Abavelisi bakhetha uhlaziyo olubalulekileyo lweTwin Screw Plastic Extruder imveliso eninzi ukukhulisa ukusebenza kakuhle kunye nokuqina. Uphuculo oluqhelekileyo lubandakanya itekhnoloji eyomileyo, imigqomo emitsha yesikwere, kunye nezinto ezenziwe ngokutsha, njengoko kubonisiwe ngezantsi:

| NONE | Inkcazo | Iingenelo |

|---|---|---|

| Itekhnoloji engomileyo | Ususa amanyathelo omisa | Igcina amandla kunye nendawo |

| Imigqomo eNtsha yesikwere | Amaxesha obushushu akhawulezayo | Iyanciphisa ixesha lokuphumla |

| Amacandelo ahlaziywe ngokutsha | Yenzelwe ubomi obude | Yandisa ukusebenza kakuhle |

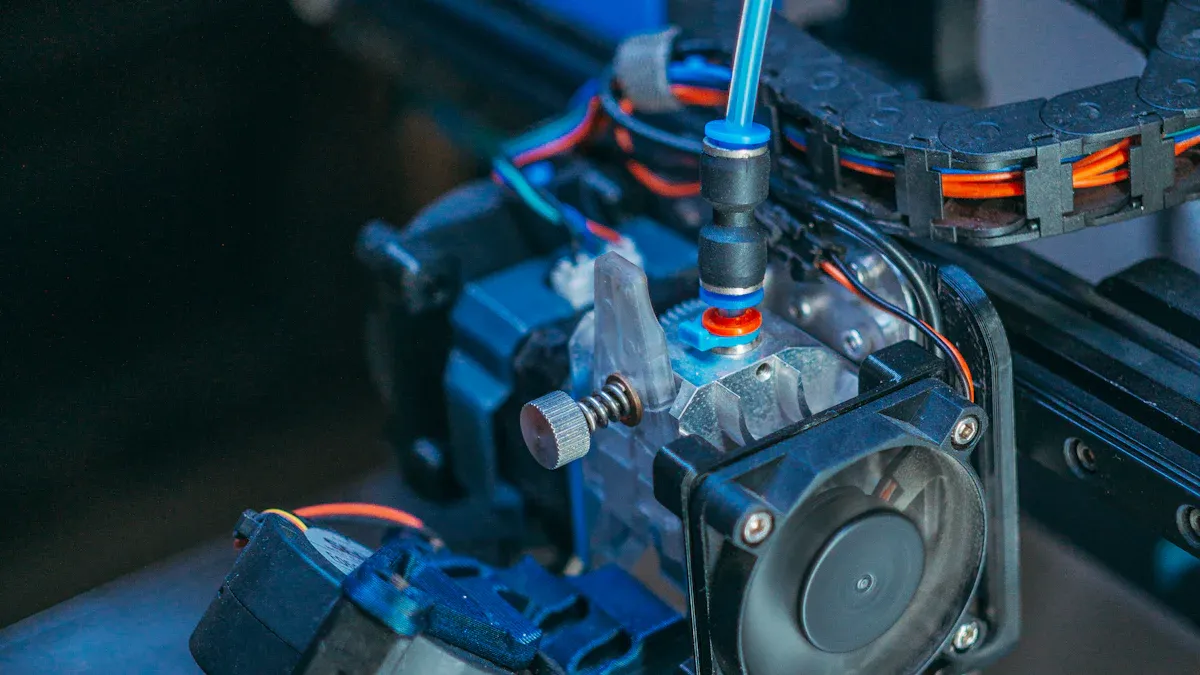

Itekhnoloji ye-CNC ephezulu kwiI-Twin Plastic Screw BarelkwayeExtrusion Machine Single Screw Barelimveliso yandisa ukuchaneka, ukuqina, kwaye inciphisa ukugcinwa. Iiplastic twin screw extruderiinzuzo kolu hlaziyo ngezakhono zokuxuba eziphuculweyo kunye nokuphuculwa kolawulo lwemithombo.

