I-extrusion ye-Screw extrusion isebenzisa isikrufu esinye esijikelezayo, ngelixa i-twin screw extrusion ixhomekeke kwizikrufu ezibini ezidibanisayo zokudibanisa okuphuculweyo. Lo mahluko uchaphazela umgangatho wemveliso kunye nolawulo lwenkqubo. Ukuze kube lula, ukuveliswa kwevolumu ephezulu, aI-Plastic Screw Barel enyeilungele iimfuno ezininzi.I-Twin Screw Extruder BarrelskwayeIzikrufu zamawele zePlastiki Extrudersukugqwesa kumxube onzima.

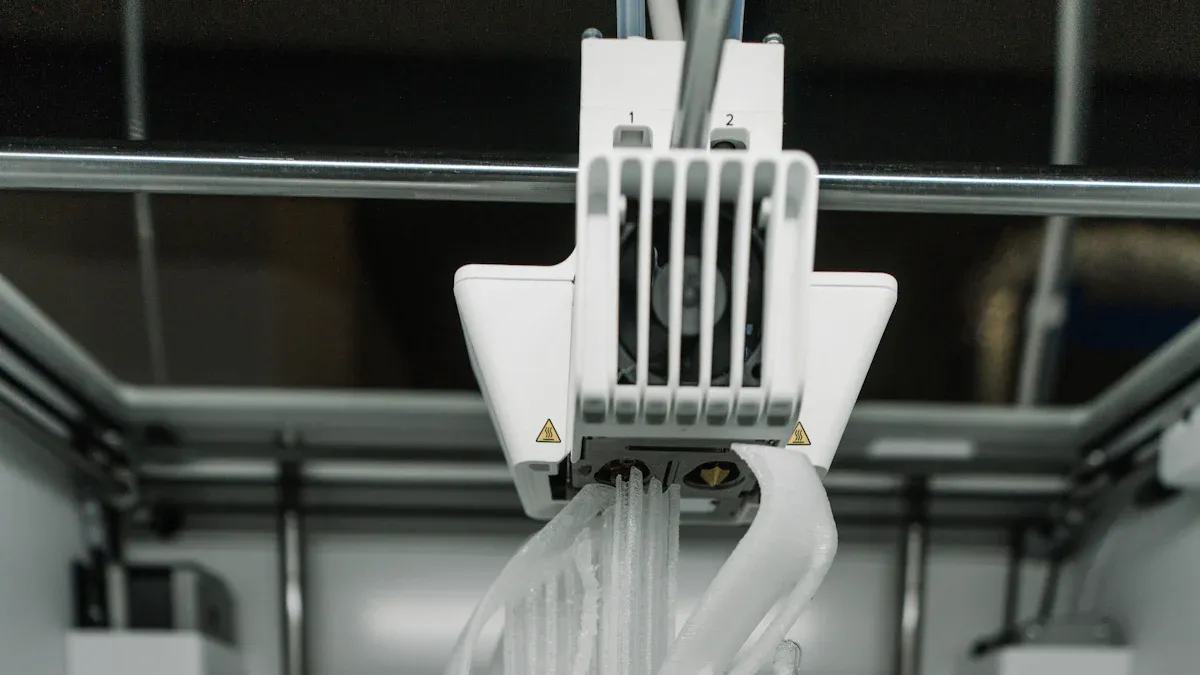

Isikruru esiSinye sicacisiwe

Indlela I-Screw Extrusion esebenza ngayo enye

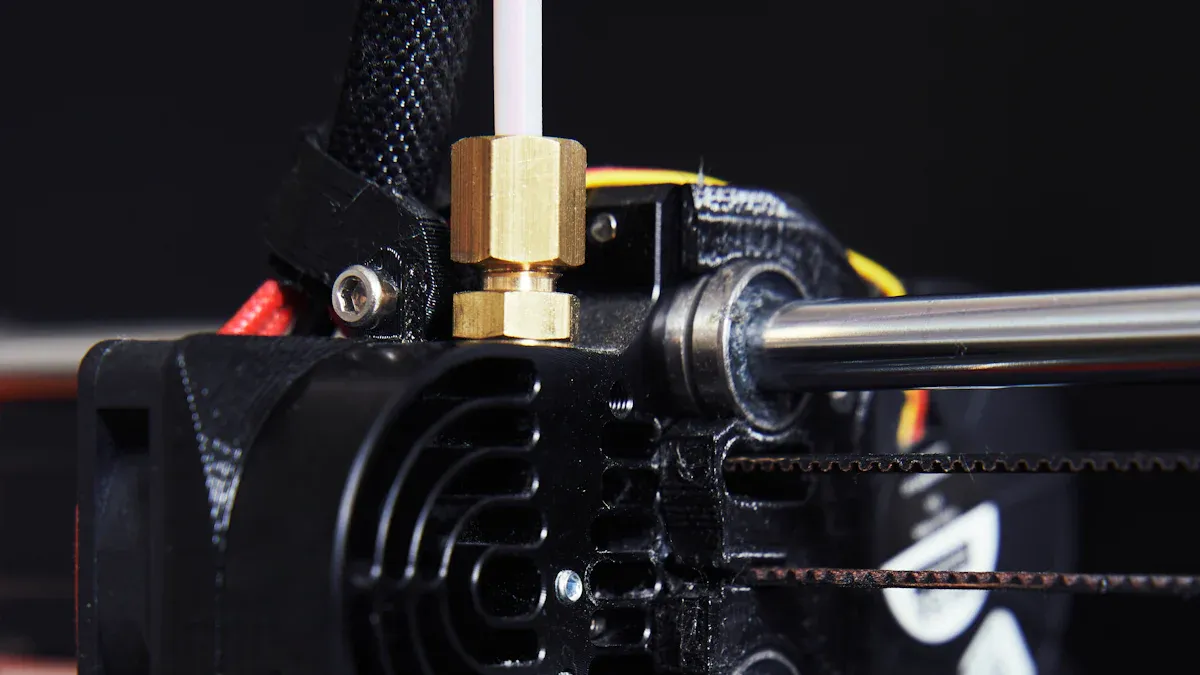

I-extrusion ye-screw enye isebenzisa isikrufu esinye esijikelezayo ngaphakathi kombhobho oshushu. Isikrufu sihambisa iplastiki ekrwada okanye imathiriyeli yerabha phambili, apho ukukhuhlana nobushushu bunyibilika. Isixhobo esinyibilikisiweyo sidlula kwidayisi ukwenza imilo eqhubekayo. Abasebenzisi balawula iiparamitha zenkqubo engundoqo ezifana nobushushu bomphanda (udla ngokuba yi-160–180 °C), isantya sokujija, kunye nobushushu bokufa. Isantya seyunithi yokuthatha kunye nobushushu betanki yamanzi kunceda ukulawula ubukhulu bemveliso yokugqibela kunye nokupholisa. Isikrufu siyasebenzaimisebenzi emithathu ephambili: ukuhambisa, ukunyibilika, kunye nokuxuba. Uyilo lomphandaiimpawu ezifana nokuthambisa okuqinileyo kunye nokucwenga kwechrome kunciphisa ukukhuhlana kunye nokuncamathela, ukuqinisekisa ukusebenza kakuhle.

