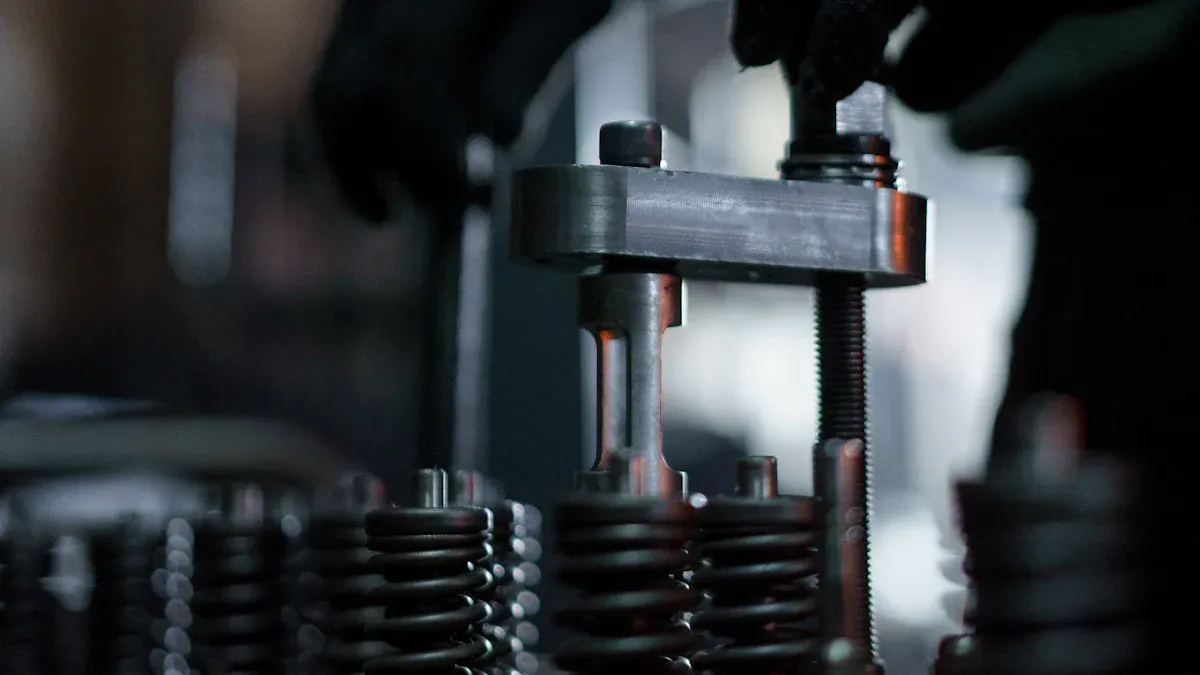

Imigqomo yesikrufu yesitofu isentliziyweni yayo nayiphi na inkqubo yokubumba inaliti. Ukuchonga umonakalo ngokukhawuleza kunokonga ixesha kunye nemali. Iimpawu ezifana nengxolo engaqhelekanga okanye umgangatho wemveliso ongahambelaniyo udla ngokuthetha ingxaki. Imiba yokufunyanwa kwangoko. Umzekelo, abimetallic naliti jija kunye umphanda, eyaziwa ngokomelela, isenokuphelelwa ukuba isetyenziswe ngendlela engafanelekanga. Ukutshekishwa rhoqo kunceda ukuphepha ixesha lokunciphisa iindleko. A ethembekileyoumenzi inaliti yomphandainokunika isikhokelo malunga nokugcinwa kunye neendlela zokutshintsha.

Iimpawu eziqhelekileyo zomonakalo kwimibhobho ye-Injection Screw

Ukuchonga umonakalo kwiinaliti yesijihukwangethuba kunokonga ixesha nemali. Ukwazi into emayijonge kunceda abaqhubi basebenze ngokukhawuleza. Nazi ezinyeiimpawu eziqhelekileyo ezibonisa ingxaki.

Umonakalo obonakalayo woMphezulu

Umonakalo womphezulu lolunye lweempawu ezilula ukuzibona. Imikrwelo, izibonda, okanye imijelo engaphakathi komphanda ingabonakalisa ukunxila. La manqaku ahlala ebonakala xa izinto ezirhawukayo okanye izinto ezingcolisayo zidlula kwisistim. Ngokuhamba kwexesha, lo monakalo unokuba mbi ngakumbi, uchaphazela amandla omgqomo wokucwangcisa izinto ngokufanelekileyo.