Uphuculo oluyimfuneko kwiTwin Screw Plastic Extruder Bulk Production

Imingeni yokuSebenza kwiMveliso yoMqulu oPhezulu

Abavelisi bajongana nemiqobo emininzi xa besebenzisa iinkqubo zeTwin Screw Plastic Extruder zokuvelisa isambuku. Ukunyuka kweendleko zezinto kunye namandla kudala uxinzelelo lokuphucula ukusebenza kakuhle. Ixabiso le-high-grade steel stainless steel linyuke nge-14% ukusuka kwi-2022 ukuya ku-2023. Iindleko zombane kwizixhobo zoshishino zenyuka nge-11% eYurophu. Olu tshintsho lunyanzela iinkampani ukuba zifune ulawulo olungcono lwamandla kunye nokusetyenziswa kwempahla.

Iinkqubo ze-extruder eziphelelwe lixesha zinegalelo kumazinga aphezulu enkunkuma. Umzekelo, izinto ezilahlwayo kwizicelo zemibhobho yePVC ezomeleleyo zihlala zilinganisa malunga ne-1.5%. Izikrufu ezigugileyo zinokunyusa eli zinga ukuya kwi-10%, nto leyo ekhokelela ekunyukeni kweendleko zemveliso. Ukungahoyi ukunxitywa kwesikrufu kubangela iziphumo ezixabisa kakhulu kubavelisi.

Icebiso: Ukugcinwa rhoqo kunye nokuphuculwa kwexesha elifanelekileyo kunceda ukunciphisa inkunkuma kunye nokulawula iindleko kwimisebenzi ephezulu.

Abavelisi bakwahlangabezana nemiceli mngeni ngokusebenza kunye nolawulo lobushushu. Uphuculo olufana neenkqubo zokupholisa uxinzelelo oluphezulu kunye ne-insulation gaskets ziphucula ukutshintshiselana kobushushu kunye nokugcina iimeko zokucwangcisa ezinzile. Ukuphumeza ukondla ngecala kwandisa amanqanaba okulayishwa kwesihluzi, ngelixa izinto ezinde ze-screw zandisa ukuhamba kwezinto kwaye zithintela imiqobo.

