Umatshini wokubumba inaliti yeplastiki ngokufanelekileyo uguqula iplastiki eluhlaza ibe yimilo echanekileyo, enzima. Le nkqubo ibonelela ngeenzuzo ezimangalisayo:

- Ukuvelisa iindawo ezintsonkothileyo ngokuchaneka komgangatho ophezulu.

- Ukuhambisa umgangatho ongaguqukiyo kunye nokuphindaphinda.

- Ukunciphisa iindleko zemveliso kwimveliso enkulu.

Uyilo oluphucukileyo, olufana neSikruru sokuBumba umatshini wokuBumba weSikrolo kunyeUmatshini wokuBumba weSikruru sokuBumba, ukuphucula ukuhamba kwezinto kunye nokwandisa ukusebenza. Ukongeza, iUmatshini wokuBumba we-Barel ophindwe kabinikwayeUmatshini wokuBumba wesikrurungakumbi ukuphucula ukusebenza kakuhle kunye nemveliso kwinkqubo yokuvelisa.

IYunithi yokuTofa kumatshini wokuBumba weSikruru sokuSikrola

Iyunithi yokutofa kuMatshini wokuMbumba weSikruru woHlobo lweSikrufu idlala indima ebalulekileyo ekuguquleni iipellet zeplastiki ezikrwada zibe kwimeko etyhidiweyo kwaye zizitofwe kukungundo. Le yunithi iqulathe amacandelo amathathu aphambili: i-hopper, ibhere, kunye ne-screw mechanism. Inxalenye nganye inegalelo ekusebenzeni nasekuchanekeni kwenkqubo yokubumba.

Hopper

I-hopper isebenza njengendawo yokungena kwizinto zeplastiki ekrwada. Ibamba iipellet zeplastiki kwaye izondle emgqomeni ukuze iqhubeke nokusebenza. Iihopper zanamhlanje zihlala zibandakanya iimpawu ezifana neenkqubo zokomisa izinto zokususa ukufuma kwiipellets, ukuqinisekisa umgangatho ofanelekileyo wokunyibilika. Ngokugcina unikezelo oluhambelanayo lwezinto eziphathekayo, i-hopper isekela imijikelezo yokuvelisa engaphazamisekiyo kwi-Screw Type Injection Molding Machine.

Umphanda

Umphanda ligumbi lecylindrical eligcina i-screw mechanism. Ifudumeza iipellet zeplastiki kwindawo yazo yokunyibilika zisebenzisa iindawo zokufudumeza ezininzi. Le mimandla-eyahlulwe ngokutya, ngasemva, ephakathi, nangaphambili-ivumela ulawulo oluchanekileyo lobushushu, olubaluleke kakhulu ekuphumezeni umgangatho ofanayo wokunyibilika. Ukusasazwa kwamaqondo obushushu achanekileyo ngaphakathi komphanda kuthintela imiba efana ne-warpage, ukungachaneki kwe-dimensional, kunye nokuthotywa kwezinto. Olu lawulo lucokisekileyo luqinisekisa ukuba i-Screw Type Injection Molding Machine ihambisa imveliso ekumgangatho ophezulu rhoqo.

- Amaqondo obushushu afanelekileyo kwindawo yomphanda ayimfuneko ekusebenzeni ngokufanelekileyo.

- Izicwangciso ezingalunganga zingakhokelela kwiziphene kwimveliso yokugqibela.

- Uyilo oluphezulu luphucula ukusebenza kakuhle kwamandla kunye nokunciphisa iindleko zokusebenza.

Inkqubo yokuScrew

I-screw mechanism yintliziyo yeyunithi yokutofa. Ijikeleza ngaphakathi kombhobho, idibanisa kwaye inyibilika iipelisi zeplastiki ngelixa iqhubela phambili izinto ezityhidiweyo. Uyilo lwesikrufu luchaphazela kakhulu inkqubo yokunyibilika kunye nesitofu. Umzekelo, imileuyilo Screwphucula iplastiki ngokuqinisekisa ukutyhileka okungaguqukiyo kokucheba kunye nomthamo wokudubula. Ukongeza, iimpawu ezinjengeevalve zepoppet zibonelela ngolawulo oluchanekileyo ngokuvala kwangoko xa isikrufu siyeka.

