Itekhnoloji ye-Twin screw extruder ibonelela ngokuxutywa okuphambili kunye nokuphuma okuphezulu, iyenza ilungele ukufunwa kwemisebenzi yeplastiki. I-screw extruders enye ihlala idumile ngenxa yexabiso layo kunye nokusebenza kakuhle. Ukukhula kwemarike kubonisa imfuno eyomeleleyo, kunye namashishini afana nokupakisha kunye neemoto ezixhomekeke kwaba matshini kwimveliso enkulu.I-Twin Parallel Screw Barel SupplierkwayeIzikrufu zamawele zePlastiki Extrudersqinisekisa iziphumo ezihambelanayo, ngelixaI-Conical Twin Screw Twin ScrewUyilo lukhulisa ukuguquguquka.

Imigaqo yokuSebenza kunye noMahluko woYilo

I-Twin Screw Extruder Configuration

Sebenzisa i-twin screw extrudersizikrufu ezimbini ezidibanisayoezijikeleza kunye ngaphakathi kumphanda. Ezi zikrufu zinokujikeleza okanye zijikeleze, kuxhomekeke kwisicelo. Uyilo luvumela ukuxuba okuphezulu kunye nokudibanisa, okwenza kube lula ukucubungula uluhlu olubanzi lwezinto. Iinjineli zinokuhlengahlengisa i-screw diameter, iprofayili, kunye nejometri yomgqomo ukunyusa izinga lemveliso kunye nomgangatho wemveliso. Ukwakhiwa komgqomo wemodyuli kunye neenkqubo zokulawula eziphambili zinceda ukugcina ubushushu obuchanekileyo kunye noxinzelelo. Ezi mpawu ziphucula ukufana kwemveliso kunye neempawu zoomatshini, ngakumbi kwizicelo ezifunwayo njengeUkuveliswa kombhobho wePVC.

Phawula:Idizayini ye-intermeshing yandisa ukusebenza kakuhle kokuxuba kunye nokuxhasa ukuzicoca, okunciphisa ixesha lokuphumla.

Isikruru esiSinye soYilo lwe-Extruder

I-screw extruders enye inoyilo olulula kunye ne-helical screw enye ngaphakathi kombhobho. Olu luyilo lusebenzisa iindawo ezincinci ezihambayo, okwenza kube lula ukusebenza kunye nokugcina. Isikrufu sityhala imathiriyeli phambili ikakhulu ngokuqhutywa kokutsala, okusebenza kakuhle kwimathiriyeli yokuqukuqela okuzinzileyo. Ukupholisa isijivu sangaphakathi kunye nokumila kwentambo yoxande kunceda ukulawula ubushushu kunye nokuqinisekisa ukusetyenzwa okuzinzileyo. Ubungakanani obubambeneyo kunye nolwakhiwo oluthe ngqo lwenza i-screw extruders enye ibe yindleko kwaye ifanele imveliso enkulu.

| Ukucaciswa koyilo / Umba weendleko | Iimpawu ze-Screw Extruder enye |

|---|---|

| Ubulula kuYilo | Amalungu amancinci ahambayo, kulula ukusebenza kunye nokugcina |

| Imali eyinkunzi kunye neeNdleko zokuSebenza | Iindleko zotyalo-mali eziphantsi kunye nokugcinwa kwazo |

| Ukusebenza kakuhle kwamandla | Isebenzisa amandla amancinci kwimisebenzi elula |

| Isondlo | Ukuqhaqha ngokukhawuleza kunye nokucoca |

| Umsebenzi | Iphakamileyo kwizinto ezilula |

Ukuqukuqela kwezinto eziphathekayo kunye neNdlela yokuDibana

Ukuhamba kwezinto kwi-twin screw extruder kubandakanya ukuhamba kokutsala, ukuhamba koxinzelelo, kunye nokuhamba kokuvuza. Izikrufu ze-intermeshing zenza i-chear kunye ne-kneading effects, eziphucula ukuxuba kunye nokusabalalisa okongeziweyo. Izikrufu ezijikelezayo ziphucula ukusebenza kakuhle kokuxuba kunye nokunceda ukulawula ubushushu, ukunciphisa umngcipheko wokuthotywa kwezinto. Ngokwahlukileyo, i-screw extruders enye ixhomekeke kakhulu ekuhambeni kokutsala, okunciphisa amandla okuxuba kodwa iqinisekisa imveliso ezinzileyo yezixhobo ezilula. Screw geometry, isantya, kunye ne-viscosity yezinto zonke zinempembelelo yokuhamba kunye nokusebenza kokuxuba.

