Umbhobho wesikrufu wenaliti yeplastiki umi entliziyweni yayo yonke inkqubo yokubumba. Xa bekhetha umgangatho ophezuluPlastic Machine Screw Barelokanye aPlastic Twin Screw Extruder Barel, abavelisi babona ukuhamba kakuhle kwezinto, iziphene ezimbalwa, kunye neendleko eziphantsi.iStainless Steel Twin Screw Extruder Bareliinketho zikwanceda ukwandisa ubomi besixhobo kunye nokunciphisa ixesha lokuphumla.

Iindima eziphambili zePlastiki yokuSikrola i-Screw Barel

Ukunyibilika kunye neHomogenizing Material yePlastiki

Umphanda we-screw owenziwe ngenaliti yeplastiki udlala indima enkulu ekuguquleni iipellet zeplastiki eziqinileyo zibe yimathiriyeli egudileyo, etyhidiweyo. Ngaphakathi kwi-barrel, i-screw ijikeleza kwaye iqhube iipellets phambili. Njengoko iipellet zihamba, ukukhuhlana kunye neebhanti zesifudumezi ziyanyibilika. Umphanda ugcina ubushushu bulinganayo, ngoko ke iplastiki inyibilika ngesantya esifanelekileyo. Le nkqubo inceda ukuphepha amaqhuma okanye iindawo ezibandayo kwizinto eziphathekayo.

Ingcebiso: I-screw barrel ineendawo ezintathu eziphambili-ukutya, ucinezelo kunye nokulinganisa. Indawo nganye inomsebenzi owodwa. Indawo yokutya iyashukuma kwaye ifudumeza iipellets. Indawo yoxinzelelo iyayinyibilikisa iplastiki kwaye isuse umoya. Indawo yokulinganisa iqinisekisa ukuba inyibilika igudile kwaye ilungele ukutofa.

| Zowuni | Imisebenzi yokuqala |

|---|---|

| Indawo yokutya | Uhambisa iipellet, uzifudumeze kwangaphambili, kwaye uhlanganiselwe ukususa iipokotho zomoya. |

| Indawo yoxinzelelo | Inyibilikisa iplastiki kwaye isuse umoya ngoxinzelelo kunye nokucheba. |

| Indawo yokulinganisa | I-Homogenizes inyibilika, yakha uxinzelelo, kwaye izinzisa ukuhamba ngokutofwa. |

Ukulawula ubushushu kubaluleke kakhulu. Umzekelo, i-UPVC eqinile ifuna ukufudumeza ngononophelo phakathi kwe-180-190 °C. I-screw barrel isebenzisa zombini izifudumezi zangaphandle kunye nentshukumo yesikrufu ngokwaso ukwenza ubungakanani obufanelekileyo bobushushu. Le bhalansi igcina iplastiki ingatshi okanye incamathele. Isantya sesikrufu sikwachaphazela indlela iplastiki inyibilika ngayo. Ukuba isikrufu sijika ngokucotha kakhulu, ukunyibilika kusenokungabi shushu ngokwaneleyo. Ukuba ijika ngokukhawuleza kakhulu, iplastiki inokutshisa kakhulu. Umphanda we-screw wokwenza inaliti yeplastiki uqinisekisa ukuba inyibilika ilungile kuyo yonke imbumbulu.

Ukuxuba izongezo kunye nokuqinisekisa ukuhambelana koMbala

Abavelisi bahlala bongeza imibala okanye izongezo ezikhethekileyo kwiiplastiki. Iplastiki yokubumba umbhobho wesikrufu udibanisa ezi zithako zibe yinyibilika. Uyilo lwe-screw, kunye namacandelo akhethekileyo okuxuba, inceda ukudibanisa yonke into ngokulinganayo. Oku kuxutywa kumisa amabala okanye amabala ukuba angabonakali kwimveliso yokugqibela.

Ukuhambelana kombala kunokuba nzima. Ngamaxesha athile,i-pigments eyomileyo inamathele ngaphakathi kwe-hopper okanye ayixube kakuhle. Ukufuma kunokonakalisa intlaka kunye nomgangatho webala. Idosi echanekileyo yemibala ibalulekile. Oomatshini basebenzisa iiblender zegravimetric ukulinganisa isixa esifanelekileyo. Uyilo lokungunda lukwanceda ukugcina imibala nakwindawo ezahlukeneyo.

