I-PE encinci ye-granulators yokusingqongileyo inceda abavelisi banciphise ukusetyenziswa kwamandla kunye neempawu ezintle kunye neteknoloji entsha. Iimodeli zamva nje zibonisa iziphumo ezinomtsalane:

| Metric | 2025 Ukunciphisa vs. Iminyaka Edlulileyo |

|---|---|

| Ukusetyenziswa kwamandla (kW-h/tonne) | 40% ngaphantsi |

| Ukukhutshelwa kweGasi yoGcino | 33% ngaphantsi |

| Ukusetyenziswa kweFossil Fuel | Ngama-45% ngaphantsi |

Basebenzisaiimotor ezisebenza ngamandla, inkunkuma yokubuyisela ubushushu, kunye neenkqubo zokupholisa umoya. AnUmatshini wokusingqongileyo oMncinci wePelletizerkwayeUmatshini weGranulator ongenaManziinokuphathaI-Pvc Pelletizing Extrusionngokufanelekileyo.

Iimpawu Zokugcina Umbane ze-PE Small Environmental Granulators

IiNkqubo zeeMoto eziFanelekileyo

Iigranulator ze-PE ezincinci zokusingqongileyo ngo-2025 zisebenzisa itekhnoloji yemoto ephucukileyo ukonga amandla kunye nokunyusa ukusebenza. Aba matshini baxhomekeke kwizixhobo zokuqhuba umbane ngamandla ombane ukusuka kwi-22 kW ukuya kwi-110 kW, kuxhomekeke kubungakanani bemodeli. Iinjini zisebenza ngamandla ukusuka kwi-200 ukuya kwi-1200 kg / h, izenza zigqibelele kwimisebenzi encinci naphakathi yokuphinda isetyenziswe. Itheyibhile engezantsi ibonisa ezinye iinkcukacha eziphambili zobugcisa:

| Inkcazo | Iinkcukacha |

|---|---|

| Uluhlu lwamandla eMotor | 22 kW ukuya kwi-110 kW |

| Uhlobo Lokuqhuba | Izixhobo zombane zokuqhuba |

| Amandla oMncedisi wokuQhuba | 1.1 kW |

| Uluhlu lwezakhono | 200-1200 kg / h |

| Isicelo | PE kunye nezinye iplastiki granulation |

Ezi njini zisebenza kakuhle kakhulu zisebenzisa ii-servo drives kunye nolawulo olukrelekrele. Banceda abaqhubi ukuba bonge ukuya kuthi ga kwi-40% yamandla ngaphezulu xa kuthelekiswa neenjini ezindala. Ukubeka iliso ngexesha langempela kunye ne-automation igcina inkqubo isebenza kakuhle, ukunciphisa ixesha lokunciphisa kunye nokunciphisa iindleko zombane.

I-Blade eLungelweyo kunye noYilo loThutho

Iblade kunye nenkqubo yokuhambisa kwi-PE igranulator encinci yokusingqongileyo idlala indima enkulu ekongeni amandla. Abavelisi basebenzisa iincakuba ezenziwe nge-alloys eziphambili njenge-tungsten carbide okanye intsimbi enesantya esiphezulu. Ezi zixhobo zihlala ixesha elide kwaye zisikwe ngokufanelekileyo. Nazi ezinye iindlela zokunceda iiblades ezilungiselelwe:

- Ii-angles ze-blade ezichanekileyo zinciphisa umthwalo wemoto kunye nokusetyenziswa kwamandla.

- Iingubo eziphezulu, ezifana ne-titanium nitride, i-friction ephantsi ukuya kuma-40%.

- Ukucocwa rhoqo kwe-ultrasonic kugcina ii-blade zibukhali kwaye kuthintela ukwakhiwa kwentsalela.

- Iincakuba ezisicaba zisebenza ngcono kwiiplastiki ezithambileyo, zehlisa ukuxhathisa kunye nokonga amandla.

- Izinto ezinobunzima obuphezulu zonyusa umthamo wemveliso ukuya kuthi ga kwi-30%.

