Xa ndibona umonakalo obonakalayo womphezulu, ukuvaleka okuphindaphindiweyo, okanye umgangatho wemveliso ongahambelaniyo kwi-Parallel Twin Screw Barrel ye-Extruder, ndiyazi ukuba lixesha lokuqwalasela ukutshintshwa. Ukufunyaniswa kwangoko konga iindleko kwaye kugcina imveliso isebenza kakuhle. Ndihlala ndijonge eyamI-Twin Plastic Screw Barel, I-Conical Twin Screw Twin Screw, kwayeI-Twin Screw Extruder Barrelskule miqondiso isilumkiso.

Ukunxitywa ngokugqithisileyo kwi-Parallel Twin Screw Barel ye-Extruder

Umonakalo obonakalayo woMphezulu

Xa ndijonga kwamI-Parallel Twin Screw BarelKwi-Extruder, ndijonge iimpawu ezicacileyo zomonakalo ongaphezulu. Ndihlala ndibona i-grooves enzulu kwi-screw elements, ngamanye amaxesha ifikelela kwi-3 mm. Umonakalo omkhulu womatshini kumphezulu ongaphakathi womgqomo ubonakala kwangoko. Ndiphinde ndijonge iintanda kwincam ye-screw shaft kunye nawo nawuphi na umonakalo kwiringi ye-visco-seal. Ngamanye amaxesha, ndibona ukungcangcazela okungaqhelekanga phambi kokusilela. Ezi mpawu zilumkisayo zindixelela ukuba umphanda okanye izikrufu zinokufuna ukutshintshwa kwakamsinyane.

- Umonakalo omkhulu ngoomatshini ngaphakathi komphanda

- Ukugrumba okunzulu kwizikhonkwane (ukuya kuthi ga kwi-3 mm)

- Ukususwa ekunxityweni, ngamanye amaxesha kude kube yi-26 mm

- Iintanda kwincam ye-screw shaft okanye i-visco-seal ring eyonakeleyo

- Amanqanaba okungcangcazela angaqhelekanga phambi kokusilela

Utshintsho kwidayamitha yomgqomo

Ndihlala ndilinganisa i-diameter ye-barrel ukujonga ukunxiba. Imigangatho yoshishino icebisa ukuba ukunyamezela ukunxitywa okwamkelekileyo kwi-barrel kuphakathi kwe-0.1 kunye ne-0.2 mm (0.004 ukuya kwi-0.008 intshi). Ukuba ndibona i-diameter itshintshile ngaphaya kwale mida, ndiyazi ukuba umgqomo uphelile. Nantsi ireferensi ekhawulezayo:

