Amandla e-shear adlala indima ebalulekileyo ekusebenzeni kwe-plastic twin screw extruder. Ibhekisa kumandla abangela ukuba iileya zemathiriyeli zityibilike ngokuchaseneyo, zibe nefuthe elibonakalayo kwiimpawu zemathiriyeli. Umzekelo, amandla aphezulu okucheba aphucula ukuxubana kunye nokuhanjiswa kobushushu. KwiI-Twin Plastic Screw Barel, idizayini yendawo yokunyibilika iqinisekisa ukuhamba kakuhle kwezinto ngelixa ukunciphisa i-spikes yeqondo lokushisa, njengoko uxinzelelo lwe-40 bar lunokuphakamisa amaqondo okushisa ngama-20 ° C. Ukongeza, aI-Conical Twin Screw Extruder Screw Barelkwandisa ngakumbi ezi nkqubo ngokulinganisa amandla okucheba kunye ne-throughput, ngelixa iI-Twin Screw Bareluyilo lunegalelo ekusebenzeni kakuhle ngokubanzi kwinkqubo yokukhupha.

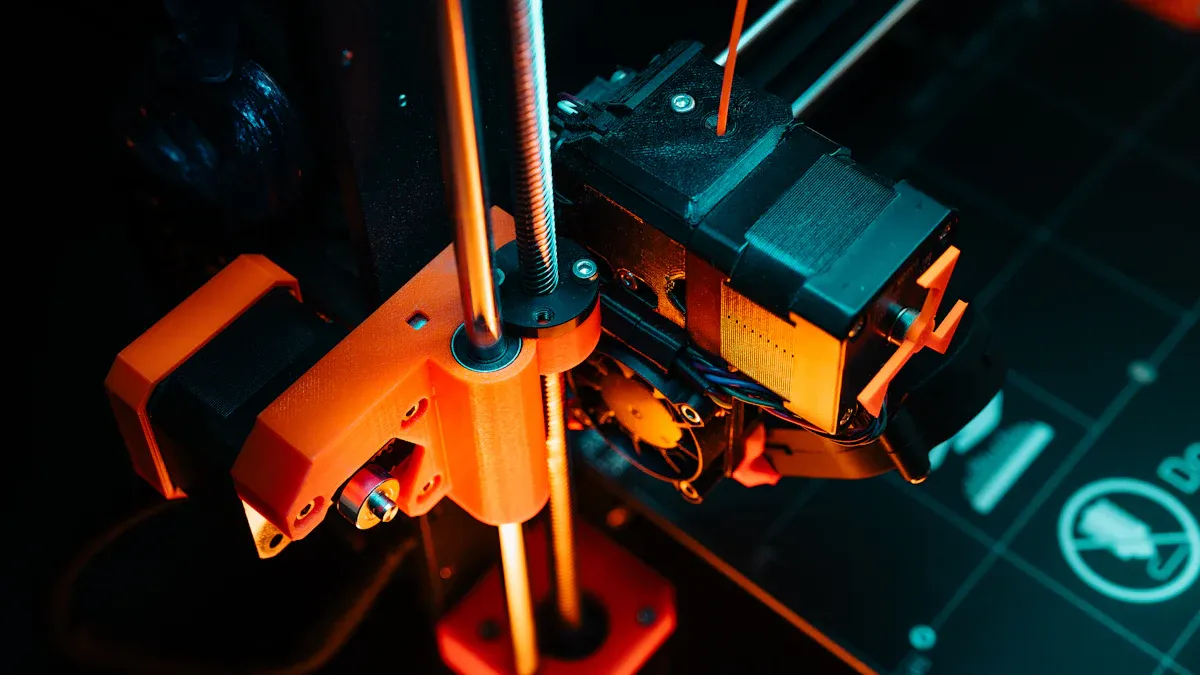

Basics of Plastic Twin Screw Extruder

Amacandelo angundoqo we-Extruder

A iplastiki iwele Screw extruderiqulathe amacandelo amaninzi abalulekileyo asebenza kunye ukucubungula imathiriyeli ngokufanelekileyo. Ezi ziquka:

- Hopper: Indawo yokungena apho imathiriyeli ekrwada yondliwa khona kwisistim.