Iplanti yaseJamani yokurisayikilisha yabona ukutsiba kwe-22% ekusebenzeni kakuhle kunye ne-14% yehla kusetyenziso lwamandla ngetoni nganye emva kokutshintshela kwizinto ezingcono ze-blade. Xa iiblade zihlala zibukhali kwaye zicocekile, umatshini wonke usebenza ngcono kwaye usebenzisa amandla amancinci.

I-Smart Automation kunye noLawulo lweNkqubo

I-automation ehlakaniphile yenza ukuba i-PE encinci yeegranulator zokusingqongileyo isebenze ngakumbi. Aba matshini basebenzisa iinkqubo zokulawula i-PLC kunye nezikrini zokuchukumisa ukuze zisebenze lula. Izinto ezizenzekelayo ziquka:

- Ukulawulwa kokutya okuzenzekelayo kokuhamba kwezinto eziphathekayo.

- Iinkqubo zokuhluza iindlela ezimbini ezivumela abasebenzisi ukuba batshintshe izikrini ngaphandle kokuyeka.

- Iinkqubo zokucoca ngasemva zokukhuphela inkunkuma ngokuzenzekelayo.

- Ukulungelelaniswa ngokuzenzekelayo kwesantya semela ye-pelletizing kunye noxinzelelo lweepellets ezifanayo.

- Ukusombulula ingxaki kwi-Intanethi kunye nokwenza ngcono iparamitha ngolawulo lwamafu.

Icebiso: I-automation ehlakaniphile ayigcini nje ngokugcina amandla kodwa ikwanciphisa nesidingo somsebenzi wezandla. Abaqhubi banokugxila kweminye imisebenzi ngelixa umatshini uphatha uhlengahlengiso lwesiqhelo.

Uyilo oludityanisiweyo ludibanisa i-shredders, ii-compactors, kunye ne-extruders kwinkqubo enye. Olu cwangciso lugcina inkqubo isebenza ngaphandle kokuphumla okude, oku kuthetha ukuba amandla achithwa kancinci kunye nemveliso ephezulu.

UkuBuyiswa koBubushushu beNkunkuma kunye nokusetyenziswa

Iigranulator ze-PE ezincinci zokusingqongileyo azivumeli ubushushu obuxabisekileyo buchithe. Ngexesha lokusebenza, aba matshini bavelisa ubushushu. Esikhundleni sokuphulukana nayo, inkqubo ibamba kwaye iphinde isebenzise obu bushushu kwamanye amanyathelo okuvelisa, njengezinto zokufudumala kwangaphambili okanye ukufudumeza indawo yokusebenza. Le ndlela ithoba imfuno yezixhobo zokufudumeza ezongezelelweyo kwaye inciphisa ukusetyenziswa kwamandla ngokubanzi.

- Ukubuyiswa kobushushu benkunkuma kuxhasa iinjongo zokusingqongileyo ngokunciphisa ukukhutshwa kwegesi ye-greenhouse.

- Ukusebenzisa kwakhona ubushushu kunceda abavelisi ukuba bahlangabezane namandla angqongqo kunye nemigangatho yokusingqongileyo.

- Inkqubo ikwagcina iindleko zokusebenza ziphantsi, okwenza iigranulator zibe lutyalo-mali oluhlakaniphile.

Ngokudibanisa eziiimpawu zokugcina amandla, I-PE i-granulators encinci yokusingqongileyo ibeka umgangatho omtsha wokusebenza kakuhle kunye nokuzinza kwi-recycling yeplastiki.