Iimpawu zokucoca kunye nokuzicoca

I-twin screw extruders iyagqwesa ekususeni igesi kuba izikrufu ezidibanisayo zonyusa indawo yomphezulu wokukhutshwa kwerhasi. Ezinye iisistim zonyusa ukusebenza kwe-degassing ukuya kuthi ga kwi-500% xa kuthelekiswa noyilo lwesijiva esinye. Iimpawu zokuzicoca, ezifana nesenzo se-screw sokuzisula, kunceda ukugcina inkqubo ehambelanayo kunye nokunciphisa ixesha lokuphumla. Iinkqubo zokuhluza eziphambili kunye nolawulo oluchanekileyo lweeparamitha ze-extrusion zixhasa ngakumbi ezi zibonelelo. I-screw extruders enye inikezela ngokucoca ngokuthe ngqo ngenxa yolwakhiwo olulula, kodwa ayihambelani nokusebenza kakuhle kwe-twin screw systems.

Uthelekiso lweNtsebenzo

Ukuxuba Ubuchule kunye neHomogeneity

Umgangatho wokuxuba umi njengento echazayo ekusebenzeni kwe-extrusion. I-twin screw extruders ihambisa ukuxuba okuphezulu ngenxa yezikrufu zazo ezibini ezidibanisayo. Ezi zikrufu zisasaza kwaye zisasaze izongezo ngokufanelekileyo, zivelisa ukunyibilika okulinganayo. Indlela yokuzisula phakathi kwe-screws ikhusela ukwakhiwa kwezinto kwaye iqinisekisa ukuxuba ngokucokisekileyo. Kwizifundo ezilawulwayo, i-twin screw extruders ivelise imixube eyomileyo yokuphefumlela umgubo ngeukudibanisa ukufana kunye nokusebenza kwe-aerosolilingana okanye ingcono kunokuxuba ibhetshi ephezulu yokucheba. Abaphandi bafumanisa ukuba iiparamitha zenkqubo ezifana nesantya se-screw kunye nesantya sokutya asizange sichaphazele kakhulu ukuhambelana kwemveliso yokugqibela. Oku komelela kuvumela abavelisi ukuba bafezekise imixube efanayo kunye nomgangatho wemveliso ongaguqukiyo, nangona kuqulunqo olunzima.

I-twin screw extruders ivumela ukulungelelaniswa kwamandla okuxuba ngokulungelelanisa iiprofayili ze-screw kunye nezinto. Oku bhetyebhetye kwenza ukulungelelaniswa kwemathiriyeli ethile kunye nezicelo, okukhokelela ekwandiseni ukusasazwa kunye nokudityaniswa okufanayo.

UkuSebenza kunye nokuNgaguquguquki kweziphumo

Ukusebenza kunye nokuhambelana kwemveliso kubalulekile kwimveliso yemizi-mveliso. I-twin screw extruders iphumeleleamazinga aphezulu okuphumelelakunye nokusetyenzwa kwemathiriyeli ngokufanelekileyo kuneemodeli zesijivu esinye. Bagcina ulawulo lwenkqubo oluchanekileyo, olukhokelela kumgangatho wemveliso ohambelanayo kunye neziphene ezimbalwa. Le theyibhile ingezantsi ishwankathela iiyantlukwano eziphambili:

| Uhlobo lwe-Extruder | Iimpawu zoMsebenzi | Iimpawu zokuNxibelelana kweziphumo |

|---|---|---|

| I-twin screw extruder | Ukusebenza okuphezulu; ukusebenza kakuhle; uwonga amandla | Ulawulo lwenkqubo oluchanekileyo; ukuxuba okuphezulu; umgangatho wemveliso ongaguqukiyo; iziphene ezimbalwa kunye nenkcitho encinci |

| Isikrufu esinye | Ukusebenza okuphakathi; ilula kwaye iyabiza | Imingeni enokungaguquguquki koxinzelelo; isakhono esilinganiselweyo sokuxuba; ukuhanjiswa kwezinto ezingalinganiyo kunye neziphene zemveliso |

I-screw extruders enye inokufumana ukuguquguquka koxinzelelo kunye nemiqobo yokuhamba kwezinto, ezinokuchaphazela ukufana kwemveliso. I-Twin screw extruders, kwelinye icala, ibonelela ngokusebenza okuzinzileyo kunye neziphumo ezithembekileyo, zibenza zilungele imveliso enkulu.

