastiki luthathwa ngokubanzi njengesona sisombululo sisebenzayo sokudibanisa kushishino lweplastiki. Oku kubenza babaluleke kakhulu kubavelisi abafuna ukufikelela ngokuchanekileyo kunye nokuthembeka ekubumbeni inaliti.

Izinto eziluncedo kwi-Screw Extruders enye

I-twin screw extruders zeplastiki zibonelela ngeenzuzo ezininzi ngaphezulu kwe-screw esebenza nabo, ngakumbi ngokwezakhono zokusetyenzwa, ukuguquguquka, kunye nokusebenza kakuhle. Le theyibhile ilandelayo ibalaselisa iiyantlukwano eziphambili:

| Uphawu | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ukuqhuba izakhono | I-extrusion esisiseko kunye nokudibanisa okulula. | Uphatha izinto eziyinkimbinkimbi kunye nokuxuba okuyinkimbinkimbi. |

| Ukuphumelela kunye nokusebenza ngokufanelekileyo | Imveliso esezantsi, ilungele imveliso encinci. | Ukuphumelela okuphezulu, ukuqinisekisa umgangatho ongcono wemveliso. |

| Ukuguquguquka kunye nokuguquguquka | Ukuguquguquka okulinganiselwe, ukusebenza okulula. | Iguquguquka kakhulu ngeeparamitha ezilungelelanisiweyo. |

| Izinto eziphathekayo | Ifanelekile kwisiseko se-thermoplastics kunye nezihlungi. | Efanelekileyo kwimiqulu eyinkimbinkimbi kunye nezixhobo eziphezulu ze-viscosity. |

| Ukuxuba Ukukwazi | Kwanele kwimixube elula. | Ukuxuba okuphezulu, kukulungele ukudibanisa okongeziweyo. |

| Ukukhupha igassing kunye ne-Devolatilization | Ubunakho obulinganiselweyo. | Isakhono esigqwesileyo, ukuhlangabezana nemigangatho engqongqo yobulunga. |

Ezi zibonelelo zenza i-twin screw extruders yeplastiki ibe lolona khetho lukhethwayo kubavelisi ngenjongo yokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Ukukwazi kwabo ukuphatha izinto ezahlukeneyo kunye nokwakheka okuyinkimbinkimbi kuqinisekisa ukuba bahlala besisiseko seenkqubo zokubumba iinaliti zanamhlanje.