| Icandelo | Ukunyamezela ukunxiba (mm) | Ukunxiba Ukunyamezela (ii-intshi) |

|---|---|---|

| Screw | 0.1 | 0.004 |

| Umphanda | 0.1 ukuya ku-0.2 | 0.004 ukuba 0.008 |

Ukwandiswa kweCrew-to-Barrel Clearance

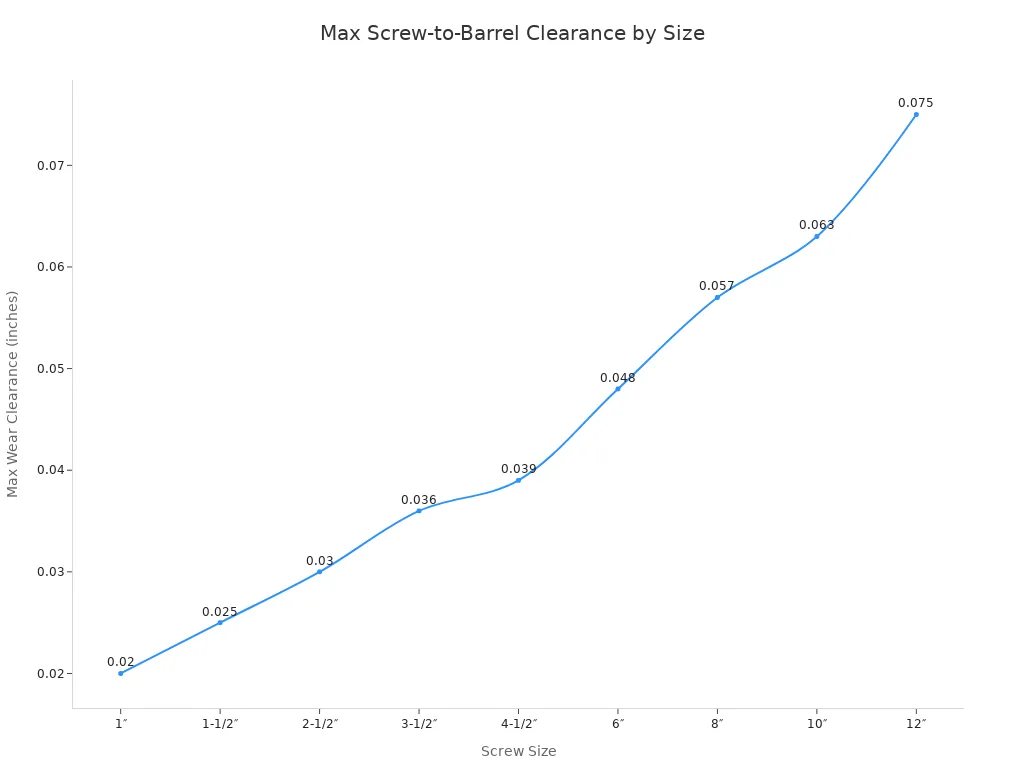

Ndiyiqwalasela ngokukhawuleza i-gap phakathi kwe-screw kunye ne-barrel. Ukuba olu coceko lukhula kakhulu, iingxaki ziqala ukubonakala. Itshathi engezantsi ibonisa obona kukhutshwa banconyiweyo bobukhulu obahlukeneyo bezikrufu:

Xa umsantsa usanda, ndibona ukubuya umva ngakumbi kunye nokuvuza kweplastiki. Oku kubangela ukuba uxinzelelo kunye nomthamo uguquguquke. Iplastiki inokutshisa kakhulu, eyonakalisa umgangatho wemveliso. Ngokufuthi kufuneka ndinyuse isantya somatshini kunye nokusetyenziswa kwamandla ukuze nje ndiqhubeke. Isikhewu esincinci sigcina yonke into ivaliwe kwaye isebenza kakuhle, kodwa umsantsa omkhulu ukhokelela ekuvuzeni kunye nesiphumo esisezantsi. Ukuba ndibona le miba, ndiyazi iParallel Twin Screw Barrel yam ye-Extruder ifuna ukuhoywa.

UkuNcitshiswa kokuSebenza kweParallel Twin Screw Barel ye-Extruder

Amaxabiso emveliso asezantsi

Xa ukusebenza kwe-extruder yam kwehla, ndiyibona kwangoko. Umatshini uvelisa izinto ezincinci ngexesha elifanayo. Ndijonga iI-Parallel Twin Screw Barel ye-Extruderngenxa yeempawu zokuguga. Izikrufu ezigugileyo okanye imiphanda zicothisa intshukumo yeplastiki. Oku kuthetha ukuba ndifumana iimveliso ezimbalwa ezigqityiweyo ngeyure nganye. Ngamanye amaxesha, ndibona ihopper ihlala ixesha elide kunesiqhelo. Oku kundixelela ukuba umatshini awukwazi ukuhambelana nemfuno.

