Uhlobo lokuvuthela umbhobho wesikrufu endiwukhethayo luchaphazela kakhulu iinkqubo zokubumba, ngakumbi xa usebenzisa iUmatshini webhotile wokuvuthela iPC. A ekhethwe kakuhlevuthela umphanda wokubumbakwandisa ukusebenza kakuhle kwemveliso ngelixa kuncitshiswa amaxabiso alahliweyo. Ukulungelelanisa ukhetho lwam kunye neemfuno ezikhethekileyo zokuvelisa kuqinisekisa ukusebenza kakuhle, ngakumbi xa kusenziwa oomatshini abafanaIsitofu Solula Umatshini wokuBumba.

Isishwankathelo seMigqomo yeScrew yokuvuthela

Inkcazo kunye noMsebenzi

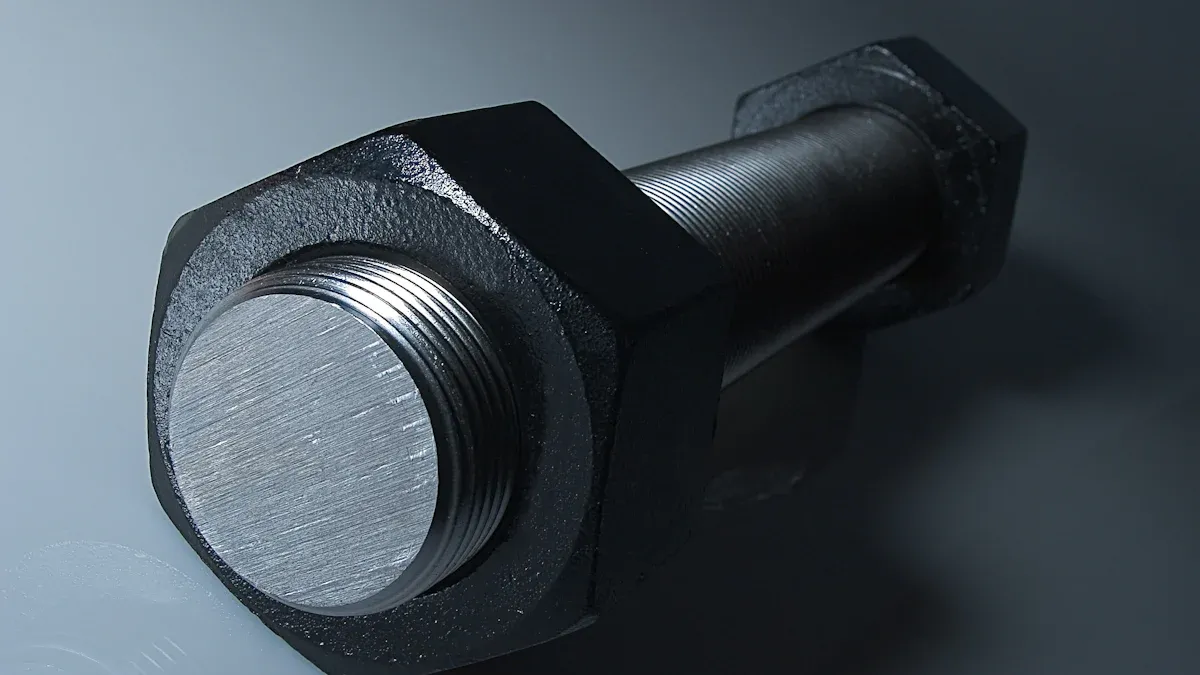

Umbhobho wokuvuthela yisikrufu licandelo elibalulekileyo kwinkqubo yokubumba. Isebenza njengomjelo apho imathiriyeli ekrwada, ngokwesiqhelo i-thermoplastics, iguqulwa ibe ziimveliso ezisebenzisekayo. Uyilo lwe-screw barrel luchaphazela ngokuthe ngqo i-shear kwizinto eziphathekayo, ezichaphazela ukushisa kwe-melt. Obu budlelwane bubalulekile ekufezekiseni ulwakhiwo lwecawa olulolona lufanelekileyo kunye nokunciphisa amaxesha okujikela. Ndifumene ukuba ukusebenzisa i-screw eyenzelwe ngokukodwa izinto eziphathekayo, ezifana ne-HDPE okanye i-PP, iphakamisa kakhulu imveliso kunye nokusebenza kakuhle. Isikrufu senjongo jikelele sinokuthi sibeke esichengeni ukusebenza, nto leyo ekhokelela kukungasebenzi kakuhle.