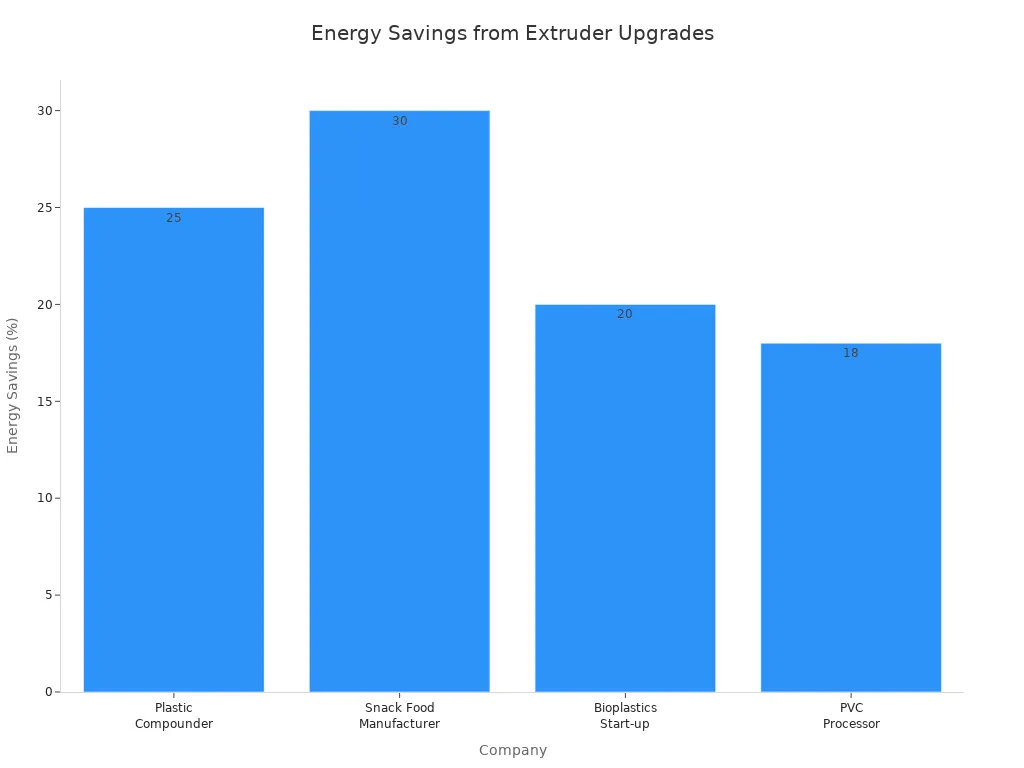

Ukusetyenziswa kwamandla kuhlala kuyinkxalabo ebalulekileyo. Ukuphucula uyilo lwe-screw kunye nokusetyenziswa kweenkqubo zokulawula ubushushu kukhokelela ekongeni amandla okubalulekileyo. Ukulungiswa kwakhona ngetekhnoloji ye-servo motor kukhulisa ukusebenza kakuhle. Uhlengahlengiso kuyilo lwesijiva kunye nolungelelwaniso lokutyisa lunokuchaphazela ngokuthe ngqo ukusetyenziswa kwamandla oomatshini.

Kutheni ukuphuculwa kungxamisekile kwiMarike yanamhlanje

Imarike yetekhnoloji yeTwin Screw Plastic Extruder iyaqhubeka nokuvela ngokukhawuleza. Abavelisi kufuneka baphendule kwiindlela ezintsha kunye neemfuno zabathengi ukuze bahlale bekhuphisana. Itheyibhile engezantsi iqaqambisa iindlela eziphambili zeemarike eziqhuba imfuno yophuculo olukhawulezileyo:

| Uhlobo lweNdlela | Inkcazo |

|---|---|

| Ukusebenza okuninzi | I-twin screw extruders ngoku isebenzela i-polymer, ukutya, ukutya, kunye namanye amashishini. |

| Imveliso enkulu | Iiyunithi ezinkulu zinciphisa iindleko kunye nokuxhasa iimfuno zeshishini lepetrochemical. |

| Ukuchaneka | Iimveliso zexabiso eliphezulu zifuna i-extrusion echanekileyo, efana ne-multi-layer co-extruded films. |

| Ubuchwephesha obukrelekrele | Ukubeka iliso ngexesha langempela kunye nolawulo luphucula ukuchaneka nokuzinza. |

Abathengi balindele umgangatho ophezulu wemveliso kunye nokuhambelana. Iinkqubo ze-Twin Screw Plastic Extruder zihambisa ukuxuba okuphezulu kunye ne-degassing, okunciphisa iziphene kunye nokuphucula iziphumo. Ezi mpawu zingqina ukuba ziyimfuneko kumacandelo obugcisa aneemfuno ezingqongqo zomgangatho. Uphuculo kwitekhnoloji ye-extruder yonyusa ukuchaneka kunye nolawulo, ngelixa iinkqubo ezikrelekrele zivumela uhlengahlengiso lwexesha lokwenyani kwiiparamitha ezibalulekileyo.

Abavelisi abatyala imali kumava ophuculo oluyimfunekoimbuyekezo ebalulekileyo. Iindleko zokugcinwa okuphantsi kunye nokunciphisa ixesha lokunciphisa kubangela ukonga ixesha elide. Uyilo oluqinileyo luqinisekisa ukuqina kunye nokuphuculwa kwemveliso, ukwenza iinkqubo eziphuculweyo zeTwin Screw Plastic Extruder ukhetho oluthembekileyo kwimveliso eninzi.