Umgangatho weMveliso ongahambelaniyo

Ndihlala ndijonge utshintsho kumgangatho weemveliso zam. Ukuba ndibona iindawo ezirhabaxa okanye iimilo ezingalinganiyo, ndiyazi ukuba kukho undonakele. Imiphanda nezikrufu ezigugileyo zinokubangela ukuxubana kakubi kunye nokunyibilika okungalinganiyo. Oku kukhokelela kwiingxaki ezifana nokunyibilika kokwaphuka okanye ukwakhiwa kokufa. Nantsi itheyibhile ebonisa imiba yomgangatho wemveliso eqhelekileyo enxulunyaniswa nokunxitywa kwemiphanda:

| Umba woMgangatho weMveliso | Inkcazo |

|---|---|

| Ukunxila kunye nokukrazula okugqithisileyo | Kukhokelela ekuncitshisweni kwemveliso, ukuxutywa okungahambelaniyo, kunye nokunyuka kweendleko zokugcina. |

| Nyibilika ukwaphuka | Iziphumo kumhlaba orhabaxa okanye ongaqhelekanga, ochaphazela inkangeleko kunye neempawu zoomatshini. |

| Die Yakha-Up | Ibangela umgangatho okumgangatho ophantsi kunye nokungahambelani komda ngenxa yokuthotywa kwepolymer. |

Xa ndibona ezi ngxaki, ndiyazi ukuba lixesha lokuhlola umgqomo kunye nezikrufu.

UkuSetyenziswa kwaMandla okwandisiweyo

Ndinikela ingqalelo kumatyala am amandla. Xa i-extruder isebenzisa amandla amaninzi kunangaphambili, ndiyazi ukuba ukusebenza kakuhle kwehlile. Izinto ezigugileyo zezikrufu zinyanzela umatshini ukuba usebenze nzima. Oku kwandisa ukusetyenziswa kwamandla kunye neendleko. Ndisolokojonga izikrufu kunye nomgqomoxa ndibona i-spike ekusebenziseni amandla. Ukutshintsha iindawo ezigugileyo kunceda ukubuyisela ukusebenza kakuhle kwaye konga imali.

Imiba yoLondolozo lwarhoqo kunye noLungiso

Ukuvinjwa okuphindaphindiweyo okanye iiJam

Ndihlala ndijongana nezithintelo okanye iijam kwi-extruder yam xa inkqubo ingasebenzi kakuhle. Ziliqela izinto ezinokubangela le miba:

- Ukubuyisela umva iibhloko zokuxova ngamanye amaxesha kudala imimandla yoxinzelelo oluphezulu, ekhokelela ekuxinaniseni kunye nemiqobo.

- Ukukhutshwa ngokugqithiseleyo phakathi kwe-screw kunye ne-barrel kuvumela izinto ukuba zibuyele ngasemva, zibangele utshintsho lwevolumu kunye neejam.

- Iinqwelomoya ezigugileyo okanye imikrwelo ngaphakathi komphanda iphazamisa inkqubo yokuxuba. Oku kubangela amasuntswana anganyibilikiyo kunye nobukhulu bezinto ezingalinganiyo.

- Ukuba uyilo lwe-screw aluhambelani neempawu zezinto eziphathekayo, ndibona umthwalo wequbuliso ukhula okanye ukwehla kwezinto eziphathekayo, ezinokumisa imveliso.

Xa ndiphawula ezi ngxaki, ndiyaziizixhobo zam zifuna ukuhoywa.

Iingxolo ezingaqhelekanga okanye iiVibrations

Iingxolo okanye iintshukumo ezingaqhelekanga zihlala zibamba ingqalelo yam ngexesha lokusebenza. Ezi zandi zihlala zibonisa iingxaki ezinzulu. Ndifunde ukubukela oku kulandelayo:

| Uhlobo lokungaphumeleli | Unobangela | Ukusebenza |

|---|---|---|

| Iibheringi zonakele | Ukusetyenziswa kwexesha elide, ukuthambisa kakubi, ukugcwala, okanye ukufakela ngokungafanelekanga | Ukonyuka kokungcangcazela kunye nengxolo, ukujikeleziswa kwesikrufu esingazinzanga, ukungahambi kakuhle kwesikrufu esinokwenzeka |

| Ukusilela kwebhokisi yegiya | Ukunxiba, ukungabikho kokuthambisa, ukungcoliseka kweoyile, okanye umthwalo ogqithisileyo | Ingxolo yegiya, ubushushu obuphezulu beoyile, ukusebenza kakuhle okuphantsi, umngcipheko wokuqhekeka kwegiya |

Ngamanye amaxesha, ndiphinda ndive izandi ezingaqhelekanga ezivela ekungalungelelaniseni kakuhle, iibheringi ezaphukileyo, okanye izinto zasemzini ngaphakathi kombhobho. Ezi mpawu zindixelela ukuba ndiyeke kwaye ndihlole iParallel Twin Screw Barrel ye-Extruder ngoko nangoko.