Imiba ephambili ekufuneka iqwalaselwe xa ukhetha iTwin Screw Plastic Extruders

Ukuhambelana ne-Injection Molding Machines

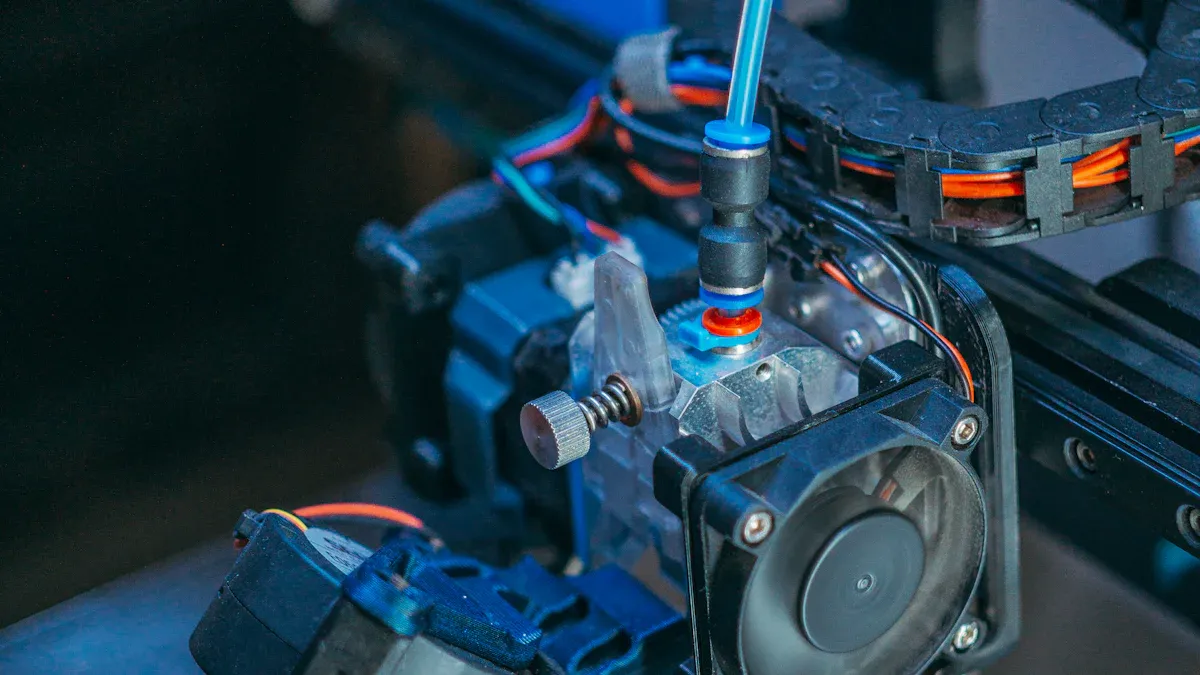

Ukukhetha i-twin screw extruder yeplastiki ehambelana neenkcukacha zomatshini wakho wokubumba wenaliti kubalulekile. Ukuhambelana kuqinisekisa ukuhlanganiswa okungenamthungo, ukunciphisa ixesha lokuphumla kunye nokuphucula ukusebenza kakuhle. Abavelisi kufuneka bavavanye umthamo wemveliso ye-extruder, uyilo lwe-screw, kunye nezakhono zokuphatha izinto ukuze zihambelane neemfuno zoomatshini babo bokubumba. Umzekelo, i-extruder ene-torque ephezulu yoxinaniso kunye nesantya se-screw inokuphatha izinto ezintsonkothileyo, iqinisekisa ukondla okungaguqukiyo kunye neenkqubo zokunyibilika.

I-extruder ehambelana kakuhle iphinda inciphise ukusetyenziswa kwamandla kunye nokunxiba kumalungu. Le theyibhile ilandelayo iqaqambisa indlela imiba ephambili efana nesantya sescrew kunye neempawu zemathiriyeli ezinempembelelo ekusebenzeni:

| Umba ongundoqo | Impembelelo ekuSetyenzisweni kwamandla | Impembelelo kuxinzelelo | Impembelelo kwiTorque |

|---|---|---|---|

| Isantya sokuJikelezisa isikruru (n) | Ukunciphisa kakhulu ukusetyenziswa kwamandla athile (i-45% iyancipha) kunye nesantya esongeziweyo | Ukunyuka koxinzelelo nge-3.1 MPa (65%) ngesantya esiphezulu | Ukonyuka kwetorque ngesantya esiphezulu |

| Umxholo weSebe (u) | Akukho mpembelelo ibalulekileyo ekusebenziseni amandla | Ukunyuka koxinzelelo lwe-3.8 MPa (75%) kunye nomxholo we-bran oncitshisiweyo | Ukunciphisa i-torque nge-34% ngokunyuka kwe-bran content |

Ukuqonda ezi metrics kunceda abavelisi bakhethe i-extruder encedisa ukuseta isitofu sokubumba.

Iinketho zoLungiselelo kwiiNkqubo eziZodwa

I-twin screw extruders zeplastiki zibonelela ngeendlela ezingenakuthelekiswa nanto zokwenza ngokwezifiso, zibenza zilungele usetyenziso olwahlukeneyo. Aba matshini bavumela abavelisi ukuba balungelelanise uyilo lwezikrufu kwiiyunithi ezithile zokusebenza, ezinje ngokuxuba, ukudiliza, okanye ukudibanisa. Isikrufu ngasinye sisebenzela injongo eyahlukileyo, kwaye uhlengahlengiso oluncinci lunokuba nefuthe kakhulu kwiziphumo zokwenziwa kwezinto.

Iimpawu eziphambili zokwenza ngokwezifiso ziquka:

- Ulungelelwaniso lwe-screw oluthambileyo ukulungiselela ukudibanisa kunye nokuhamba kwezinto.

- Amacandelo omgqomo ohlengahlengiswayo ukuze kuphuculwe inkqubo ye-extrusion ngaphandle kohlengahlengiso olubanzi.

