I-twin yeplastiki ye-screw barrel ibumba ukusebenza kakuhle kunye nomgangatho wemigca ye-extrusion yanamhlanje. Iinkokeli zentengiso ziqaqambisa indima yayo kuzinzo kunye nokusungula izinto ezintsha.

- Abavelisi babona ukunyuka kwemfuno njengothungelwano lwe-sensor ehlakaniphile kunye nabalawuli abaqhutywa yi-AI baphucula ukusetyenziswa kwamandla kunye nokunciphisa ixesha lokuphumla.

- I-Twin Parallel Screw Barel Abavelisixela ukwamkelwa okumandla ngenxa yokuqina okuphuculweyo kunye nokwenza ngokwezifiso.

- Iibhareli zeScrew eziNyekwayeIifektri zePlastiki enye yeScrew Barelisadlala indima, kodwa uyilo lwamawele ngokulawula ngaphezulu kwesiqingatha semarike yaseMelika.

Imisebenzi engundoqo ye-Twin Plastic Screw Barrel

Ukuhanjiswa kwezinto kunye nokuxuba

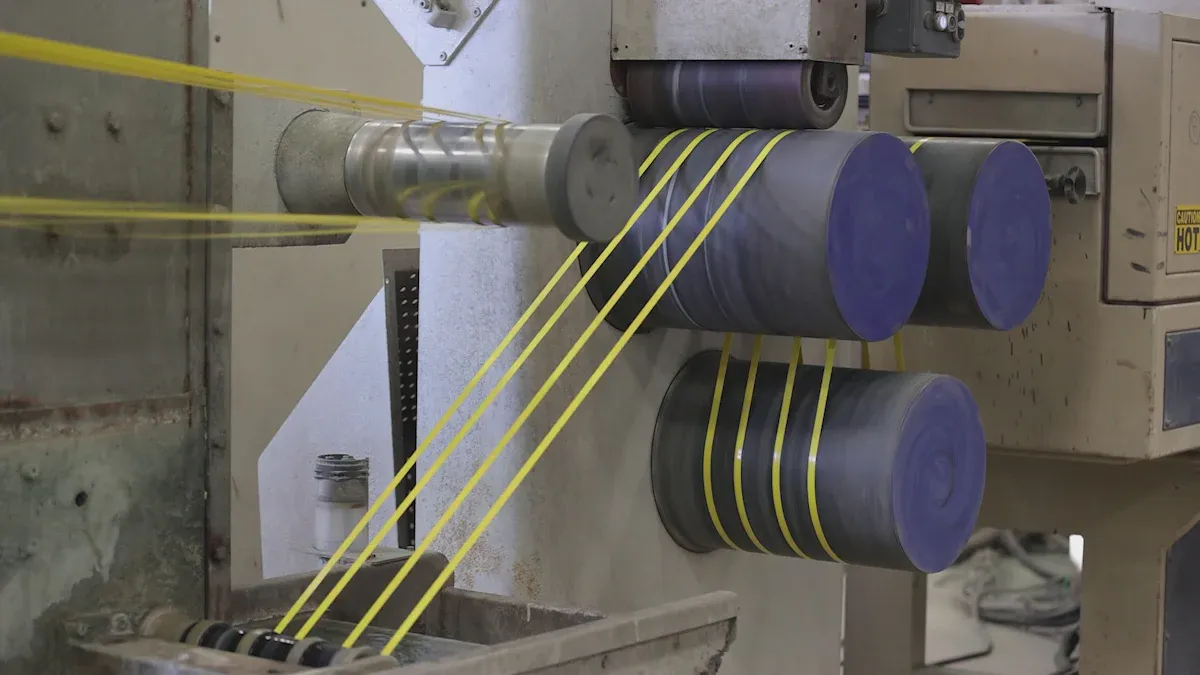

Umphanda we-screw weplastiki iwele udlala indima ebalulekileyo ekushukumeni nasekudibaniseni izinto ezikrwada ngaphakathi kwi-extruder. Iinjineli ziyila iinqwelomoya ezijijwayo ukuze zibambe kwaye zityhale iigranule zeplastiki phambili. Esi senzo siqinisekisa ukuba izinto zihamba kakuhle ukusuka kwindawo yokutya ukuya kwindawo yoxinzelelo. Abaphandi baye bafunda indlela le migqomo esebenza ngayo kwaye bafumana amanqaku amaninzi abalulekileyo:

- I-Potente kunye ne-Melish yahlula indawo yokuhambisa kwiindawo zokutya kunye noxinzelelo. Basebenzisa amandla kunye ne-torque balances ukubala imveliso ephezulu kakhulu, utshintsho loxinzelelo, kunye namandla afunekayo ukuqhuba izikrufu. Umsebenzi wabo ubonisa ukuba i-plastic screw barrel ye-twin ihambisa izinto eziqinileyo nezizinzileyo.