Ukuphindaphinda okuPhezulu kokuLungisa

Xa ndizifumana ndilungisa i-extruder rhoqo, ndiyazi ukuba kukho undonakele.Ukulungiswa rhoqo kuthethainkqubo iyaguga. Ndilandelela ukuba ndibeka kangaphi indawo amalungu okanye ndilungisa iijam. Ukuba ishedyuli yokulungisa iba mfutshane, ndicinga ngokutshintsha umgqomo okanye izikrufu. Oku kundinceda ndiphephe iintsilelo ezinkulu kwaye igcine umgca wam wemveliso usebenza kakuhle.

Ukuvuza kweMathiriyeli okanye Usulelo kwi-Parallel Twin Screw Barrel ye-Extruder

Iimpawu zokuvuza kwi-Barrel

Xa ndiqhuba i-extruder yam, ndihlala njalokhangela iindawo ezivuzayoujikeleze umphanda. Ukuvuza kungabonisa iingxaki ezinkulu ngaphakathi kumatshini. Ndihlala ndibona amachibi amancinci ezinto ezityhidiweyo kufutshane nezibuko lokuphuma okanye ecaleni kwemibhobho. Ngamanye amaxesha, ndibona ivumba elitshisayo okanye umsi, ondixelela ukuba imathiriyeli iyabaleka apho ingafanelanga ukubaleka.

Imiba emininzi inokubangela oku kuvuza:

- Ukubuyela umva kwezinto ukusuka kwidizayini yesikrufu esingafanelekanga

- Izibuko lokukhuphela elilambathayo okanye uyilo lokungenisa umoya olubamba imathiriyeli etyhidiweyo

- Ukunxiba koomatshinioko kwandisa isithuba phakathi kwesikrufu kunye nomphanda

- Ukulawulwa kokushisa okungafanelekanga, okunokugqithisa kunye nokulimaza umbhobho

- Ukucutshungulwa kwezinto ezinqabileyo okanye ukuqhuba umatshini ixesha elide, okwandisa ukunxiba

- Iingxaki zokuthambisa eziphakamisa ukukhuhlane kwaye zibangele ukuguga ngakumbi

Ukuba ndibona nayiphi na kwezi miqondiso, ndiyazi ukuba i-Parallel Twin Screw Barrel yam ye-Extruder ifuna ukujongwa ngokusondeleyo.

Ungcoliseko kwiMveliso yokuGqibela

Ndihlala ndihlola iimveliso zam ezigqityiweyo ukufumana iimpawu zosulelo. Xa umphanda uphela okanye usilela, ndidla ngokubona utshintsho kwinkangeleko namandla emveliso. Itheyibhile engezantsi ibonisa ezinyeiingxaki eziqhelekileyokwaye zikhangeleka njani:

| Khupha | Isiphumo kuMgangatho weMveliso | Iimpawu ezibonakalayo |

|---|---|---|

| Ukudilika komphezulu | Iingqimba ezibuthathaka, ukuxobuka, okanye ukugqabhuka | Ukukrazula okanye ukukrazula kumphezulu |

| Ukutshintsha kombala | Imivimbo yombala, amabala angaqhelekanga, amandla ancitshisiweyo | Imijelo okanye amabala ombala ongaqhelekanga |

| Amanqaku omdlalo | Iindawo ezinqabileyo, ukuxhathisa impembelelo embi, amanqaku angaphezulu | Isilivere okanye inamafu imigca |

Xa ndibona ezi ziphene, ndiyazi ukuba ukosuleleka okanye ukunxitywa ngaphakathi kombhobho kusengunobangela. Ndisebenza ngokukhawuleza ukukhusela umonakalo omkhulu kwaye ndigcine iimveliso zam zikumgangatho ophezulu.