Kubo bonke oomatshini bokuBumba boMbane boMbane beSikrikri sombane, isikrufu somatshini sibonelela ngolawulo olungenakuthelekiswa nanto kwisantya, uxinzelelo, kunye nokuma. Oku kuchanekileyo kunciphisa iiyantlukwano phakathi kwemijikelo, ukuqinisekisa ukuba amaxabiso okugcwalisa angaguqukiyo kunye nobukhulu bokudubula. Olu phuculo aluphuculi kuphela umgangatho wokunyibilika kodwa lukwaphucula ukusebenza kakuhle kwenkqubo yokubumba.

- Ukuzenzekela kunye nokudityaniswa kweerobhothi konyusa ngakumbi imveliso yemveliso.

- Uyilo lwezikrufu ezonga amandla lunegalelo ekongeni iindleko.

- Ukusetyenziswa kwemathiriyeli okuzinzileyo kuhambelana neendlela zale mihla zokuvelisa.

Iyunithi yokutofa kwi-Screw Type Injection Molding Machine ingumzekelo we-synergy yobunjineli obuphambili kunye nolawulo oluchanekileyo. Amacandelo ayo asebenza kunye ngaphandle komthungo ukuhambisa umgangatho ophezulu, osebenzayo, kunye nemveliso ethembekileyo.

IiYunithi zokuBamba kunye nokuMngunda

Iiyunithi zokubambelela kunye nokungunda zizinto ezibalulekileyo zomatshini wokubumba inaliti yeplastiki. Baqinisekisa ukuba isikhunta sihlala sivaliwe ngokukhuselekileyo ngexesha lenkqubo yokutofa kwaye iququzelele ukubunjwa kwamacandelo achanekileyo, aphezulu. Ezi yunithi ziquka i-mold, platens, kunye ne-motor drive, nganye idlala indima eyahlukileyo kwinkqubo yokubumba.

Ngundo

Umngundo usebenza njengomngxuma apho iplastiki etyhidiweyo imila khona. Uyilo lwayo luchaphazela ngokuthe ngqo umgangatho kunye nokuhambelana kwemveliso yokugqibela.Iindlela ezigqwesileyo kuyilo lokungundaGxininisa ubukhulu bodonga obufanayo ukuthintela iziphene ezifana ne-warping kunye namanqaku e-sinki ngexesha lokupholisa. Utshintsho olugudileyo phakathi kobunzima obahlukeneyo, obuphunyezwe ngee-chamfers okanye iifillet, bongeza ngakumbi imfezeko yesakhiwo.

- Ubukhulu obufanelekileyo bodonga buphepha iziphene zokuthambisa ezifana ne-warping kunye nokutshona.

- Amandla esakhiwo anokuphuculwa ngeembambo kunye neegussets endaweni yokunyusa ubukhulu.

- Uyilo lweeMfuniselo (i-DOE) ubuchule bunceda ekuchongeni iziphene kwangethuba, ukuqinisekisa ukusebenza ngokupheleleyo kunye nokuthembeka.

Kumatshini wokuMbumba weSikruru sokuSikrola, ukuchaneka komngundo kuqinisekisa ukuba uyilo oluntsonkothileyo kunye nokunyamezelana okuqinileyo kuyafezekiswa. Esi sikhundla senza ukuba silungele ukuvelisa iindawo ezinzima ezinomgangatho ohambelanayo.