- Umphanda: Igumbi eliphambili apho imathiriyeli inyibilika kwaye ixutywe.

- Screw Conveyor: Uxanduva lokuthutha izinto nge-extruder.

- Inkqubo yokufudumeza: Ibonelela ngobushushu obuyimfuneko bokunyibilikisa iikhompawundi zeplastiki.

- Ulawulo lobushushu: Iqinisekisa iimeko zokuqhubekeka ezingaguqukiyo.

- Intloko ye-Extrusion: Ibumba imathiriyeli kwifomu efunwayo njengoko iphuma kwi-extruder.

Icandelo ngalinye lidlala indima ebalulekileyo ekuqinisekiseni ukuba i-extruder isebenza kakuhle kwaye inikezela ngemveliso ekumgangatho ophezulu. Umzekelo, isantya esiguquguqukayo se-screw sivumela ulawulo oluchanekileyo lwenkqubo ye-extrusion, ngelixa ukufa okuthathelwa indawo kwenza ukuveliswa kweemilo ezahlukeneyo kunye nobukhulu.

Indima yeZikrufu kunye neMgqomo kwiSizukulwana soMkhosi weShear

Izikrufu kunye nebhere zisembindini wokuvelisa amandla okucheba kwi-plastic twin screw extruder. Izikrufu zijikeleza ngaphakathi kombhobho, zenza ukungqubana kunye noxinzelelo olunyibilikayo kwaye luxube izinto. Izinto ezinje ngesantya se-screw, idayamitha yokufa, kunye nokuziphatha kwezinto eziphathekayo kunempembelelo enkulu kwi-shear force. Umzekelo:

| Ipharamitha | Impembelelo kwiSizukulwana soMkhosi weShear |

|---|---|

| Isantya seScrew | Izantya eziphakamileyo zonyusa umthamo kunye namandla achithwayo, okomeleza amandla okucheba. |

| Die Diameter | Iimitha ezinkulu zinciphisa uxinzelelo kunye namandla, zichaphazela amandla okucheba. |

| Izinto Zokuziphatha | Izixhobo zokucheba ezicekethekileyo zibonisa uxinzelelo oluphantsi kunye namandla xa kuthelekiswa nolwelo lwaseNewton. |

Ezi ntsebenziswano ziqinisekisa ukuqhutyelwa kwezinto ezifanelekileyo kunye nokuxuba okufanayo.

I-Material Flow Dynamics kwi-Extruder

I-Material flow dynamics kwi-plastic twin screw extruder imisela umgangatho wokuxuba kunye nemveliso yokugqibela. Iindlela zokubala ezikwizinga eliphezulu, ezifana neCFD, ziphucule ukuqondwa kwezi ntshukumo. Ubuchwephesha obufana nomthamo we-volume-of-fluid (VOF) kunye neendlela ezibekwe kwinqanaba lokulandelela i-interfaces yamanzi ngexesha lokuxuba, ukuqinisekisa ulawulo oluchanekileyo kwinkqubo. I-twin screw extruders isetyenziswa kakhulu kumashishini afana namayeza ngenxa yobuchule bazo obuphezulu bokuxuba. Ngaphantsi kweemeko eziqhelekileyo (30 kg / hr, 200 rpm), uxinzelelo kwelinye igumbi eline-C lifikelela malunga ne-2.2 MPa, kunye noxinzelelo lwe-0.3 MPa kwindawo ye-intermeshing kunye ne-0.5 MPa kwi-screw element. Ezi metrics zigxininisa ukusebenza kakuhle kwe-extruder ekuphatheni izinto ezahlukeneyo.