Ukuphelelwa lixesha kunye nemingeni ehambelanayo

Uyilo lwemiphanda oluphelelwe lixesha

Ndihlala ndibona ii-extruders ezindala zisokola ukuhambisana neemfuno ezintsha zemveliso. Xa ndisebenzisa iuyilo lomphanda oluphelelwe lixesha, ndiqaphela ukuba ayikwazi ukuphatha izinto zamva nje okanye ukuhambisa ukusebenza kakuhle njengezixhobo zanamhlanje. Kule minyaka ilishumi idlulileyo, abavelisi benze uphuculo olukhulu kwi-parallel twin screw barrels. Olu phuculo lundinceda ndiqhube iintlobo ezininzi zeeplastiki kunye nezongezo. Ndithembele kuyilo lwamva nje ukunyusa imveliso kunye nokuphucula umgangatho wemveliso. Nantsi itheyibhile ebonisa olona tshintsho lubalulekileyo:

| Ukuqhubela phambili | Impembelelo kuMsebenzi |

|---|---|

| Uluhlu oluphuculweyo lokusetyenzwa kwezinto | Ukukwazi ukucubungula izinto ezibonakalayo kunye nezixhobo ezinzima |

| Amazinga aphezulu emveliso | Ukunyuka kwamazinga emveliso xa kuthelekiswa ne-single-screw extruders |

| Ukunciphisa ukuthotywa kwe-thermal | Ixesha elifutshane lokuhlala elikhokelela kumgangatho ongcono wezinto eziphathekayo |

| Uyilo lwemodyuli | Ukuphuculwa kokuxutywa kokusebenza kunye nokuguquguquka kokusebenza |

Xa ndithelekisa izixhobo zam ezidala nezi zitsha, ndiyabona ukuba ndiphoswa kangakanani kukungaphuculi.

Ukungahambelani nezinto ezintsha okanye iinkqubo

Ndihlala ndidinga ukusebenza ngeepolymer ezintsha okanye izongezo. Ngamanye amaxesha, i-Parallel Twin Screw Barrel yam endala ye-Extruder ayikwazi ukuphatha olu tshintsho. Ndibona ukuxutywa kakubi, ukunyibilika okungalinganiyo, okanye ukuxinana koomatshini. Imigqomo emitsha isebenzisa izinto ezisikruphu zemodyuli kunye nolawulo olungcono lobushushu. Ezi mpawu ndivumele nditshintshe imathiriyeli okanye nditshintshe iinkqubo ngokukhawuleza. Ukuba umphanda wam awukwazi ukuqhubeka, ndisengozini yokuphulukana neshishini okanye ndiwa ngasemva kwabo bakhuphisana nabo. Ndihlala ndijonga ukuba izixhobo zam zihambelana neemfuno zeshishini zamva nje ngaphambi kokuqalisa iprojekthi entsha.

Iingcebiso zokuHlola kunye nokuBeka iliso kwi-Parallel Twin Screw barel ye-Extruder

Iitshekhi ezibonwayo rhoqo

Ndihlala ndiqala usuku lwam ngokuhamba ngononophelo malunga ne-extruder yam. Ndikhangela iintanda kwimigqomo okanye izibonda kwisakhelo. Ndijonga iibholithi ezikhululekileyo kwaye ndiziqinise kwangoko ukuze ndiyeke ukungcangcazela. Ndiqinisekisa ukuba inkqubo yokuthambisa igcwele kwaye ijonge ukuvuza. Ndikwahlola isixokelelwano sokupholisa ukuze ndibone ukuba umgangatho wokupholisa kunye nokuhamba kwawo kuchanekile. Ndijonga lonke uqhagamshelo lombane ukuqinisekisa ukuba lukhuselekile kwaye alonakalanga. Ndijonga izikrufu ngeempawu zokuguga okanye ukungcola. Iingcebiso zokubhabha kufuneka zihlale zibukhali, kwaye akufanele kubekho indawo eninzi phakathi kwe-screw kunye ne-barrel. Ukuba ndibona imikrwelo okanye ukubola ngaphakathi kombhobho, ndilungisa ingxaki ngaphambi kokuba ndiqalise imveliso.