Abanini-zithuthi kufuneka kwakhona bajonge ukujika kombala okanye ukugqobhoza. Le miba inokuthi ibhekisele ekudlekeni, ngakumbi ukuba umphanda uphethe izinto ezidlayo. Ukuhlolwa okubonakalayo rhoqo kunokubamba ezi ngxaki ngaphambi kokuba zinyuke.

Ingcebiso:Sebenzisa isibane ukuze uhlole umgqomo ngaphakathi ukuze ubone umonakalo.

Ukuthotywa koMsebenzi

Xa i-injection screw barrel iqala ukusilela, ukusebenza kuthatha ukubetha. Oomatshini banokusokola ukugcina ukunyibilika okungaguqukiyo okanye ukuxubana. Oku kukhokelela kumgangatho wemveliso ongalinganiyo, nto leyo enokukhathaza abathengi kwaye yandise inkunkuma.

Ukuqonda ngcono indlela umonakalo owuchaphazela ngayo umsebenzi, qwalasela oku kulandelayoiimetriki:

| Metric | Impembelelo yomonakalo |

|---|---|

| Ukunyibilikisa ukusebenza kakuhle | Iyancipha njengoko ukukhutshwa kunyuka ngenxa yokuguga |

| Ixabiso leMveliso | Inokufikelela kumanqanaba angamkelekanga ngenxa yokunxiba |

| Ireyithi ye-Scrap | Ukunyuka njengomgangatho wenxalenye kuncipha ngokunxiba |

| Ixesha lomjikelo | Ukonyuka njengoko uhlengahlengiso lwenziwa ukuhlawulela ukunxitywa |

Olu tshintsho lunokuphazamisa iishedyuli zemveliso kunye nokunyusa iindleko.Ukubeka esweni ezi metricsinceda abaqhubi bachonge xa umphanda ufuna ukuhoywa.

Ukuvuza kweMathiriyeli okanye uKwakha-Up

Ukuvuza kwezinto okanye ukwakheka okujikeleze umphanda ziimpawu ezicacileyo zengxaki. Ukuvuza kaninzi kwenzeka xa amatywina omgqomo okanye izinto ezicoliweyo zigugile. Oku kunokukhokelela kwizinto ezichithwayo kunye neendawo zokusebenza ezimdaka.

Ngakolunye uhlangothi, ukwakhiwa kwezinto ngaphakathi kombhobho kunokuthintela ukuhamba kweplastiki. Lo mbandela udla ngokwenzeka xa umphanda ungacocwanga kakuhle okanye xa kusetyenziswa izinto ezingahambelaniyo. Ukwakhiwa kunokubangela ukufudumala, okungonakalisa umgqomo ngakumbi.

Phawula:Ukujongana nokuvuza okanye ukwakha ngokukhawuleza kunokuthintela umonakalo omkhulu kwaye ugcine imveliso isebenza kakuhle.

Iimbangela zomonakalo kwimibhobho yesikruru yokutofa

Ukuqonda ukuba yintoni ebangela umonakalo kwi-injection screw barrel kunokunceda abaqhubi bathatheamanyathelo okuthintela. Nazi amatyala aphambili emva kokugqoka kunye nokukrazula.

Izinto eziAbrasive okanye ezingahambelaniyo

Izinto eziphathekayo okanye ezingahambelaniyo noyilo lombhobho zingabangela umonakalo omkhulu. Umzekelo, iiplastiki ezigcwalisiweyo okanye iiplastiki zobunjineli zihlala ziqulathe amasuntswana aqinileyo aguga kumphezulu wombhobho ngokuhamba kwexesha. Ukuba umphanda awenziwanga kwizinto ezihlala ixesha elide njenge-bimetallic alloys, kunokuba nzima ukuphatha ezi mathiriyeli ngokufanelekileyo.

