I-Conical Twin Screw Barrel ibonakalisa uyilo oludityanisiweyo oluphucula ukuxubana kwezinto kunye nokuhambisa ukusebenza kakuhle. Kwi-extrusion yeplastiki, iI-Conical twin screw extruder PVCinkqubo iqinisekisa ukunyibilika nokusetyenzwa kwemathiriyeli yePVC. Abavelisi abahamba phambili, kubandakanywaI-Conical Twin Screw Extruder Barels Factory, sebenzisa ubuchule obuphezulu bomzekelo kunye nokuchanekai-tapered twin screw barrel kunye ne-screwiiparamitha zokwandisa ukusebenza.

| Ubungakanani beMarike ka-2024 | Iqikelelwe ngo-2033 | I-CAGR (2025-2033) |

|---|---|---|

| I-USD 1.2 yezigidigidi | I-USD 2.5 yezigidigidi | 8.9% |

Iinjineli zixhomekeke kwi-tapered twin screw barrel kunye nesikrufu ukufumana iziphumo ezihambelanayo nezikumgangatho ophezulu.

Izixhobo zeConical Twin Screw Barel kunye noYilo

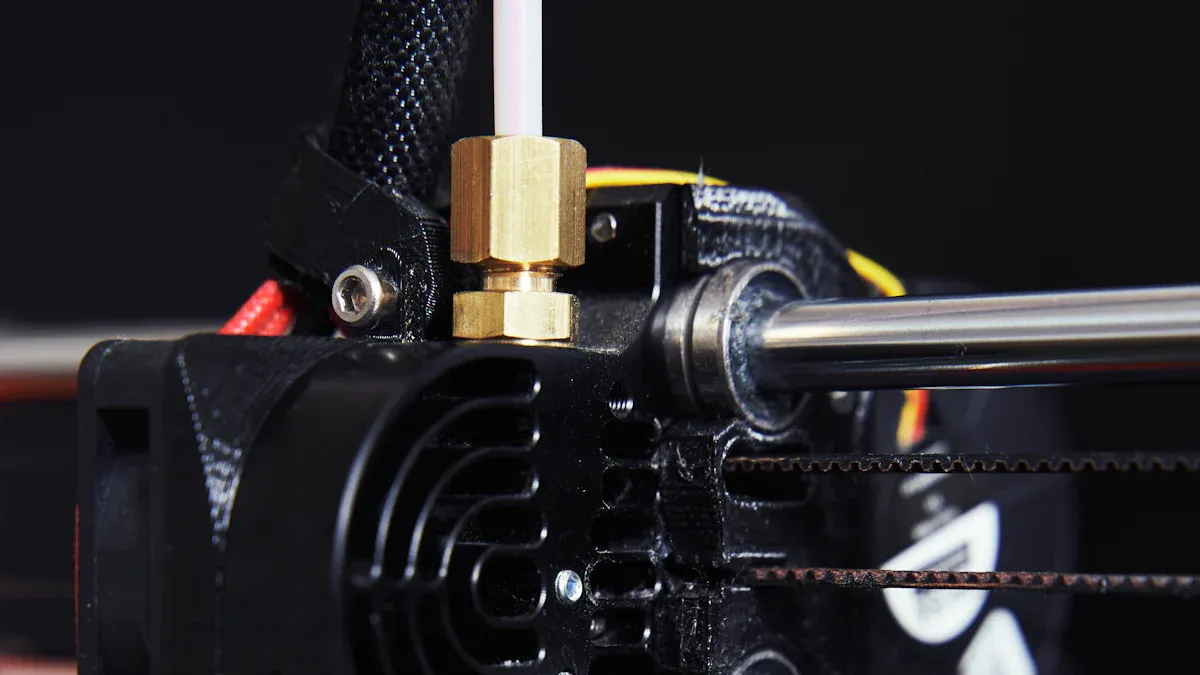

Ulwakhiwo kunye neJiyometri eneTapered

Ubume be-aI-Conical Twin Screw Barrelibalasele ngenxa yejiyometri yayo enetapered. Olu luyilo lubonisa ukuhla kancinci kwedayamitha yesikrufu ukusuka kwindawo yokutya ukuya kwindawo yokukhupha. I-tapering yenza ukuhanjiswa kwamandla okucheba okuguquguqukayo kunye okufanayo. Oku kunceda ukuphucula ukuxuba kunye nokuqinisekisa ukuba izinto zidibanisa ngokulinganayo. Ijometri iphinda inciphise umthamo ngaphakathi kombhobho njengoko izinto zihamba phambili. Olu tshintsho lukhulisa ukuhanjiswa kwezinto kwaye lunciphisa umngcipheko wokuvaleka.

Uyilo lwe-tapered lunciphisa ukuxhathisa kunye nokusetyenziswa kwamandla, okwandisa ukusebenza kakuhle kwamandla. Ikwakhuthaza nokusasazwa kobushushu. Oku kuthintela iindawo ezishushu kunye nokuphucula ulawulo lwe-thermal. Ijometri ibangela iipatheni zokuhamba ezintsonkothileyo eziphucula ukusebenza kakuhle kokuxuba. Ngenxa yoko, inkqubo ayifuni ukucheba okugqithisileyo okanye igalelo lamandla elongezelelweyo. Ukunciphisa okulawulwayo kwi-diameter kuvumela ulawulo oluchanekileyo malunga nokuba izinto ezihlala ixesha elide kangakanani kwi-barrel. Oku kukhokelela ekusebenzeni ngokufanelekileyo kunye neempawu zezinto eziphathekayo ezingcono.

