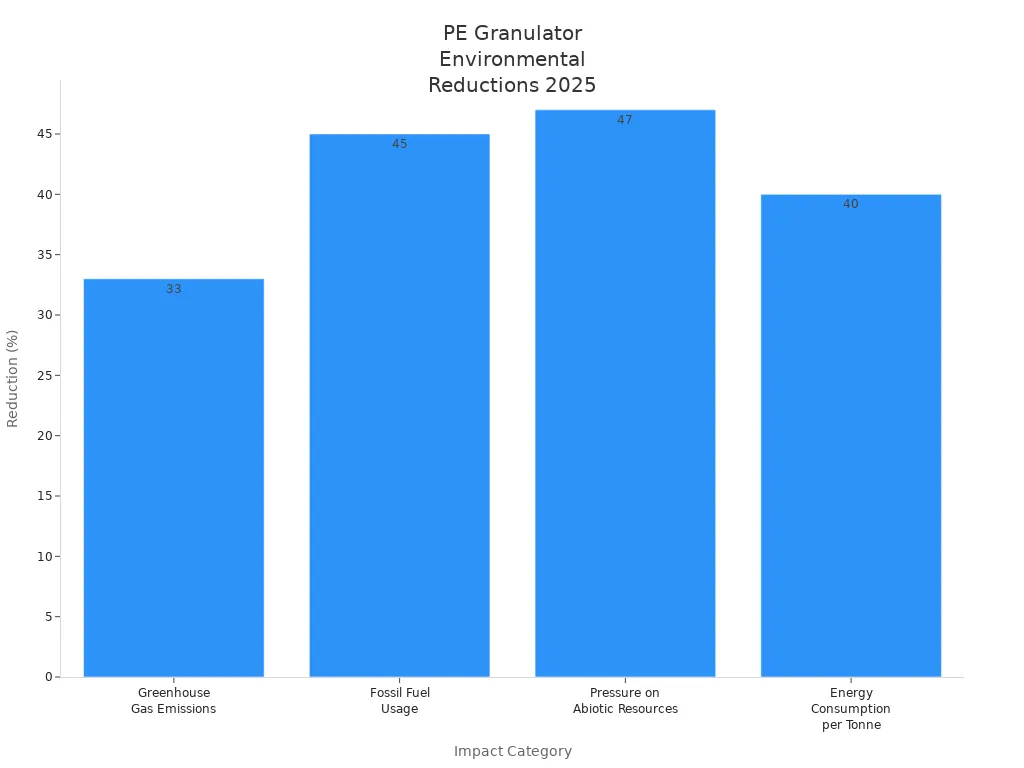

Iigranulator ze-PE ezincinci zokusingqongileyo ngo-2025 zisebenzisa iimotor ezinomgangatho ophezulu, ukuphuculwa kwenkqubo, kunye nexesha lokwenyani lokuzenzekelayo ukusika ukusetyenziswa kwamandla. Abaqhubi babona iziphumo ezikhawulezileyo, ezinje ngeI-40% yehla kusetyenziso lwamandla ngetoni nganyexa kuthelekiswa nemveliumatshini wokujija omnye or kuphume isikrufu esinyeiinkqubo. Inkunkuma yokubuyisela ubushushu nayo ixhasaumatshini wegranulator ongenamanziimisebenzi.

| Metric | Ukuncipha okuphunyeziweyo ngo-2025 xa kuthelekiswa neMinyaka edlulileyo |

|---|---|

| UkuNcitshiswa kokukhutshwa kweGesi yokuGcina | I-33% iyancipha |

| UkuNcitshiswa koSetyenziso lweFossil | I-45% iyancipha |

| Uxinzelelo kwiZibonelelo zeAbiotic | I-47% iyancipha |

| Ukusetyenziswa kwamandla ngeToni nganye | Isezantsi nge-10 kW-h/toni, ngama-40% ngaphantsi kwezixhobo zemveli |