Qaphela: Uyilo olukwinqanaba eliphezulu loyilo, njengesithintelo okanye izikrufu zeMaddock, zaphula amaqhuma kwaye zisasaze iimibala ngcono. Ezi ziyilo zinakokhulisa ukusebenza kakuhle kokuxuba ngaphezulu kwe-20% kwaye unciphise amazinga okulahlwa ukuya kuthi ga kwi-30%. Ukucoca rhoqo kunye nokugcinwa kwe-screw barrel isebenza ngokugqibeleleyo, ukuze imibala ihlale iyinyani ukusuka kwibhetshi ukuya kwibhetshi.

Ukuhambisa kunye nokuTofa iPlastiki etyhidiweyo

Nje ukuba iplastiki inyibilikisiwe kwaye ixutywe, i-screw barrel ihambisa imathiriyeli etyhidiweyo kwisingundo. I-screw ijikeleza ngaphakathi kwi-barrel evuthayo, iqhubela inyibilika phambili. Xa imathiriyeli eyaneleyo yakha, isikrufu sisebenza njengeplunger. Igalela iplastiki etyhidiweyo kumngundo ngoxinzelelo oluphezulu.

Nantsi indlela inkqubo esebenza ngayo:

- Iipelisi zeplastiki zingena kwicandelo lokutya kwaye ziqhubele phambili njengoko i-screw ijika.

- I-friction kunye nobushushu bunyibilika iipellet.

- Isikrufu sicinezela ukunyibilika, siqinisekisa ukuba sigudile kwaye silinganayo.

- Isikrufu siqhubela phambili kwaye sifaka iplastiki etyhidiweyo kumngundo.

Iiplastiki naliti yokubumba umphanda jijwaigcina yonke into ihamba kakuhle. Ilawula uxinzelelo kunye nokuhamba, ngoko ukudubula ngalunye kugcwalisa ukubumba ngokugqibeleleyo. Izinto ezinzima zomgqomo ziphakama ukuze zinxibe kwaye zikrazule, ziqinisekisa ukuba inkqubo ihlala ithembekile ekuhambeni kwexesha.

Ukuphucula ukusebenza kunye nePlastiki eLungileyo yokuMonda i-Screw Barrel

Impembelelo ye-Screw Geometry kunye noYilo lwemiphanda

Screw ijometriimilo indlela iplastiki inyibilika ngayo kwaye ixube ngaphakathi komphanda. Ubude, ukumila komsonto, inowuthi, kunye nesantya sesikrufu zonke zidlala indima. Xa iinjineli zihlengahlengisa ezi parameters, zinokulawula ubungakanani bobushushu kunye nokucheba okufunyanwa yiplastiki. Oku kunceda ukudala ukunyibilika okufanayo kunye nokunciphisa iziphene ezifana ne-streaks okanye amaqamza.

Umlinganiselo wokunyanzeliswa, othelekisa ubunzulu bokutya kwe-screw kunye neendawo zokulinganisa iimitha, kuchaphazela indlela iplastiki eqiniswe ngayo. Umlinganiselo ophezulu wonyusa ukuxinana kunye nokuxubana kodwa usenokungafanelani neeplastiki ezingevani nobushushu. Uxinzelelo lwangasemva lubalulekile. Ityhala i-resin etyhidiweyo ngakumbi, iqhekeza amasuntswana anganyibilikiyo kunye nokuphucula ukuxuba. Nangona kunjalo, uxinzelelo oluninzi lwasemva lungonakalisa izinto ezibuthathaka.

