Ukukhetha i-extruder efanelekileyo kubalulekile kwimveliso esebenzayo. I-screw extruders enye, ebambe ngaphezulu kwe-40% yesabelo semarike yehlabathi ngo-2023, ihlala idumile kwizicelo ezilula. Nangona kunjalo, njengoko imfuno ye-automation kunye nemveliso elula ikhula, ukuqonda umahluko phakathi kwe-twin screw extruder kunye neqabane layo,i-extrusion twin screw, iqinisekisa ukusebenza okungcono kunye neendleko ezifanelekileyo. Ukongeza, kwizicelo ezifuna izinto ezahlukeneyo, iumatshini wokubumba isikhonkwanekwayeumatshini wokutofa ngokujijazibonelela ngezisombululo eziphambili ezijongene neemfuno ezahlukeneyo zemveliso.

Isikruru esiNye Extruder Overview

Inkcazo kunye nokusebenza

A isikrufu esinye isikrufuIbonisa isikrufu esinye esijikelezayo esigcinwe ngaphakathi kwebhari egqunywe ngubushushu. Olu luyilo luvumela ulawulo oluchanekileyo kwiiparamitha ezinje ngeqondo lobushushu, isantya se-screw, kunye noxinzelelo lomphanda. Ezi zicwangciso zihlengahlengiswa ngokusekelwe kwizinto ezicutshungulwayo, ziqinisekisa ukunyibilika ngokufanelekileyo kunye nokubunjwa. Ukulula kwendlela yayo kuyenza ibe lukhetho oluthembekileyo kumashishini amaninzi, ngakumbi xa kusetyenzwa i-thermoplastics okanye ezinye izinto ezinokuziphatha okuqikelelweyo.

Izicelo eziqhelekileyo

I-screw extruders enye isetyenziswa ngokubanzi kuwo wonke amashishini ahlukeneyo. Nantsi ukujonga ngokukhawuleza kwizicelo zabo:

| Ishishini | Inkcazo yesicelo | Uqikelelo lokuKhula kweMarike |

|---|---|---|

| Iiplastiki | Ukunyibilika kunye nokwenza i-thermoplastics, eqhutywa ngokunyuka kwemveliso ye-PE kunye ne-PP. | I-CAGR emalunga ne-4-5% ukuya ku-2030 |

| Ukulungiswa kokutya | Ukuvelisa ukutya okugayiweyo okufana nesnacks kunye neecereals. | Imarike yehlabathi kulindeleke ukuba ifikelele ngaphezulu kwe-75 yeebhiliyoni zeedola ngo-2026 |

| Ukudibanisa irabha | Ukuxuba kunye nokubumba iikhompawundi zerabha zamatayara kunye nokusetyenziswa kweemoto. | Ukuveliswa kwamatayara kwihlabathi kuqikelelwa ukuba kudlule iiyunithi ezibhiliyoni ezi-2 ngonyaka ngo-2025 |

| I-Biomedical | Imveliso ye-Biopolymer yokupakishwa okuzinzileyo kunye nezixhobo zonyango. | Imarike ekhulayo kunye nenkqubela phambili kwitekhnoloji ye-extrusion. |

Iingenelo

I-screw extruders enye ibonelela ngeenzuzo ezininzi ezenza zibe lukhetho oludumileyo:

- Iindleko-Ukusebenza: Uyilo lwazo olulula lukhokelela kukutyalomali olusezantsi kunye nokugcinwa kweendleko.

- Ulawulo loxinzelelo: Abalawuli abaphezulu banokunciphisa ukuhluka koxinzelelo nge-20-40%, kuxhomekeke kwi-viscosity yezinto. Oku kuqinisekisa umgangatho wemveliso ongaguqukiyo.

- Ukusebenziseka lula: Iimpawu zokuzilungisa zenza lula ukusebenza, ukuphelisa imfuno yohlengahlengiso lwezandla.

- Ukuguquguquka: Baphatha uluhlu olubanzi lwemathiriyeli, ezenza ukuba zilungele usetyenziso olwahlukeneyo.