Eli nqanaba lokuguquguquka liqinisekisa ukuba abavelisi banokuhlangabezana neemfuno ezizodwa zokuvelisa ngelixa begcina iindleko ezifanelekileyo. Umzekelo, amashishini afuna imathiriyeli ye-viscosity ephezulu okanye imiqulu entsonkothileyo izuza kwezi mpawu zinokwenzeka.

Iimetriki zokuSebenza: iTorque, isantya, kunye nokuPhuhliswa kwezinto

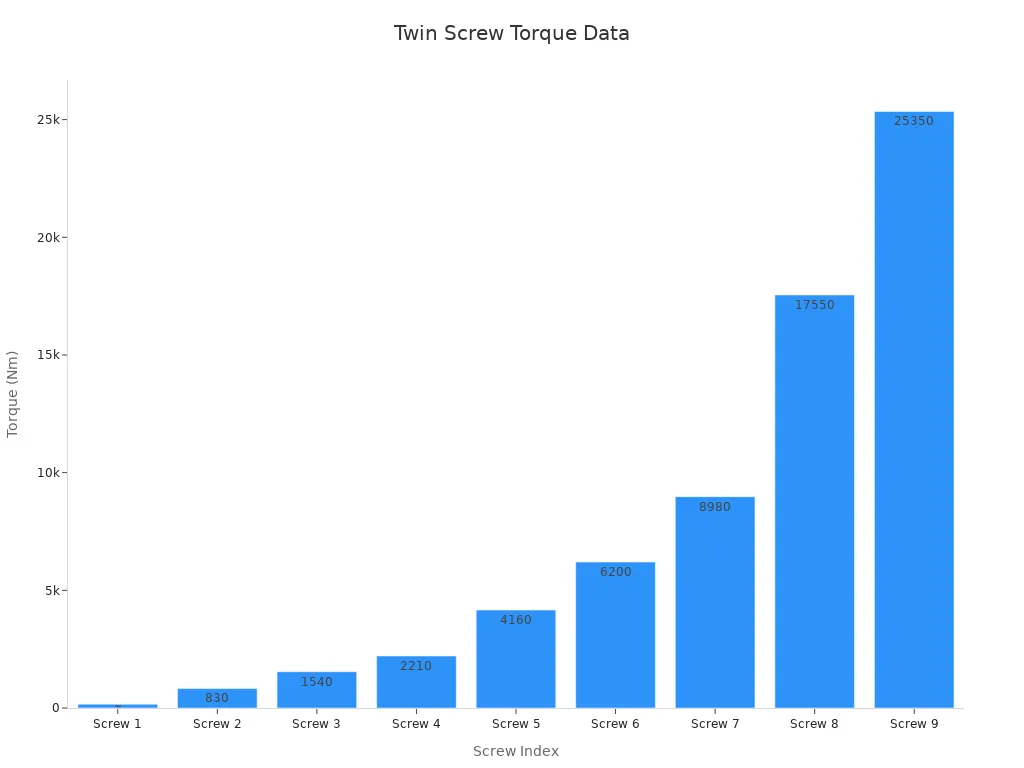

Iimethrikhi zokusebenza zidlala indima ebalulekileyo ekumiseleni ukusebenza kakuhle kwe-twin screw extruders zeplastiki.Ubuninzi beTorque, isantya sokujija, kunye ne-throughput material yiparameters ezibalulekileyo eziphembelela amandla omatshini wokucubungula izinto ngokufanelekileyo. Uxinaniso lwetorque ephezulu, umzekelo, ivumela i-extruder ukuba iphathe izicelo eziyimfuneko, ezinjengokudibanisa iipolymers ezomeleziweyo okanye ukusetyenzwa kwemathiriyeli ye-viscosity ephezulu.

Itheyibhile engezantsi ibonelela ngomfanekiso wedatha yokusebenza ye-twin screw extruders:

| Ipharamitha | Ixabiso |

|---|---|

| Ubuninzi beTorque | Amandla aphezulu ukuya kuthi ga kwi-18 Nm/cm³ |

| ITorque kwisikrufu ngasinye (Nm) | 160, 830, 1540, 2210, 4160, 6200, 8980, 17550, 25350 |

| Isantya seScrew (rpm) | I-1200 kwiimodeli ezininzi, ezinye kwi-500 |

| UPhumezo lweMathiriyeli | Umthamo we-2,700 kg / h kwi-PP + i-glass fiber application |

Ezi metrics ziqaqambisa ukusebenza okuphezulu kwe-twin screw extruders xa kuthelekiswa nemigangatho yoshishino, ezenza zibe lukhetho oluthembekileyo kwimveliso ephezulu.

