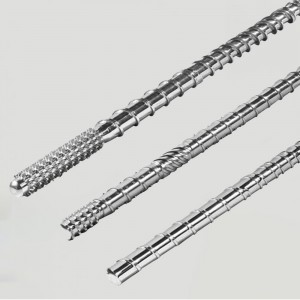

ISikrolo esinye sePlastiki Extruder

Ngophuculo lokwazisa ngokusingqongileyo, ukwenziwa ngokutsha kweplastiki kuye kwaba ngumba oshushu namhlanje.I-screw extruder enye idlala indima ebalulekileyo kwinkqubo yokubuyisela iiplastiki.Ngokuphinda kusetyenziswe inkunkuma yeplastiki, emva kokunyibilika kunye nokukhutshwa, inokwenziwa ibe yimveliso yeplastiki kwakhona.Oku akugcini nje ukusindisa izinto eziluhlaza, kodwa kunciphisa ukungcoliseka kwendalo.

Umgaqo wokusebenza we-screw extruder enye umi ngolu hlobo lulandelayo:

1. Ukutya: amaqhekeza eplastiki okanye umgubo wongezwa kwicandelo lokutya le-screw extruder ngokusebenzisa i-port feed.

2. Ukutya kunye nokunyibilika: I-screw ijikeleza kwi-barrel ukuze iqhube iincinci zeplastiki phambili, kwaye isebenzise ukushisa okuphezulu kunye noxinzelelo oluphezulu ngexesha elifanayo.Njengoko iplastiki ifudunyezwa yi-friction ngaphakathi kwe-screw kunye ne-barrel, iplastiki iqala ukunyibilika kwaye yenze into efanayo.

3. Ukunyusa uxinzelelo kunye nommandla wokunyibilika: intambo ye-screw kancane kancane iba yincinci, yenza indlela yezothutho ibe mxinwa, ngaloo ndlela ikhulise uxinzelelo lweplastiki kwi-barrel, kunye nokufudumeza okuqhubekayo, ukunyibilika kunye nokuxuba iplastiki.

4. I-Extrusion: Kumbhobho osemva kwendawo yokunyibilika, isikrufu siqala ukutshintsha imilo, sityhalela iplastiki etyhidiweyo ukuya kwindawo yokuphuma yomphanda, kwaye sicinezela ngakumbi iplastiki ngomngxuma wokungunda wombhobho.

5. Ukupholisa kunye nokubunjwa: Iplastiki ekhutshiweyo ingena emanzini okupholisa ngomngxuma wokubumba ukuze iphole ngokukhawuleza, ukuze iqiniswe kwaye ibunjwe.Ngokuqhelekileyo, imingxuma yokufa kunye nenkqubo yokupholisa ye-extruder ziyilwe ngokwemilo yemveliso efunekayo.

6. Ukusika kunye nokuqokelela: I-molding extruded ikhutshwe ngokuqhubekayo kwi-mold hole, kwaye emva koko inqunywe ubude obufunekayo, kwaye iqokelelwe kwaye ihlanganiswe ngamabhande okuhambisa okanye ezinye izixhobo zokuqokelela.

1. Ukusetyenziswa kweteknoloji ye-automation

Ngophuhliso oluqhubekayo lwetekhnoloji ye-automation, i-extruders-screw extruders nayo ihlaziywa rhoqo.Inkqubo yokulawula ngokuzenzekelayo inokuqonda ukujonga ixesha lokwenyani kunye nokulungelelaniswa kwemeko eqhubayo ye-extruder, ukuphucula ukusebenza kwemveliso kunye nokuzinza komgangatho.Uyilo oludityanisiweyo kunye nojongano lokusebenza olukrelekrele nalo lwenza kube lula ukuqonda ukusebenza.

2. Imfuno yokukhuselwa kokusingqongileyo okuluhlaza

Ehlabathini, imfuno yokukhuselwa kokusingqongileyo eluhlaza iya ingxamiseka ngakumbi.Ii-extruders ezine-screw enye nazo ziya kuphuhliswa ngendlela ehambelana nokusingqongileyo.Umzekelo, uphuhliso lwemathiriyeli ekrwada yerabha ehambelana nokusingqongileyo kunye nemathiriyeli enokubola, kunye nophando logcino lwamandla amatsha kunye nokunciphisa ukusetyenziswa kwetekhnoloji yindlela yophuhliso lwexesha elizayo.