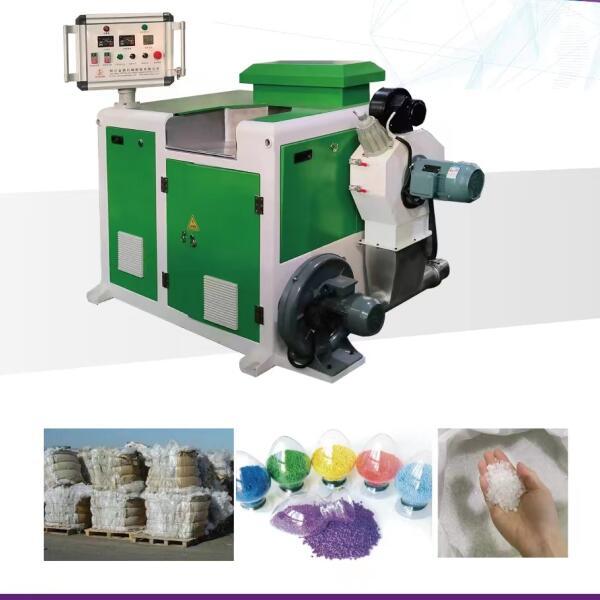

PE Small Environmental Granulators: Energy-Saving Technologies

IiMotor eziSebenza ngokuPhezulu kunye neZixhobo zoThutho

I-PE encinci ye-granulators yokusingqongileyo kwi-2025 ithembele kuyoiimotor eziphezulu kunye nezixhobo zothumelo oluphezuluukuphumeza ukonga amandla okubalulekileyo. Ezi motors ziguqula amandla ombane zibe ngamandla oomatshini kunye nelahleko encinci, iqinisekisa ukuba uninzi lwamandla egalelo aqhuba inkqubo yegranulation. Izixhobo zothumelo ezikwinqanaba eliphezulu zikwaphucula ngakumbi obu buchule ngokukhulisa indlela amandla ahamba ngayo ukusuka kwimoto ukuya kumacandelo okusika kunye ne-extrusion. Xa zidityanisiwe, obu buchwepheshe bunciphisa ukusetyenziswa kwamandla ngokubanzi ngexesha lokusebenza. Oku kudityaniswa kwenza isicwangciso esibanzi sokugcina amandla esixhasa ukusetyenziswa kwamandla aphantsi kunye nokusebenza kakuhle kwemveliso. Abavelisi baxhamla kumatyala aphantsi ombane kunye nokusebenza kwezixhobo eziphuculweyo. Ukusetyenziswa kweenjini eziphezulu kunye nezixhobo zothumelo zikwanyusa ixesha lokuphila kwegranulator, ukunciphisa iimfuno zokugcina kunye nexesha lokuphumla.

Ingcebiso:Ukunyuselwa kwiinjini ezikumgangatho ophezulu kunye neenkqubo zothumelo kunokunciphisa ukusetyenziswa kwamandla ukuya kuthi ga kwi-30% xa kuthelekiswa neemodeli ezindala.

Ukuzenzekela ngobukrelekrele kunye nokuPhuculwa kweNkqubo

I-automation ekrelekrele ime kumbindi we-PE yangoku yegranulator yokusingqongileyo. Ezi nkqubo zisebenzisa ulawulo olulumkileyo ukujonga kunye nokulungelelanisa izikhombisi zokusebenza eziphambili ezifana nobushushu, isantya semoto, kunye nokungcangcazela. Abaqhubi banokuthembela kwiimpawu ezifana nezikrini ze-PLC zokuchukumisa, ezivumela uhlengahlengiso oluguqukayo kwiqondo lokushisa kunye nobukhulu bepellet. Izinzwa zibona imiba efana nokuvala ukufa okanye ukugcwala kwemoto, ukunciphisa umngcipheko wexesha lokuphumla elingalindelekanga.

- I-Smart granulator ilawula umkhondo wezalathisi zokusebenza ukulungiselela ukugcinwa kwangaphambili.

- Iisistim ezisekelwe kwi-AI zazisa ucwangciso lolondolozo, njengaxa utshintsha iimela okanye iibheringi zegrisi.

- Iiplatifti ezisekelwe kwifu zivumela ukubeka iliso kude kunye nokuthumela izikhumbuzo zokugcinwa.

- Iingcingo zekhabhinethi yamandla zixhasa ukudibanisa lula kunye nezinye izixhobo.

- Ukuzenzekelayo kunciphisa ukungenelela ngesandla, ukuphucula ukhuseleko nokuthembeka.

- Ukulungiswa kwenkqubo kucokisekileyo iiparamitha zokusebenza, ukulungelelanisa igranulation kunye nokunciphisa inkcitho yamandla.

- Uyilo lwemodyuli luvumela ukwenziwa kwezinto ezahlukeneyo kunye neemfuno zemveliso.

Ubuchule bokuphucula inkqubo bongeza ngakumbi ukusebenza kakuhle kwamandla. Uyilo lomatshini oludityanisiweyo ludibanisa ukukrazula, ukusika, ukukhupha, kunye ne-pelletizing ibe ngumsebenzi omnye oqhubekayo. Le ndlela inciphisa umsebenzi, ixesha, kunye nokusetyenziswa kwamandla. Iindlela zokutyisa ezingaguquguqukiyo zizinzisa ukuhamba kwezinto, zithintela ukwehla nokuphucula umgangatho wemveliso. Iimpawu ezizenzekelayo ezifana nolawulo lokutya okuzenzekelayo, izihluzi zetshaneli ezimbini, kunye nokulungiswa ngokuzenzekelayo kwesantya semela kuqinisekisa imveliso egudileyo nesebenzayo. Iimoto ezonga amandla, iidrive zesantya eziguquguqukayo, kunye neenkqubo zokupholisa eziphambili nazo zinegalelo ekusetyenzisweni okuphantsi kwamandla.