Izinto ezingahambelaniyo, ezifana ne-PVC, zifuna imigqomo enezinto ezichasene ne-corrosion. Ukusebenzisa uhlobo olungalunganga lomphanda kunokukhokelela ekuwohlokeni okukhawulezayo. Abaqhubi kufuneka bahlale behambelana neenkcukacha zombhobho kwizinto ezicutshungulwayo ukuphepha umonakalo ongeyomfuneko.

Ingcebiso:Jonga ukuhambelana kwezinto kunye nomgqomo ngaphambi kokuba uqalise imveliso ukuthintela ukulungiswa okuxabisa kakhulu.

Ungcoliseko kunye naMasuntswana angaphandle

Ukungcola kunye neengqungquthela zangaphandle kwizinto eziluhlaza ngomnye unobangela oqhelekileyo womonakalo.Ukungcola kwesinyithi okanye inkunkumainokukrwela okanye igqobhoze ingaphakathi lomphanda, inciphise ukusebenza kwawo kakuhle. Ukuchaneka okuphantsi ngexesha lokwenziwa okanye unyango olungonelanga lobushushu lunokwenza ukuba umphanda ube sesichengeni sosulelo.

Ukunciphisa lo mngcipheko, abaqhubi kufuneka bahlole imathiriyeli ekrwada ukungcola phambi kokusetyenziswa. Ukucocwa rhoqo kombhobho kunokuthintela ukwakha kunye nokungcoliswa kokuchaphazela ukusebenza.

- Imithombo yosulelo eqhelekileyo ibandakanya:

- Izinto zesinyithi kwizinto eziluhlaza

- Ukungcola okufana nobumdaka okanye uthuli

- Imathiriyeli eyintsalela evela kwimijikelo yemveliso yangaphambili

Ukunqongophala kweSondlo okanye Ukusetyenziswa Ngokugqithisileyo

Ukungahoywaukugcinwa kwesiqhelookanye ukusebenzisa umphanda ngokugqithiseleyo kunokukhokelela ekunxibeni kwangaphambili. Ukusebenza ixesha elide ngaphandle kwekhefu kwandisa umngcipheko wokushisa, okunokunciphisa isakhiwo sombhobho. Ukongezelela, amaqondo okushisa aphantsi ngexesha leplastiki angabangela ukuguga okungalinganiyo kwi-screw kunye ne-barrel assembly.

Abanini-zithuthi kufuneka balandele ishedyuli yolondolozo ukuze bawugcine umphanda ukwimeko entle. Oku kubandakanya ukucoca, ukuthambisa, kunye nokujonga iimpawu zokuguga. Ukusetyenziswa kakhulu kunokuphetshwa ngokubambelela kumaxesha okusebenza acetyiswayo kunye nokuqinisekisa ukuba useto lomatshini lulungiselelwe ukusebenza kakuhle.

Phawula:Ukugcinwa rhoqo akuthinteli kuphela umonakalo kodwa kwandisa ixesha lokuphila le-injection screw barrel.