Advanced CNC kunye Nitriding Technology for Twin Screw Plastic Extruder

Ukuchaneka kwe-CNC kunye nokuNxibelelana kwi-Extruder Manufacturing

Imveliso yanamhlanje ifuna ukuchaneka okuphezulu kunye nokuphindaphinda. Ubuchwephesha be-CNC obuphezulu buhambisa ezi mpawu kwi-Twin Screw Plastic Extruder components. Oomatshini be-CNC basebenzisa ulawulo lwekhompyutha ukubumba izikrufu kunye nemigqomo enemilinganiselo echanekileyo. Le nkqubo iqinisekisa ukuba inxalenye nganye ihambelana ngokugqibeleleyo kwaye yenza ngokuthembekileyo kwimveliso ephezulu.

Iimpawu eziphambili zeenkqubo eziphambili ze-CNC ziquka ubukrelekrele bokwenziwa, abenzi boluvo abaphambili, kunye ne-servo-driven extruders. Ezi mpawu zisebenza kunye ukwandisa inkqubo ye-extrusion. Ngokomzekelo, i-intelligence yokwenziwa ihlalutya idatha kwaye iqikelele iziphumo, ivumela ukulungiswa kwexesha langempela kwiqondo lokushisa kunye noxinzelelo. Abenzi boluvo abakwizinga eliphezulu bajonga iiparamitha ezibalulekileyo, banikezela ngengxelo ekhawulezileyo yolungiso. I-extruders eqhutywa yi-Servo ilawula isantya se-screw kunye noxinzelelo, oluqinisekisa ukufana kwimveliso yokugqibela. Izifudumezi ezikumgangatho ophezulu kunye neenkqubo zokulawula ezizenzekelayo ziphucula ngakumbi ukusetyenziswa kwamandla kunye nomgangatho wemveliso.

| Uphawu | Inkcazo |

|---|---|

| Ubukrelekrele bokwenziwa (AI) | Ukwandisa iinkqubo ze-extrusion ngokuhlalutya idatha, ukuqikelela iziphumo, kunye nokwenza uhlengahlengiso lwexesha langempela kwiiparamitha ezifana nobushushu kunye noxinzelelo. |

| Izivamvo eziphezulu | Ubeka iliso kubushushu, uxinzelelo, kunye namazinga okuhamba kwezinto ngokuchaneka okuphezulu, ukubonelela ngengxelo yexesha langempela lolungiso olukhawulezileyo. |

| I-Extruders eqhutywa yi-Servo | Inikezela ngokuchaneka ekulawuleni isantya se-screw kunye noxinzelelo, iqinisekisa ukufana kwiimveliso ezikhutshiweyo. |

| Ukusebenza kakuhle kwamandla | Izifudumezi ezisebenza kakuhle kakhulu zinciphisa ilahleko yamandla kwaye zibonelela ngokukhawuleza, ukufudumeza okufanayo ukwenzela ukuhambelana kwenkqubo. |

| Iinkqubo zolawulo oluzenzekelayo | Lungiselela ngamandla iiparamitha zenkqubo ngexesha lokwenyani ukomeleza ukusebenza kakuhle kunye nomgangatho wemveliso. |

Olu phuculo lunceda abavelisi ukuba bafumane iziphumo ezingaguqukiyo, banciphise inkunkuma, kwaye bagcine imigangatho ephezulu kwibhetshi nganye.