IiNzuzo eziSebenzayo kunye neMpembelelo yokusiNgqongileyo

UkuSetyenziswa kwamandla okuSebenza okuphantsi

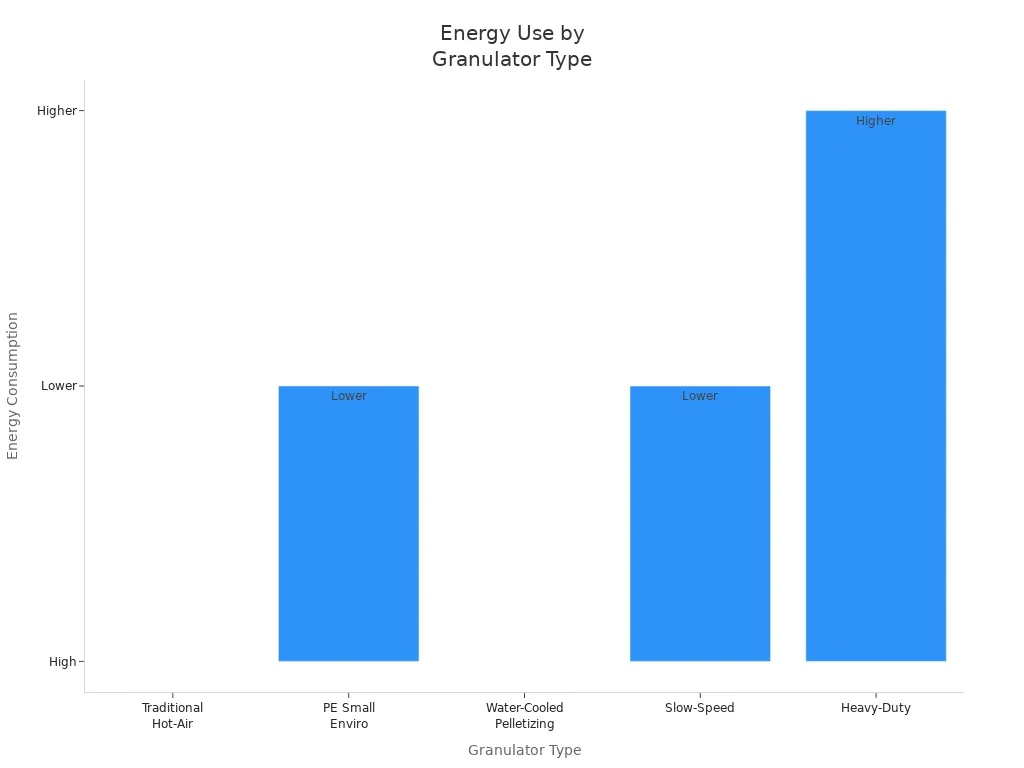

I-PE encinci ye-granulators yokusingqongileyo ivelele ekusebenziseni kwabo amandla aphantsi. Iigranulator ezininzi zemveli, ezifana nomoya oshushu okanye iinkqubo zokupholisa amanzi, zisebenzisa umbane omninzi kwaye zidala ungcoliseko oluninzi. Itheyibhile engezantsi ibonisa indlela iintlobo ezahlukeneyo zegranulator ezithelekisa ngayo:

| Uhlobo lweGranulator | Ukusetyenziswa kwamandla | Impembelelo yokusingqongileyo | Amanqaku okusebenza |

|---|---|---|---|

| IiGranulator zePlastiki zeSintu ezishushu zoMoya | Phezulu | Ungcoliseko olubalulekileyo | Ngaphezulu kwe-75% yezixhobo; ifuna ukuphuculwa |

| IiGranulators eziNcinane ze-PE ezihambelana nokuSingqongileyo | Iphantsi ngenxa yokupholisa umoya kunye nokusebenza kweqondo eliphantsi | Ukukhutshwa okucuthiweyo ngenxa yokonga amandla | Isebenzisa izixhobo ezivuselelekayo kunye nenkunkuma yokubuyisela ubushushu |

| IiNkqubo zokuPelletizing zamanzi ezipholileyo | Phezulu (amanzi nombane) | Umthwalo wokusingqongileyo kusetyenziso lwamanzi | Inyathelo elikhulu, ukusebenza nzima |

| IiGranulator zesantya esicothayo | Ngasezantsi | Ingxolo ephantsi kunye nokunxiba | Ilungele iinxalenye ezincinci, ecaleni kokusetyenziswa kwe-press |

| IiGranulator zoMsebenzi oMnzi | Phezulu | Iphezulu ngenxa yokwenziwa komsebenzi | Ngezixhobo ezomeleleyo; amandla amancinci |

Ukupholiswa komoya, ukusebenza kweqondo lobushushu eliphantsi kunceda ezi granulator zisebenzise amandla amancinci. Baphinde batsibe inyathelo lokumisa, eligcina amandla angakumbi.