I-Shear Force Mechanism kwi-Twin Screw Extrusion

Isizukulwana soMkhosi we-Shear kwiNkqubo yokuKhusela

Amandla okucheba kwinkqubo ye-twin screw extrusion ivela kwintsebenziswano phakathi kwezikrufu ezijikelezayo kunye nomphanda omileyo. Njengoko izikhonkwane zijikeleza, zenza ukukhuhlana kunye noxinzelelo, okubangela ukuba izinto eziphathekayo zigxumeke kwaye zihambe. Olu tshintsho luvelisa amandla okucheba adlala indima ebalulekileyo ekunyibilikeni, ukuxuba, kunye ne-homogenizing imathiriyeli. Uyilo lokuhlangana kwezikrufu luqinisekisa ukuba amava ezinto eziphathekayo afumana ukucheba okuhambelanayo kuyo yonke le nkqubo.

Uhlalutyo lwamanani usebenzisa indlela ye-volume-of-fluid (VOF) ibonakalise iindlela ze-hydrodynamic ezibandakanyekayo kule nkqubo. Igxininisa indlela amandla okucheba, i-viscosity ratios, kunye ne-turbulence echaphazela ngayo i-microstructure ye-alloys engabonakaliyo ngexesha lokuxuba. Ezi ziphumo zigxininisa ukubaluleka kwemikhosi yokucheba ekunqumeni ukuziphatha kwe-rheological kunye nokusebenza ngokubanzi kwenkqubo ye-extrusion.

Uphononongo lovavanyo luxhasa ngakumbi le ndlela. Umzekelo, uphando malunga ne-polypropylene-clay nanocomposites ibonise ukuba i-screw extruders iphumelele ukusasazwa okuphezulu xa kuthelekiswa ne-screw extruders enye. Oku kubalelwa kumandla aphezulu okucheba aveliswa kwiinkqubo ze-screw ezingamawele, ezithi ziphucule ukukhutshwa kwemathiriyeli kunye nokuphucula iimpawu zabo zomatshini kunye ne-thermal.

Izinto ezichaphazela amandla e-Shear

Izinto ezininzi zinefuthe kwisizukulwana kunye nobukhulu bamandla okucheba kwi-plastic twin screw extruder. Ezi ziquka isantya se-screw, ijometri ye-screw, kunye ne-viscosity yezinto.

- Isantya seScrew: Ukwandisa isantya se-screw kuphakamisa izinga lokucheba, okukhokelela kwimikhosi ephezulu yokucheba. Nangona kunjalo, isantya esigqithisileyo sinokubangela ukuthotywa kwezinto okanye ukufudumeza.

- Ijiyometri ekrwada: Uyilo lwezikrufu, kubandakanywa nokuphakama kwazo, ubunzulu benqwelomoya, kunye ne-engile edibeneyo, ichaphazela ngokuthe ngqo isenzo sokucheba. Umzekelo, izikrufu ezineenqwelomoya ezinzulu zenza amandla okucheba asezantsi, ngelixa ii-engile ezibambeneyo eziqina ngakumbi zinyusa ukucheba.

- Viscosity yezinto eziphathekayo: Izinto eziphezulu ze-viscosity zifuna amandla amakhulu okucheba ukufezekisa ukuxuba okufanelekileyo kunye nokunyibilika. Ngokwahlukileyo, izinto eziphantsi kwe-viscosity zinokuhamba ngokulula, zinciphisa ukusebenza kwesenzo sokucheba.

Uphononongo lweenkcukacha-manani luhlalutye le miba ngokweenkcukacha. Umzekelo, uphando lubonakalise ukuba ubunzima obuqokelelweyo bonyuka ngokuhambelana nesantya se-screw kodwa behla ngesantya sokutya. Iimeko ezifanelekileyo zokucwangcisa, ezifana nesantya sokutya se-3.6 kg / h kwisantya se-screw se-95 rpm, ukwandisa ubushushu ngelixa unciphisa ukuphuka kwefayibha. Ezi ziphumo zigxininisa imfuneko yokulungelelanisa le miba ukuze kuphunyezwe i-extrusion esebenzayo.

Iindlela zokulawula uMkhosi wokucheba

Ukulawula amandla okucheba kubalulekile ekwandiseni inkqubo ye-extrusion kunye nokuqinisekisa umgangatho wemveliso ongaguqukiyo. Iindlela ezininzi zinokusetyenziswa ukulawula amandla okucheba kwi-twin screw extruder:

- Ukulungelelanisa iScrew Speed: AbaSebenzi banokunyusa okanye banciphise isantya se-screw ukuguqula isantya sokucheba kunye nokufezekisa izinto eziphathekayo ezifunwayo.