Ezinye iimpawu zoyilo ezibalulekileyo ziquka:

- Ukunyuswa komlinganiselo wobude ukuya kububanzi, eyandisa indlela yokucubungula kwaye ivumela ixesha elingakumbi lokuguqulwa kwezinto eziphathekayo.

- Iindawo ezininzi zokushisa, nganye zilawulwa ngokuzimeleyo, kulawulo oluchanekileyo lwe-thermal.

- Ukunciphisa uxinzelelo lwe-shear, olukhusela izinto ezithintela ukushisa kunye nokuphucula ukuqikelelwa kwenkqubo.

- I-Versatility ekuqhubeni izixhobo ezahlukeneyo, enkosi kuyilo oluguquguqukayo lwetapered.

Izinto Ezingundoqo Ezisetyenzisiweyo

Abavelisi bakhetha imathiriyeliAmacandelo e-Conical Twin Screw Barrelngokusekelwe ekomeleleni kunye nokusebenza. I-barrel kunye nezikrufu zihlala zisebenzisa i-alloy steels eqinile. Ezi zixhobo zixhathisa ukugqoka kunye nokubola, okubalulekileyo ekusebenzeni kwexesha elide. Eminye imigqomo ifumana unyango olukhethekileyo lomphezulu okanye iingubo zokwaleka. Olu nyango luqhubela phambili ukwandisa ukuxhathisa kwi-abrasion kunye nokuhlaselwa kweekhemikhali.

Izinto eziqhelekileyo ziquka:

- Intsimbi ye-nitrided, enikezela ngobulukhuni bomphezulu obalaseleyo.

- I-Bimetallic alloys, enika ukhuseleko olongezelelweyo kwiindawo eziphezulu zokunxiba.

- Intsimbi engatyiwayo, exhathisa ukubola xa kusetyenzwa iikhompawundi ezinobundlobongela okanye ezisebenzayo.

Ukukhethwa kwezinto eziphathekayo kuxhomekeke kuhlobo lwepolymer okanye i-compound eyenziwa. Umzekelo, imigqomo esetyenziselwa i-PVC extrusion isoloko ifuna izinto ezinokumelana nendalo eyonakalisayo yeekhompawundi ezisekwe kwiklorine. Olu khetho olucokisekileyo luqinisekisa ukuba i-Conical Twin Screw Barrel igcina ukusebenza okuphezulu kunye nobomi obude benkonzo.