Ukuphatha izinto eziphathekayo kunye nokuGuquguquka

Ukuphathwa kwezinto eziphathekayo kunye nokuguquguquka kugqiba indlela i-extruder ehambelana ngayo nemathiriyeli ekrwada eyahlukeneyo kunye nokwakheka. I-twin screw extruders iyagqwesa ekusetyenzweni komgubo, imathiriyeli enzima ukuzondla, kunye nemixube entsonkothileyo. Banikezela ngokuxuba okuphezulu kunye nokusabalalisa, ukuphatha uluhlu olubanzi lwe-viscosity, kwaye bafake izongezo ezininzi ngokulula. Le theyibhile ingezantsi iqaqambisa le mahluko:

| Uphawu | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ifomu yezinto eziphathekayo | Eyona nto ingcono kwiipellet kunye neegranules | Kungcono umgubo kunye nezixhobo ezinzima ukuzondla |

| Ukuxuba Amandla | Kulinganiselwe ukusabalalisa ukuxuba | Ukuxubana okugqithisileyo kunye nokusabalalisa |

| Ubuzaza bobushushu | Ixesha elide lokuhlala | Lifutshane, ixesha lokuhlala elilawulwa ngakumbi |

| I-Additive Incorporation | Udibaniso olongezelelweyo olusisiseko | Iphatha ukwakheka okuntsokothileyo kunye nezongezo ezininzi |

| Uluhlu lweViscosity | Uluhlu olulinganiselwe | Uluhlu olubanzi lwe-viscosity amandla |

I-Twin screw extruders ikwabonelela ngolawulo lwenkqubo eyomeleziweyo, kubandakanya nolawulo oluchanekileyo lobushushu kunye namaxesha amafutshane okuhlala. Ezi mpawu zixhamla kwizinto ezithintela ukushisa kunye neendlela zokupheka ezinzima. I-screw extruders enye ihlala inexabiso kwaye ithembekile kwiipellets ezifanayo kodwa ayinakho ukuguquguquka kunyeizakhono zokuxuba eziphambiliyeenkqubo ezimbini zokujija.

Degassing Efficiency

I-Degassing isusa iigesi ezibanjwe kunye nomswakama kwizinto eziphathekayo ngexesha lokukhupha. I-twin screw extruders ibonelela ngokugqwesileyo kokukhupha igesi ngenxa yoyilo lwazo lwe-screw intermeshing, olunyusa indawo yomphezulu wokukhutshwa kwegesi. Olu phawu lungqina ukuba luxabiseke kakhulu kwizicelo ezifuna ukusulungeka kwemveliso ephezulu okanye xa kusetyenzwa izinto ezithanda ukwenziwa kwegesi. Ukukhutshwa kwegesi okuphuculweyo kukhokelela kwiziphene ezimbalwa kunye nokuphucula umgangatho wemveliso. I-screw extruders enye ibonelela ngesiseko sokususa igesi kodwa ayinakuhambelana nempumelelo ye-twin screw extruders kwizicelo ezifunayo.

Ukuzicoca kunye nokuZigcina

Iimpawu zokuzicoca zinciphisa ixesha lokuphumla kunye nokwenza lula ukugcinwa. I-twin screw extruders zisebenzisa i-self-zosula isenzo se-screw ukuthintela ukwakhiwa kwezinto kunye nokuxhasa umsebenzi oqhubekayo. Idatha yovavanyo ibonisa ukuba ukulungelelanisa iiparamitha ze-extruder ezifana nobubanzi kunye nokuphakama kwe-maleko kunokuphucula uburhabaxa bomphezulu kunye nokumanzi, ukuphucula ukusebenza kokuzicoca. Izinto ezifana ne-thermoplastic elastomers zibonisa amanani aphezulu okuzicoca, okuguqulela ukucocwa okuncinci kwezandla kunye neendleko eziphantsi zokugcinwa. I-screw extruders enye kulula ukuyiqhawula kwaye icoceke ngenxa yoyilo lwazo olulula, kodwa aziboneleli kwinqanaba elifanayo lokuzicoca ngokuzenzekela njenge-twin screw systems.