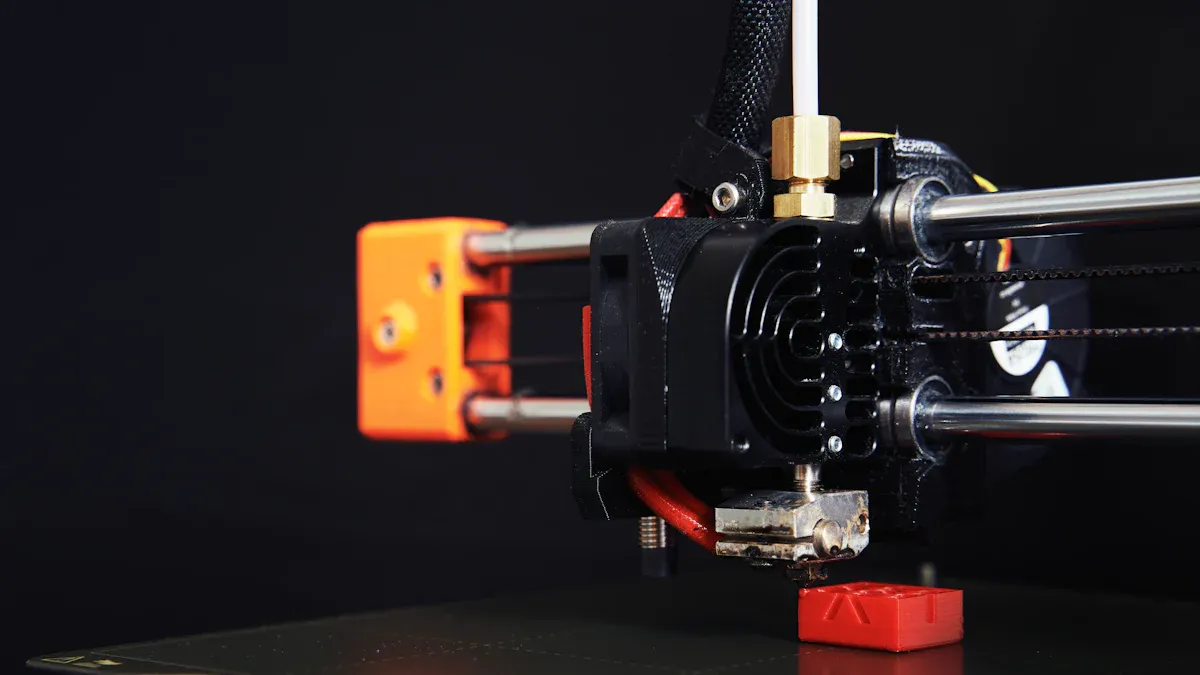

I-Nitriding yoLwamelelo oluQhelekileyo kunye noKuxhathisa ukuNxitywa

Itekhnoloji yeNitriding idlala indima ebalulekileyo ekwandiseni ubomi bezikrufu kunye nemigqomo kwiinkqubo zeTwin Screw Plastic Extruder. Le nkqubo iphatha umphezulu wesinyithi kwi-atmosphere ye-nitrogen ephezulu malunga ne-950 ° F (510 ° C). Isiphumo singumaleko onzima wangaphandle kunye nobunzima becala phakathi kwe-55 kunye ne-65 Rc. Olu luhlu olunzima luyamelana nokunxiba kwizinto ezinqabileyo kwaye lugcina amandla awo ngokuhamba kwexesha.

I-Nitriding ibonelela ngeenzuzo ezininzi ngaphezu kolunye unyango olungaphezulu. Inika ukuxhathisa okungcono kunokunxitywa kwe-carburizing, kunye ne-nitrided layer ebonisa i-50% yobunzima bokunxiba obuphantsi phantsi kwemithwalo efanayo. Izifundo ze-Tribological ziqinisekisa ukuba i-nitriding igqwesa ukungcwatywa, nokuba umaleko we-carburized ujiyile. Inkqubo idala ityala elincinci, elinzima elinciphisa ngokuthe ngcembe ubunzima, elinceda ukukhusela umonakalo ongaphezulu.

- Itekhnoloji yeNitriding ibonelela ngokumelana nokunxiba okuphezulu xa kuthelekiswa ne-carburizing kwizikrufu ze-extruder kunye nemigqomo.

- Umaleko we-nitrided ubonisa i-50% yobunzima bokunxiba obuphantsi phantsi kweemeko ezifanayo zomthwalo.