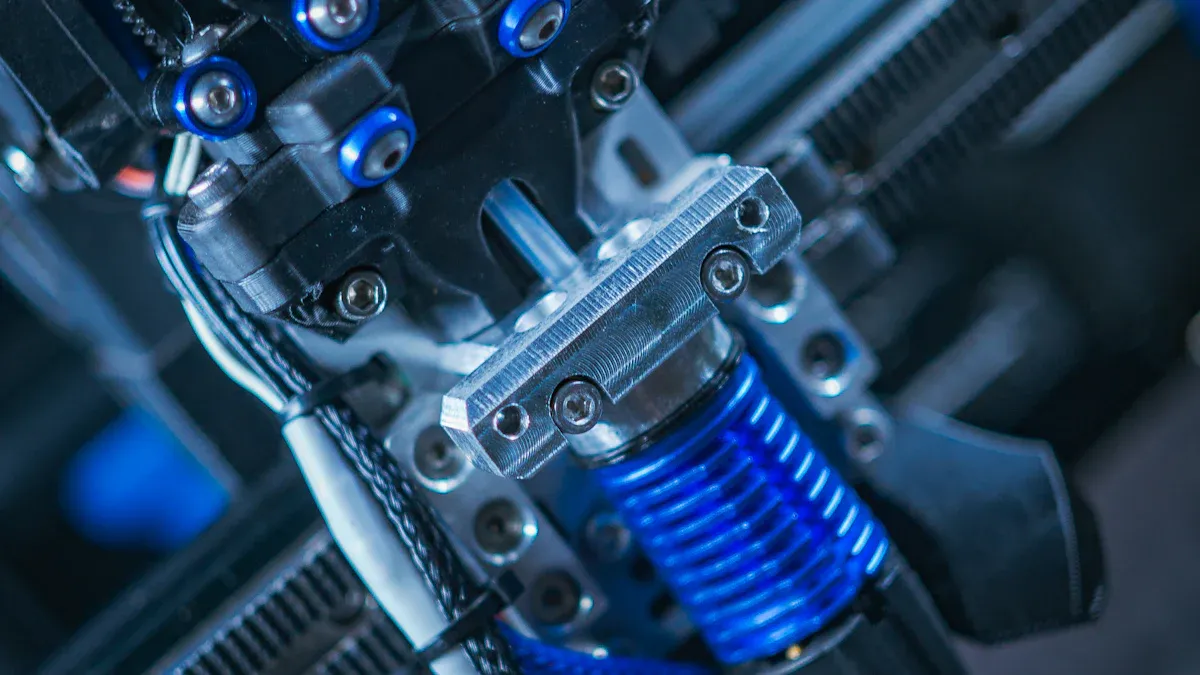

Iintlobo zeScrew kunye neendima zazo

Isikrufu siyinxalenye ebalulekileyo yeConical Twin Screw Barrel. Izinto ezahlukeneyo ze-screw zenza imisebenzi ethile ngexesha lenkqubo ye-extrusion. Iinjineli ziyila ezi zinto ukwenza ukuxubana, ukunyibilika kunye nokuhambisa.

| Screw Element Uhlobo | IParameter yobungakanani bulinganisiwe | Indima ekuxubeni / isiphumo kwiNkqubo |

|---|---|---|

| Ii Elements zeNkokeli eziNye | Ukuhanjiswa kwexesha lokuHlala | Impembelelo yokuxuba i-axial kunye neempawu zokuhamba |

| Ukudibanisa iiPaddles | I-Viscous Dissipation, i-RTD | Ukwandisa ukuxuba kunye nokusabalalisa ukuxuba ngokunyusa ukucheba kunye namandla okwandisa |

| UReverse Pitch Elements | Ukusasazeka kwegophe, ukuzinza | Lungisa iipateni zokuhamba ukuze unciphise ukungazinzi kunye nokuphucula ukuxuba okuxutywayo |

Izinto ezikhokelayo zodwa zilawula ixesha elide lezinto ezihlala emgqomeni kwaye zincede ukuziqhubela phambili. Ukuxuba ama-paddles kwandisa amandla okucheba kunye nokwelula, okuqhekeza kunye nokudibanisa izinto ngokucokisekileyo. Izinto zesandi ezibuyiselwe umva zitshintsha indlela yokuhamba kwayo. Oku kunciphisa iindawo apho imathiriyeli inokudodobala kwaye iphucule ukuxubana ngokubanzi.