Indima kwiBlow Molding

Ekubumbeni ukuvuthela, umbhobho ovuthuzayo udlala indima ebalulekileyo ekuqinisekiseni ukufana kwezinto. Ezilandelayoiimpawu zinegalelo kulo mba ubalulekileyo:

| Uphawu | Igalelo kwi-Homogeneity yezinto eziphathekayo |

|---|---|

| Ukuqukuqela kwezinto eziphathekayo | Kubalulekile ukuvelisa iibhotile ezikumgangatho ophezulu kunye neeparini ezifanayo. |

| Ukuphuculwa kweMelt Homogeneity | Iphunyezwe ngeegrooves zehelical kunye nezikrufu zokuthintela, ziqinisekisa nokuba ziyanyibilika. |

| Ukwenziwa ngokwezifiso koYilo | Yenzelwe iresin ezithile, ukunciphisa inkunkuma kunye nokuphucula umgangatho wenxalenye. |

| Ulawulo lobushushu | Ukugcina ukuhamba kwezinto ezifanelekileyo, ukuthintela ukunyibilika okungalinganiyo kunye nokuthotywa. |

Iintsingiselo zangoku kwitekhnoloji ye-screw barrel, efana nophuhliso lwemibhobho ye-bimetallic, iphucula ukuqina kunye nokusebenza. Ezi nkqubela phambili, kunye neenkqubo eziphuculweyo zokufudumeza kunye nokupholisa, zinegalelo kulawulo olungcono lobushushu ngexesha lokulungiswa. Ndiqaphele ukuba olu tshintsho lukhokelela ekucuthweni kweendleko zokusebenza kunye nokuphuculwa komgangatho wemveliso, ukwenza ukhetho olufanelekileyo lokuvuthela i-screw barrel nangakumbi.

Iindidi zokuvuthela i-Screw Barrels

Imigqomo yeSikrikri esinye

Imigqomo ye-screw enyeziphakathi kwezona ntlobo zixhaphakileyo zisetyenziswa ekubumbeni isivuthelo. Ndiyabubulela ubulula kunye nokusebenza kwabo ekunyibilikeni nasekuxubeni imathiriyeli ekrwada. Le migqomo iqinisekisa ukunyakaza okuzinzileyo kweplastiki enyibilikayo ngexesha lokuvelisa, okubalulekileyo ekugcineni uxinzelelo kunye nokuhamba. Ndiqaphele ukuba zisebenza ngokukodwa kumashishini ahlukeneyo, kuquka:

| Ishishini | Inkcazo yesicelo |

|---|---|

| Ishishini lePlastiki | I-Extrusion kunye nenaliti yokubumba imibhobho, amaphepha, kunye neeprofayili. |

| Ishishini lokuPakisha | Ifilimu, iphepha, kunye nokuvuthela izicelo zokubumba. |

| Ushishino lweemoto | Ukwenziwa kwezixhobo zeplastiki kunye neenxalenye zangaphakathi. |

| Ishishini loKwakha | Ukwandiswa kwemibhobho yePVC, iiprofayili zefestile, kunye namaphepha okugquma. |

| Ishishini lokuRecycling | Ukusetyenzwa kwenkunkuma yeplastiki kwiigranuli eziphinda zisetyenziswe. |

Uyilo lombhobho we-screw-screw luvumela ukunyibilika okusebenzayo, okuyimfuneko ekuveliseni iimveliso ezibunjiweyo ezikumgangatho ophezulu. Ndifumanisa ukuba zisebenza ngokukodwa xa zisebenza kunye nezinto ezifana ne-HDPE kunye ne-PP, njengoko zibonelela ngolawulo oluyimfuneko kwi-melt flow.