Iipleyiti

Iipleyiti zinkulu, iipleyiti ezisicaba ezibamba ukungunda endaweni kwaye zisasaze amandla okubamba ngokulinganayo. Uyilo lwabo kunye nokuthembeka kwesakhiwo kubalulekile ekugcineni ukulungelelaniswa kokungunda kunye nokuqinisekisa uxinzelelo olufanayo ngexesha lenkqubo yokutofa. Iimpawu eziphambili zobugcisa ezichaphazela ukusebenza kweplaten ziquka impembelelo yobunzima, umthamo wokuthwala umthwalo, kunye nokulungiswa kwesakhiwo.

| Ipharamitha | Impembelelo kuLungelelwaniso lokungunda |

|---|---|

| Impembelelo yobunzima | Yenza phantse i-70% yobunzima bubonke bomatshini, ochaphazela uzinzo kunye nokulungelelaniswa. |

| Ukubaluleka kwezoqoqosho | Ukuphucula uyilo kunciphisa ukusetyenziswa kwempahla ekrwada, ukwandisa ukusebenza kakuhle kweendleko. |

| Impembelelo yoMsebenzi | Uqinisekisa ulungelelwaniso olufanelekileyo lokungunda kunye nokuhanjiswa koxinzelelo olufanayo, okubalulekileyo kwimveliso ekumgangatho ophezulu. |

| UkuPhuculwa koLwakhiwo | Ukwandisa ubungakanani, imilo, kunye nokuhanjiswa kwezinto eziphathekayo ukwenzela ukulungelelaniswa okungcono. |

| Umthwalo wokuthwala umthamo | Ukuphucula ukuqina kunye nokuxhasa ulungelelwaniso lokungunda phantsi koxinzelelo lokusebenza. |

Kumatshini wokuMbumba weSikruru sokuSikrola, iipleyiti zinegalelo kubuchule bomatshini bokuvelisa iinxalenye ezinomgangatho ophezulu wokuchaneka. Uyilo lwabo olomeleleyo luqinisekisa ukuqina kunye nokusebenza okungaguquguqukiyo, naphantsi kwamandla aphezulu okubamba.

Imoto Drive

I-motor drive inika amandla indlela yokubambelela, eyenza ukuba ukungunda kuvuleke kwaye kuvalwe ngokuchanekileyo. Idlala indima ebalulekileyo ekugcineni isantya kunye nokuchaneka kwenkqubo yokubamba.Iimoto zangoku, ngakumbi kubo bonke oomatshini bombane, banikezela ngolawulo olongeziweyo kumandla okubamba kunye nokubeka. Oku kuchanekileyo kunciphisa ukunxiba kwi-mold kunye nokunciphisa amaxesha okujikeleza, ukuphucula ukusebenza kakuhle.

Iimoto ezonga amandla zikwanegalelo ekongeni iindleko kunye nokuzinza. Ngokwandisa ukusetyenziswa kwamandla, bahambelana neendlela zanamhlanje zokuvelisa ezibeka phambili uxanduva lokusingqongileyo. Kwi-Screw Type Injection Molding Machine, i-motor drive iqinisekisa ukusebenza ngokungenamthungo, ukuxhasa ukuveliswa kwesantya esiphezulu ngaphandle kokubeka umgangatho.

Ingcebiso:Ukugcinwa rhoqo kwe-motor drive kunokwandisa ubomi bayo kwaye kuthintele ixesha lokuphumla elingalindelekanga, ukuqinisekisa imveliso engaphazamisekiyo.

Iiyunithi zokubambelela kunye nokungunda ngumzekelo we-synergy yobunjineli kunye nokuchaneka koomatshini bokubumba inaliti yeplastiki. Uyilo kunye nokusebenza kwabo kuchaphazela ngokuthe ngqo amandla omatshini okuvelisa iindawo ezikumgangatho ophezulu ngokufanelekileyo nangokuthembeka.

Iinkqubo zokulawula ubushushu kunye nobushushu

Iinkqubo ezisebenzayo zokufudumeza kunye nokulawula ubushushu ziyimfuneko ekugcineni umgangatho kunye nokuhambelana kweenkqubo zokubumba inaliti yeplastiki. Ezi nkqubo ziqinisekisa ukuba izinto zeplastiki zifikelela kwindawo echanekileyo yokunyibilika kwaye ubushushu be-mold buhlala buzinzile kulo lonke umjikelezo.