Iinjineli zinokuhlengahlengisa ukucwangciswa kwezi zinto ze-screw ukuze zihambelane neemfuno zezinto ezahlukeneyo kunye neenkqubo. Oku kuguquguquka kwenza i-Conical Twin Screw Barrel ilungele uluhlu olubanzi lwezicelo ze-extrusion.

Indlela iConical Twin Screw Barrel esebenza ngayo kwiPlastiki Extrusion

Imigaqo yokuSebenza

I-Conical Twin Screw Barrel isebenza ngokugxininisa ukuguquguquka kunye nokusebenza kakuhle. Iinjineli ziyila ezi nkqubo ukuze zikwazi ukujongana noluhlu olubanzi lweemfuno zeplastikhi. I-conical geometry ivelisa i-torque ephezulu ngelixa igcina iplastiki ethambileyo. Olu phawu luyimfuneko ekusetyenzweni kwemathiriyeli ebuthathaka kubushushu kunye nokucheba. I-screws inommandla ophezulu kunye neprofayili ye-shear ephantsi, evumela ukuhanjiswa kobushushu ngokufanelekileyo ngexesha lokukhupha.

Abavelisi bahlala befaka iingubo zobunikazi, ezifana ne-nitride okanye i-tungsten, kwizikrufu kunye nemigqomo. Ezi zogquma zonyusa ukumelana nokunxiba kunye nokuphucula ukuhanjiswa kobushushu. Uyilo lwemodyuli kunye nolungelelwaniso lwe-screw oluzenzekelayo lunceda ukunyusa inkqubo ye-extrusion yezicelo ezahlukeneyo. Umgangatho ophezulu we-DIN yensimbi yenza isiseko sezinto eziphathekayo, kunye neenketho ze-chrome plating okanye i-carbide encapsulation yokusetyenziswa okufunwayo.

AbaSebenzi bajonga iiparamitha ezininzi ngexesha le-extrusion:

- Ubushushu

- Uxinzelelo lwenyibilika

- Torque

- Isantya sokukrazula

- Izinga lokutya

Le milinganiselo ibonisa indlela izinto eziphathekayo eziziphatha ngayo ngaphakathi kombhobho kwaye ziqinisekisa ukusebenza kakuhle kwenkqubo.

Ukunyibilika, ukuxuba, kunye neNkqubo yokuhambisa

Ukunyibilika, ukuxuba, kunye neendlela zokuhambisa zixhomekeke kulawulo oluchanekileyo lweparamitha zenkqubo kunye noyilo lwesijiva. Le theyibhile ilandelayo ibonisa indlela iparameter nganye okanye isiqalelo soyilo esiqinisekisa ngayo ezi ndlela:

| Inkqubo yeParamitha / iNqanaba loYilo | Indima ekuQiniselweni kweNkqubo |

|---|---|

| Isantya seScrew (rpm) | Ilawula izinga lokucheba, ifuthe lokunyibilika kunye noxinzelelo lokuxuba |

| Ireyithi yokutyisa | Ichaphazela ixesha lokuhlala kunye nokusebenza kakuhle kokunyibilika |

| Torque | Ibonisa umthwalo womatshini kunye negalelo lamandla lokunyibilika nokuhambisa |

| Uxinzelelo | Ibonakalisa ukuchasana nokuhamba kwezinto kunye nokusebenza kakuhle kokuhambisa |

| Ubushushu | Ijonga imeko yokunyibilika kunye neemeko zobushushu |

| Ukuhanjiswa kwexesha lokuHlala (RTD) | Iqinisekisa ukudibanisa ukufana kunye nexesha lokuvezwa lokucheba kunye nobushushu |

| Ijiyometri ekrwada | Imisela isantya sokuhambisa, ukuqina kokucheba, kunye nodidi lokuxuba |

| Ukuxuba Elements | Ukuququzelela ukuxuba kunye nokusabalalisa, okuchaphazela ukunyibilika kwe-homogeneity |