Izinto ezilungileyo zeSikruru esiNye Extrusion

Abavelisi bayakhethaesinye isijivu extrusionngenxa yokulula kwayo kunye nokusebenza kakuhle kweendleko. Uyilo luvumela ukusebenza lula kunye nokugcinwa. Utyalo-mali lokuqala olusezantsi kunye neendleko zokusebenza zenza kube nomtsalane kumashishini amaninzi.Ukusebenza kakuhle kwamandlaimile, njengoko inkqubo isebenzisa ukufudumeza okulungiselelwe kunye neendawo ezimbalwa ezihambayo. Abaqhubi banokufikelela umgangatho wemveliso ohambelanayo ngokulungelelanisa ubushushu, uxinzelelo, kunye nesantya se-screw. Inkqubo iphatha uluhlu olubanzi lwemathiriyeli ekrwada, iyenza isebenziseke kwiimfuno ezahlukeneyo zemveliso.

Ingcebiso: Ukugcinwa rhoqo kunye nokujongwa kwamandla ngexesha lokwenyani kunokuphucula ngakumbi ukusebenza kakuhle kunye nomgangatho wemveliso.

Unyino lweSikruphu esinye

I-extrusion ye-screw enye ijongene nemingeni ethile. Imveliso isenokungazinzi kwizantya eziphezulu zokujija, oko kucutha izinga lemveliso. Ukugcina ukushisa okunyibilikayo kunye ne-homogeneity yemveliso kunokuba nzima, ngakumbi ngezinto eziyinkimbinkimbi. Inkqubo inokuzabalaza ngokuxutywa okuphambili okanye imixube efuna ulawulo oluchanekileyo. Ukuziphatha kokutya kunye nokuhanjiswa kuxhomekeke kakhulu kuyilo lwesijiva kunye nejometri yokuvula umxhesho.