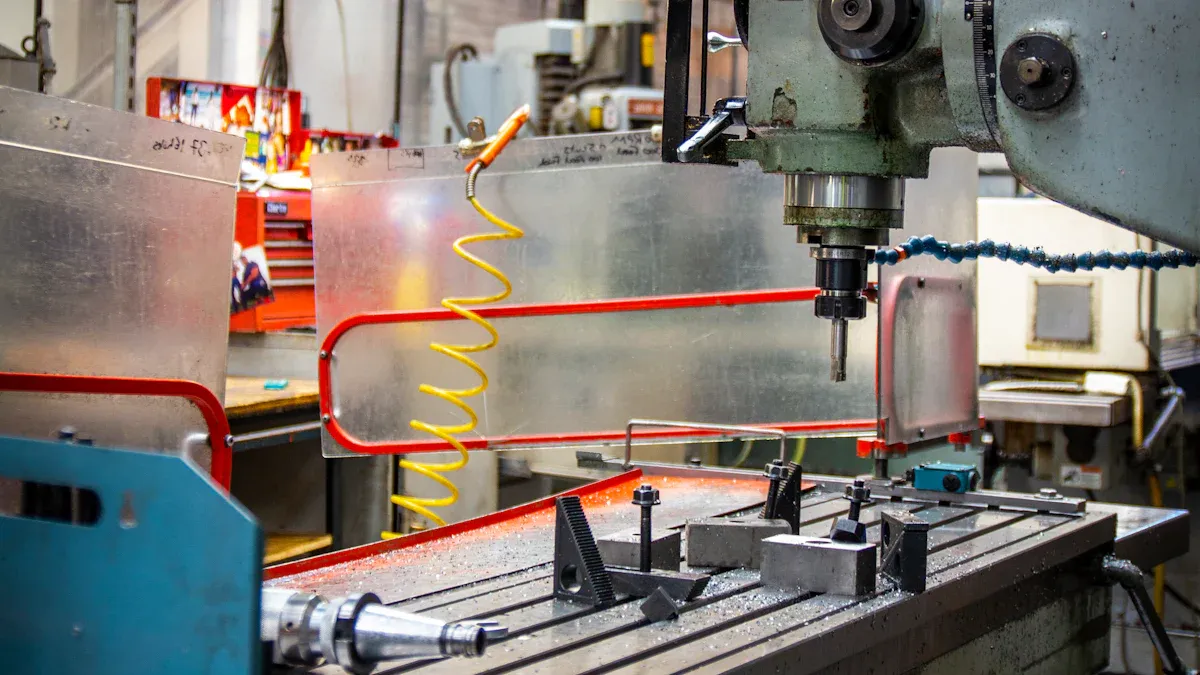

Iindlela zokuHlola ii-Barrels zokuTofwa

Ukuhlola imigqomo yesikrufu sokutofa rhoqo kunceda abaqhubi ukuba babambe umonakalo kwangethuba kwaye banqande ukulungiswa okuxabisa imali eninzi. Nazi iindlela ezintathu ezisebenzayo zokuqinisekisa ukuba imigqomo ihlala ikwimeko ephezulu.

Uviwo Olubonwayo

Iitshekhi ezibonwayo yeyona ndlela ilula yokubona umonakalo. Abasebenzi banokujonga imikrwelo, izibonda, okanye ukuguquka kombala ngaphakathi komphanda. Ezi mpawu zihlala zibonisa ukuguga okanye ukubola. Ukusebenzisa isibane kwenza kube lula ukubona iindawo ekunzima ukufikelela kuzo.

Ukonakala kuxhaphake ngakumbi xa imigqomo ilungisa izinto ezifana nePVC okanye ezinye iiplastiki ezidlekayo. Ukuhlolwa okubonakalayo rhoqo kunokubamba le miba ngaphambi kokuba ibe mandundu. Abanini-zithuthi kufuneka bajonge ukwakhiwa kwemathiriyeli okanye ukuvuza okujikeleze umphanda. Ezi ngxaki zinokuphazamisa imveliso kwaye zikhokelela kumonakalo omkhulu.

Ingcebiso:Cwangcisa uhlolo olubonakalayo rhoqo ngeveki ukuze uhlale uphambi kwemiba enokubakho.

Ukusebenzisa izixhobo zoMlinganiso

Izixhobo zokulinganisa zibonelela ngedatha echanekileyo malunga nokunxitywa kwemibhobho. Banceda abaqhubi babone iimpawu zakwangoko zomonakalo onokuthi ungabonakali. Enye inkqubo esebenzayo yiInkqubo ye-EMT yeGlycon, esebenzisa i-Micro-Epsilon sensors ukulinganisa ukunxiba ngaphakathi kombhobho.

Nantsi indlela ezisebenza ngayo ezi zixhobo:

| Isixhobo sokulinganisa | Inkcazo |

|---|---|

| Inkqubo ye-EMT yeGlycon | Isebenzisa izinzwa zeMicro-Epsilon kumlinganiselo wokunxitywa ochanekileyo kwimibhobho yesikrufu sokutofa. |

| Iinzwa zeMicro-Epsilon | Izixhobo zoluvo ezomeleleyo ezibonelela ngofundo oluchanekileyo kumaqondo obushushu asebenzayo ukuya kuthi ga kwi-600°F. |

| Inkqubo yokulinganisa | Kubandakanya ukususa iplagi yombhobho, ukufaka inzwa, kunye nokulinganisa umgama phakathi kwe-screw OD kunye ne-ID yomgqomo. |

| Ugqithiso lweenkcukacha | Idatha yokunxiba kunye nemveliso ithunyelwa kwi-Electronic Measurement and Tracking portal ukuze ihlalutywe. |

| Uhlalutyo oluqikelelweyo | Ivumela ukubalwa kweereyithi zokunxiba kunye noqikelelo lokunxitywa kwexesha elizayo, ukulungiselela iishedyuli zokutshintsha. |

Ezi zixhobo azigcini nje ukulinganisa ukunxiba kodwa zibonelela ngohlalutyo oluqikelelweyo. Abaqhubi banokusebenzisa le datha ukucwangcisa ukugcinwa kunye nokutshintshwa, ukunciphisa ixesha lokuphumla.