- U-Wilczyński no-White baqaphela ukuba iigranuli ezininzi zeplastiki zihamba kwindawo esezantsi yomphanda, kufutshane ne-screw flights. Umphanda kunye nezijija zifudumeza iigranules njengoko zihamba, nto leyo ebanceda ukuba banyibilike ngokulinganayo.

- Ezinye iingcaphephe, ezifana noMhlophe kunye ne-Bawiskar, zenze iimodeli ezichaza indlela i-plastic screw barrel ewenza ngayo umaleko onyibilikayo kwaye ixube iindawo eziqinileyo kunye nezilulwelo. Ezi modeli zinceda iifektri ukuba ziqonde kwaye ziphucule ukuxuba kunye nokunyibilika.

I-twin yeplastiki ye-screw barrel iqinisekisa ukuba yonke inxalenye yempahla iyaxutywa kwaye ishushu. Le nkqubo ikhokelela kumgangatho ongcono wemveliso kunye neziphene ezimbalwa.

Ukunyibilika, i-Homogenization, kunye noLawulo loxinzelelo

Ukunyibilika kunye nokudibanisa iplastiki ngokulinganayo ngomnye umsebenzi ongundoqo we-twin screw barrel. Umphanda kufuneka kwakhona ulawule uxinzelelo ukugcina inkqubo izinzile. Iinjineli zisebenzisa izinto ezininzi zoyilo ukufezekisa ezi njongo. Le theyibhile ilandelayo ibonisa indlela iiparamitha zesikrufu ezahlukeneyo kunye neemeko zenkqubo ekuchaphazela ngayo ukunyibilika, ukudibanisa, kunye noxinzelelo:

| Screw Parameter | Impembelelo / Iinkcukacha zamanani |

|---|---|

| L/D Umlinganiselo | Umlinganiselo ophezulu we-L / D uphucula ukudibanisa i-polymer kunye neplastiki ngokwandisa ixesha lokuhlala kunye nokusabalalisa ubushushu |

| Umlinganiselo woxinzelelo | Imilinganiselo yoxinzelelo oluphezulu yonyusa iplastiki kunye noxinaniso; amaxabiso afanelekileyo axhomekeke kuhlobo lwemathiriyeli |

| Imilinganiselo yokuNxinzelela kwiiPlastiki eziqhelekileyo | I-PE: 3-4, i-PP: 2.5-4, i-PS: 2-4, i-PVC eqinile (i-Granules): 2-3, i-PVC eqinile (i-Powder): i-3-4, i-PVC e-Flexible (i-Granules): 3.2-3.5, i-PVC e-Flexible (i-Powder): 3-5, 5.5, 6:-2. I-POM: 2.8-4, i-PPE: 2-3.5, i-PA66: 3.7, i-PA1010: i-3, i-Polyester eyongeziweyo: 3.5-3.7 |

| Ipharamitha / Umba | Isiphumo samanani / iNkcazelo |

|---|---|

| Uxinzelelo kwigumbi elimilise u-C | Ngokumalunga ne-2.2 MPa |

| Ukuhla koxinzelelo kwindawo yokuhlangana | 0.3 MPa |

| Uxinzelelo lwehla kwi-screw element | 0.5 MPa |

| Ukunyuka kobushushu ngenxa yoxinzelelo | Uxinzelelo lwe-bar ye-40 lubangela ~ 20 ° C ukunyuka kweqondo lokushisa |

| Elona nqanaba lokutya kunye nesantya sokujija | I-3.6 kg / ireyithi yokutya kwi-95 rpm iphakamisa ubushushu kwaye inciphise ukuphuka kwefayibha |

| Umthombo wokuvelisa ubushushu | Malunga ne-80% yobushushu obunyibilikayo obuveliswa kukukhuhlana kweeshear |

| Isiphumo sesantya se-screw kuxinzelelo | Uxinzelelo oluqokelelweyo lonyuka ngokulandelelana kunye nesantya sokujija |

| Impembelelo yesantya sesondlo kuxinzelelo | Uxinzelelo oluqokelelweyo luyehla ngesantya sokutya |

Ezi ziphumo zibonisa ukuba umphanda we-screw weplastiki iwele unokulawula ukuba kungakanani ubushushu kunye noxinzelelo olufunyanwa yimathiriyeli. Izicwangciso ezifanelekileyo zinceda iplastiki inyibilike ngokupheleleyo kwaye idibanise kakuhle. Olu lawulo lukhokelela kwiimveliso ezinamandla, ezifanayo.