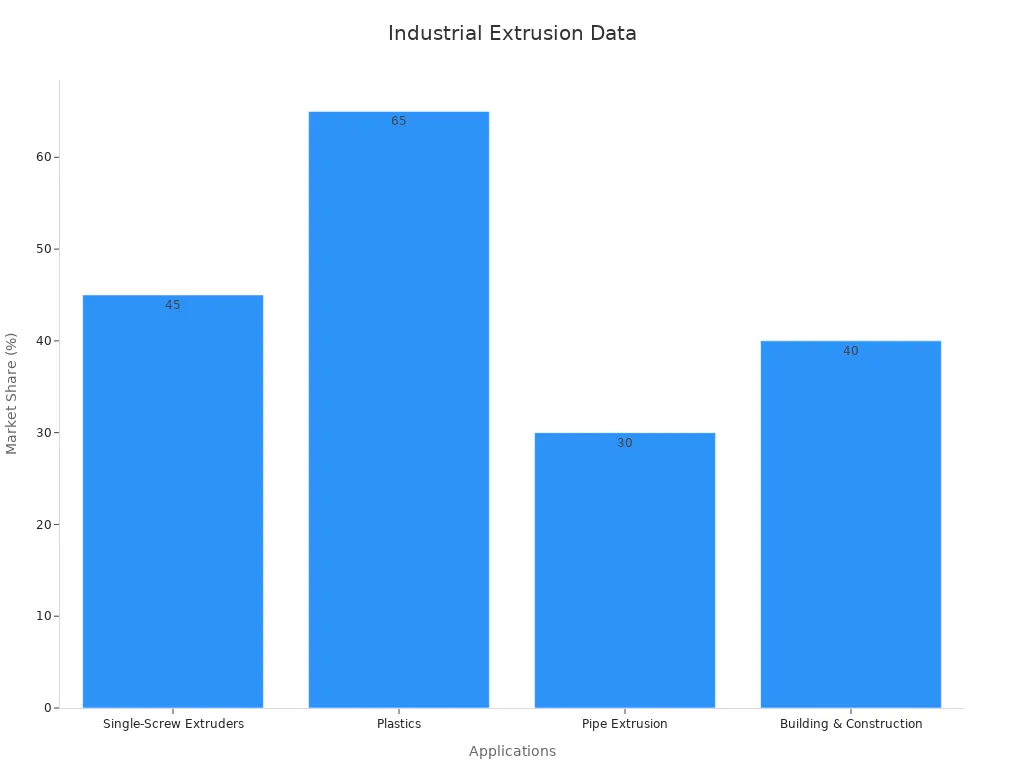

Usetyenziso oluQhelekileyo lweSikruru esiSinye sokuKhutshwa

I-extrusion ye-screw enye ifumana ukusetyenziswa kumashishini amaninzi. Ukupakishwa kukhokelela kwimarike, malunga nesabelo se-60%, ukuvelisa iifilimu kunye namaphepha avela kwiipolymers ezifana ne-PE, PP, kunye ne-PVC. Icandelo lokwakha liyisebenzisela imibhobho kunye neeprofayili, ngelixa abavelisi beemoto baxhomekeke kuyo kwiindawo zangaphakathi nangaphandle. Amashishini ezonyango, izinto zabathengi, kunye namashishini ombane nawo ayazuza kobu bugcisa.

| Uhlobo loMzekelo | I-Screw Diameter (mm) | L:D Umlinganiselo | Amandla eMoto (kW) | Umthamo wemveliso (kg/hr) | Amanqaku ngokuSebenza kunye neMigangatho |

|---|---|---|---|---|---|

| Isikruru esiNye esiSebenzayo phezulu | 60 – 120 | 38:1 | 110 – 315 | 465 - 1300 | 20-30% izinga eliphezulu; Siemens AC motors, CE-eqinisekisiweyo |

| UmGangatho oMgangatho oNye Screw | 60 – 120 | 33:1 | 55 – 315 | 150 - 900 | Amacandelo asemgangathweni osemgangathweni |