Abaqhubi bahlengahlengisa ezi parameters ukufezekisa ukunyibilika okufanayo, ukuxuba ngokucokisekileyo, kunye nokuthuthwa kwezinto ezifanelekileyo. Uyilo lweConical Twin Screw Barrel luqinisekisa ukuba isigaba ngasinye senkqubo sixhasa iziphumo eziphezulu ze-extrusion.

I-Conical Twin Screw Barrel vs. Ezinye iintlobo

I-Conical vs. Parallel Twin Screw Barrels

I-Conical kunye ne-parallel twin screw barrel zisebenza indima efanayo kwi-extrusion yeplastiki, kodwa uyilo lwazo lwenza izibonelelo ezahlukeneyo zokusetyenzwa. Uyilo lwe-conical lusebenzisa izikrufu ezirhangqiweyo, ezenza umsantsa omncinci njengoko izinto zihambela phambili. Olu phawu lunyusa ucinezelo lwemathiriyeli kwaye luphucula ukukhupha umoya. Ikwavumela ukuhanjiswa kwetorque ephezulu, iyenze ilungele izixhobo ezinoxinano oluphantsi okanye ezo zibamba igesi. I-parallel twin screw barrels, kwelinye icala, sebenzisa izikrufu ezinobubanzi obungaguqukiyo. Ezi nkqubo zigqwesa ekuxubeni nasekudibaniseni, ngakumbi xa izikrufu zijikeleza kwicala elinye. Uyilo olunxuseneyo lukhuthaza ukuzicoca kunye nokusasazwa okufanayo. Iimodeli zemathematika zibonisa ukuba i-conical twin screw barrels iphucula umthamo wokuthatha kunye nokuveliswa koxinzelelo, nto leyo ekhokelela kubuchule obungcono be-extrusion xa kuthelekiswa noyilo oluhambelanayo.

- Imigqomo yeConical: Ingcono kuxinzelelo, ukukhupha umoya, kunye netorque.

- Imigqomo ehambelanayo: Ingcono ukuxuba, ukudibanisa, kunye nokuzicoca.

IiNzuzo eziZodwa zoYilo lweConical

Uyilo lweconical lubonelela ngeenzuzo ezininzi ezizodwa. Iphucula imveliso kunye nemveliso, ngakumbi kwimveliso yemibhobho yePVC. Ukucuthwa ngokuthe ngcembe kumthamo we-screw channel kwandisa uxinzelelo kunye nokuphucula ukuxutywa. Olu yilo lukwaxhasa ukucheba okuthambileyo, okukhusela izinto ezingevani nobushushu. Abaqhubi banokuhlengahlengisa isantya se-screw kunye nedayamitha ukuze kunyuswe izinga lemveliso kunye nomgangatho wokunyibilika. I-conical twin screw barrel iphucula ukuxuba, okukhokelela kumbala ofanayo kunye neempawu ezingcono zoomatshini kwiimveliso ezigqityiweyo. Iisistim zolawulo ezikwinqanaba eliphezulu zongeza ngakumbi inkqubo esebenzayo kunye nokungaguquguquki kwemveliso.

Uyilo lwe-conical lukwanceda ukunciphisa ukusetyenziswa kwamandla kunye nenkcitho, ukuxhasa imveliso engabizi kakhulu kunye nezinzileyo.