Ukugcinwa rhoqo kunye nokulungiswa kwe-extruder okulungiselelwe kunceda ukugcina ukusebenza okuphezulu kunye nokwandisa ubomi besixhobo.

Ukufaneleka kwesicelo

Plastic Twin Screw Extruder Applications

A iplastiki iwele Screw extruderisebenzela uluhlu olubanzi lwamashishini afuna ukuxubana okuphambili, ulawulo oluchanekileyo, kunye nokuguquguquka. Abavelisi basebenzisa aba matshini ukudibanisa, ukuveliswa kwe-masterbatch, ukudibanisa i-polymer, kunye nokucubungula iiplastiki ezihlaziyiweyo. Uyilo lweemodyuli luvumela iinjineli ukuba zilungelelanise iiprofayili ze-screw kwizixhobo ezithile, ukuphucula ukusebenza kakuhle kunye nomgangatho wemveliso. Iinkampani kumacandelo eemoto kunye nolwakhiwo zixhomekeke kwi-twin screw extruders kumacandelo asebenza kakhulu. Iingxelo zobuchwephesha ziqaqambisa uphuculo kwimveliso esebenzayo kunye nomgangatho wefomula, ngakumbi kwizicelo ezifana nokuguqulwa kweplastiki yobunjineli kunye nokusetyenzwa kwakhona kwemathiriyeli. Imakethi ye-extruder barrel iyaqhubeka nokuvela, ngokwanda kokwamkelwa kwamawele kunye ne-multi-screw extruders kumacandelo aphezulu kunye namacandelo afuna ukuchaneka afana namayeza kunye nokulungiswa kokutya.

Eyona nto isetyenziswayo kwiSikruru esinye

Izikrufu zesikrufu esinyehlala ulukhetho olukhethiweyo lwemisebenzi elula, ephezulu yokuvelisa. Aba matshini bagqwesa ekuveliseni iimveliso ezinemixube engaguqukiyo, eyomileyo, efana nepasta, ukutya okusisiseko kwezilwanyana zasekhaya, kunye nokutya okusekwe kwirayisi. Uyilo lwabo oluchanekileyo luqinisekisa ukugcinwa okuphantsi kunye neendleko zokusebenza. Le theyibhile ingezantsi ishwankathela ezona meko zilungileyo zokusetyenziswa:

| Uhlobo lweMveliso | Uhlobo Olukhethwayo Lokukhupha | Ukuqiqa |

|---|---|---|

| Ipasta | I-Screw enye | Ukuqulunqwa okulula okomileyo, ukuxuba okuncinci |

| Ukutya Kwezilwanyana Ezisisiseko | Umntu omnye okanye Twin Screw | Zomibini ziyasebenza, isikrufu esinye siyabiza |

| Amashwamshwam erayisi ePuffed | I-Screw enye | Igalelo elomileyo elihambelanayo, i-throughput ephezulu |

Umenzi wamashwamshwam ovelisa iibhola zerayisi ezikhukhumeleyo ufumene iziqhushumbisi zesikrufu esinye ezilungele iiresiphi ezilula. Nangona kunjalo, xa utshintshela kwiimveliso ze-multigrain, zazifuna i-twin screw extruder yokuxuba okungcono kunye nokunciphisa inkunkuma.

Imizekelo yoShishino

- Iinkampani zokutya ezifana noNestlé kunye noKellogg batyala imali koomatshini bokufakelwa ukuze kuhlangatyezwane nemfuno ekhulayo yokutya okucoliweyo.

- Ulwakhiwo kunye necandelo leemoto lixhomekeke kumacandelo akhutshiweyo, kunye neefemu ezifana neBausano kunye neKraussMaffei ezibonelela ngezisombululo ezilungiselelweyo.

- Imveliso eyongeziweyo idibanisa kunye ne-extrusion yemveliso eyenziwe ngokwezifiso, njengoko kubonwa nge-CEAD kunye ne-Arburg.

- Iindlela ezilawulayo kunye nokusingqongileyo ziqhuba ukwamkelwa kwezixhobo zokukhupha ezonga amandla, ezihambelana ne-biodegradable-compatible extrusion.

Ubutsha betekhnoloji, kubandakanya i-automation kunye nokunxibelelana kwe-IoT, iyaqhubeka nokuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso kuwo wonke amashishini.