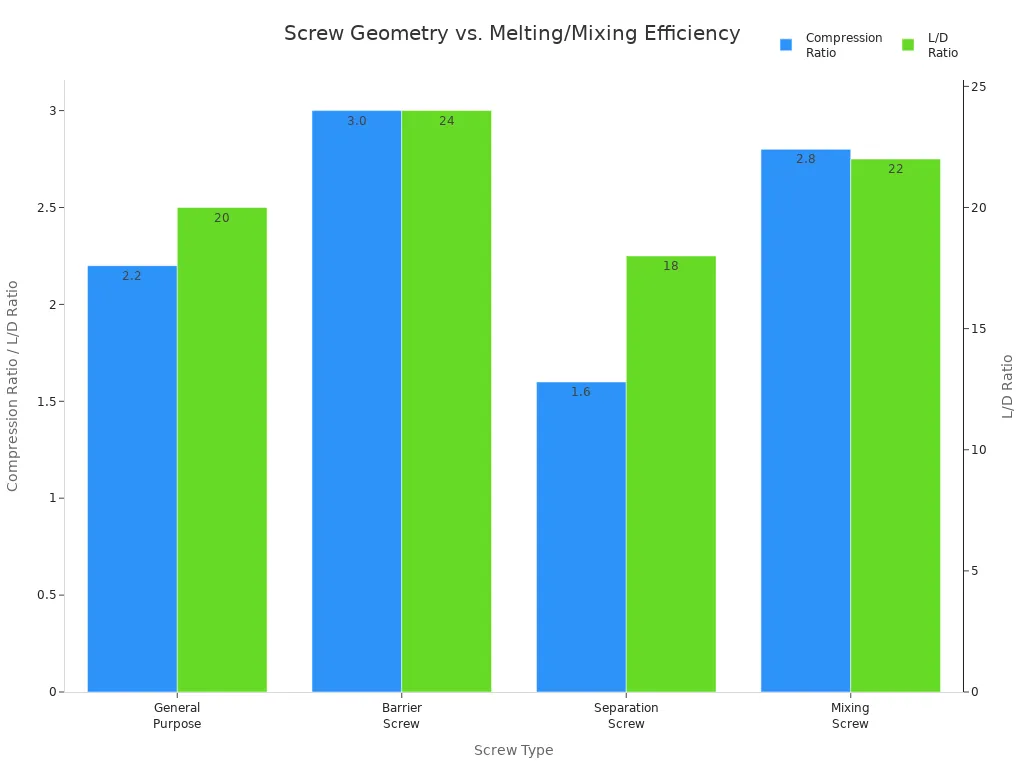

Nantsi itheyibhile ebonisa ukuba iintlobo ezahlukeneyo zezikrufu kunye nejometri yazo zikuchaphazela njani ukunyibilika kunye nokusebenza kakuhle kokuxuba:

| Uhlobo lweScrew | Izinto ezifanelekileyo | Umlinganiselo woxinzelelo | L/D Umlinganiselo | Ukusetyenziswa okuqhelekileyo | Impembelelo ekunyibilikeni nasekuxubeni ngokuFanelekileyo |

|---|---|---|---|---|---|

| Iinjongo jikelele | ABS, PP, PE | 2.2:1 | 20:1 | Izindlu zesixhobo | Ukunyibilika okuguquguqukayo kunye nokuxuba kunye nokucheba okuphakathi kunye nokufana. |

| I-Barrier Screw | PA+GF, PC | 3.0:1 | 24:1 | Amacandelo Olwakhiwo | Ukucheba okuphezulu kunye nokuxuba, ngcono ukunyibilika kwe-homogeneity kunye nomgangatho wemveliso. |

| Ukwahlula Screw | I-PVC, i-POM | 1.6:1 | 18:1 | Imibhobho, Amacandelo | Ilawula ukucheba, inciphisa ukuthotywa, iqinisekisa ukunyibilika okufanayo. |

| Ukuxuba Screw | PMMA, PC+GF | 2.8:1 | 22:1 | Izigqubuthelo zokukhanya | Ukuxuba okuphuculweyo, ukunyibilika okufanayo, ukuphuculwa kweempawu ze-optical. |

Iinjineli zihlala zisebenzisa iitshathi ukuthelekisa ijiyometri yesikrufu. Itshathi engezantsi ibonisa ukuba umlinganiselo woxinzelelo kunye nomlinganiselo we-L/D wahluka njani kwiindidi zezikrufu ezahlukeneyo:

I-Plastiki ye-Injection yokubumba i-screw barrel eyenziwe kakuhle kunye nejometri efanelekileyo iqinisekisa iplastiki ezinzileyo, ubushushu obungaguqukiyo bokunyibilika, kunye nokuhamba kwezinto ezigudileyo. Oku kukhokelela kwiglosi engcono, iziphene ezimbalwa, kunye neendawo ezibunjiweyo ezomeleleyo.

UKhetho lweMathiriyeli yoKuhlala ixesha elide kunye nokuNxitywa kokuNxitywa

Ukukhetha izixhobo ezifanelekileyo ze-screw barrel kwenza umahluko omkhulu kwindlela ehlala ngayo kunye nokuba isebenza kakuhle kangakanani. Abavelisi basebenzisa iintsimbi ezomeleleyo kunye neengubo zokwaleka eziphambili ukulwa nokunxiba kunye nokudleka. Ngokomzekelo, i-38CrMoAlA insimbi ye-nitrided isebenza kakuhle kwimisebenzi esemgangathweni, ngelixa i-SKD61 (H13) insimbi yesixhobo ibamba ii-resin zobunjineli ezinzima. Imibhobho ye-Bimetallic ene-tungsten carbide okanye i-nickel-based alloys inika ukuchasana okuphezulu kwi-abrasion kunye neekhemikhali.