Usetyenziso oluqhelekileyo

I-Conical Twin Screw Barrel ifumana ukusetyenziswa kumashishini amaninzi. IyaqhubaImibhobho yePVC, iiprofayili, kunye namaphephangobuchule obuphezulu. Abavelisi bayisebenzisela iiplastiki ekunzima ukuzisebenzisa kwakhona kunye neepolima zodidi lwezonyango. Uyilo luxhasa amazinga aphezulu emveliso, ngeIiprofayili zifikelela kwi-550 lb/hr kunye nemibhobho ukuya kuthi ga kwi-1000 lb/hr. Ikwaphucula umgangatho wemveliso ngokunciphisa imingxunya kunye nokuqinisekisa ukufuma okufanayo. Amashishini afana namayeza, iiplastiki, kunye neembumba ziyazuza kuyilo lwemodyuli kunye nokuguquguquka.

| Indawo yesicelo | Ubonelelo olunikezelweyo |

|---|---|

| Ukwenziwa koMbhobho wePVC | Imveliso ephezulu, ukunyibilika okufanayo, umgangatho ozinzile |

| Ukwandiswa kweProfayili | Ukudibanisa okuphuculweyo, imilinganiselo echanekileyo |

| IiPolima zonyango | Ukusetyenzwa ngobunono, iipropati ezihambelanayo |

| IiPlastiki eziRecycled | Ukuphathwa kwezinto ezininzi, ukonga iindleko |

Ukukhetha i-Conical Twin Screw Barrel

Ukuhambelana kwezinto

Ukukhetha i-Conical Twin Screw Barrel echanekileyo iqala ngokuqonda ukuhambelana kwezinto. Iinjineli kufuneka zitshatise umgqomo kunye noyilo lwe-screw kwiipropathi ezithile zezinto ezilungiswayo. Umzekelo,Iikhompawundi zePVCIfuna uqwalaselo lwesijija olwahlukileyo kunepololefins okanye iiplastiki zobunjineli. Izifundo zamanani zinceda iinjineli ukuba zilinganise indlela izikrufu ezahlukeneyo zoyilo kunye nokuseta umgqomo okuchaphazela ukuhamba kwezinto, ukunyibilika, kunye nokuxuba. Olu linganiso lubonisa indlela ijiyometri ejijwa ngayo kunye neeparamitha zenkqubo-ezifana neqondo lobushushu, isantya se-screw, kunye nesantya sokutya-ziyichaphazela njani indlela yokuziphatha kwezinto ngaphakathi komphanda.

Xa kusenziwa izinto ezibuthathaka, iinjineli kufuneka zilawule ukucheba kunye nobushushu ukuthintela ukuthotywa. Bahlengahlengisa indawo yokubeka isikrufu kunye nobude bomphanda ukuze baqinisekise ukuxutywa nokunyibilika. Izinto ezirhabaxa okanye ezidlekayo zifuna imibhobho ekhethekileyo okanye iileyile ezijijwayo ukunqanda umonakalo. Ngokukhetha ngononophelo indibaniselwano elungileyo yeScrew kunye nomgqomo, abaqhubi bagcina ingqibelelo yezinto kwaye bafezekise umgangatho wemveliso ohambelanayo.

Ingcebiso: Soloko uphonononga indawo yokunyibilika kwemathiriyeli, i-viscosity, kunye nokuphinda usebenze ngemichiza phambi kokuba ukhethe umbhobho kunye nokumiswa kwesikrufu.

Nxiba ukuxhathisa kunye noKuhlala ixesha elide

Ukuqina kudlala indima ephambili ekusebenzeni kunye nobomi be-twin screw barrel. Abavelisi basebenzisa i-alloy steels yamandla aphezulu, i-nitrided surfaces, kunye ne-bimetallic linings ukumelana nokuguga kunye nokubola. Ezi zixhobo zikhusela umbhobho kunye nezikrufu kwi-abrasion ebangelwa izihlungi, iifiber zeglasi, okanye izongezo zamaminerali. Ukusetyenziswa kwe-abrasive kakhulu okanye eyonakalisayo, iinjineli zingakhankanya unyango olongezelelweyo lomphezulu okanye iingubo.