IiNdleko noHlahlo-lwabiwo-mali

Iindleko yinto ebalulekileyo xa ukhetha i-twin screw plastic extruder. Abavelisi kufuneka balinganise iindleko zotyalo-mali lokuqala kunye nokusebenza kakuhle kwexesha elide. Ngelixa ii-extruders ezisebenza kakuhle kakhulu zinokuba neendleko eziphezulu zangaphambili, ukusebenza kakuhle kwazo kwamandla, ukuqina, kunye neemfuno ezicuthiweyo zokulondolozwa zihlala zikhokelela kwiindleko eziphantsi zizonke.

Izinto eziphembelela iindleko ziquka:

- Screw kunye nomgangatho wempahla yomphanda.

- Iimfuno zokwenza ngokwezifiso.

- Iimpawu eziphambili ezifana nolawulo oluzenzekelayo kunye neenkqubo zokubeka iliso.

Utyalo-mali kwi-extruder ephezulu evela kumenzi ohloniphekileyo iqinisekisa ukusebenza okungcono kunye nokufumaneka kwamacandelo angasese, ukunciphisa ixesha lokunciphisa kunye neendleko zokugcina.

Ukuthembeka kunye neemfuno zoLondolozo

Ukuthembeka kubalulekile ekugcineni umgangatho wemveliso ongaguqukiyo. I-twin screw extruders yeplastiki enezinto ezikumgangatho ophezulu, ezinjengezikrufu, imigqomo, kunye neebhokisi zegiya, zinika ukuqina nokusebenza okungcono. Ukugcinwa rhoqo kubalulekile ngokulinganayo ukukhusela ukusilela koomatshini kunye nokwandisa ubomi bomatshini.

Iindlela zogcino ezingundoqo ziquka:

- Iiparamitha zenkqubo yokubeka iliso ukuchonga imiba enokubakho kwangethuba.

- Ukuphumeza iinkqubo zothintelo lolondolozo ukunciphisa ukuguga nokukrala.

- Abasebenzi boqeqesho ukuba baqaphele iipatheni kwiindlela ezijikajikayo ukuze kulungiswe ingxaki.

Izikrufu ze-Extruder kunye namava emigqomo yokunxiba ngokuhamba kwexesha, ezinokuchaphazela amaxabiso emveliso kunye nobushushu bokukhupha. Abavelisi kufuneka bathathele ingqalelo iimpembelelo zoqoqosho zokutshintsha izinto ezigugileyo ukugcina ingeniso. Ukukhetha i-extruder ethembekileyo kunciphisa le mingeni, iqinisekisa impumelelo yokusebenza kwexesha elide.

Ukuphonononga abavelisi kunye nababoneleli

Iikhrayitheriya zokuKhetha uMvelisi oHloniphekileyo

Ukukhetha umenzi ofanelekileyokwi-twin screw extruders yeplastiki ibalulekile ekuqinisekiseni impumelelo yexesha elide kwimisebenzi yokubumba inaliti. Abavelisi abahloniphekileyo babonisa ukuzinikela kwizinto ezintsha, umgangatho, kunye nokwaneliseka kwabathengi. Ukuphonononga izicwangciso zabo kunye nobukho beemarike kunika ulwazi oluxabisekileyo ekuthembekeni kwabo.

| Uhlobo lweSicwangciso | Inkcazo |

|---|---|

| Utshintsho oluqhubekayo | Iinkampani zityala imali kwi-R&D ukomeleza ukusebenza kunye nokusebenza kakuhle kwee-extruders, ukuhlangabezana neemfuno ezahlukeneyo zeshishini. |

| Intsebenziswano yobuChule | Umanyano kunye nabadlali beshishini kunye namaziko ophando ukukhulisa ubuchwephesha kunye nokwandisa izicelo. |

| Ukudityaniswa kunye nokufunyanwa | Ukuphucula izakhono zemveliso kunye nokufikelela kwiimarike ngokudityaniswa kobuchule kunye nokufunyanwa. |

Abavelisi ababeka phambili ezi zicwangciso bahlala bezisa izisombululo ezikumgangatho ophezulu ezilungiselelwe iimfuno zeshishini. Umzekelo, iZhejiang Jinteng Machinery Manufacturing Co., Ltd. ingumzekelo wale ndlela ngokudibanisa ubunakho bokuyila obuphambili kunye nezixhobo zomatshini ezichanekileyo. Ukugxila kwabo kwizinto ezintsha kunye nokulawula umgangatho kuqinisekisa ukusebenza okuhambelanayo kunye nokwaneliseka kwabathengi.