Ukulinganiselwa

Ngelixa i-screw extruders enye inezinto ezininzi, zinemingeni ethile:

| Umngeni | Inkcazo |

|---|---|

| Ukuxutywa kwezinto ezilinganiselweyo | Ukufezekisa ukusabalalisa okufanayo kwezongezo okanye iifayili kunokuba nzima. |

| Imiba yokuNxina koxinzelelo | Iiyantlukwano kwi-feedstock zihlala zikhokelela ekuguquguqukeni koxinzelelo. |

| Imiqobo yokuHamba kwezinto | Izinto eziphezulu ze-viscosity zingenakuzalisa ukufa ngokupheleleyo, okubangelwa iimveliso eziphosakeleyo. |

Ngaphandle kwale mida, i-screw extruders enye ihlala iyinketho ethembekileyo kwizicelo ezilula. Kwiinkqubo ezintsonkothileyo, i-Twin Screw Extruder inokuba yinto efanelekileyo ngenxa yobuchule bayo bokuxuba obuphezulu.

I-Twin Screw Extruder Overview

Inkcazo kunye nokusebenza

I-twin screw extruder isebenzisa izikrufu ezibini ezidibanisayo ezijikelezayo ngaphakathi komphanda ukucubungula imathiriyeli. Olu luyilo luvumela ukuxubana okungcono, ukuxova, kunye nokucheba izixhobo xa kuthelekiswa neenkqubo zesijija esinye. I-screws inokujikeleza kwicala elifanayo (i-co-rotating) okanye i-counter-rotation (i-counter-roting), kuxhomekeke kwisicelo. Oku kuguquguquka kwenza kube yinto efanelekileyo yokuphatha izinto ezinzima okanye iinkqubo ezifuna ulawulo oluchanekileyo kwiqondo lokushisa kunye noxinzelelo.

Izicelo eziqhelekileyo

I-Twin screw extruders isetyenziswa kakhulu kumashishini afuna ukusebenza okuphezulu kunye nokuguquguquka. Abanyeizicelo eziqhelekileyoziquka:

- Ukudibanisa

- Extrusion

- Ukurisayikilisha

- Pelletizing

Ezi zicelo zigxininisa amandla e-extruder ukuphatha izinto ezahlukeneyo kunye neenkqubo ngokufanelekileyo.

Iingenelo

I-Twin screw extruders zibonelela ngeenzuzo ezininzi ezenza ukuba ziukhetho olukhethiweyokwimisebenzi entsonkothileyo:

- Ukuxutywa okuPhuculweyo: Izikrufu ze-intermeshing ziqinisekisa ukuhanjiswa okufanayo kwezongezo kunye nezihluzi.

- Ukuguquguquka: Bangakwazi ukucubungula uluhlu olubanzi lwezinto eziphathekayo, kubandakanywa i-viscosity ephezulu kunye ne-heat-sensitive compounds.

- Ukuthotyelwa koMgaqo: Uyilo olukwinqanaba eliphezulu luhlangabezana nokukhutshwa okungqongqo kunye nemigangatho yokhuseleko lwemathiriyeli, efana ne-REACH kunye ne-ASTM International benchmarks.

| I-Metric/Standard | Inkcazo |

|---|---|

| Imimiselo yokukhutshwa | Iibhokisi zegiya ze-twin-screw extruder zinciphisa ukuvuza kweoyile kwaye zihambelane nemigaqo engqongqo yokukhutshwa ngamatywina aphezulu kunye nezithambiso zokwenziwa. |

| Ukuthotyelwa kwezinto | Ukuthotyelwa kwemithetho yezempilo kunye nokhuseleko efana ne-REACH iqinisekisa ukusetyenziswa kwezinto ezingenayo ityhefu ekusetyenzweni kokutya kunye namayeza. |

| ImiGangatho yokuSebenza | Uyilo lwe-Gearbox luvavanywa ngokungqongqo ngokuchasene nebenchmarks ezibekwe yimibutho efana ne-ASTM International, ekhokelela kuphuculo lokuqhuba kwe-thermal kunye nokumelana noxinzelelo. |

Ukulinganiselwa

Ngelixa i-twin screw extruders igqwesa ekusebenzeni, iza nemiceli mngeni embalwa:

- Iindleko zokuqala eziPhezulu: Uyilo oluphambili kunye neteknoloji ikhokelela kutyalo-mali lwangaphambili.

- Ulungiso oluntsonkothileyo: Inkqubo entsonkothileyo ifuna ulwazi olukhethekileyo lokulungiswa kunye nokugcinwa.