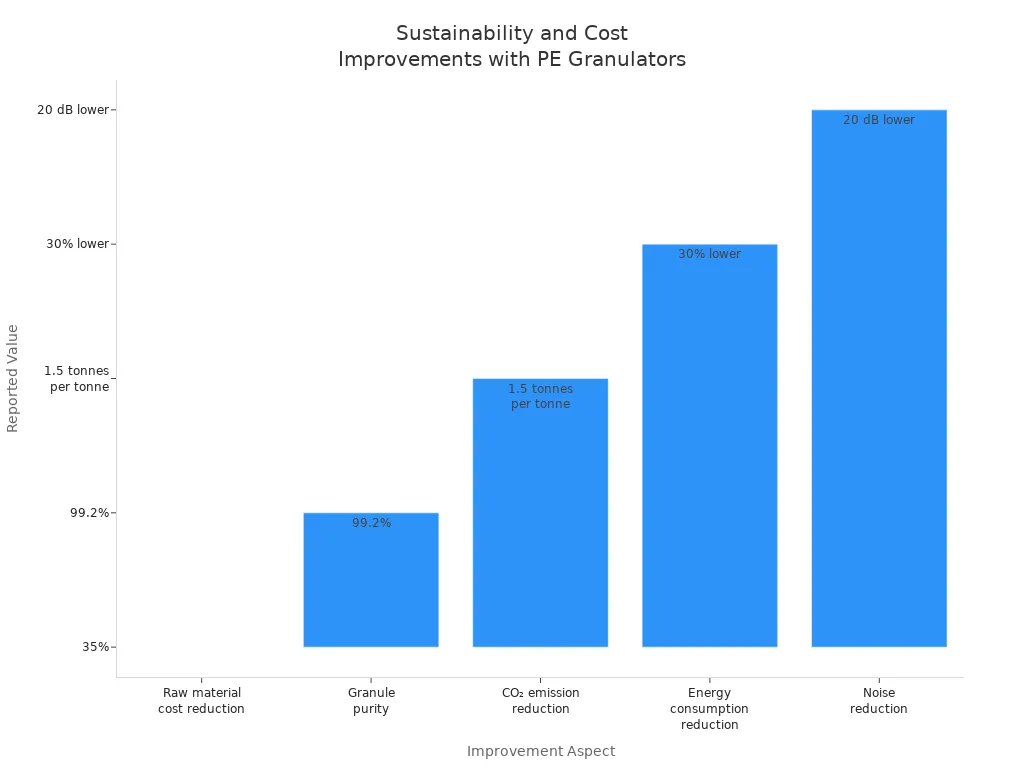

Ukuthotywa kweCarbon Footprint kunye nokuThotyelwa

Aba matshini banceda iinkampani ukuba zicuthe indawo yazo yekhabhoni. Basebenzisa amandla amancinci kwaye baphinde basebenzise inkunkuma yeplastiki kwindawo, oko kuthetha ukuba iilori ezimbalwa endleleni kunye nongcoliseko oluncinci.Oomatshini abancinci beplastiki bokurisayikilishakananjalo gcina inkunkuma kwindawo yokulahla inkunkuma. Ngokuguqula iplastiki endala ibe yipellet entsha, banciphisa isidingo semathiriyeli ekrwada emitsha. Iinkampani ezininzi ngoku zidibana nemithetho engqongqo yokusingqongileyo ngenxa yolu hlaziyo.

Qaphela: Umenzi wemoto waseJamani wonge iitoni ezingama-300 zeplastiki entsha ngonyaka ngokugaya ngokutsha inkunkuma enkulu ngeegranulator ezincinci.