Izifudumezi zemiphanda

Izifudumezi zemiphandazidlala indima ebalulekileyo ekunyibilikiseni iipellet zeplastiki ukuya kubushushu bazo obufanelekileyo. Basebenzisa iindawo zokufudumeza ezininzi ukufikelela kulawulo oluchanekileyo lobushushu, olubalulekileyo kumgangatho ofanayo wokunyibilika. Ulawulo olusebenzayo lobushushu luphucula ukusebenza kakuhle kwamandla kwaye luphucule ukugqitywa komphezulu weendawo ezibunjiweyo.

- Ukulawulwa ngokufanelekileyo kwamaqondo obushushu emigqomo kuthintela ukuthotywa kwezinto, ngakumbi ngexesha lokuhlala elongezelelweyo.

- Ukugcina iqondo lobushushu lenyibilika ekujoliswe kulo malunga ne-490 ° F kuqinisekisa ukuhamba kwezinto eziphathekayo kunye nokunciphisa iziphene.

- Ukuguquguquka kweqondo lobushushu lomphanda kunokuchaphazela kakubi umgangatho wemveliso, nto leyo eyenza ukuba uqwalaselo olusondeleyo lube yimfuneko.

Uyilo lwemiphanda oluphezulu luhlala lubandakanya izinto zokufudumeza amandla, ukunciphisa iindleko zokusebenza ngelixa ugcina ukusebenza okuphezulu. Ezi mpawu zihambelana neendlela zale mihla zokuvelisa ezibeka phambili ukuzinza nokusebenza kakuhle.

Izifudumezi zokungunda

Izifudumezi zokungunda zilawula ubushushu bomngundo, ziqinisekisa umgangatho ongaguqukiyo wenxalenye kunye nokunciphisa amaxesha okujikeleza. Ubukhulu bezinto zokubumba buchaphazela kakhulu amazinga okushisa ukushisa. Amacandelo atyebileyo agcina ubushushu ixesha elide, ngelixa amacandelo amancinci ephola ngokukhawuleza. Ukulungelelanisa useto lwesifudumezi sokungunda ngokusekwe kubukhulu bezinto ezithintela imiba efana ne-warping kwaye iqinisekisa ukuhanjiswa kobushushu obufanayo.

Ubuchwephesha bokuBumba beNzululwazi bongeza ngakumbi ukusebenza kwesifudumezi sokungunda. Ezi ndlela zinciphisa amaxesha okuqalisa, zinciphisa amaxabiso ezinto ezilahliweyo, kwaye ziphucule ukuhambelana kwenkqubo. Ngokugcina ubushushu obuchanekileyo bokungunda, abavelisi bafumana inzuzo ephezulu kunye nokusebenza kakuhle.

Indlela Yokulawula Ubushushu

Iindlela yokulawula ubushushuiqinisekisa ukuzinza kunye nokuchaneka ngexesha lokubumba. Izicwangciso eziphucukileyo, ezinje ngolawulo oluluzinge olunohlengahlengiso, dibanisa ulawulo lwe-PID lwendabuko kunye nengqiqo engaqondakaliyo ukwandisa ubushushu bomphanda. Le ndlela inciphisa i-overshoot kunye ne-oscillation, iphucula ukusebenza kwenkqubo ngokubanzi.

| Isicwangciso soLawulo | Inkcazo |

|---|---|

| Ulawulo oluFuzzy olunoLungiselelwayo lweNgcali | Idibanisa ingcaphephe, ifuzzy, kunye nolawulo lwe-PID lokuphucula uzinzo kunye nokuchaneka. |

| Ulawulo lwe-PID | Indlela yesiNtu ethambekele ekudubuleni kakhulu kunye ne-oscillation. |

| Umzekelo woLawulo lokuQikelela | Iingoma zesantya sokutofa, ukuphucula ukuchaneka kwiinkqubo zokubumba. |

Iimodeli zokufunda ngoomatshini, ezinjengee-algorithms zamahlathi, zikwanegalelo ekusebenzeni kakuhle kwamandla ngokuchonga izinto eziphambili ezichaphazela ukusetyenziswa kwamandla. Ezi zinto zintsha zenza ukuba abavelisi balungelelanise ukusetyenziswa kwamandla kunye nomgangatho wenxalenye, ukongezelela ngakumbi ukuzinza kwemisebenzi yokubumba inaliti.