UkuBuyiswa koBubushushu beNkunkuma kunye nokusetyenziswa

Ukubuyiswa kobushushu benkunkuma kubonisa ukuqhubela phambili okukhulu kwi-PE encinci yegranulator yokusingqongileyo. Ngexesha lenkqubo yegranulation, oomatshini bavelisa ubushushu njengemveliso. Endaweni yokuvumela obu bushushu bubaleke, iinkqubo zale mihla ziyabubamba buphinde bubusebenzise. Ubuchwephesha obufana neempompo zobushushu obuphezulu kunye neenkqubo zokugcina ubushushu obufihlakeleyo zisebenzisa izixhobo zokutshintsha isigaba (PCMs) zibuyisela ubushushu obuphantsi kobushushu obuphantsi kwaye buphuculwe ukuze busetyenziswe kwinkqubo yokuvelisa umphunga okanye ukufudumeza indawo. Kwiifektri zokubonisa, iinkqubo zempompo zobushushu ezidibeneyo zifumene ngaphezulu kwe-80% yobushushu benkunkuma, ukunciphisa ukuthembela kubushushu bombane ukuya ngaphantsi kwe-20%. Oku akuphuculi nje ukusebenza kakuhle kwamandla ngokubanzi kodwa kuzisa imbuyekezo eqinileyo yezoqoqosho, ehlala izihlawulela phantsi kweminyaka emithathu. Ukudityaniswa kokugcinwa kobushushu kunye neepompo zobushushu kwenza ukuba kusebenze ngokuqhubekayo kunye nokutshintshwa komthwalo, ukusika ngakumbi iindleko zamandla kunye nokunciphisa ukukhutshwa kwe-CO2.

| Iteknoloji | Umsebenzi | Impembelelo ekuSetyenzisweni kwamandla |

|---|---|---|

| Impompo yobushushu obuphezulu | Ukuphucula ubushushu benkunkuma ukwenzela inkqubo yomphunga | Yehlisa ukufudumeza kombane |

| Ugcino lobushushu obuLatent (PCM) | Igcina kwaye ikhuphe ubushushu njengoko bufuneka | Yenza ukushenxiswa komthwalo |

| Inkqubo yeHybrid | Udibanisa zombini ukusebenza okuphezulu | Ibuyisela i-81.1% yobushushu benkunkuma |

I-PE encinci ye-granulators yokusingqongileyo ibeka umgangatho omtsha wokusebenza kakuhle kwamandla ekuhlaziyweni kweplastiki. Itekhnoloji yabo ehambele phambili yokonga amandla inceda abavelisi banciphise iindleko, baphucule imveliso, kwaye baxhase iinjongo zokusingqongileyo.

Izibonelelo zePE Small Environmental Granulators ngo-2025

Iindleko zokuSebenza eziNcitshisiweyo kunye nokusetyenziswa kwamandla

Abavelisi babona ugcino lweendleko olucacileyo xa besebenzisa iigranulator ze-PE ezincinci zokusingqongileyo. Iimodeli ezipholileyo zomoya zisusa imfuno yamanzi, egcina imali yokucoca amanzi kunye nokugcinwa kwezixhobo. Ezi granulators zisebenzisa amandla amancinci kuneenkqubo zokupholisa amanzi ngenxa yoyilo lwazo olulula kunye nokuphucula ukusebenza kakuhle. Ukugcinwa kuba lula, kwaye umngcipheko wokuqhekeka kwiingxaki zenkqubo yamanzi uyehla. Abanini-zithuthi banokuqhuba aba matshini kwiindawo ezingenamanzi amancinane okanye umoya ongekho mgangathweni, nto leyo egcina imveliso izinzileyo. Ukupholisa okufanayo kuphucula umgangatho wemveliso kwaye kunciphisa inkunkuma.

- Ukusebenza ngokupholisa umoya kuphelisa iindleko zamanzi kunye nokugcinwa okunxulumene noko.

- Ukusetyenziswa kwamandla aphantsi kuthetha amatyala amancinci ombane.

- Isakhiwo esilula sinciphisa iimfuno zokulungisa kunye nexesha lokuphumla.

- Ukusebenza okuzinzileyo kwiindawo ezinzima kuqinisekisa imveliso ethembekileyo.

- Umgangatho ongcono wemveliso ukhokelela kwinkcitho encinci kunye nokusebenza okuphezulu.