- Ukwenza uYilo lweScrew: Ukulungelelanisa ijiyometri yesikrufu, njengokutshintsha ibala okanye ubunzulu bokubhabha, kuvumela ulawulo oluchanekileyo kwisenzo sokucheba.

- Ukusebenzisa iiModeli zokuShear-Thinning: Le mifuziselo inceda ukuqikelela impatho ebonakalayo phantsi kweemeko ezahlukeneyo zokucheba, ivumela ulawulo olungcono lwenkqubo. Nangona kunjalo, ukuthembela kuphela kwezi modeli kunokukhokelela ekujongeni phantsi kweeparamitha eziphambili ezifana noxinzelelo kunye ne-viscosity.

- Ukusebenzisa iiNkqubo zokuBeka iliso eziPhezulu: Ukujongwa kwexesha langempela kwiiparameters ezifana nobushushu, uxinzelelo, kunye ne-torque kunika ulwazi oluxabisekileyo kwinkqubo ye-extrusion. Le datha ingasetyenziselwa ukwenza uhlengahlengiso kunye nokugcina amanqanaba afanelekileyo omkhosi wokucheba.

Uphando lubonise ukuba indima yesikrufu ekugqithiseni ubushushu ibalulekile ekulawuleni amandla okucheba. I-recirculation circuit ifom ngaphakathi kwe-extruder, enceda ukusabalalisa ubushushu ngokulinganayo kwaye inqande ukugqithiswa kwendawo. Oku kuqinisekisa ukuba i-polymer inyibilika ngokufanayo, iphucula ukusebenza kakuhle kwenkqubo ye-extrusion.

Impembelelo yoMmandla wokucheba kwiiPropati zeMpahla

Iimpembelelo zokuxuba kunye ne-Homogeneity

Amandla e-Shear adlala indima ebalulekileyo ekufezekiseni ukuxubana okufanayo kunye ne-homogeneity kwizinto ezicutshungulwa yi-plastic twin screw extruder. Ukusebenzisana phakathi kwe-screws kunye ne-barrel kudala ukukhuhlana, okwenza kube lula ukudibanisa iipolymers kunye nezongezo. Le nkqubo iqinisekisa ukuba imveliso yokugqibela ibonisa iipropati ezihambelanayo kwisakhiwo sayo yonke.

Izifundo zophando ziqaqambisa imiba emininzi yempembelelo yamandla okucheba:

| Umba we-Shear Force Impact | Inkcazo |

|---|---|

| Ukuqhekeka kweFayibha | Amandla e-shear kwi-matrix etyhidiweyo ikhokelela ekuqhekekeni kwefayibha, echaphazela iipropati zesakhiwo semveliso yokugqibela. |

| Isizukulwana sobushushu | Malunga ne-80% yobushushu obufunekayo ekunyibilikeni iveliswa kukukhuhlana ngenxa yokucheba phakathi kwezikrufu kunye nomphanda. |

| Ukudibanisa Ukusebenza | Uyilo lweendawo zokuxuba kunye nezinto ezihamba phambili kunye nokubuyisela umva zichaphazela amandla oxinzelelo kunye nokusebenza kakuhle kokuxuba. |

| Ukuhanjiswa kwexesha lokuHlala | I-RTD ichaphazela kakhulu iimpawu zemveliso ngokumisela ixesha lokuvezwa kubushushu, uxinzelelo, kunye nokucheba. |

Ukongeza, ukunyusa isantya se-rotor ngexesha le-polypropylene-sisal-melt-mixing kubangela ukophuka kwefiber ngakumbi, ukuvelisa ubude obuncinci befiber. Le nto, ebonwa kwimicu yendalo, yenzeka ngenxa yokuba i-shear iyahlula iintsinga ezihlanganisiweyo, inciphisa ububanzi bayo. Ezi ziphumo zigxininisa ukubaluleka kokwandisa amandla okucheba ukulungelelanisa ukuxubana okusebenzayo kunye nokuthembeka kwempahla.