| Uhlobo lwezinto eziphathekayo | Nxiba ukuxhathisa | Ukunyangwa kokuMhlwa | Ubulukhuni obuqhelekileyo | Iimbalasane zeSicelo |

|---|---|---|---|---|

| 38CrMoAlA Nitrided Steel | ★★★☆☆ | ★★☆☆☆ | ~1000 HV (Nitrided) | Ithembekile kwizicelo eziqhelekileyo |

| SKD61 (H13) Isixhobo sentsimbi | ★★★★☆ | ★★★☆☆ | 48–52 HRC | Iirensi zobunjineli ezinzima, uxinzelelo lwe-thermal |

| Iibhareli zeBimetallic | ★★★★★ | ★★★★☆ | 60–68 HRC | I-Abrasive, i-fiberglass, i-flame retardant, iiplastiki ezisetyenzisiweyo |

Olunye ukhetho oludumileyo lubandakanya i-AISI 4140 kunye ne-4340 i-alloy steels yokusetyenziswa ngokubanzi, i-D2 kunye ne-CPM yesixhobo sentsimbi yeeplastiki ezinqabileyo, kunye ne-Hastelloy okanye i-Inconel yeendawo ezinobungozi. Unyango lwakumphezulu olufana ne-nitriding kunye ne-chromium plating zonyusa ubulukhuni kunye nobomi. Xa abavelisi bekhetha izinto ezifanelekileyo, banciphisa ixesha lokunciphisa kunye neendleko zokulondoloza, ukugcina imveliso ihamba kakuhle.

Ingcebiso: Imigqomo ye-Bimetallic enomxholo ophezulu we-tungsten carbide ihlala ixesha elide, ngakumbi xa ilungisa i-abrasive okanye i-polymers egcweleyo.

Ukuthelekisa iScrew Barrel kwiiPlastiki ezahlukeneyo

Ayizizo zonke iiplastiki eziziphatha ngendlela efanayo ngexesha lokubumba. Uhlobo ngalunye ludinga uyilo oluthile lwe-screw barrel ukufumana iziphumo ezilungileyo. Iinjineli zijonga ubushushu obunyibilikayo beplastiki, imbonakalo yayo kunye nokuzinza kwayo. Badibanisa ijiyometri ejikijelwayo, ubunzulu begroove, kunye neengubo zokwaleka zemibhobho kwiimfuno zemathiriyeli.

Ngokomzekelo, i-polycarbonate (i-PC) idinga i-screw ende kunye nomlinganiselo wokunyanzeliswa ngokuthe ngcembe kunye necandelo lokuxuba ukukhusela ukuthotywa. Inayiloni (PA) idinga isikrufu esiguqukayo esinomlinganiselo ophezulu wocinezelo kunye nomsantsa omncinci phakathi kwesikrufu kunye nomphanda ukulawula ukucheba. I-PVC ifuna umphanda ongagugiyo kunye nesikrufu esichetywayo esisezantsi ukunqanda ukutshisa kakhulu kunye nokwakhiwa kwezinto.

| Uhlobo lwePlastiki | Iiparamitha zoYilo lweScrew | Impembelelo kuMgangatho |

|---|---|---|

| Polycarbonate (PC) | Umlinganiselo omkhulu we-L / D (~ 26), i-screw ngokuthe ngcembe, i-compression ratio ~ 2.6, icandelo lokuxuba | Iplastiki enhle, ikhusela ukuthotywa, iphucula i-homogeneity |

| Inayiloni (PA) | Mutant screw, L / D 18-20, compression ratio 3-3.5, umsantsa encinane | Ithintela ukushisa, ilawula ukucheba, igcina umgangatho wokunyibilika |

| PMMA | Screw kancinane, L/D 20-22, compression ratio 2.3-2.6, ukuxuba ring | Ukunyibilika ngokuchanekileyo, kuthintela imiba yokufuma, kugcina ukuchaneka |

| I-PET | I-L / D ~ 20, i-screw ye-shear ephantsi, i-compression ratio 1.8-2, akukho ndawo yokuxuba | Ithintela ukushisa, ilawula ukucheba, ilungele izinto ezisetyenzisiweyo |

| I-PVC | Isikrufu sokucheba esisezantsi, umphanda onganyanyekiyo, L/D 16-20, akukho msesane wokutshekisha | Ikhusela ubushushu kunye nokugqwala, ulawulo oluzinzileyo lobushushu |

Ukutshatisa umbhobho wesikrufu wePlasitiki wePlastiki kunceda ukunqanda iziphene ezifana nokutshintsha kombala, ukunyibilika okungagqibekanga, okanye ukugoba. Ikwaphucula amaxesha omjikelezo kunye nokusebenza kakuhle kwamandla.