Impembelelo yokusingqongileyo kunye nokuNcitshiswa kweCarbon Footprint

Iigranulator ze-PE ezincinci zokusingqongileyo zinceda iinkampani zehlise impembelelo yazo yokusingqongileyo. Banqumla ukukhutshwa kwekhabhoni kunyeukusetyenziswa kwamandla, ukwenza inkqubo yeplastiki ibe luhlaza.

| Uncedo lwendalo esingqongileyo | Iinkcukacha |

|---|---|

| Ukunciphisa ukukhutshwa kweCO2 | I-1.5 yeetoni ze-CO2 ezincitshisiweyo ngetoni nganye yeepellets ezihlaziyiweyo |

| UkuNcitshiswa kokusetyenziswa kwamandla | I-30% yamandla angaphantsi asetyenziswa zigranulator ezintsha ezinesantya esiphantsi |

| UkuNcitshiswa kwengxolo | 20dB amanqanaba asezantsi engxolo |

| UkuPhuculwa kweRayithi yokurisayikilisha | Ukurisayikilisha okuvaliweyo kunciphisa ukusetyenziswa kwemathiriyeli ekrwada |

| Umzekelo we-Case-Automotive | Iitoni ezingama-300 zeplastiki entsha zigcinwa ngonyaka ngokurisayikilishwa kwenkunkuma enkulu |

| Umzekelo weCase – kweZolimo | Umyinge wama-85% woguqulo oluphunyezwe ngamafama aseIndiya asebenzisa iipelitisi ezincinci |

Aba matshini bakwaxhasa uqoqosho lwesetyhula ngokuguqula inkunkuma yeplastiki ibe ziigranuli eziphinda zisetyenziswe. Le nkqubo inciphisa inkunkuma yokulahla inkunkuma kwaye igcina ubutyebi bendalo.

Ukuthotyelwa kunye nokuziqhelanisa neMigangatho yoShishino

I-PE encinci yegranulator yokusingqongileyo inceda iinkampani ukuba zihlangabezane nemithetho engqongqo yokusingqongileyo kwimimandla emininzi. Oomatshini baxhasa ukurisayikilishwa kunye nokunciphisa ukusetyenziswa kwetiphu, okuhambelana neenkqubo zikarhulumente zokungalahli inkunkuma. Iimodeli ezininzi zihlangabezana nemigangatho yezizwe ngezizwe njenge-ISCC PLUS, elandelela ukusetyenziswa kwe-feedstock ezinzileyo kwaye iqinisekisa ukuthotyelwa kweenjongo zentlalo kunye nokusingqongileyo. Uyilo lwabo oluguquguqukayo luhambelana nemisebenzi emikhulu kunye nencinci, inceda amashishini aqhelane nokutshintsha kwemimiselo. Advanced automation kunyeiimpawu zokugcina amandlayenza kube lula ukulandela imithetho emitsha kwizinto ezikhutshwayo kunye nengxolo. Iinkampani ezikuMntla Melika naseYurophu zisebenzisa ezi granulators ukuxhasa iinjongo zoqoqosho lwesetyhula kunye nokuhlangabezana nemigangatho yasekhaya neyehlabathi.

Iigranulator ze-PE ezincinci zokusingqongileyo zifezekisa ukusebenza kakuhle kwamandla ngokusebenzisa uyilo olunesantya esisezantsi, iimpawu ezinokwenziwa ngokwezifiso, kunye nobuchwepheshe bokurisayikilisha obuphambili. Aba matshini banceda amashishini athobe iindleko, anciphise inkcitho, aze axhase uqoqosho olujikelezayo. Iinkampani ezikhetha ezi granulator ziphucula ukuzinza, ukuhlangabezana nemigaqo, kunye nokudala ikamva elicocekileyo.

FAQ

Ingaba i-PE encinci yegranulator yokusingqongileyo iwonga njani amandla?

Igranulator isebenzisa iimotor eziphezulu kunye ne-automation ephezulu. Ezi mpawu zinciphisa ukusetyenziswa kombane kwaye zinciphisa inkunkuma ngexesha lokwenziwa kwegranule yeplastiki.

Ingcebiso:Ukugcinwa rhoqo kunceda ukugcina ukonga amandla kuphezulu.

Ngaba igranulator ingaphatha iintlobo ezahlukeneyo zenkunkuma yeplastiki?

Ewe. Umatshini uxhasa izinto ezahlukeneyo zeplastiki. Abaqhubi banokuhlengahlengisa izicwangciso zohlobo ngalunye, ukuqinisekisa i-granulation engaguqukiyo kunye nomgangatho ophumayo.

Luluphi ugcino olufunwa yigranulator?

Abanini-zithuthi kufuneka bajonge iinjini, izihluzi ezicocekileyo, kwaye bajonge iincakuba zokusika rhoqo. Ulawulo olulula kunye neengxenye zeemodyuli zenza ukugcinwa kwesiqhelo kukhawuleze kwaye kube lula.

Ixesha lokuposa: Jul-17-2025