Impembelelo kwiiPropati zeThermal kunye nokusasazwa koBushushu

Amandla e-Shear achaphazela kakhulu iipropati zokushisa kunye nokusabalalisa ubushushu ngexesha lokukhupha. Ukukhuhlana okwenziwa zizikrufu kwenza malunga ne-80% yobushushu obufunekayo ukunyibilikisa iikhompawundi zeplastiki. Oku kusasazwa kobushushu kuqinisekisa ukunyibilika okufanayo kunye nokuthintela ukufudumeza kwendawo, okunokuthoba umgangatho wezinto.

Uyilo lweendawo zokuxuba ze-extruder zongeza ngakumbi ukuhanjiswa kobushushu. Izinto ezihamba phambili kunye nokubuyisela umva zenza uxinzelelo oluphucula ukuhanjiswa kwe-thermal. Ukwabiwa kwexesha lokuhlala (RTD) nako kudlala indima ebalulekileyo. Izinto ezivezwe kumandla okucheba angaguqukiyo zifumana ukufudumeza okufanayo, okukhokelela kuzinzo olungcono lwe-thermal.

Ngokomzekelo, ukulinganisa kwamanani kubonisa ukuba amandla okucheba achaphazela i-microstructure ye-alloys engabonakaliyo ngexesha lokuxuba. La mandla aphembelela i-viscosity ratios kunye ne-turbulence, iqinisekisa nokuba ukuhanjiswa kobushushu kuyo yonke into. Iziphumo ezinjalo ziqaqambisa ukubaluleka kwamandla e-chear ekugcineni ukulingana kwe-thermal ngexesha lokukhupha.

Utshintsho kwiiPropati zoomatshini kunye nokomelela kwezinto

Amandla e-Shear achaphazela ngokuthe ngqo iipropathi zoomatshini kunye namandla ezinto ezikhutshiweyo. Ukwahluka kokuqina kwe-shear kunokuguqula ubume bemolekyuli, okukhokelela kutshintsho kumandla okuqina, ukuqina, kunye nokuqina.

Uphando lwamanani lubonisa ezi ziphumo:

- Incopho yamandla okucheba ee-engile eziguquguqukayo ezidityanisiweyo zesampulu zonyuka ngokungekho mgca kunye noxinzelelo oluqhelekileyo, ngelixa amandla okucheba okushiyekileyo abonisa ukunxibelelana okuncinci kunye ne-morphology edibeneyo.

- Kuxinzelelo oluqhelekileyo olusezantsi, iisampuli zibonisa i-shear dilatancy, eyancipha kumanqanaba aphezulu oxinzelelo. Oku kuziphatha kubonisa unxulumano olubi phakathi kokufuduswa okuqhelekileyo kunye ne-tangential.

- Iimpawu zokungaphumeleli ziyahluka ngee-angles ezihlangeneyo. Izowuni ezinobude obuphezulu zibonisa iintanda ezithe nkqo kunye nokucheba, ngelixa iindawo ezineengile ezisezantsi zibonisa ukusilela kokucheba ecaleni kwendlela yokucheba.

Ezi ziphumo zigxininisa imfuneko yokulawula amandla okucheba ukuze kuphunyezwe iimpawu ezinqwenelekayo zoomatshini. Umzekelo, ukucheba okugqithisileyo kunokubangela ukophuka kwefiber, ukunciphisa amandla ezinto eziphathekayo. Ngokuchasene noko, ukucheba okungonelanga kunokubangela ukuxubana okungaphelelanga, kubeke esichengeni umgangatho wemveliso.

Imizekelo: Ukuziphatha kweMathiriyeli phantsi kweeMeko eziguquguqukayo zokucheba

Izifundo zophando zibonelela ngezimvo ezixabisekileyo malunga nendlela amandla okucheba ayichaphazela ngayo indlela yokuziphatha kwezinto eziphathekayo. Uphando kwi-polypropylene-clay nanocomposites lubonisa okoamawele Scruders extrudersukufezekisa ukusasazwa okuphezulu xa kuthelekiswa neenkqubo zesijija esinye. Amandla aphezulu okucheba aphucula i-exfoliation, ukuphucula iimpawu zoomatshini kunye ne-thermal.