Ukuqwalaselwa kokuSebenza

Ukusebenziseka ngokulula kunye noQeqesho

Abaqhubi bafumana iinkqubo ze-extruder zanamhlanje ezisebenzisekayo ngenxa yojongano oluphambili lolawulo. Ezi nkqubo zibonisa idatha yexesha lokwenyani, ii-alam, kunye nokuphononongwa kwegraphical, ezinceda abaqhubi ukuba babeke iliso kwaye balungelelanise inkqubo ngokukhawuleza. Iimfuno zoqeqesho zixhomekeke kuhlobo lwe-extruder. I-screw extruders enye inoyilo oluthe ngqo, ukuze abasebenzisi abatsha bafunde ukusebenza okusisiseko kunye nokusombulula ingxaki ngexesha elifutshane.I-twin screw extruderszibonelela ngeempawu ezingakumbi, ezinjengolawulo lweresiphi kunye nolungiso lweengxaki olukude, olufuna uqeqesho olongezelelweyo. Iinkqubo zokulawula kunye neziganeko kunye nokuqokelela idatha kunceda abaqhubi baphendule kwiinguqu zenkqubo kunye nokugcina umgangatho wemveliso.

Icebiso: Utyalo-mali kuqeqesho lwabaqhubi luphucula uzinzo lwenkqubo kwaye lunciphisa umngcipheko weempazamo.

ULondolozo kunye nexesha lokuphumla

Ukugcinwa rhoqo kugcina ii-extruders zisebenza ngokufanelekileyo kwaye zandisa ubomi bazo. Iishedyuli zogcino ziyahluka phakathi kwesikrufu esinye kunye ne-twin screw extruders. Itheyibhile engezantsi igxininisa iinkalo eziphambili ekugxilwe kuzo:

| Uhlobo lwe-Extruder | Iindawo ekugxilwe kuzo kuLondolozo | Iimbalasane zeshedyuli |

|---|---|---|

| I-Screw enye | Ukutya ukupholisa umqala, ukunxitywa kwesikrufu/umgqomo, ukujongwa kwe-thrust bear | Ukutshintsha kweoli rhoqo kwiiyure ze-4,000-5,000 |

| I-Twin Screw | Ulungelelwaniso lweScrew, ukuhanjiswa kwetorque, ukujongwa kwecandelo lomphanda | Inkqubo yokupholisa icocwa rhoqo kwiinyanga ezintandathu |

Iirekhodi zogcino lomkhondo wokuhlolwa, ukulungiswa, kunye nokutshintshwa kwenxalenye. Ezi rekhodi zinceda amaqela abone imiba eqhubekayo kwaye acwangcise ulondolozo lothintelo. Ulondolozo lothintelo lunakhoukunciphisa ixesha lokuphumla ukuya kuthi ga kwi-45%kwaye wongeze iminyaka kubomi besixhobo.

- Amaxwebhu ogcino axhasa ukulungisa iingxaki kunye nokucwangciswa okusebenzayo.

- Ukungahoywa kweerekhodi kukhokelela kwixesha elide lokunciphisa kunye nokulungiswa okuphindaphindiweyo.

Iindleko kunye neMbuyiselo kuTyalo-mali

Iindleko kunye nembuyekezo kutyalo-mali (ROI) zidlala indima enkulu ekukhetheni i-extruder. Ukubumba i-Extrusion ngokuqhelekileyo kufuna autyalo-mali lokuqala olusezantsikunezinye iindlela, ezifana nokubumba inaliti. Iinkqubo ezizenzekelayo zinciphisa iindleko zabasebenzi kunye nenkunkuma yezinto eziphathekayo, ukuphucula ukusebenza kakuhle kwemveliso. Ukusebenza ngokuqhubekayo kunciphisa ixesha lokuphumla, elinyusa i-ROI kwiiprojekthi eziphezulu. Iinkampani zihlala zikhetha i-extrusion yezahlulo ezilula ukunyusa ukonga iindleko, ngelixa iindawo ezintsonkothileyo, ezichanekileyo zinokuthethelela iindleko eziphezulu ngaphambili kwezinye iinkqubo. Ukuphononongwa ngononophelo kweendleko zezixhobo, ukusetyenziswa kwezinto eziphathekayo, kunye neemfuno zabasebenzi ziqinisekisa ixabiso lexesha elide.