Icebiso: Ndihlala ndibhalela nayiphi naukuvuza kwimibhobho okanye kwimibhobhongokukhawuleza ukuphepha ukuchitha izinto eziphathekayo.

Ukulinganisa ukuNxitywa kunye noNyamezelo

Ndisebenzisa izixhobo ezichanekileyo ukulinganisa i-diameter ye-barrel kunye nokukhutshwa kwe-screw-to-barrel. Ndithelekisa imilinganiselo yam kunye nokunyamezela okucetyiswayo. Ukuba ndibona idiamitha yomphanda okanye umsantsa ukhule kakhulu, ndiyazi ukuba lixesha lokucwangcisa ukulungiswa okanye ukutshintshwa. Ndigcina ilog yale milinganiso ukuze ndikwazi ukubona utshintsho ekuhambeni kwexesha. Oku kundinceda ndibambe iingxaki kwangethuba kwaye ndigcine eyamI-Parallel Twin Screw BarelI-Extruder isebenza kakuhle.

Ukubonisana neziKhokelo zoMvelisi

Ndihlala ndifunda incwadi yomenzi phambi kokwenza naluphi na utshintsho. Le ncwadana yemigaqo indinika ukunyamezela okuchanekileyo, iishedyuli zolondolozo, kunye namanyathelo okuhlola. Ndiyalilandela icebiso labo lokucoca, ukuthambisa, kunye nokutshintsha inxalenye. Ukuba ndinemibuzo, ndiqhagamshelana nomvelisi ngenkxaso. Oku kundinceda ndikhusele izixhobo zam kwaye ndigcine umgca wam wemveliso ukhuselekile.

Ukwenza iSigqibo sokuTshintsha

Uhlalutyo lweendleko-Nzuzo

Xa ndithatha isigqibo sokuba ndithathe indawo yam yeParallel Twin Screw Barrel ye-Extruder, ndihlala ndiqala ngeuhlalutyo lweendleko-inzuzo. Ndijonge izinto ezininzi ezibalulekileyo ezichaphazela umgca wam ophantsi. Ndifuna ukuqiniseka ukuba utyalo-mali lwam luhlawula ekuhambeni kwexesha. Nantsi itheyibhile endinceda ndithelekise amanqaku aphambili:

| Umba | Inkcazo |

|---|---|

| Ukusebenza kakuhle kwamandla | Ukongiwa kwamandla kukhokelela ekuncitshisweni kweendleko zexesha elide, ukuphucula ukukhuphisana kwishishini. |

| Izixhobo zoBomi | Uyilo oluqinileyo kunye namacandelo ahlala ixesha elide akhulisa ixesha lokuphila kwezikrufu kunye nemigqomo, ukunciphisa iindleko zokutshintsha. |

| Iindleko zoLondolozo | Ukugcinwa rhoqo kunokunciphisa ixesha lokuphumla kunye nokuphepha ukulungiswa kweendleko ezingxamisekileyo, okuchaphazela iindleko ezipheleleyo. |

| Ukuhambelana komgangatho | Umgangatho ohambelanayo ukhusela iziphene zemveliso kunye nemiba yokulawula, enokuthi ifake iindleko ezongezelelweyo. |

| Ubuchule bokusebenza | Ukusebenza okuphuculweyo kunciphisa ukusetyenziswa kwamandla kunye nokwandisa i-throughput, echaphazela inzuzo yonke. |

Ndijonga into nganye kwaye ndizibuze ukuba umphanda wangoku uyahlangabezana neemfuno zam. Ukuba ndibona ukunyuka kwamatyala ombane okanye ukulungiswa rhoqo, ndiyazi ukuba lixesha lokuthatha amanyathelo. Umgangatho wemveliso ohambelanayo nawo ubalulekile. Ukuba ndibona iziphene, ndiqwalasela iindleko zokuthengisa ezilahlekileyo kunye nezikhalazo zabathengi. Ngokulinganisa la manqaku, ndenza isigqibo esifanelekileyo kwishishini lam.