I-Twin Screw Extrusion Overview

Indlela i-Twin Screw Extrusion esebenza ngayo

I-twin screw extrusionisebenzisa izikrufu ezibini ezidibanisayo ezijikeleza ngaphakathi kumbhobho oshushu. Abasebenzisi bondla imathiriyeli ekrwada njengeepellets okanye umgubo kwihopper. Izikrufu zihambisa izinto phambili, zicinezele kwaye ziyixove. Ukushisa kwi-barrel kunye ne-friction evela kwizikrufu kunyibilike izinto. Izikhonkwane ezikhethekileyo zixuba kwaye zidibanise i-homogenize ukunyibilika, uqinisekisa nokuba ukusasazwa kwezongezo. Isixhobo esinyibilikisiweyo sidlula kwintsinjana yenze imveliso yokugqibela. Imigqomo yemodyuli eneendawo zokufudumeza kunye nokupholisa ivumela ulawulo oluchanekileyo lobushushu. Iindawo zokungenisa umoya zisusa umoya kunye nokuguquguquka, ukuphucula umgangatho wemveliso.

Amandla e-Twin Screw Extrusion

I-twin screw extrusion ibonelela ngeenzuzo ezininzi:

- Ukuxuba okuphezulu kunye ne-homogenization ngenxa ye-screws intermeshing.

- Amandla aphezulu okuchebaukuphucula ukudibanisa kunye nokufana kwemveliso.

- Uyilo lwemodyuli luvumela uhlengahlengiso olulula lwezixhobo ezahlukeneyo.

- Ukulawulwa kweqondo lokushisa okuphuculweyo kunciphisa ukuthotywa kwe-thermal.

- Imveliso ephezulu kunye nemveliso ixhasa ukwenziwa kwezinto ezinkulu.

- Ulungelelwaniso lwe-screw oluthambileyo lukhulisa ukusetyenzwa kweepholima ezahlukeneyo.

- Ukulawulwa kwenkqubo engcono kunye nohlengahlengiso oluzimeleyo lwesantya se-screw kunye nobushushu.

- Ubomi bezixhobo ezide njengoko umthwalo wabelwe phakathi kwezikrufu ezibini.

| Inkalo yobuGcisa | Inkcazo |

|---|---|

| Ukuxubana okuPhakamileyo kunye ne-Homogenization | Izikrufu ze-Intermeshing zenza i-chear kunye nemiphumo yokuxova ukuxuba okufanayo. |

| Ukusebenza okuphezulu kunye neMveliso | Izikrufu ezijikelezayo zivumela amazinga aphezulu emveliso kunye nokusebenza kakuhle. |

| Ukuguquguquka | Iyakwazi ukucubungula iipolymers ezahlukeneyo kunye nokwakheka okuntsokothileyo. |

Ubuthathaka be-Twin Screw Extrusion

- I-Twin screw extruders inesakhiwo esinzima kunye neendleko eziphezulu.

- Ukuhamba kwezinto ngaphakathi kwe-extruder kunzima ukwenza imodeli kunye nokuqikelela.

- Ukuguquguquka koxinzelelo kunokwenzeka ngenxa yejometri yesikrufu.

- Ukubeka iliso kobungakanani bamasuntswana kunye nokuzinza kwenkqubo kuzisa imingeni.

- Ukunyusa ukusuka kwilebhu ukuya kwimveliso kufuna ukulungiswa ngononophelo.