Olunye uphononongo kwiintsinga zendalo lutyhila ukuba ukucheba okusetyenzisiweyo ngexesha lokudityaniswa kwahlula iintsinga ezidityanisiweyo, kucutha ubukhulu bazo. Le nkqubo iphucula i-homogeneity yemathiriyeli kodwa inokuthi ibeke esichengeni isidima sayo solwakhiwo.

Kusetyenziso lwemizi-mveliso, ukuqinisa amandla okucheba kungqineke kubalulekile ekuveliseni iimveliso ezikumgangatho ophezulu. Ngokomzekelo, ukulungelelanisa isantya se-screw kunye nejometri kwi-plastic twin screw extruder iqinisekisa ukuxuba okufanayo kunye neempawu eziphathekayo eziphathekayo. Ezi zifundo zophononongo zigxininisa ukubaluleka kokulungelelanisa amandla okucheba kwizicelo ezithile.

IziCwangciso zokuSebenza zePlastiki yeTwin Screw Extruder

Uyilo lweScrew kunye noLungiso loLungiso

Ukuphucula uyilo lwesijivaibalulekile ekuphuculeni ukusebenza kweplastic twin screw extruder. Ulungelelwaniso lokujija ijometri, olufana nepitch, ubunzulu benqwelomoya, kunye ne-engile edibanisayo, ichaphazela ngokuthe ngqo ukuveliswa kwamandla okucheba kunye nokuhamba kwezinto. Umzekelo, izikrufu ezineenqwelomoya ezinzulu zinciphisa ubunzulu be-chear, ngelixa ii-engile ezibambeneyo eziqinileyo ziphucula ukusebenza kakuhle kokuxuba.

Abasebenzisi bahlala belungiselela ulungelelwaniso lwezikrufu ukuze lutshatise iipropati zemathiriyeli ezithile. Iiplastiki ze-viscosity eziphezulu zixhamla kwizikrufu eziyilwe ngobunzulu obukhulu benqwelomoya ukuququzelela ukuhamba kakuhle. Ngokwahlukileyo, izinto ezisezantsi ze-viscosity zifuna i-angles intermeshing eqinile ukuqinisekisa ukucheba okwaneleyo. Olu hlengahlengiso luphucula i-homogeneity yezinto kunye nokunciphisa ukusetyenziswa kwamandla ngexesha le-extrusion.

Ukulinganisa amandla okucheba kunye nobushushu

Ukugcina ulungelelwaniso phakathi kwamandla okucheba kunye nobushushu kubalulekile ukuze kuphunyezwe umgangatho ongaguqukiyo we-extrusion. Ukucheba okugqithisileyo kunokukhokelela ekutshiseni, ngelixa ukucheba okungonelanga kunokubangela ukuxuba okungaphelelanga. Ukulawula uxinzelelo ngaphakathi kwe-extruder kudlala indima ebalulekileyo ekulawuleni ezi ziguquguqukayo.

Umzekelo, ifomyula ibonisa ubudlelwane phakathi koxinzelelo kunye nobushushu: ∆T (°C) = ∆P (ibha) ÷ 2. Ukucutshungulwa kwe-500 kg / hr kuxinzelelo lokufa kwe-40 bar kunokunyusa ubushushu bokunyibilika malunga ne-20 °C. Ukudibanisa impompo yegiya kunciphisa uxinzelelo lokukhutshwa, ukunciphisa ama-spikes obushushu kunye nokunxiba kwizikrufu zokukhupha. Ukulawulwa koxinzelelo lwe-loop evaliweyo kwandisa ngakumbi ukuzinza kwe-extrusion, ukuqinisekisa ukuhanjiswa kobushushu obufanayo kunye neempawu ezifanelekileyo zezinto.