Phawula:Ukutshala imali kwizixhobo zokulinganisa kunokugcina imali kwixesha elide ngokuthintela ukungaphumeleli okungalindelekanga.

Uvavanyo lokuSebenza

Iimvavanyo zokusebenza zityhila indlela umphanda owuphatha kakuhle ngayo imveliso. Abasebenzisi banokubeka iliso kwiibenchmarks ezifana nokutshintsha kobushushu, izinga lokucheba, kunye nobubanzi beslot ukuze babone umonakalo. Umzekelo, umgqomo owonakele unokuzabalaza ukugcina amaqondo obushushu ahambelanayo, okukhokelela kumgangatho wemveliso ongalinganiyo.

Nalu ulwahlulo lwemilinganiselo ephambili:

| IBenchmark yoVavanyo lokuSebenza | Unxulumano kunye nokufunyanwa komonakalo |

|---|---|

| Utshintsho lobushushu | Ulungelelwaniso oluhle kunye nenqanaba le-offset; i-offset iyancipha ngokunyuka kobushushu. |

| Ireyithi yokucheba | Ichaphazela ubushushu; utshintsho olubalulekileyo olujongwe kwizantya eziphezulu. |

| Utshintsho olunzulu | Ulungelelaniso oluhle; i-offset iyancipha ngokunyuka kobunzulu. |

| Slot Ububanzi | Yandisa iqondo lokushisa lokucheba, elichaphazela ubushushu bokutya kunye noxinzelelo. |

Ukubeka esweni ezi benchmarks kunceda abaqhubi bachonge xa umphanda ufuna ukuhoywa. Umzekelo, ukuba izinga lokucheba litshintsha kakhulu, oko kunokuthetha ukuba umgqomo unxibe ngokungalinganiyo. Ukujongana nale miba kwangethuba kuqinisekisa imveliso engaguqukiyo kwaye kunciphisa inkcitho.

Ingcebiso:Rekhoda idatha yokusebenza rhoqo ukuze ubone iintsingiselo kunye nokuthintela umonakalo.

Ukuthintela Ukonakaliswa Kwimibhobho ye-Screw yokutofa

IiNdlela zokuGcinwa kweSiqhelo

Ukugcinwa kwesiqhelo ngumqoloyokugcina umbhobho wesikrufu sokutofa ukwimeko ephezulu. Abaqhubi abathathayoubunini bemisebenzi yolondolozobahlala beqinisekisa ukhathalelo olungcono lwezixhobo. Le ndlela yokwenza izinto esebenzayo yandisa ubomi boomatshini kwaye inqanda ukophuka okungalindelekanga.

Nazi ezinye iindlela zolungiso ezibalulekileyo:

- Hlola kwaye ucoce izikrufu kunye nemigqomo rhoqoukuphepha ukwakhiwa kwezinto.

- Gcoba iindawo ezihambayo ukuze unciphise ukukhuhlana kunye nokuguga.

- Gcina amaqondo obushushu obuphezulu okuthintela ukufudumeza.

- Ukubeka iliso ekunxibeni kwaye uqinisekise ukulungelelaniswa okufanelekileyo ngexesha lofakelo.

Ingcebiso:Yenza uluhlu lokutshekisha lolondolozo kwaye ucwangcise ixesha lokuphumla rhoqo lokuhlola. Ukuxhobisa abaqhubi ngezixhobo ezifanelekileyo nako kunokunceda ukulungisa imiba emincinci ngoko nangoko.