Ukusetyenziswa okuqhelekileyo kwi-Twin Screw Extrusion

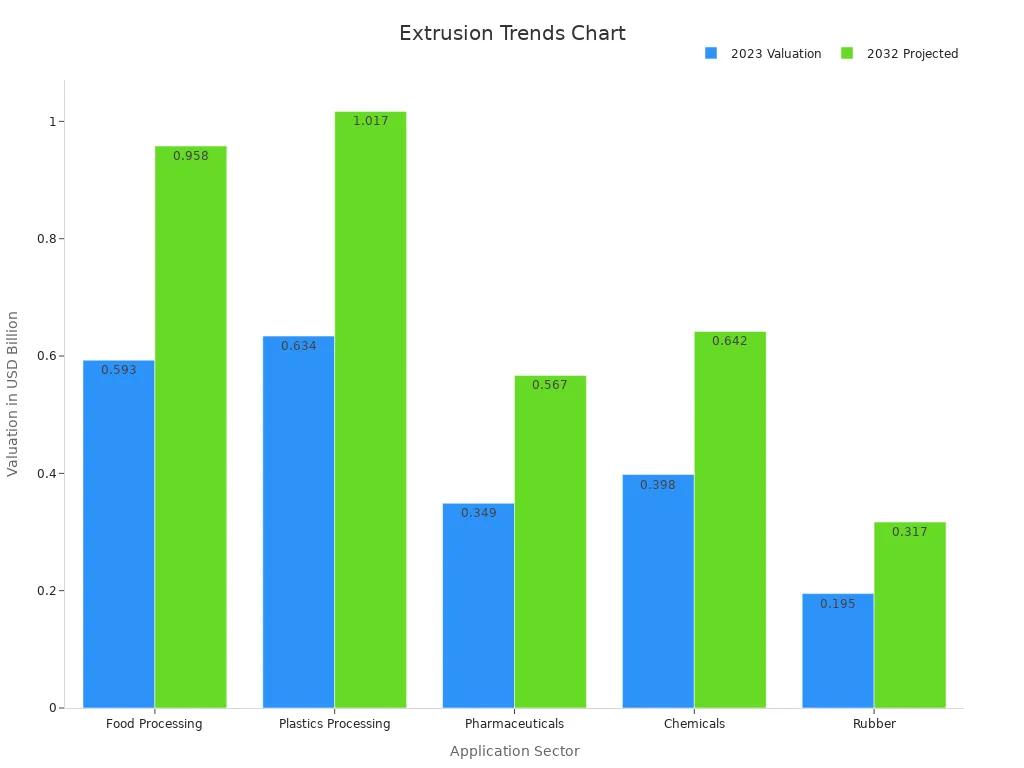

I-twin screw extruders idlala indima ephambili kumashishini amaninzi. Abavelisi bazisebenzisela ukudibanisa iiplastiki, ukusetyenzwa kwemathiriyeli ehlaziyiweyo, kunye nokuvelisa i-bioplastics. Ishishini lokutya lithembele kubo ukuze bafumane amashwamshwam, iicereals, kunye nokutya kwezilwanyana zasekhaya. Iinkampani ezixuba amayeza zisebenzisa i-twin screw extrusion ukwenza iifom zedosi eqinileyo. Amacandelo eekhemikhali kunye nerabha nawo ayazuza kumxube wawo ochanekileyo kunye nolawulo. Imakethi ye-twin screw extruders iyaqhubeka nokukhula, iqhutywa yimfuno e-Asia-Pacific, eYurophu, nakuMntla Melika.

I-Single Screw Extrusion vs Twin Screw Extrusion: Uthelekiso olungundoqo

Iiyantlukwano zoYilo kunye neMechanism

I-extrusion yesikrufu esinyeisebenzisa isikrufu esinye esijikelezayo esinepateni ye-helical elula. Olu luyilo lutyhala izinto phambili ngombhobho. Ngokwahlukileyo, i-twin screw extruders ibonisa izikrufu ezimbini ezidibanisayo. Ezi zikrufu zinokujikeleza ngendlela enye okanye ezichaseneyo kwaye zihlala zibandakanya iibhloko zokuxova ukuze kuxutywe ngcono. Itheyibhile engezantsi ibonisa umahluko ongundoqo wobugcisa:

| Umba | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| I-Screw Design | Isikrufu esinye esijikelezayo esinepateni ye-helical elula etyhalela phambili imathiriyeli. | Izikrufu ezibini ezidibanisayo, ezinokwenzeka ngokubambisana okanye ezijikelezayo, ezinejometri ezintsonkothileyo ezibandakanya iibhloko zokuxova. |

| Ukuxuba Ukukwazi | Ifanelekile kwizinto ezilinganayo kunye nokuxuba okulula. | Ukuxuba okuphezulu ngenxa ye-screws edibeneyo, eyenza ukusasazwa okungcono kwezongezo kunye nezihluzi. |

| UkuPhuma kunye nesiphumo | Ngokubanzi asezantsi amanqanaba okuphumelela kunye nemveliso. | Imveliso ephezulu kunye nemveliso, ilungele imveliso enkulu. |

| Ulawulo lobushushu | Ulawulo olusisiseko kubushushu, isantya sokujija, kunye noxinzelelo lomphanda. | Ulawulo oluphuculweyo lobushushu ngokufudumeza kwangaphakathi/imimandla yokupholisa ecaleni kombhobho. |

| Ukuphatha Izinto | Isebenza kwi-thermoplastics, i-elastomers, kunye neeplastiki ezisetyenzisiweyo kwakhona ezinomgangatho wemveliso ongaguqukiyo. | Ifaneleke ngcono i-high-viscosity, i-heat-sensitive, kunye neendlela eziyinkimbinkimbi ezifuna ulawulo oluchanekileyo. |