IiYunithi zeHydraulic kunye noLawulo

I-hydraulic kunye neeyunithi zokulawula zizinto ezibalulekileyo zomatshini wokubumba inaliti yeplastiki. Ezi nkqubo zisebenza kunye ukuqinisekisa ukusebenza okuchanekileyo, ukusebenza kakuhle, kunyeumgangatho wemveliso ohambelanayo.

Inkqubo yeHydraulic

Inkqubo ye-hydraulic inika amandla ukuhamba kwenaliti kunye neendlela zokubambelela. Ivelisa amandla afunekayo ukujova iplastiki etyhidiweyo kwi-mold kwaye igcine uxinzelelo lwe-clamping ngexesha lenkqubo yokubumba. Iimpompo ze-hydraulic, i-valve, kunye neesilinda zenza undoqo wale nkqubo, ukuhambisa ukusebenza okulawulwayo nokuthembekileyo.

Iinkqubo zangoku zamanzi aphantsi komhlaba zibandakanya itekhnoloji ephezuluukwandisa ukusebenza kakuhle. Iimpompo zokufuduka eziguquguqukayo zilungelelanisa izinga lokuhamba ngokusekwe kwiimfuno zokusebenza komatshini, ukunciphisa ukusetyenziswa kwamandla. Ukongezelela, iivalve ezilinganayo zinika ulawulo oluchanekileyo phezu koxinzelelo kunye nokuhamba, ukuqinisekisa ukunyakaza okugudileyo nokuchanekileyo. Ezi mpawu zinegalelo kubuchule bomatshini bokuvelisa iindawo ezikumgangatho ophezulu nenkunkuma encinane.

Ingcebiso:Ukugcinwa rhoqo kwamalungu e-hydraulic, okufana nokukhangela ukuvuza kunye nokubeka esweni umgangatho we-oyile, kunokwandisa ubomi benkqubo kwaye kuthintele ixesha lokunciphisa.

Iphaneli yokulawula

Iphaneli yokulawula isebenza njengengqondo yomatshini wokubumba inaliti. Ibeka iliso kwaye ilawule yonke imisebenzi yomatshini, iqinisekisa ukusebenza kakuhle. Ukuxhotyiswa ngeenzwa, iphaneli yokulawula iqokelela idatha yexesha langempela kwiiparamitha ezibalulekileyo ezifana nobushushu, uxinzelelo kunye nesikhundla. Njengokuba:

- Izinzwa zilinganisa kwaye zinike ingxelo malunga nobushushu kunye noxinzelelo.

- Izinzwa zenwebu yeringi ziqinisekisa imilinganiselo yendawo echanekileyo kusetyenziswa iiseli zegeji yoxinzelelo.

Iimodeli zokufunda zoomatshini ezidityaniswe kwiphaneli yolawulo ngakumbi ziphucula amandla ayo. Ezi modeli ziqikelela umgangatho weparameters ezinje ngoxinzelelo lwesivuno kunye nemodulus, ukongeza useto lwenkqubo kwiziphumo ezingaguqukiyo. Iziphumo zovavanyo ziqinisekisa le mizekelo ngokuthelekisa amaxabiso aqikelelweyo kunye neziphumo zangempela, ziqinisekisa ukusebenza kwazo ekuphuculeni ukusebenza kakuhle kwemveliso.

Iiyunithi ze-hydraulic kunye nokulawula zenza umzekelo we-synergy yobuchwepheshe bomatshini kunye nedijithali, ukuqinisekisa ukuchaneka kunye nokuthembeka kumatshini wokubumba inaliti yeplastiki.

Ukutya kunye neendlela zokukhupha

Iyunithi yokondla

Iiyunithi yokutyaiqinisekisa unikezelo olungaguqukiyo lwezinto zeplastiki ekrwada kumatshini wokubumba inaliti. Ngokuqhelekileyo iqulethe i-hopper kunye ne-screw yokutya. I-hopper igcina iipelisi zeplastiki kwaye iqondise kwi-barrel, apho izinto zihamba khona. I-Gravity kunye nee-vibrations ezilawulwayo ziququzelela ukuhamba kakuhle kweepellets, ukuthintela ukuvinjelwa okanye ukuphazamiseka ngexesha lokuvelisa.