Imigqomo ye-Twin-Screw

Imigqomo ye-twin-screw ibonelela ngeenzuzo ezibalulekileyo kuyilo lwe-screw-screw, ngakumbi malunga nokuxuba kunye nokulungiswa kwezinto. Ndizibonele ngokwam ukuba izikrufu zazo ezidibanisayo zenza njani isenzo sokuzosula, esonyusa ukusebenza kakuhle kokuxuba. Eli nqaku liqinisekisa ukusasazwa ngokucokisekileyo kwezongezo kunye nemibala, ekhokelela kumgangatho ofanayo wemveliso.

| Uphawu | I-Twin-Screw Extruder | Isikruru Esisodwa |

|---|---|---|

| Ukudibanisa Ukusebenza | Ubuchule bokuxuba obuphezulu ngenxa ye-meshing kunye nokujikeleza | Ikhono lokuxuba elingaphantsi |

| Ukuzinza kwezinto | Ugcina uzinzo kunye nokufana ngexesha lokucubungula | Ukuzinza kancinci ngexesha lokucubungula |

| Isantya Sokukhupha | Isantya sokukhupha ngokukhawuleza | Isantya esicothayo se-extrusion |

| Ukusetyenziswa kwamandla | Ukusetyenziswa kwamandla aphantsi ngeyunithi nganye | Ukusetyenziswa kwamandla aphezulu |

Kwimveliso ephezulu yokubumba imigqomo, imigqomo ye-screw-screw igqwesa ngenxa yesakhono sazo sokuxuba esiphuculweyo kunye nokuphuma okuphezulu. Ndifumene ukuba bayakwazi ukuphatha izinto ezahlukeneyo, kubandakanya iipolymers eziphezulu ze-viscosity kunye neekhompawundi ezingevayo kubushushu, zibenze ziguquguquke kwizicelo ezahlukeneyo.

Imibhobho ye-Barrier-Screw

Imigqomo ye-Barrier-screw barrel idlala indima ebalulekileyo ekulawuleni ukunyibilika kunye noxinzelelo ngexesha lokubumba. Uyilo lwabo lubonisa iziteshi ezihambelanayo eziququzelela ukuguqulwa ngokuthe ngcembe kweepellets eziqinileyo zibe yinyibilika. Olu yilo luphucula ukusebenza kakuhle kwamandla kwaye luqinisekisa ulawulo olungcono lokunyibilika kokunyibilika, okubalulekileyo ekuveliseni iimveliso ezikumgangatho ophezulu.

Izibonelelo zokusebenzisa imigqomo ye-barrier-screw ziquka:

- Ukunyibilika okuphuculweyo kunye nokusebenza kakuhle kokuxuba.

- Ukulawulwa kweqondo lokushisa eliphuculweyo, elithintela ukuthotywa kwezinto ezibucayi.

- Ukuthotywa okucuthiweyo kokutsala, okukhokelela kumgangatho ongcono wokunyibilika.

Ndiqaphele ukuba le migqomo ichaphazela kakhulu umgangatho weemveliso ezigqityiweyo ezibunjiweyo. Banceda ukugcina i-viscosity ye-melt engaguqukiyo, eyimfuneko ekufezekiseni ubuninzi bodonga obufanayo kunye nokunyaniseka kwemveliso.

Ukuxuba-Screw imigqomo

Imigqomo yokuxuba-i-screw yenzelwe ukubaukwandisa umbala kunye nokusasazwa okongeziweyoekubumbeni ukuvuthela. Ndihlala ndisebenzisa isithintelo kunye noyilo lweMaddock, njengoko luqinisekisa ukunyibilika ngcono ukufana kunye nokuthintela amasuntswana anganyibilikiyo ekuvaleni inkqubo. Esi sixhobo sikhokelela kwiziphene ezimbalwa kunye nokuphucula ukuhambelana kombala kwiimveliso zokugqibela.