Itheyibhile engezantsi ishwankathela ukhetho lwemathiriyeli eqhelekileyo kunye noncedo lwazo:

| Uhlobo lwezinto eziphathekayo | Ubonelelo olunikezelweyo | Usetyenziso oluqhelekileyo |

|---|---|---|

| Nitrided Steel | Ubunzima bomgangatho ophezulu | Ukusetyenzwa kwepolymer okusemgangathweni |

| Ingxubevange yeBimetallic | Ukuxhatshazwa okuphezulu kwe-abrasion | Iiplastiki ezizaliswe okanye eziqinisiweyo |

| Yenziwe ngentsimbi eshayinayo | Ukumelana nokubola | Iikhompawundi ezisebenzayo okanye ezinobundlobongela |

Ukuhlolwa rhoqo kunye nokutshintshwa kwangethuba kwamalungu agugileyo kunceda ukugcina umgangatho we-extrusion ongaguqukiyo. Ukukhetha izinto ezifanelekileyo zombhobho kunye nezikrufu kunciphisa ixesha lokuphumla kwaye kwandise ubomi besixhobo.

Ugcino kunye noFakelo lweNgqwalasela

Ukugcinwa ngokufanelekileyo kunye nofakelo kuqinisekisa ukusebenza okuthembekileyo kunye nobomi benkonzo ende ye-conical twin screw barrel. Ii-extruders zangoku, ezifana ne-Gemini® Conical Twin Screw Extruders, zinezikrufu ezisezantsi ze-rpm ezineenkqubo zangaphakathi zokupholisa amanzi, iibhokisi zegiya ezomeleleyo, kunye nezifudumezi ezisebenza kakuhle zomoya opholileyo. Ezi mpawu zifuna ukucwangciswa ngenyameko ngexesha lofakelo. Abanini-zithuthi kufuneka babonelele ngeziseko zokupholisa ezisebenzayo, inkxaso eyomeleleyo yebhokisi yegiya, kunye neendlela ezaneleyo zokutya ukuze bafezekise ukusebenza kakuhle.

Iinkqubo zesondlo, ezifana nezo zinikezelwa nguMilacron, zibandakanya ukugcina kunye nokwakha imibhobho kunye nezikrufu. Ezi nkonzo zivumela abaqhubi ukuba bandise ubomi bezixhobo zabo kunye nokugcina ingqibelelo yokufakela. Ukwakhiwa kwakhona kwe-gearbox kunye nokuphuculwa kudlala indima ebalulekileyo ekugcineni i-extruder izinzile kwaye ithembekile.

Qaphela: Cwangcisa uhlolo lwarhoqo kwaye ugcine iirekhodi ezineenkcukacha zolondolozo. Ukufikelela ngokukhawuleza kwiinkonzo zokwakhiwa kwakhona kunye neendawo ezisecaleni kunceda ukunciphisa ixesha lokuphumla kunye nokuqinisekisa imveliso eqhubekayo.

Impembelelo ye-Conical Twin Screw Barrel kwi-Extrusion Performance

Ucikizeko kunye noMgangatho weZiphumo

I-Conical Twin Screw Barrel iphucula ukusebenza kakuhle kwe-extrusion ngokulungiselela ukuhamba kwezinto kunye nokuxuba. Uyilo lwe-screw intermeshing kunye ne-conical shape yandisa indawo ephezulu kwicandelo leplastiki. Olu luyilo lunceda ukusabalalisa ubushushu ngokulinganayo kwaye kunciphisa inkcitho yamandla. Abaqhubi baqaphela ngakumbi ukuhanjiswa kwenyibiliki efanayo kunye nolawulo olungcono lobushushu. Ezi mpawu zinciphisa umngcipheko wokuthotywa kwezinto kunye nokuphucula ukuhambelana kwemveliso.