| Inkqubo yokuguquguquka | Ukuguquguquka okuncinci, ukusebenza okulula kunye nokugcinwa. | Ukuguquguquka okukhulu ngenxa yoyilo lwe-screw yemodyuli kunye neeparamitha ezilungelelanisiweyo. |

| Ukukhupha amandla | Ubuncinci bokukhupha igesi kunye namandla okuphelisa amandla. | I-degassing esebenzayo kunye ne-devolatilization, ibalulekile kulawulo lomgangatho. |

| Imizekelo yosetyenziso | Iifilimu zeplastiki, imibhobho, i-compounding, i-wire coating, i-extrusion yamaphepha, ukulungiswa kokutya. | Ukudityaniswa kwepolymer, ukwenziwa kokutya, amayeza, kunye nokulungiswa kwezinto ezintsonkothileyo. |

Abaphandi abafana noShen et al. kunye noSastrohartono et al. baye babonisa ukuba i-twin screw extruders inikezela ngeempawu zoyilo eziphucukileyo, ezinje nge-chear flux kunye nokusebenza kakuhle kwamandla, ngakumbi kwizinto ezintsonkothileyo.

Ukuxuba kunye nokuLungiselela izakhono

Ukuxuba kunye nokwenza amandla abeka obu buchwepheshe bumbini. I-extrusion ye-screw enye isebenza kakuhle kwizinto ezilula, ezilinganayo. Inokusingatha imisebenzi yokuxuba esisiseko, kodwa iyazabalaza nokudibanisa okuphambili okanye ukwakheka okudinga ulawulo oluchanekileyo. I-twin screw extruders iyagqwesa ekuxubeni. Izikrufu zabo ezidibanisayo zenza ukucheba okuqinileyo kunye neziphumo zokuxova. Esi senzo siqinisekisa nokusasazeka kwezongezo kunye nezihluzi, ezibaluleke kakhulu kwiimveliso ezikumgangatho ophezulu. Abaqhubi banokuhlengahlengisa izinto ezisijiva kunye neendawo zemigqomo ukulungisa kakuhle inkqubo yezinto ezahlukeneyo. Ngenxa yoko, ii-twin screw systems zixhasa iiresiphi ezintsonkothileyo kunye neemfuno ezifuna imveliso.

Qaphela: Kubavelisi abafuna ukudibanisa iipolymers ezininzi okanye ukongeza iifayili, i-twin screw extruders inika inzuzo ecacileyo ekusebenzeni kokuxuba.

Ukuphumelela kunye nokusebenza ngokufanelekileyo

Ukuphumelela kunye nokusebenza kakuhle kudlala indima enkulu ekukhetheni phakathi kwezi nkqubo. I-extrusion ye-screw enye ngokuqhelekileyo inikezela nge-throughput ephantsi, iyenza ilungele imveliso ekujoliswe kuyo encinci. Isebenza ngesantya esicothayo kwaye inikezela ngeziphumo ezingaguqukiyo kwiimveliso eziqhelekileyo. I-Twin screw extruders, kwelinye icala, ifikelela kwi-throughput ephezulu kunye nezantya zokusetyenzwa ngokukhawuleza. Baxhasa iimfuno ezinkulu zomthamo kunye nokugcina umgangatho wemveliso nangona igranulation enzima. Itheyibhile engezantsi ithelekisa iimetriki eziphambili:

| Metric | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Umsebenzi | Imveliso ephantsi, ifanelekile kwiithagethi zemveliso ephantsi | Imveliso ephezulu, ilungele iimfuno ezinkulu zomthamo |

| Isantya sokusebenza | Izantya zokucotha ezicothayo | Izantya zokuqhubekeka ezikhawulezayo |

| Umgangatho weMveliso | Ubunzima bokuxuba obuncinci, igranulation encinci | Ukuxuba okuphuculweyo, kuxhasa i-granulation enzima |

| Iindleko zokuSebenza | Iindleko zokusebenza eziphantsi ngenxa yokulula kunye nokusebenza kakuhle kwamandla | Iindleko eziphezulu zokusebenza ngenxa yobunzima kunye nokugcinwa |

| Ukuba bhetyebhetye | Ukusebenza okuncinci, okulula ngakumbi | Ukuguquguquka okukhulu, kunokusingatha iifomyula ezinzima |

| Amaxabiso emveliso | Amazinga emveliso asezantsi ngokubanzi | Amazinga aphezulu emveliso |

I-twin screw extruders zihlala zithethelela iindleko zazo eziphezulu zokusebenza kunye nokwanda kwemveliso kunye nokukwazi ukuphatha izinto ezinzima kakhulu.