Izibonelelo zokuxuba-i-screw barrel ziquka:

- Ukuphucula ukusebenza kakuhle kokunyibilika, ukunciphisa ukuthotywa kwe-thermal.

- Umgangatho wokuxuba ophuculweyo, okhokelela kwi-homogenization engcono ye-polymer blends.

- Ulawulo olungcono kuxinzelelo kunye nokuhamba, ukuqinisekisa ukuchaneka kwe-dimensional.

Ndifumanisa ukuba le migqomo inenzuzo ngakumbi xa isebenza kunye ne-polymer blends eyinkimbinkimbi, njengoko ibonelela ngezinto eziyimfuneko kunye nokusebenza kakuhle kwimveliso ephezulu.

Ukukhetha i-Right Blowing Screw Barrel

Izinto Emaziqwalaselwe

Xa ukhetha umbhobho wokuvuthela, ndiqwalasela izinto ezininzi ezibalulekileyo zokuqinisekisa ukusebenza kakuhle. Uhlobo ngalunye lwepolymer luneemfuno ezizodwa ezichaphazela ukhetho lwam. Nantsi eminye imiba ephambili:

- Ukuhambelana kwezinto: Iipolima ezahlukeneyo zifuna uyilo oluthile lwe-screw. Ngokomzekelo, xa ndisebenza kunye ne-PMMA, ndikhetha i-screw encinci kunye nobude-to-diameter ratio ye-20-22 kunye ne-compression ratio ye-2.3 ukuya kwi-2.6. Kwi-PET, ndikhetha i-screw ye-shear ephantsi kunye ne-compression ratio ye-1.8-2, ukuphepha indawo yokuxuba kwisiphelo sangaphambili. I-PVC ifuna uyilo oluphantsi lokucheba kunye nezixhobo zobungqina bokumhlwa kunye nomlinganiselo wobude ukuya kububanzi obuyi-16-20.

- Ijiyometri ekrwada: Ijometri yombhobho we-screw ichaphazela kakhulu ukusetyenzwa. Ndihlala ndibhekisa kwiitafile elandelayo ukukhokela izigqibo zam:

| Uhlobo lweScrew | L/D Umlinganiselo | Inkcazo yesicelo |

|---|---|---|

| Iinjongo jikelele | ~20:1 | Ifanelekile kwiiplastiki eziqhelekileyo kodwa ingabonisa ukuhluka kombala. |

| Izikrufu Zomqobo | ~24:1 | Ukuphucula ukuxutywa kweeplastiki ezomeleziweyo. |

| Izikrufu zokwahlula | ~18:1 | Inceda izixhobo ezingevani nobushushu ziphephe ukuthotywa. |

| Ukuxuba Izikrufu | ~22:1 | Ibonelela ngokunyibilika okufanayo kwiiplastiki ezikhethekileyo. |

- Iimeko zokusingqongileyo: Ndikwanikela ingqalelo kubushushu kunye nokufuma kwegumbi lomatshini. Ukugcina indawo ezinzileyo kunceda ukuthintela ukungasebenzi kakuhle kwezixhobo. Ndiyaqinisekisaubushushu buhlala phakathi kwe 25℃ – 30℃ kunye nokufuma kwi 40% – 60%.

Impembelelo kwiMveliso eFanelekileyo

Umbhobho wokuvuthela ochanekileyo unokunyusa kakhulu ukusebenza kakuhle kwemveliso. Ndiqaphele ukuba isikhonkwane esiyilwe kakuhle sikhulisa ixesha lomjikelo ngokulungelelanisa neenjongo zeprosesa. Nazi ezinye izinto ezinefuthe ekusebenzeni kakuhle:

- Ijiyometri ekrwada: Nantsi keeyona parameter ibalulekileyo echaphazela impumelelokunye nophuhliso loxinzelelo. Uyilo olufanelekileyo lunokukhokelela kumazinga okuvelisa ngokukhawuleza.