Qaphela: Ukuphucula imigqomo ye-screw kwiiplastiki ezithile kunokunyusa umthamo ukuya kuthi ga kwi-25% kwaye kunciphise iziphene, ukonga ixesha kunye nemali.

Iingcebiso zoLondolozo kuBomi obude kunye nokuthembeka

Ukugcinwa rhoqo kugcina i-screw barrel isebenza kangangoko. Abanini-zithuthi kufuneka bahlole umphanda ukuba unxitywe na, ukukrweleka, okanye ukugqobhoza nanini na xa isikrufu sisusiwe. Ukucoca ngeekhompawundi zokuhlanjululwa kwezorhwebo kususa intsalela kwaye kuthintele ukwakhiwa kwekhabhoni. Uxinzelelo lokubek'esweni, ubushushu, kunye nesantya se-screw kunceda ukubona iingxaki kwangethuba.

Nanga amanye amacebiso olondolozo olusebenzayo:

- Jonga umgqomo wesikrufu ngokubonakalayo kunye neegeyiji ngalo lonke ixesha kususwa isikrufu.

- Coca umgqomo qho ngeveki xa uqhuba, okanye qho ngeentsuku ezi-2-3 ukuba utshintsha iiplastiki rhoqo.

- Thambisa iindawo ezihambayo yonke imihla kwaye uzithambise ngeveki ngegrisi ekumgangatho ophezulu.

- Sebenzisa imathiriyeli ekrwada esulungekileyo kwaye uyigcine ngokufanelekileyo ukuthintela ukosuleleka.

- Ukuqeqesha abasebenzi ukuba baqaphele iimpawu kunye nokugcina iinkcukacha zokulondolozwa.

- Iindawo ezisecaleni zesitokhwe zokunciphisa ixesha lokuphumla.

- Emva kokuvalwa, sebenzisa isikrufu ngesantya esisezantsi ukuze usasaze iplastiki eshiyekileyo, coca ngezicoci ezikhethekileyo, kwaye usebenzise ioyile ekhuselayo.

I-Callout: Imibhobho ye-Bimetallic ene-iron-based liners ingahlala ngokuphindwe kathathu kunezikrini eziqhelekileyo.Ukulungelelaniswa okufanelekileyo kunye nokuthambisaukwandisa ubomi kunye nokunciphisa ukugcinwa rhoqo.

I-Plassic Injection molding screw barrel egcinwe kakuhle ihambisa umgangatho ongaguqukiyo, inciphisa ixesha lokuphumla, kwaye ixhasa imveliso esebenzayo.

I-Plastic Injection molding screw barrel idlala indima ephambili ekunikezeni umgangatho wemveliso ohambelanayo kunye nemveliso esebenzayo.

- Imigqomo ye-screw ekumgangatho ophezulu iphucula ukunyibilika kokunyibilika, ukunciphisa i-scrap, kunye nokwandisa ukusebenza kakuhle.

- Ukugcinwa rhoqo kuthintela ixesha lokuphumla kunye nokwandisa ubomi besixhobo.

- Izinto eziphathekayo kunye nokugcinwa kwamandla kongeza ngokukhawuleza.

- Ukutshintsha ngokukhawuleza konyusa umthamo kunye nenzuzo.

FAQ

Zeziphi iimpawu ezibonisa ukuba umgqomo wesikrufu ufuna ukutshintshwa?

Abaqhubi baqaphela ukunyibilika okungalinganiyo, ukwanda kweziphene, okanye imijikelo ecothayo. Baphinde babone ukunxiba okubonakalayo, imikrwelo, okanye imingxuma ngaphakathi kombhobho.

Kukangaphi umntu kufuneka ecoce umphanda ojijwayo?

Uninzi lwabavelisi bacoca umgqomo ngeveki. Ukuba batshintsha iiplastiki rhoqo, bazicoca rhoqo emva kweentsuku ezimbini ukuya kwezintathu.

Ngaba umphanda omnye ojijwayo ungasebenza kuzo zonke iiplastiki?

Hayi, uhlobo ngalunye lweplastiki ludinga uyilo oluthile lombhobho we-screw. Ukusebenzisa umdlalo ochanekileyo kuphucula umgangatho wemveliso kwaye kunciphisa inkunkuma.

Ixesha lokuposa: Aug-15-2025