Ukuguquguquka kunye nokuguquguquka

Ukuguquguquka kunye nokuguquguquka kubalulekile kwimveliso yanamhlanje. I-extrusion ye-screw enye inikezela ukusebenza okuthembekileyo kwiimveliso eziqhelekileyo kunye nezixhobo. Nangona kunjalo, inika ukuguquguquka okulinganiselweyo xa utshintshela phakathi kweendlela ezahlukeneyo okanye iintlobo zemveliso. I-twin screw extruders igqame kule ndawo. Kumboniso wokurhweba we-K 2016, imigca ye-screw eqhubela phambili ibonise utshintsho olukhawulezayo phakathi kwezinto, imibala, kunye nobukhulu. Ezinye iinkqubo zitshintshe iifomathi ngemizuzu, hayi iiyure. Ezi extruders zicubungule iifilimu ezinomaleko amaninzi ukuya kuthi ga kwi-11, izinto zokuphatha ezifana ne-EVOH, inayiloni, kunye namabakala ahlukeneyo e-polyethylene. Idatha yemveliso ibonise aI-45.8% yokunciphisa inkunkuma yezinto eziphathekayokwaye phantse i-29% yokonga amandla emva kokuphucula kwiinkqubo eziguquguqukayo ze-screw. Imbuyekezo yexesha lotyalo-mali nayo yacuthwa ngaphezulu kwe-26%. Olu phuculo luqaqambisa iingenelo zokusebenza kwe-twin screw extruders kwindawo entsonkothileyo, yezinto ezininzi.

IiNdleko kunye neeNgqwalasela zoLondolozo

Iindleko kunye nokugcinwa kuchaphazela isigqibo sokugqibela kubenzi abaninzi. Iinkqubo zokukhupha isikrufu esinye zibiza kancinci ukuthenga nokusebenza. Uyilo lwazo olulula luthetha iindawo ezimbalwa zokugcina kunye nokunciphisa ukusetyenziswa kwamandla. Ukugcinwa kwesiqhelo kuqondile, kwaye ixesha lokuphumla lihlala lincinci. I-Twin screw extruders ifuna utyalo-mali oluphezulu lokuqala. Ubume bazo obuntsonkothileyo kunye neempawu eziphambili zikhokelela ekwandeni kweemfuno zokugcina kunye nokusetyenziswa kwamandla aphezulu. Nangona kunjalo, kwiinkampani ezivelisa ixabiso eliphezulu okanye iimveliso ezintsonkothileyo, izibonelelo zokuguquguquka, ukuhanjiswa, kunye nomgangatho zihlala zingaphezulu kweendleko ezongezelelweyo. Ukukhetha inkqubo efanelekileyo kuxhomekeke ekulinganiseni le miba kunye neenjongo zemveliso kunye nohlahlo lwabiwo-mali.

Ukukhetha i-Extruder eLungileyo kwiimfuno zakho

Ukufaneleka kwezinto

Ukukhetha i-extruder efanelekileyo iqala ngokuqonda ukuhambelana kwezinto. Amacandelo omatshini aphambili afanaisantya screw, idayamitha, kunye nobude-to-diameter ratiokuchaphazela kakuhle indlela extruder iinkqubo ezahlukeneyo izinto. Ngokomzekelo, umlinganiselo ophezulu we-L / D unceda ngezinto eziyinkimbinkimbi ezifuna ukunyibilika ngokucokisekileyo kunye nokuxuba. Uyilo lwebhareli, kubandakanya imimandla yobushushu kunye nokuphuma umoya, ixhasa izinto ezibuthathaka okanye ezisetyenzisiweyo. Izikhokelo zeshishini zincoma ukuthelekisa i-extruder kwiqondo lobushushu lokulungiswa kwezinto, i-viscosity, kunye nesantya sokuhamba. I-screw extrusion enye isebenza kakuhle kwi-mass process ye-thermoplastics, ngelixa i-screw extruders ibamba ukwakheka okuntsokothileyo ekutyeni, kumayeza, nakumashishini epolymer.