Ukutshintshwa kwexesha lokunciphisa ixesha lokuphumla

Ndihlala ndicwangcisa indawo yam ukugcina ixesha lokuphumla lisezantsi kangangoko. Ndicwangcisa umsebenzi ngexesha lemveliso ecothayo okanye ukugcinwa kweefestile. Ukubeka ixesha ngononophelo kundinceda ndiphephe ingeniso elahlekileyo kwaye ndigcine iqela lam livelisa imveliso. Ndisebenzisa itheyibhile ukulandelela inzuzo yocwangciso olulungileyo:

| Inzuzo | Ipesenti yokuNcitshiswa |

|---|---|

| Amaxabiso enkunkuma | 12–18% |

| Iindleko zamandla | 10% |

| Ixesha lokuphumla | ukuya kuthi ga kwi-30% |

Xa ndibuyisela umgqomo ngexesha elifanelekileyo, ndibona inkunkuma encinci kunye neendleko zamandla eziphantsi. Iqela lam ligqiba umsebenzi ngokukhawuleza, kwaye imveliso iqala kwakhona ngokukhawuleza. Ndihlala ndinxibelelana nabasebenzi bam kunye nababoneleli bam ukuqinisekisa ukuba yonke into ihamba kakuhle. Ixesha elilungileyo likhusela inzuzo yam kwaye ligcina abathengi bam bonwabile.

Ndihlala ndijonge ezi mpawu kumi-parallel twin screw barrelye-extruder:

- Ndibeka iliso kwisithuba sokunxiba; umsebenzi wokulungisa ukuya kuthi ga0.3mm, kodwa ndibuyisela umphanda ukuba umsantsa uyakhula okanye umaleko we-nitriding uyasilela.

- Ndilinganisela iindleko zokulungisa xa kuthelekiswa nokutshintshwa kunye nokuguga komkhondo ukunqanda ixesha lokuphumla.

- Ndihlola izixhobo zam rhoqo500–1,000 iiyure.

- Ukuhlolwa kwesiqhelo kundinceda ndibambe iingxaki kwangethuba.

Ukubeka iliso rhoqo kugcina imveliso yam isebenza kakuhle kwaye konga imali.

FAQ

Ndingawujonga kangaphi umphanda wam we-parallel screw ukuze unxitywe?

Ndijonga umgqomo wam rhoqo kwiiyure zokusebenza ezingama-500 ukuya kwi-1,000. Ukuhlolwa rhoqo kundinceda ukuba ndibambe iingxaki kwangoko kwaye ndigcine i-extruder yam isebenza kakuhle.

Ingcebiso: Ndihlala ndingena kwiziphumo zohlolo ukwenzela ireferensi yexesha elizayo.

Ngowuphi ucoceko oluphezulu lwe-screw-to-barrel ngaphambi kokutshintshwa?

Ndiyitshintsha i-barrel xa i-gap screw-to-barrel idlula i-0.3 mm. Oku kuthintela ukuvuza kunye nokugcina umgangatho wemveliso uphezulu.

| Icandelo | Ubukhulu boSulelo (mm) |

|---|---|

| Screw-to-Barrel | 0.3 |

Ndingawulungisa umphanda ogugileyo endaweni yokuwutshintsha?

Ndilungisa iimpahla ezincinci ukuya kuthi ga kwi-0.3 mm. Ukuba umaleko we-nitriding uyasilela okanye umonakalo unzima, ndikhetha ukutshintshwa kwentsebenzo engcono.

Ixesha lokuposa: Aug-28-2025