Ugcino lweendleko kunye nokusebenza ngokufanelekileyo kweMveliso

Abavelisi babona ukonga kokwenyani ngezi granulator. Iimotor ezikumgangatho ophezulu kunye ne-smart automation esezantsi amatyala ombane. Umsebenzi wezandla ophantsi uthetha iimpazamo ezimbalwa kunye nexesha elincinci lokuphumla. Itheyibhile engezantsi ibonisa indlela aindlela ecwangcisiweyo yongeza impumelelo kunye nengeniso:

| Iqonga | Inkcazo | Izenzo eziphambili |

|---|---|---|

| Ukucwangcisa | Chaza iinjongo kunye nee-KPIs | Misela iinjongo ze-SMART, yabela izixhobo |

| Ukubulawa | Yenza utshintsho kwi-env elawulwayo | Iiprojekthi ezilingwayo, hlengahlengisa uqeqesho |

| Uvavanyo | Jonga inkqubela kwaye uqokelele ingxelo | Sebenzisa uhlalutyo lwedatha, lungisa njengoko kufuneka |

| Ukwandiswa | Ukulinganisa izenzo eziyimpumelelo | Hlanganisa izifundo ezifundiweyo, qeqesha |

Ukuhla kwe-20% kwixesha lokujikeleza kunokukhokelela kwingeniso eninzi. Ukubuyiswa kobushushu obusetyenzisiweyo kunye nokusetyenziswa kwamandla aphantsi nako kunciphisa iindleko.

Ubungakanani obubambeneyo kunye nokuSebenza kweSithuba

Uyilo oludityanisiweyo lwezi granulators lugcina indawo yomgangatho oxabisekileyo. Iindibano zocweyo ezincinci kunye namaziko okurisayikilisha anokuzifakela ngaphandle kokutshintsha uyilo lwazo. Abaqhubi bazifumana kulula ukuzigcina kwaye zicocekile, oku kuthetha ukuba ixesha lokuphumla lincinci. Ukuseta iimodyuli zixhasa ukuphinda kusetyenziswe i-loop evaliweyo, okwenza yonke inkqubo isebenze ngakumbi kwaye izinzile.

Ingcebiso: Unyawo oluncinci luthetha indawo enkulu yezinye izixhobo okanye ukwandiswa kwexesha elizayo.

I-PE encinci ye-granulators yokusingqongileyo ibeka umgangatho omtsha wokuphumelela kwamandla ngo-2025. Abavelisi babona inzuzo yokwenene:

- Iindleko eziphantsi kunye nenkcitho encinci

- Amazinga aphezulu okurisayikilisha

- Inkxaso kwiinjongo zozinzo

- Ukubuyisela ngokukhawuleza kunye nokuthotyelwa okuqinileyo

FAQ

Ingaba i-PE encinci yegranulator yokusingqongileyo inceda njani ukonga amandla?

Igranulator isebenzisa iimotor eziphezulu kunye ne-automation smart. Ezi mpawu zinciphisa ukusetyenziswa kombane kwaye zigcina imveliso izinzile.

Ingcebiso: Ulawulo olulumkileyo luvumela abasebenzisi ukuba bahlengahlengise iisetingi ngokukhawuleza ukonga ngakumbi.

Ngaba iindibano zocweyo ezincinci zingasebenzisa le granulator?

Ewe, banako. Ubungakanani obubambeneyo buhambelana neendawo ezixineneyo. Abasebenzisi bakufumana kulula ukuyifaka kunye nokugcina.

- Ifaka imigca emincinci yemveliso

- Kulula ukusebenza

Zeziphi izinto ezinokuthi inkqubo ye-PE encinci yegranulator yokusingqongileyo?

IyaphathaPE kunye nezinye iiplastiki. Lo matshini usebenza kakuhle ukurisayikilisha inkunkuma yeplastiki kwiipellets ezintsha.

| Uhlobo lwezinto eziphathekayo | Ifanelekile kwiGranulation? |

|---|---|

| PE | ✅ |

| PP | ✅ |

| I-PVC | ✅ |

Ixesha lokuposa: Aug-14-2025