- Uphononongo lwe-Tribological lubonisa ukuba i-nitriding iluncedo ngakumbi kune-carburizing ngenxa yeempawu ezingcono zokunxiba ngaphandle komgangatho ongqindilili we-carburized.

- I-Nitriding ibandakanya ukunyanga izikrufu okanye imigqomo kwindawo ephezulu yenitrogen ejikeleze i-950 ° F (510 ° C), okukhokelela kubunzima obukhulu (55 - 65 Rc).

- Inkqubo ye-nitriding idala i-case ebhityileyo eyancipha kwi-hardness, enceda ukugcina ukuxhathisa ukunxiba ngokuchasene nezixhobo ezinqabileyo.

- Iintsimbi ze-nitriding ezifanelekileyo, ezifana ne-Crucible Nitriding 135, ziphucula ubulukhuni obuphunyeziweyo ngenkqubo.

I-Nitriding ikwanceda ukuthintela iindlela zokusilela eziqhelekileyo kumacandelo e-extruder. Ezi ziqukaumjikelo ophantsi ukugoba ukudinwa, ukwaphuka brittle, kunye nokudinwa ukudibana. Itheyibhile engezantsi ichaza ezi ndlela zokusilela kunye nendlela i-nitriding ezilungisa ngayo.

| Imo Yokusilela | Inkcazo |

|---|---|

| Ukudinwa ukugoba komjikelo ophantsi | Inkqubo yokusilela okuphambili ekhokelela ekuqhekekeni okumtyumkileyo kwegiya yephini. |

| Ukuqhekeka okuncinci | Isiphumo sokudinwa okugoba komjikelo ophantsi, okubonisa indawo yokungaphumeleli ebalulekileyo. |

| I-Carburization kunye nokugqiba umphezulu | Ukugqithiswa kwe-carburization kunye nokugqiba okungahambi kakuhle komphezulu wehlisa umda wokudinwa, okufaka isandla ekuqhekekeni. |

| Ukudinwa koqhagamshelwano | Okuqhelekileyo kwiintsilelo zegiya, okukhokelela kwimiba ebalulekileyo yokusebenza. |

| Ukugoba izinyo ukudinwa | Enye indlela exhaphakileyo yokungaphumeleli kwiigiya, ehlala isenziwa mandundu lunyango olungelulo. |

Ngokukhetha i-nitriding, abavelisi banyusa ukuqina kwezixhobo zabo zeTwin Screw Plastic Extruder kunye nokunciphisa umngcipheko wokuqhekeka kweendleko.

Amanyathelo aSebenzisayo okuPhucula i-Twin Screw Extruders yePlastiki ekhoyo

Ukuphucula iinkqubo ezikhoyo zeTwin Screw Plastic Extruder kufuna ucwangciso olucokisekileyo. Abavelisi kufuneka baqale bahlole imeko yangoku yezixhobo zabo. Kufuneka bachonge ukuba ngawaphi amacandelo anokuxhamla kakhulu kumatshini we-CNC okanye unyango lwe-nitriding.

Ukuqwalaselwa kweendleko kudlala indima enkulu ekuphuculeni izigqibo. Ubungakanani be-extruder, iindleko zempahla, kunye nobunzima bokwenza konke kuchaphazela utyalo-mali lulonke. Ii-extruders ezincinci zineendleko eziphantsi zezinto kunye neemfuno ezilula zokuvelisa. I-extruders ephakathi kunye nenkulu ifuna izixhobo ezingaphezulu kunye nobuchwepheshe obuphambili, okwandisa iindleko.

| Ubungakanani be-Extruder | Iindleko zezinto eziphathekayo | Ukuntsonkotha koveliso |

|---|---|---|

| Incinci | Phantsi | Elula |

| Phakathi | Phakathi | Phakathi |

| Enkulu | Phezulu | Intsonkothile |

Abavelisi kufuneka kwakhona baqwalasele ukuhambelana kwezinto kunye nomthamo wemveliso. I-extruders eyahlukeneyo iphatha izinto ezahlukeneyo, ezinokuchaphazela iindleko zokuphucula. Ukusebenza komthamo ophezulu kunokufuna iimpawu eziphambili, ezifana ne-automation kunye neenkqubo zokusebenzisa amandla. Ngelixa ezi mpawu zonyusa iindleko zokuqala, zihlala zikhokelela kugcino lwexesha elide ngokugcinwa okuncitshisiweyo kunye nokusetyenziswa kwamandla.