Indima yoPhononongo lwabathengi kunye nobungqina

Uphononongo lwabathengi kunye nobungqina bubonelela ngengqiqo ebalulekileyo kwigama lomenzi kunye nokuthembeka kwemveliso. Ezi akhawunti zazibonela ngokwazo zigxininisa amava ehlabathi lokwenyani, zinceda abathengi abanokuba ngabathengi benze izigqibo ezinolwazi. Uphononongo oluhle luhlala lugxininisa imiba ephambili efana nokuqina kwemveliso, ukusebenza ngokulula, kunye nenkxaso emva kokuthengisa.

Ingcebiso: Jonga uphononongo oluneenkcukacha namava okusebenza kwexesha elide. Olu lwazi luhlala lutyhila ixabiso lokwenyani le-extruder ngaphaya kokuthengwa kwayo kokuqala.

Ubungqina obuvela kwiingcali zoshishino zinokuqinisekisa amabango omenzi. Umzekelo, impendulo evela kwiinkampani ezisebenzisa i-twin screw extruders yezixhobo ze-viscosity ephezulu okanye ukwakheka okuntsokothileyo kunokuqinisekisa amandla omatshini. Ipateni engaguqukiyo yokuphononongwa okuhle ibonisa ukuzibophelela komenzi kumgangatho kunye nokwaneliseka kwabathengi.

Ukubaluleka kweeWaranti kunye neNkxaso yobuGcisa

Iwaranti kunye nenkxaso yobugcisa idlala indima ebalulekileyo ekuqinisekiseni imisebenzi yemveliso engaphazanyiswa. Iwaranti ebanzi ibonisa intembeko yomenzi ekomelezeni nasekusebenzeni kwemveliso yabo.Inkxaso yobugcisa ethembekileyoinciphisa ixesha lokuphumla kwaye ijongane nemingeni yokusebenza ngokufanelekileyo.

Izibonelelo eziphambili zenkxaso eyomeleleyo yasemva kokuthenga ibandakanya:

- Ukugcinwa okuthembekileyo kuqinisekisa ukusebenza kakuhle.

- Ukufikelela ngokulula kwiindawo ezisecaleni kunciphisa ukulibaziseka kwemveliso.

- Inkxaso yobugcisa ebanzi iququzelela imisebenzi engaphazanyiswa.

Abavelisi ababonelela ngeewaranti ezibanzi kunye neenkonzo zenkxaso eziphendulayo zibonisa ukuzinikela kwimpumelelo yabathengi. Umzekelo, iinkampani ezixhotyiswe ngezixhobo zokubeka iliso eziphambili kunye novavanyo zinokubonelela ngoxilongo oluchanekileyo kunye nezisombululo ezikhawulezayo. Eli nqanaba lenkxaso alonyusi nje ixesha elide lomatshini kodwa lakha ukuthembana kubathengi.

Phawula: Hlala uqinisekisa ubukho beendawo ezisecaleni kunye nokuphendula kwamaqela enkxaso yobugcisa phambi kokuba ugqibezele ukuthenga. Ezi zinto zinefuthe elibonakalayo ekusebenzeni kwexesha elide.

Ukukhetha i-extruder yeplastiki yesikrufu esifanelekileyo kubandakanya ukuvavanya ukuhambelana, ukwenza ngokwezifiso, ukusebenza, iindleko, kunye nokuthembeka. Abavelisi kufuneka babeke phambili abaniki-nkonzo abathembekileyo ngeewaranti ezinamandla kunye nenkxaso yobugcisa. Ukuphepha ukwenza izigqibo ngokungxama kuqinisekisa impumelelo yexesha elide.

Ingcebiso: Yenza uluhlu lwezinto ezifunekayo kwaye uthelekise iinketho ngokucwangcisiweyo ukwenza ukuthenga unolwazi.

Ixesha lokuposa: May-22-2025