Isikhokelo sezigqibo

Ukukhetha Ngokusekwe kwiiMfuno zokuSebenza

Ukukhetha inkqubo ye-extruder elungileyo kuxhomekeke kuphononongo olucokisekileyo lweemfuno zokusebenza. Abenzi abaninzi basebenzisaizikhokelo zokuthatha izigqiboezidibanisa uhlalutyo lwe-techno-economic, imodeli yoqikelelo lweendleko, kunye nezixhobo ezincediswa yi-AI. Ezi zicwangciso zinceda abasebenzisi baqhathanise iinketho ezisekelwe kwindleko, ixesha lokwakha, izakhiwo zezinto eziphathekayo, kunye neemfuno ezikhethekileyo kwishishini. Iindlela ezininzi zokwenza izigqibo, ezifana ne-AHP, i-TOPSIS, kunye ne-VIKOR, zivumela amaqela ukuba ahlole zombini izinto ezinobungakanani kunye nomgangatho. I-Interactive AI chatbots ngoku ibonelela ngolwazi olulungelelanisiweyo, ukuzoba kuluhlu lwedatha enkulu yophando ukuxhasa ukhetho olunolwazi. Uphononongo lwemeko lubonisa ukuba le ndlela iphucula ukuchaneka kwesigqibo, kunye noqikelelo lweendleko oluhambelana ngokusondeleyo neekowuteshini zehlabathi lokwenyani kumacandelo ahlukeneyo. Inkqubo ixhobisa abasebenzisi ukuba benze izigqibo ezizimeleyo ngokubonisa idatha ebanzi, kunokunyanzelisa isisombululo esisodwa.

Ingcebiso: Sebenzisa izixhobo ezisebenzisanayo kunye nezifundo zemeko ukuthelekisa ukusebenza, iindleko, kunye nokuhambelana kwezinto ngaphambi kokuba wenze ukhetho lokugqibela.

Imibuzo Engundoqo Emawuqwalaselwe

Xa ukhetha phakathi kwe-aIsikrufu esinye okanye isikrufu se-twin extruder, amaqela afanele ahlolisise eziliqelaizinto oomatshini kunye nokusebenza:

- Yintoni i-drive kunye ne-resistance forces ebandakanyekayo kwinkqubo yokukhupha?

- Yeyiphi indlela ye-extrusion ehambelana kakuhle nesicelo?

- Uyilo lwegumbi luchaphazela njani uxinzelelo lwe-extrusion kunye nokuhamba?

- Loluphi ulungelelwaniso lwendawo yokuphuma luya kwandisa umgangatho wemveliso?

- Ngaba iimpawu eziphambili ezifana nokuxuba okwesibini okanye ukomeleza kuyafuneka?

- Iipropati eziphathekayo kunye neeparamitha zokusebenza zisebenzisana njani?

| Ukuqwalasela | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Inkqubo yokuguquguquka | I-flexible encinci, kulula ukuyisebenzisa kunye nokugcina | Ibhetyebhetye ngakumbi, ixhasa ukuguquguquka okubanzi kokwakheka |

| Iindleko zokuqala | Ixabiso eliphantsi lokuthenga | Utyalo-mali lokuqala oluphezulu |

| Iindleko zokuSebenza | Ukusetyenziswa kwamandla aphantsi kunye neendleko zokugcina | Iindleko eziphezulu zokusebenza nokugcinwa kwazo |

| Ubuchule boMveliso | Ulawulo olulula, ubunzima obuphantsi, imveliso ephantsi | Ukuphumelela okuphezulu, ukuxuba okungcono, umgangatho wemveliso ophuculweyo |

| Ukuhambelana kwezinto | Ifanelekile kwiintlobo ezininzi zezinto eziphathekayo | Ingcono kwiinkqubo ezintsonkothileyo kunye nokwakheka okuphezulu |

Iingcali zoshishino zincomela ukuhlalutya iinjongo zemveliso, ixabiso lilonke, kunye neemfuno zezinto eziphathekayo. Ukubonisana neengcali kunokunceda ukuqinisekisa ukuba i-extruder ekhethiweyo ihlangabezana neemfuno zangoku nezexesha elizayo.