- Ukuhambelana kwezinto kuchaphazela iindleko zokuphucula.

- Umthamo wemveliso umisela imfuno ye-high-capacity extruders.

- Iimpawu zobuchwepheshe, ezifana ne-automation kunye nokusebenza kakuhle kwamandla, zifuna utyalo-mali oluphezulu kodwa zibonelela ngolondolozo lwexesha elide.

Ingcebiso: Ukusebenzisana nabavelisi abanamava, njengeZhejiang Jinteng Machinery Manufacturing Co., Ltd., iqinisekisa ukufikelela kwi-CNC ephezulu kunye neteknoloji ye-nitriding. Ubungcali babo bunceda ukulungelelanisa inkqubo yokuphucula kunye nokwandisa ukusebenza kwezixhobo.

Ngokulandela la manyathelo, abavelisi banokuphucula iinkqubo zabo zeTwin Screw Plastic Extruder, baphucule ukusebenza kakuhle, kwaye bandise ubomi besixhobo.

Abavelisi bafezekisa ukusebenza kakuhle okuphezulu kunye nokuzinza ngokuphucula i-extruders nge-CNC kunye ne-nitriding technology. Le theyibhile ingezantsi igxininisa iinzuzo zexesha elide:

| Inzuzo | Inkcazo |

|---|---|

| UFaneka oluPhezulu lweMveliso | Ukwandisa ukusebenza kakuhle, ukwandisa ubomi benkonzo, kunye nokwandisa ixesha eliqhubekayo lokusebenza koomatshini. |

| Ukungqinelana nokuchaneka | Ivelisa iindawo ezinokunyamezelana okuqinileyo kunye nokuchaneka okuphezulu komgangatho wemveliso engaguqukiyo. |

| Iindleko-Ukusebenza | Inciphisa inkcitho yezinto eziphathekayo, inciphisa izinto ezilahliweyo, kwaye yandise ukusetyenziswa kwezinto. |

Amanyathelo alandelayo: Tyala imali kwitekhnoloji ephucukileyo, gxila kwizinto ezisebenzisekayo eco-friendly, kunye nabaqhubi boololiwe ukuze basebenze kakuhle.

FAQ

Zeziphi iingenelo eziziswa yitekhnoloji ye-CNC kuphuculo lwe-twin screw extruder?

Itekhnoloji yeCNCiqinisekisa ukwenziwa okuchanekileyo. Iphucula ukuhambelana kwenxalenye kunye nokunciphisa inkunkuma. Abavelisi bafezekisa ukusebenza kakuhle okuphezulu kunye nomgangatho ongcono wemveliso ngophuculo lwe-CNC.

I-nitriding yandisa njani ubomi bezikrufu ze-extruder kunye nemigqomo?

I-nitriding yenza umaleko oqinileyo. Olu luhlu luyamelana nokunxiba kunye nokukrazula. Isixhobo sihlala ixesha elide kwaye sifuna ukutshintshwa rhoqo.

Ngaba ii-extruders ezikhoyo zinokuphuculwa nge-CNC kunye neteknoloji ye-nitriding?

Ewe. Abavelisi banokubuyisela iinkqubo zangoku. Ukuphuculwa kuphucula ukusebenza, ukwandisa ukuqina, kunye nokunciphisa iindleko zokulondoloza.

Icebiso: Dibana nabavelisi abanamava ngezona zisombululo zohlaziyo zilungele iimfuno ezithile zemveliso.

Ixesha lokuposa: Sep-02-2025