Ngaphandle kwale mida, i-twin screw extruders ihlala ilukhetho oluphezulu kumashishini afuna ukuchaneka kunye nokusebenza kakuhle.

Umahluko oPhambili phakathi kweSikruru esiNye kunye nesiXhobo seTwin

Uyilo kunye noBuchule

Iuyilo of single kunye namawele extruders screwzihluke kakhulu, zichaphazela ukusebenza kwazo. I-screw extruder enye sisebenzisa isikrufu esinye esijikelezayo ngaphakathi kombhobho, sixhomekeke kubunzulu betshaneli ukulawula ukuhamba kwezinto kunye nokufikelela kwimveliso oyifunayo. Le ndlela ichanekileyo yenza kube lula ukusebenza kodwa inciphisa amandla ayo okuxuba imathiriyeli ngokufanelekileyo.

Kwelinye icala, i-twin screw extruders ifaka izikrufu ezibini ezidibanisayo ezijikeleza nokuba kwicala elinye (ezijikelezayo) okanye amacala achaseneyo (i-counter-rotating). Olu luyilo luvumela ukuxuba okungcono, ukuxova, kunye nokucheba izinto. Izikrufu zamawele zinokufaka i-chear ephezulu ngokunyuswa okuncinci, enkosi kwiinguqu ezininzi kubunzulu betshaneli. Oku kubenza balungele iinkqubo ezintsonkothileyo ezifana nokudibanisa okunyibilikayo kunye nokusasaza izihluzi eziqinileyo.

I-twin screw extruders nayo iyagqwesa ekuzicocini, ukunciphisa ixesha lokuphumla ngexesha lokutshintsha kwezinto-isici sokunqongophala kwe-screw systems.

Izakhono zokuLungiselela izinto

Xa kuziwa ekusetyenzweni kwezinto, i-screw extruders enye ifanelekile kwizicelo ezisisiseko ezifana ne-plastiki extrusion kunye nokudibanisa okulula. Baphatha i-thermoplastics, i-rubbers, kunye ne-fillers ngokufanelekileyo kodwa bayazabalaza kunye ne-viscosity ephezulu okanye izinto ezithintela ukushisa. Ukukwazi kwabo ukuxuba okulinganiselweyo kwenza ukuba bangabikho kulungelelanise ukwakheka okudinga ukusabalalisa okongeziweyo okufanayo.

I-twin screw extruders, nangona kunjalo, iyakhanya ekuphatheni izinto ezahlukeneyo. Banikezela ngezakhono ezigqwesileyo zokuxuba, zibenza balungele ukubandakanya izongezo okanye izihluzi kwiindlela ezintsonkothileyo. Ukukwazi kwabo ukulungelelanisa iiparitha zokucubungula kuqinisekisa ukuguquguquka, ukuvumela abavelisi ukuba basebenze kunye ne-high-viscosity compounds kunye nezixhobo ezithintekayo ukushisa. Ukongeza, izikrufu ezingamawele zigqwesa ekususeni igassing kunye ne-devolatilization, ziqinisekisa ulawulo olungqongqo lomgangatho wezinto eziguquguqukayo.

| Uphawu | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Ukuqhuba izakhono | Ifanelekile kwisiseko seplastiki ye-extrusion kunye nokudibanisa okulula. | Iphatha uluhlu olubanzi lwemathiriyeli enokuxuba okuntsonkothileyo. |

| Ukuphumelela kunye nokusebenza ngokufanelekileyo | Imveliso ephantsi, ilungele imveliso ekujoliswe kuyo ephantsi. | Ukusebenza okuphezulu, okukhokelela kumgangatho ongcono wemveliso. |

| Ukuguquguquka kunye nokuguquguquka | Ukuguquguquka okusezantsi, ukusebenza okulula, kungabizi kakhulu ukwenza. | Ukuguquguquka okuphezulu, iiparamitha zokulungisa ezilungelelanisiweyo. |

| Izinto eziphathekayo | Yamkelekile kwi-thermoplastics, i-rubbers, kunye ne-fillers. | Ukuphuculwa kokuphathwa kwezinto eziyinkimbinkimbi kunye nezixhobo eziphezulu ze-viscosity. |

| Ukuxuba Ukukwazi | Kwanele kwimixube elula. | Ukuxuba okugqwesileyo, kukulungele ukubandakanya izongezo. |

| Ukukhupha igassing kunye ne-Devolatilization | Ubunakho obulinganiselweyo, akufanelekanga ukususwa okuguquguqukayo. | Isakhono esilungileyo, esilungele ulawulo olungqongqo lomgangatho. |