Ukuthungelwa komkhosi wokucheba kwizicelo zePlastiki eziKhethekileyo

Ukulungelelanisa amandla okucheba kwizicelo ezithile kuphucula ukusebenza kwemathiriyeli yeplastiki. Umzekelo, ukongeza iiplasticizers kwii-PLA Composites kuphucula ukuguquguquka, ukuchasana kwempembelelo, kunye neempawu zoomatshini. Ukuskena i-electron microscopy (SEM) imifanekiso ityhila ukuba i-PLA eyenziwe ngeplastiki ibonisa ukudityaniswa okukhulu xa kuthelekiswa nezinto ezidityanisiweyo ezingafakwanga zeplastiki, ezibonisa ukuziphatha okubuthathaka.

Iimvavanyo ze-Flexural zibonisa ukuba izinto ezihlanganisiweyo zeplastiki zinexabiso eliphantsi lemodyuli eguquguqukayo, ebonisa ukwanda kokuguquguquka. Ukongeza, ukongezwa kweeplasticizers kunciphisa ukushisa kweglasi (Tg), kuququzelela ukusetyenzwa lula. Olu hlengahlengiso luqaqambisa ukubaluleka kokwenza ngokwezifiso amandla okucheba ukuhlangabezana neemfuno ezizodwa zezicelo zeplastiki ezahlukeneyo.

Ukubeka iliso ngexesha lokwenyani kunye nobuChwepheshe boMlinganiselo

Iinkqubo zokujonga ixesha langempelabonelela ngezimvo ezixabisekileyo kwinkqubo ye-extrusion, ivumela abaqhubi ukuba basebenzise amandla okucheba ngokufanelekileyo. Izinzwa zilinganisa iiparamitha eziphambili ezinje ngeqondo lobushushu, uxinzelelo, kunye netorque, zinika ulawulo oluchanekileyo kwiimeko ze-extrusion.

Ubuchule bokubeka iliso obuphezulu, obufana neenkqubo ezivaliweyo, zigcina useto loxinzelelo olungaguqukiyo kunye nokuthintela ukuguquguquka okunokuthi kubeke esichengeni umgangatho wemveliso. Ezi nkqubo zikwafumanisa ukungahambi kakuhle kokuhamba kwezinto, ezivumela abaqhubi ukuba benze uhlengahlengiso olukhawulezileyo. Ngokusebenzisa idatha yexesha lokwenyani, abavelisi baqinisekisa ukuba i-plastic twin screw extruder isebenza ngokugqibeleleyo, inika imveliso ekumgangatho ophezulu.

Amandla e-Shear ahlala alilitye lembombo le-plastic twin screw extrusion, ukubumba iipropathi zemathiriyeli ezifana nokuxuba, ukuzinza kwe-thermal, kunye namandla omatshini. Ukuphucula la mandla kuphucula umgangatho wemveliso kunye nokusebenza kakuhle kwenkqubo.

Ukwenziwa kwezinto ezintsha kulawulo lwamandla okucheba kuya kuvula amathuba amatsha ekusetyenzweni kweplastiki. Abaphandi kunye neenjineli kufuneka baphonononge iindlela eziphambili zokucokisa iziphumo ze-extrusion ngakumbi.

FAQ

Ngowuphi owona msebenzi uphambili wamandla okucheba kwi-twin screw extrusion?

Amandla e-Shear aququzelela ukunyibilika kwezinto, ukuxuba, kunye ne-homogenization. Iqinisekisa umgangatho wemveliso ohambelanayo ngokuchaphazela iimpawu zokushisa kunye nomatshini ngexesha lokukhupha.

Abaqhubi banokulawula njani amandla okucheba kwi-twin screw extruder?

AbaSebenzisi bahlengahlengisa isantya se-screw, yenze ngokwezifiso ijometri yesikrufu, kwaye ibeke iliso kwiiparamitha zexesha lokwenyani njengoxinzelelo kunye netorque ukulawula amandla okucheba ngokufanelekileyo.

Kutheni kubalulekile ukulinganisa amandla okucheba kunye nobushushu?

Ukulinganisa amandla okucheba kunye nobushushuikhusela ukuthotywa kwezinto, iqinisekisa ukuxutywa okufanayo, kunye nokugcina iimeko ezifanelekileyo zokukhutshwa kwemveliso ephezulu.

Ixesha lokuposa: Jun-11-2025