Ukuzicoca kunye nokuzinza kweNkqubo

I-twin yeplastiki ye-screw barrel ikwanceda ukugcina i-extruder icocekile kwaye izinzile. Uyilo lwe-screws kunye ne-barrel luvumela ukuzicoca. Njengoko izikrufu zijikeleza, zosulana kunye nodonga lomgqomo. Esi senzo sisusa izinto eziseleyo kwaye sithintele ukwakheka. Imigqomo ecocekileyo inciphisa ixesha lokuphumla kwaye igcine inkqubo isebenza kakuhle.

Uzinzo lwenkqubo yenye inzuzo. Umphanda we-screw weplastiki iwele ugcina uxinzelelo kunye nobushushu kuyo yonke inkqubo ye-extrusion. Oku kuzinza kuthetha ukuba umatshini unokusebenza ixesha elide ngaphandle kweengxaki. Iifektri zinokuvelisa iimveliso ezininzi ezineendawo zokumisa ezimbalwa kunye nenkunkuma encinci.

Ingcebiso: Ukugcinwa rhoqo kunye nokubekw'esweni kwe-twin screw barrel yeplastiki kunokuphucula ngakumbi inkqubo yokuzinza kunye nokwandisa ubomi besixhobo.

Ukuqhubela phambili kunye neMpembelelo yokwenyani yehlabathi yeTwin Plastic Screw Barrel ngo-2025

Izinto eziNtsha kunye neeNgqungquthela zoKuhlala ixesha elide

Abavelisi ngoku basebenzisa izixhobo eziphucukileyo kunye neengubo ukwenza amawele eplastiki yesikhonkwane umbhobho ahlale ixesha elide kwaye asebenze ngcono. Insimbi engenasici, i-CPM10V, i-ceramics, kunye neengubo ze-tungsten carbide zinceda umgqomo ukuxhathisa ukunxiba kunye nokubola. Ezi zixhobo zigcina umgqomo womelele nangona ujongene namaqondo obushushu aphezulu kunye noxinzelelo ngexesha lokukhutshwa kweplastiki. Iimvavanyo zentsebenzo zibonisa ukuba ezi zogquma ziphucula ukusebenza kakuhle kokuxuba kunye nokugcina inkqubo izinzile. Umzekelo, unyango lwe-nitriding lunokufikelela kumanqanaba obunzima be-HRC50-65, enceda umphanda ukuxhathisa ukukrazuka. Idatha yehlabathi yokwenyani evela kwiifektri ibonisa ukuba olu phuculo lunciphisa ixesha lokuphumla kwaye luthintele ukuvuza. Amaqela olondolozo nawo anika ingxelo yokuba le migqomo ifuna ukulungiswa okumbalwa kwaye ihlala ixesha elide, nto leyo yonga imali kwaye igcine imveliso isebenza kakuhle.

Izilingo zelebhu, ezifana nezo zisebenzisa i-Coperion ZSK 18 MEGAlab, iinjineli zoncedo zokuvavanya izixhobo ezintsha kunye neengubo. Olu vavanyo lulinganisa ukuba umphanda uphatha njani iiplastiki ezahlukeneyo kunye nezongezo. Iziphumo zibonisa ukuba iingubo ezitsha ziphucula ukuzinza kwe-thermal kunye nokumelana nokunxiba. Iinkampani zibona ukophuka okumbalwa kunye nomgangatho wemveliso ongcono ngenxa yolu hlaziyo.

Ubunjineli obuchanekileyo kunye noYilo lwemibhobho yeModyuli

Ubunjineli obuchanekileyo bubumba yonke indawo yebhareli ye-screw yeplastiki engamawele. Iifektri zisebenzisa oomatshini be-CNC kunye nokutshekisha umgangatho ongqongqo ukuqinisekisa ukuba umphanda ngamnye uhlangabezana nemigangatho echanekileyo. Iinjineli zilinganisa ukutyeka kwesikrufu ukuya kwi-0.015 mm kunye noburhabaxa bomphezulu ukuya kwi-Ra 0.4. Oku kunyamezelwa okuqinileyo kunceda umxube we-barrel kwaye unyibilikise iplastiki ngokulinganayo.