- Iinkangeleko zobushushu: Ndifumanisa ukuba iiprofayili zobushushu ezifanelekileyo ezisekwe kuyilo lwesijiva zongeza ukusebenza kakuhle kwamandla, ngokungangqalanga kuchaphazela ixesha lomjikelo. Uyilo oluphuculweyo lwe-screw lunegalelo kuzinzo ngelixa ulungisa iithagethi zexesha lomjikelo.

- Indawo yoxinzelelo: Indawo yocinezelo idlala indima ebalulekileyo kwi-output, ingakumbi kwi-frequencies ephezulu yokujikeleza. Ndiqinisekisa ukuba uyilo lungqamana nemveliso yam kufuneka yandise imveliso.

Impembelelo kuMgangatho weMveliso

Ukukhetha ukuvuthela umbhobho wesikrufu kuchaphazela ngokuthe ngqo umgangatho wemveliso yokugqibela. Ndigxila kwiinkalo ezininzi zokuqinisekisa iziphumo ezikumgangatho ophezulu:

- Melt Quality: I-screw barrel eyenziwe kakuhle igcina i-viscosity ye-melt engaguqukiyo, eyimfuneko ekufezekiseni ubuninzi bodonga obufanayo. Oku kuhambelana kukhokelela kwintembeko yemveliso engcono.

- Ukusetyenziswa kwamandla: Ukusebenza kakuhle kwesikrufu kunye nenkqubo yomgqomo kubalulekile kusetyenziso lwamandla. Ndifundile ukuba ukunxiba kunye nokukrazula kunokukhokelela ekungaphumeleli, ukwandisa ukusetyenziswa kwamandla njengoko isithuba phakathi kwe-screw kunye ne-barrel isanda. Oku kuchaphazela umgangatho wokunyibilika kwaye kufuna amandla amaninzi ukugcina imveliso.

- Iinkqubo zoVavanyo: Ndihlala ndiqhuba uhlolo kwaye ndibeke iliso kwiiparamitha zenkqubo ebalulekileyo njengoxinzelelo, ubushushu, kunye nesantya se-screw. Le ndlela yokusebenza indinceda ndibone imiba kwangoko kwaye ndigcine umgangatho wemveliso.

Ngokuqwalasela ngononophelo ezi zinto, ndingakhetha i-barrel yokuvuthela echanekileyo ehambelana neenjongo zam zemveliso kwaye iqinisekisa imveliso ekumgangatho ophezulu.

Ukukhetha uhlobo lombhobho owomeleleyo kubalulekile ekwandiseni iinkqubo zokubumba isivuthelo. Ndiyakukhuthaza ukuba uhlole iimfuno zakho zemveliso ethile ngaphambi kokuba wenze isigqibo.

Ixabiso elihlawulwe ngeli candelo sisiqalo nje. Ubomi bokusebenza komphanda bunokuba bufutshane ngokuyingozi, kuxhomekeke kwindlela eyenziwe kwaye isetyenziswe ngayo.

Ukukhetha ulwazi kukhokelela ekunciphiseni ukugcinwa kunye nexesha lokunciphisa, ukuqinisekisa inzuzo yeendleko zexesha elide kwimisebenzi yakho.

FAQ

Zeziphi izinto ezinefuthe ekukhetheni umbhobho wesikrufu esivuthelayo?

Ndithathela ingqalelo ukuhambelana kwezinto, ijiyometri ejijwayo, kunye neemeko zokusingqongileyo xa ukhetha umbhobho ovuthuzayo.

Ingaba i-screw barrel iyichaphazela njani impumelelo yemveliso?

I-screw barrel eyilwe kakuhle yongeza ixesha lomjikelo, iphucula i-throughput, kwaye iphucula ukusebenza kakuhle kwamandla, okukhokelela ekunyukeni kwamazinga emveliso.

Ngaba uhlobo lombhobho ojijwayo lunokuchaphazela umgangatho wemveliso?

Ewe, umphanda ochanekileyo wokujija ugcina i-viscosity enyibilikayo engaguqukiyo, iqinisekisa ubukhulu bodonga olufanayo kunye nokuthembeka kwemveliso iyonke.

Ixesha lokuposa: Sep-17-2025