Iiyunithi zokutya zale mihla zihlala zibandakanya iimpawu eziphambili ezifana neenkqubo zokomisa izinto. Ezi nkqubo zisusa umswakama kwiipellets, ezibaluleke kakhulu ekugcineni umgangatho wokunyibilika kunye nokukhusela iziphene kwimveliso yokugqibela. Ukongeza, iindlela zokutyisa ezizenzekelayo zongeza impumelelo ngokulungelelanisa unikezelo lwemathiriyeli kunye nesantya sokusebenza komatshini. Olu ngqamaniso lunciphisa inkcitho yezinto kwaye luqinisekise imijikelo yemveliso engaphazanyiswa.

Iyunithi yokukhupha

Iiyunithi yokukhuphaidlala indima ebalulekileyo ekususeni indawo ebunjiweyo kumgodi wokungunda emva kokupholisa. Isebenzisa izikhonkwane ze-ejector, iipleyiti, okanye ukuqhuma umoya ukukhulula imveliso egqityiweyo ngaphandle kokwenza umonakalo. Ukuchaneka kwixesha le-ejection kunye nokunyanzeliswa kubalulekile ukugcina ingqibelelo yecandelo elibunjiweyo kunye nokuthintela iziphene ezifana ne-warping okanye ukuqhekeka.

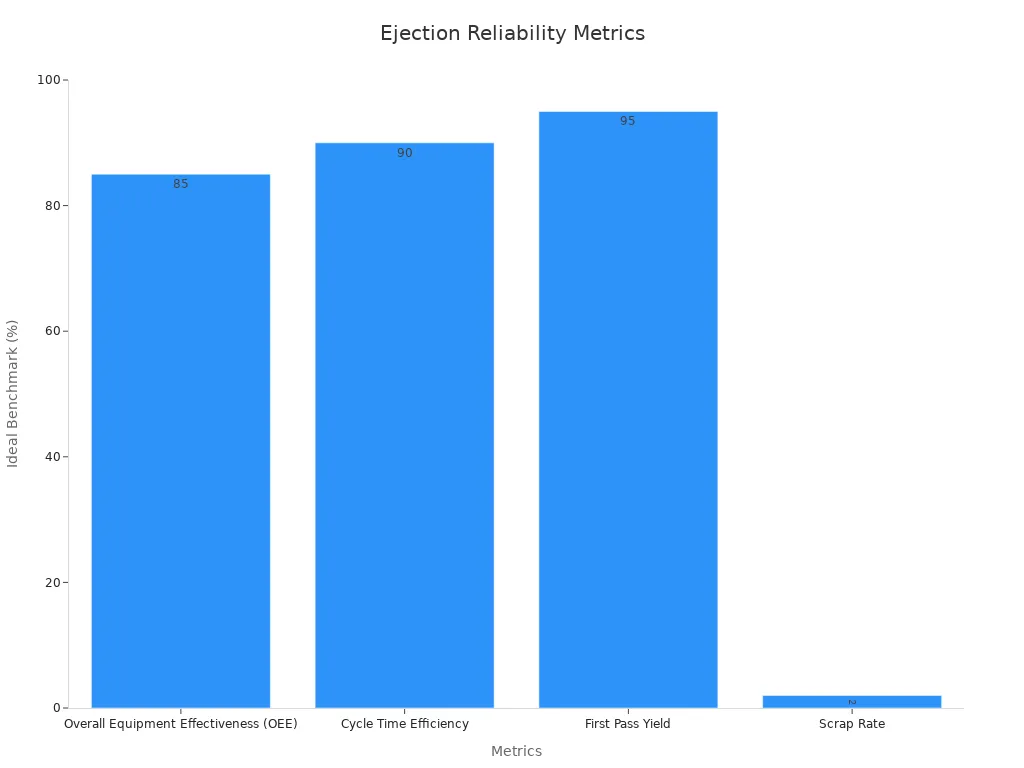

Iiyunithi ze-ejection ezithembekileyo zinciphisa kakhulu ixesha lokunciphisa umjikelezo wemveliso. Iimetriki ezinje ngokuSebenza ngokuPheleleyo kweSixhobo (OEE), ukuSebenza kweXesha loMjikelo, kunye neSivuno sokuQala sokuPhuma (FPY) siqinisekisa ukusebenza kwazo. Njengokuba:

| Metric | Inkcazo | Ibenchmark Efanelekileyo |

|---|---|---|

| Ukusebenza kweSixhobo ngokubanzi (OEE) | Ilinganisa ukusebenza kakuhle kwemveliso; ibalwe ukusuka kubukho, ukusebenza, kunye nomgangatho. | ~85% |

| Cycle Time Efficiency | Ilandelela ixesha lokugqiba umjikelo omnye wemveliso; amaxesha asezantsi aphucula ugqithiso. | 90% okanye ngaphezulu |

| I-First Pass Yield (FPY) | Ipesenti yeemveliso ezenziwe ngokuchanekileyo okokuqala; amaxabiso aphezulu abonisa iinkqubo ezisebenzayo. | >95% |

| Ireyithi ye-Scrap | Ipesenti yezinto ezilahliweyo; amazinga asezantsi aphucula inzuzo. | <2% |

Iinkqubo ze-ejection eziphezulu zidibanisa ii-sensor ukubeka iliso kunye nokulungelelanisa amandla okukhutshwa ngokukhawuleza. Ezi zinto zintsha ziqinisekisa umgangatho ohambelanayo wenxalenye ngelixa unciphisa ukunxiba kwi-mold kunye namacandelo omatshini. Ukugcinwa rhoqo kweyunithi yokukhupha kwandisa ngakumbi ukuthembeka kwayo kunye nokwandisa ubomi bayo bokusebenza.

Umatshini wokubumba inaliti yeplastiki udibanisa izinto eziphambili ukuhambisa umsebenzi obalaseleyo. Inxalenye nganye inegalelo ekusebenzeni kakuhle kwemveliso, umgangatho, nokuthembeka. Ukugqwesa kwezi nkqubo kuqinisekisa iziphumo ezizezona zilungileyo.

| Metric | Inkcazo |

|---|---|

| Ubuchule boMveliso | Ibonisa indlela imathiriyeli ekrwada eguqulwa ngayo ibe zimveliso ezigqityiweyo. |

| Ireyithi ye-Scrap | Ibonisa ipesenti yemveliso engahambelani nemigangatho yomgangatho. |

| Ixesha lokuphumla komatshini | Ichaphazela ukusebenza kakuhle kwemveliso kunye neendleko zokusebenza, kubalulekile kwingeniso. |

Ukuqonda ezi metrics kuqaqambisa indima yomatshini ekuphumezeni okungaguquguqukiyo, imveliso ekumgangatho ophezulu.

FAQ

1. Zeziphi izinto ezinokusetyenziswa koomatshini bokubumba inaliti yeplastiki?

Oomatshini bokubumba inaliti yeplastiki benza i-thermoplastics efana ne-ABS, i-polypropylene, kunye ne-nylon. Bakwaphatha iiplastiki zobunjineli ezifana ne-polycarbonate kunye ne-PEEK.

2. Ukulawula ubushushu buchaphazela njani umgangatho wemveliso?

Ulawulo oluchanekileyo lobushushu luqinisekisa umgangatho ofanayo wokunyibilika, unciphisa iziphene, kwaye uphucula ukuchaneka kwe-dimensional. Ithintela ukuthotywa kwezinto ngexesha lemijikelezo eyandisiweyo yokucubungula.

3. Ziziphi iindlela zokulondoloza eziphucula ukusebenza komatshini?

Ukuthanjiswa rhoqo, ukutshekishwa kwenkqubo yehydraulic, kunye nokucocwa kweeyunithi zokutya kuthintela ukuguga kunye nexesha lokuphumla. Izinzwa zokubek' esweni ziqinisekisa ukusebenza ngokuzinzileyo kwaye zandisa ubomi bomatshini.

Ixesha lokuposa: May-28-2025