Uyilo lwemibhobho yemodyuli ivumela utshintsho olukhawulezayo kunye nokulungiswa. Abasebenzi banokutshintsha amacandelo agugileyo ngaphandle kokuwahlula umatshini wonke. Olu luyilo luyanciphisaixesha lokuphumla ukuya kuthi ga kwi-20% kwaye unciphise iindleko zokulungisa ukuya kuthi ga kwi-30%. Itheyibhile engezantsi ibonisa uphuculo oluphambili:

| Ipharamitha | Ixabiso lamanani/uluhlu |

|---|---|

| Ukunciphisa ixesha lokuphumla ngenxa yokumodareyitha | Ukuya kuma-20% |

| Ukunciphisa iindleko zokulungisa ngenxa yokumodareyitha | Ukuya kuthi ga kwi-30% |

| Ukuqina komphezulu we-nitrided (HV) | 920 - 1000 |

| Ukuqina kwengxubevange (HRC) | 50 – 65 |

| Screw ngokuthe ngqo | 0.015 mm |

| Uburhabaxa bobuso (Ra) | 0.4 |

Olu phuculo lunceda iifektri zigcine imiphanda yazo yeplastiki engamawele ikwimo ephezulu, ekhokelela ekusebenzeni ngcono kunye nenkcitho encinci.

Ukudityaniswa ne-Smart Manufacturing kunye ne-Automation

Imveliso ehlakaniphile kunye ne-automation itshintshile indlela iifektri ezisebenzisa ngayo i-barrel ye-screw yeplastiki. Iinkqubo ezizenzekelayo ngoku zilawula ubushushu, uxinzelelo, kunye nesantya ngokuchaneka okukhulu. IiNkqubo zokuSebenza zokuSebenza (MES) zinceda ukulandelela inyathelo ngalinye lenkqubo. Ezi nkqubo ziyakhulaisantya semveliso ngama-40-50% kwaye sinciphise ixesha lokuphumla ukuya kuthi ga kwi-30%. Ukugcinwa rhoqo, okukhokelwa zizinzwa kunye nedatha, kugcina oomatshini besebenza ixesha elide.

Le theyibhile ingezantsi iqaqambisa ezinye iimpembelelo ezinokulinganiswa:

| Inkalo yoPhuculo | Impembelelo enokumetwa |

|---|---|

| Isantya seMveliso | Inyuswe ngama-40-50% |

| Ukunciphisa ixesha lokuphumla | Yehliswe ukuya kuthi ga kwi-30% |

| Uphuculo lobuchule (MES) | Ukuya kuthi ga kwi-25% inzuzo |

| UkuPhuculwa kokuHamba kwezinto | I-RTD efanayo, iziphene ezimbalwa kunye nenkcitho encinci |

| Ukusetyenziswa kwamandla | Ngaphantsi kuneendlela zemveli |

| Iindleko zokuSebenza | Incitshiswe ngokusetyenziswa kobutyebi obungcono |

| Umgangatho weMveliso | Iphuculwe rhoqo |

Iifektri ezisebenzisa iinkqubo eziqinisekisiweyo ze-ISO9001 ezinemibhobho ye-screw ephucukileyo zibona imisebenzi egudileyo kunye nomgangatho ophezulu wemveliso. Abathengi bafumana iimveliso ezingcono, kwaye iinkampani zihlala zikhuphisana kwimarike.

Ukusebenza kakuhle, uMgangatho weMveliso, kunye neeNzuzo zokuZinza

Umphanda we-screw weplasitiki uzisa iinzuzo ezicacileyo ekusebenzeni, umgangatho, kunye nozinzo. Uphuculo kwiimotor kunye nokugcina iidriveI-10-20% kumandla. Amandla okufudumeza ahla nge-10%, kwaye amaxesha omjikelezo awela kwi-30 ukuya kwi-15 imizuzwana ngokupholisa okungcono. Iinkqubo zokubuyiswa kobushushu zithatha ukuya kutsho kwi-15% yamandla alahlekileyo, zehlisa iindleko nangakumbi.