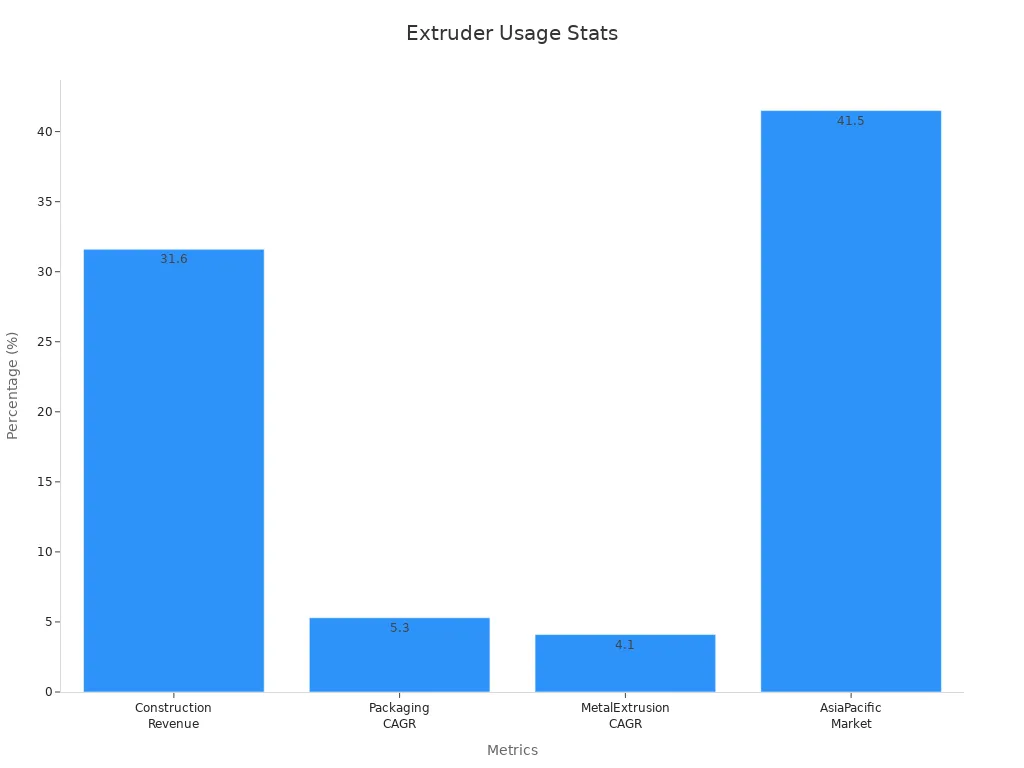

Itekhnoloji ye-Twin screw extruderixhasa ukuxubana okuphambili kunye nokuguquguquka kokulungiswa kweplastiki enzima. I-screw extruders enye ihlala ifanelekile kwimisebenzi elula, enomthamo ophezulu. Idatha yentengiso ibonisa i-6% ye-CAGR eqikelelweyo ye-twin screw extruders, ebonisa imfuno eyomeleleyo kunye nokufaneleka okubanzi kwemizi-mveliso.

| Umba | Intsingiselo/Intsingiselo |

|---|---|

| I-CAGR yemarike | ~6% (2024-2033) |

| Izicelo zoShishino | Iiplastiki, ukutya, amayeza, iikhemikhali |

| Icandelo leMveliso | I-Co-rotating twin screw extruders ikhokelela ekukhuleni |

FAQ

Zeziphi izinto ezinokuthi inkqubo yeplasitiki ye-screw extruder?

A iplastiki iwele Screw extruderiphatha i-polyethylene, i-polypropylene, i-PVC, i-ABS, kunye neeplastiki zobunjineli. Ixhasa ukudibanisa, ukudibanisa, kunye nokuveliswa kwe-masterbatch kumashishini ahlukeneyo.

Ingaba i-twin screw extruder ikuphucula njani ukuxuba xa kuthelekiswa ne-screw extruder enye?

I-twin screw extruders zisebenzisa izikrufu ezidibanisayo. Ezi zikrufu zenza ukucheba okuqinileyo kunye namandla okuxova. Esi senzo siqinisekisa ukusasazwa kakuhle okongeziweyo kunye nemveliso efanayo.

Ngaba i-twin screw extruder machine ilungele iiplastiki ezisetyenzisiweyo?

Ewe. Twin screw extruder inkqubo oomatshiniiiplastiki ezisetyenzisiweyongokufanelekileyo. Banikezela ngolawulo oluchanekileyo lobushushu kunye nokuxuba okuphambili, okuphucula umgangatho wokukhutshwa kwezinto ezisetyenzisiweyo.

Ixesha lokuposa: Jun-26-2025