Isikali seMveliso kunye neZiphumo

Isikali semveliso kunye neemfuno zemveliso zidlala indima enkulu ekukhetheni i-extruder. Amazinga aphezulu emveliso anokunyusa ukusetyenziswa kwamandla kunye neemfuno zokugcinwa. Ulungelelwaniso lwe-screw yemodyuli luvumela ubungakanani obungcono kunye nokusebenza. Uphando lubonisa ukubaumthamo kunye nenqanaba lokuzalisa impembelelo yomgangatho wemveliso kunye nokusebenza kakuhle kokuxuba. Ii-extruders ezinkulu zifuna ukulungiswa ngokucophelela kweeparamitha zokusebenza ukugcina iziphumo ezihambelanayo. Iinkampani kufuneka zilinganise iinjongo zokuvelisa kunye neendleko zokusebenza kunye nobunzima bobugcisa.

Uhlahlo lwabiwo-mali kunye neendleko

Uqwalaselo lweendleko lubandakanya iindleko zangaphambili neziqhubekayo. Itheyibhile engezantsi ichaza izinto eziphambili zeendleko:

| Ixabiso Factor | Inkcazo | Impembelelo yohlahlo lwabiwo-mali |

|---|---|---|

| Ukuthenga kokuqala | Iyahluka ngokobukhulu kunye nohlobo | Utyalo-mali olukhulu lwangaphambili |

| Isiqinisekiso | ISO 9001, CE, njl. | Linganyusa ixabiso lokuthenga |

| Isondlo | Inkonzo yarhoqo iyafuneka | Imirhumo eqhubekayo yonyaka |

| Ukusetyenziswa kwamandla | Iimodeli ezisebenzayo zigcina iindleko zexesha elide | Iphezulu ngaphambili, isezantsi ngenyanga |

| Uqeqesho | Kudingeka ukusebenza ngokufanelekileyo | I-1-3% yexabiso lokuthenga |

Abavelisi baseAsia-Pacific bahlala bexhamla kwiindleko zokusebenza eziphantsi ngenxa yeenzuzo zengingqi.

Iingcebiso eziSekwe kwiSicelo

Niniukukhetha inkqubo ye-extrusion, iinkampani kufuneka ziqwalasele umthamo wemveliso, ukuguquguquka komthengisi, kunye neemfuno zomgangatho. Kwiimveliso ezisisiseko kunye nokubaleka okuncinci, i-screw extrusion enye inikezela ngokulula kunye neendleko eziphantsi. I-twin screw extruders ifanele i-volume ephezulu, entsonkothileyo, okanye yeemveliso ezintsha ezifuna ukuxubana kunye nokuguquguquka. Imizi-mveliso efana neemoto, ukutya, kunye namayeza ahlala ekhetha iisistim ezimbini zokujija ngenxa yokuguquguquka kwazo kunye nomgangatho wemveliso. Iinkampani ezijonge ukwahlula imarike zinokutshintshela kwi-twin screw extrusion ukuze kuphunyezwe iimpawu ezizodwa zemveliso.

- I-twin screw extruderssebenzisa izikrufu ezibini zokuxuba okungcono kunye nokuhamba kwezinto ezizinzileyo.

- Baphatha iintlobo ezininzi zezinto kwaye banikezela ngemveliso ephezulu.

- I-extrusion ye-screw enye isebenza kakuhle kwizinto ezilula, eziphantsi kwe-viscosity.

- Kwiimveliso ezintsonkothileyo okanye ukusebenza kakuhle okuphezulu, iinkampani kufuneka zikhethe izikruru ezingamawele.

FAQ

Ngowuphi umahluko omkhulu phakathi kwesikrufu esinye kunye ne-twin screw extrusion?

I-extrusion ye-screw enye isebenzisa isikrufu esinye ukusetyenzwa kwesiseko. I-twin screw extrusion isebenzisa izikrufu ezibini zokuxuba ngcono kunye nokuphatha izinto ezinzima.

Yeyiphi i-extruder esebenza ngcono ukurisayikilisha iiplastiki?

I-twin screw extruders iphatha iiplastiki ezisetyenzisiweyo ngokufanelekileyo. Banikezela ngokuxuba kunye nokulawula okungcono, okuphucula umgangatho wemveliso.

Ulondolozo luthelekisa njani phakathi kwezi ntlobo zimbini?

I-screw extruders enye ifuna ukulungiswa okuncinci.I-twin screw extruders ifuna ukuhoywa ngakumbingenxa yoyilo lwabo oluntsonkothileyo kunye neenxalenye ezongezelelweyo.

Ixesha lokuposa: Jul-08-2025