Ukukhetha izixhobo ezihambelanayo

Ukukhetha izixhobo ezifanelekileyo zokuvelisaibalulekile ekuthinteleni umonakalo. Izongezo ezirhabaxa ezifana ne-calcium carbonate okanye iifiber zeglasi zinokudiliza umphezulu womphanda ngokukhawuleza. Izinto ezitshabalalisayo, ngakolunye uhlangothi, zinokusabela kunye ne-barrel, ezibangela ukuthotywa kwexesha elide.

Ukuvavanya imathiriyeli ekrwada yokuhambelana kuqinisekisa ukuqina kwaye kunciphisa umngcipheko womonakalo. Ngokomzekelo, iibhareli ze-bimetallic zilungele ukuphatha izinto ezinqabileyo okanye ezonakalisayo ngenxa yeempawu zabo zokunxiba. Abaqhubi kufuneka bahlale behambelana neenkcukacha zombhobho kunye nezinto ezilungiswayo.

Phawula:Ukusebenzisa izinto ezingahambelaniyo kunokukhokelela kwimicimbi yokusebenza kunye nokunciphisa ubomi bombhobho.

Ukulungiselela iSetingi zoomatshini

Iisetingi zoomatshini ezingalunganga zinokucinezela umgqomo wesikrufu sokutofa, okukhokelela ekunxityweni kwangaphambili. Abasebenzisi kufuneka bandise useto olufana nobushushu, uxinzelelo, kunye nesantya ukuze zihambelane nemathiriyeli elungiswayo. Umzekelo, uxinzelelo olugqithisileyo lunokubangela uxinzelelo olungadingekile kumgqomo, ngelixa amaqondo obushushu aphantsi anokubangela ukunxiba okungalinganiyo.

Ukuphononongwa rhoqo kunye nokulungelelanisa ezi zicwangciso kuqinisekisa ukusebenza kakuhle kunye nomgangatho wemveliso ongaguqukiyo. Abanini-zithuthi kufuneka kwakhona babeke iliso kwiimetrikhi zokusebenza ukuchonga imiba enokubakho kwangethuba.

Ingcebiso:Qeqesha abaqhubi ukuba baqonde impembelelo yezicwangciso zoomatshini ekusebenzeni komgqomo. Olu lwazi lubanceda benze uhlengahlengiso olunolwazi ngexesha lemveliso.

Ukuchonga umonakalo kwimibhobho yesikrufu sokutofa kwangethuba kugcina umsebenzi uqhuba kakuhle kwaye kucutha iindleko. Ukuhlolwa nokugcinwa rhoqo rhoqo kuhamba indlela ende ekwandiseni ubomi bezixhobo. Amanyathelo othintelo, njengokusebenzisa imathiriyeli ehambelanayo kunye nokuphucula useto, qinisekisa umgangatho wemveliso ongaguqukiyo.

Khumbula:Indlela esebenzayo inciphisa ixesha lokuphumla kwaye igcina imveliso isebenza kakuhle.

FAQ

Yeyiphi eyona ndlela yokucoca umbhobho wesikrufu sokutofa?

Sebenzisa ibhrashi ethambileyo kunye ne-arhente yokucoca engatshiyo. Gwema izixhobo zetsimbi ukukhusela imikrwelo. Ukucocwa rhoqo kugcina umphanda usebenza kakuhle kwaye ungonakali.

Kufuneka abasebenzi bahlole kangaphi imigqomo yesikrufu sokutofa?

Uhlolo lweveki lufanelekile. Ukutshekishwa rhoqo kunceda ukubamba ukuguga, ukuvuza, okanye ukwakha kwangethuba, kuqinisekisa imveliso egudileyo kunye nokunciphisa ixesha lokuphumla elineendleko.

Ingcebiso:Yenza uluhlu olulula lokuhlola ukuze uhlale ungaguquguquki.

Ngaba iibhareli ze-bimetallic ziyakwazi ukuphatha izinto ezinobungozi ngcono?

Ewe!Imigqomo yeBimetallic ixhathisa ukunxibakunye nokugqwala, kubenza bagqibelele kwizinto ezirhabaxa okanye ezonakalisayo njengeeplastiki ezigcweleyo okanye iiplastiki zobunjineli.

Phawula:Soloko uthelekisa uhlobo lombhobho kwizinto zokusebenza ukuze usebenze kakuhle.

Ixesha lokuposa: Jun-10-2025