Imigca yemveliso esebenzisa olu hlobo lomphanda ihlala ibona izantya ezikhawulezayo zokukhupha kunye neziphumo ezikumgangatho ophezulu.Ukusetyenziswa kwamandla kunokwehla ukuya kuthi ga kwi-30%xa kuthelekiswa nemigqomo yesintu. Ukomelela okuphuculweyo kwezikrufu kunye nemigqomo kukwathetha ixesha elincinane lokuphumla ekulondolozweni. IItheyibhile engezantsi iqaqambisa iimetrikhi zokusebenza eziphambili:

| Imethrikhi / Uphawu | Ixabiso / Inkcazo |

|---|---|

| Ubuchule boMveliso | Iphuculwe kakhulu |

| Ukusetyenziswa kwamandla | Ukunciphisa okubalulekileyo |

| Rates Scrap | Ukunciphisa okubalulekileyo |

| UkuNcitshiswa kweScrew Wear | Ukuya kuthi ga kwi-60% yokunciphisa |

| Ukwandiswa koMsebenzi | Ukuya kuthi ga kwi-25% ukunyuka |

| Inqanaba leNkunkuma | ~1.5% |

| Ixesha lokuqalisa kwimilinganiselo emitsha | I-1 ukuya kwiiyure ze-2 |

Ezi ziphumo zibonisa ukuba i-Conical Twin Screw Barrel ixhasa imveliso ezinzileyo, iyanciphisa inkunkuma, kwaye yandisa umgangatho wemveliso.

Iindleko-Ukusebenza

Abavelisi baxhamla kwiindleko-zokusebenza kolu yilo lombhobho. Ukusetyenziswa kwamandla aphantsi kunciphisa ngokuthe ngqo iindleko zokusebenza. Izinto ezomeleleyo kunye neengubo zokwaleka eziphambili zandisa ubomi bemibhobho kunye nezikrufu. Oku komelela kuthetha ukutshintshwa okumbalwa kunye nokugcinwa okuncinci rhoqo.

Amaxabiso athotyiweyo enkunkuma kunye namaxesha okuqalisa ngokukhawuleza nawo anceda ukonga imali. Abaqhubi bachitha ixesha elincinci lokucoca kunye nokulungelelanisa izixhobo. Itheyibhile engentla ibonisa ukubaamazinga enkunkuma ehla ukuya malunga ne-1.5%, kunye namaxesha okuqalisa kwimilinganiselo emitsha yemveliso afinyela ukuya kwi-1 ukuya kwiiyure ezi-2. Olu phuculo luvumela iinkampani ukuba zivelise ngakumbi ngezibonelelo ezimbalwa.

Icebiso: Utyalo-mali kwi-Conical Twin Screw Barrel kunokukhokelela kulondolozo lwexesha elide kunye nemveliso ethembekileyo.

I-Conical Twin Screw Barrel ihambisa ulawulo oluchanekileyo kunye nokusebenza okuphezulu kwi-extrusion yeplastiki. Uphononongo lubonisa ukuba iiparamitha ze-extrusion eziphuculweyo zikhokelela kwiziphumo ezingaguqukiyo kunye nezivuno eziphuculweyo. Abasebenzisi kufuneka batshatise uyilo lomphanda kwiimfuno zezinto kwaye babeke iliso kwiinkqubo eziguquguqukayo. Ukukhetha ulwazi kuqinisekisa ukusebenza okuthembekileyo kunye nomgangatho ophezulu wemveliso.

FAQ

Ngawaphi amashishini asebenzisa imiphanda ye-conical twin screw?

Abavelisi kwiiplastiki, ulwakhiwo, kunye nezixhobo zonyango ezisetyenziswa kumashishinii-conical twin screw barrelsukuvelisa imibhobho, iiprofayili, kunye neemveliso zepolymer ezikhethekileyo.

Kufuneka abaqhubi bahlole kangaphi i-conical twin screw barrel?

Abaqhubi kufunekajonga umphandarhoqo. Uninzi lweengcali zincoma ukuhlolwa kwenyanga ukuqinisekisa ukusebenza kakuhle kunye nokuthintela ixesha elingalindelekanga.

Ngaba i-conical twin screw process umphanda iyakwazi izinto ngaphandle kwePVC?

Ewe. I-Conical twin screw barrels ibamba iindidi zeepolymers, kuquka i-polyolefins kunye neeplastiki zobunjineli, ngokulungelelanisa uyilo lwe-screw kunye neeparameters zenkqubo.

Ixesha lokuposa: Jul-02-2025