Le theyibhile ingezantsi ishwankathela olu ncedo:

| Ubuchule kunye noZinzo | Ubalo oluxhasayo okanye iNkcazelo |

|---|---|

| Ukonga Amandla | 10-20% ukunciphisa |

| UkuSebenzisa uKufudumeza | I-10% yamandla angaphantsi, ixesha lomjikelo lifinyezwe ngesiqingatha |

| Inkunkuma yoBuyisa ubushushu | Ukuya kuthi ga kwi-15% amandla alahlekileyo afunyenwe |

| Ixabiso lePlastiki | Ukunyuka ukusuka kwi-104 g / s ukuya kwi-120 g / s |

| Ixesha lokuBuyisa | Isiqingatha ukusuka kwi-18 ukuya kwi-9 |

| Ugcino oluqikelelweyo | Ixesha lokuphumla licuthwe nge-15-30% |

| I-Eco-friendly Materials | Ukungqubuzana okuncinci kunye nokunxiba |

| Umgangatho weMveliso owomeleziweyo | 90% iziphene ezimbalwa, imveliso engcono |

| UkuNcitshiswa kweNkunkuma | Inkunkuma yempahla ekrwada esezantsi |

Olu phuculo lunceda iifektri zenze iimveliso ezininzi ezinamandla amancinci kunye nenkunkuma. I-twin ye-screw barrel yeplastiki ixhasa ukwenziwa okuzinzileyo ngokunciphisa iziphene kunye nokusebenzisa izixhobo ngobulumko.

Qaphela: Iinkampani ezifana neZhejiang Jinteng Machinery Manufacturing Co., Ltdubunjineli obuphambilikunye neenkqubo ezingqongqo ezisemgangathweni ukuhambisa imigqomo ethembekileyo yeplastiki yamawele. Iimveliso zabo zinceda iifektri ukuba zifezekise iimfuno zokusetyenzwa kweeplastiki zanamhlanje ngo-2025.

I-Twin Plastic Screw Barrel imi entliziyweni yetekhnoloji ye-extrusion yanamhlanje. Abavelisi bafumana impumelelo ephezulu, ubomi benkonzo obude, kunye nomgangatho wemveliso ongaguqukiyo.

- Ulwakhiwo oluzinzileyokunciphisa iindleko zokubuyisela

- Ubunjineli obuchanekileyo buphucula ukusetyenziswa kwamandla

- Uyilo oluguquguqukayo luxhasa usetyenziso olwahlukeneyo

Ezi mpawu ziqhuba impumelelo yexesha elide kwimarike ekhulayo yehlabathi.

FAQ

Yintoni eyenza umphanda weplasitiki wamawele ubaluleke kakhulu kwii-extruders zanamhlanje?

Imiphanda yeplastiki ephindwe kabini ibonelela ngokuxuba okuchanekileyo, ukunyibilika, kunye nolawulo loxinzelelo. Ezi mpawu ziqinisekisa umgangatho ophezulu wemveliso kunye nokusebenza ngokufanelekileyo kwimigca ye-extrusion ephezulu.

Ingcebiso: Ukusebenza okungaguqukiyo kuxhomekeke kwisikrufu esifanelekileyo kunye noyilo lombhobho.

Kukangaphi apho iifektri kufuneka zigcine imiphanda yeplastiki engamawele amabini?

Iifektri kufuneka zihlole kwaye zicoce imigqomo rhoqo. Uninzi lweengcali zincoma ukuhlolwa kwenyanga ukuthintela ukuguga, ukwakhiwa, kunye nexesha elingalindelekanga.

- Ukugcinwa rhoqo kwandisa ubomi besixhobo.

- Ukufunyanwa kwangaphambili kwemiba kunciphisa iindleko zokulungisa.

Ingaba abavelisi bawukhetha njani umphanda weplasitiki ongamawele ofanelekileyo?

Abavelisi bakhetha imigqomo esekelwe kuhlobo lwezinto eziphathekayo, iimfuno zemveliso, kunye neenkcukacha zoomatshini. Ukubonisana nababoneleli abanamava kuqinisekisa ukusebenza ngokugqibeleleyo kunye nokuqina.

| Into yoKhetho | Inqanaba lokubaluleka |

|---|---|

| Uhlobo lwezinto eziphathekayo | Phezulu |

| Imfuno yokuPhuma | Phezulu |

| Imodeli yomatshini | Phakathi |

Ixesha lokuposa: Jul-03-2025