Ukusebenza kunye noKucikoza

Ukusebenza kunye nokusebenza kakuhle zizinto ezibalulekileyo xa ukhetha phakathi kwezi zikhupha. I-screw extruders enye iphuhlisa ukuya kwisantya esiphezulu kunye nokusebenza kakuhle, kubenza bafanelekele usetyenziso oluqhelekileyo. Nangona kunjalo, ukuziphatha kwabo okulungileyo kunokukhokelela kumazinga aphezulu e-scrap ngenxa yomgangatho wemveliso ongaguqukiyo.

I-twin screw extruders, ngokuchaseneyo, ihambisa ukusebenza okuphezulu ngokudibanisa kunye ne-extrusion esebenzayo. Amazinga abo aphezulu okuphuma kunye nomgangatho ongcono wemveliso unciphisa amazinga e-scrap, okwenza ukuba asebenze ngokufanelekileyo kwimiqulu enzima. Ngokomzekelo, izikrufu zamawele zisebenza ngokukodwa ekusebenzeni i-polyethylene (PE), iqinisekisa iziphumo ezihambelanayo kunye nokonga amandla.

Ngelixa izikrufu ezingatshatanga zinoqoqosho kwimisebenzi elula, izikrufu ezingamawele zibonelela ngobuchule obungcono bexesha elide kwiimfuno ezizodwa.

Iindleko kunye nokuntsonkotha

Iindleko kunye nobunzima buhlala bunefuthe kwisigqibo phakathi kwe-extruders enye kunye newele. Iinkqubo zesikrufu esinye zinoqoqosho ngakumbi, kunye notyalo-mali olusezantsi kunye nokugcinwa kweendleko. Uyilo lwabo olulula lubenza bafikeleleke kumashishini amancinci naphakathi (ii-SME) kwaye kulula ukusebenza.

I-Twin screw extruders, nangona kunjalo, iza neendleko eziphezulu zangaphambili ngenxa yoyilo oluphezulu kunye netekhnoloji. Iindleko zolondolozo nazo zibalulekile, njengoko indlela yazo entsonkothileyo ifuna ulwazi olukhethekileyo lolungiso. Ngaphandle kwale mingeni, izikrufu ezingamawele zibonelela ngembuyekezo yexesha elide engcono kumashishini afuna ukuchaneka kunye nokuguquguquka.

| Umba | I-Twin Screw Extruders |

|---|---|

| Utyalo-mali lokuqala | Iindleko eziphezulu zotyalo-mali lokuqala |

| Iindleko zoLondolozo | Iindleko eziqhubekayo zokulungisa |

| Impembelelo yeMarike | Inciphisa ukwandiswa kweemarike zee-SMEs |

| Izithintelo Zokukhuliswa Kwabanye | Iindleko eziphezulu zidala imiqobo yokwamkelwa kobuchwephesha obutsha |

Abavelisi kufuneka bavavanye le miba ngononophelo ukufumanisa ukuba yeyiphi i-extruder ehambelana neenjongo zabo zemveliso kunye nohlahlo lwabiwo-mali.

Izinto Emaziqwalaselwe Xa Ukhetha

IiMfuno zokuSebenza kunye nezinto eziphathekayo

Inyathelo lokuqala ekukhetheni i-extruder elungileyo kukuqonda isicelo sakho kunye nezixhobo oza kuziqhuba. Amashishini ahlukeneyo aneemfuno ezizodwa, kwaye i-extruder kufuneka ihambelane nezo mfuno. Umzekelo, i-screw extruders enye isebenza kakuhle kwizicelo ezithe ngqo ezifana ne-plastiki extrusion. Nangona kunjalo, amashishini afana namayeza okanye ukwenza iimoto ahlala efuna ubuchule obuphezulu be-twin screw extruder.

Imiba ephambili ekufuneka iqwalaselwe ibandakanya:

- Ukuphatha Izinto: Ukuhamba kwezinto ezihambelanayo kubalulekile ukuphepha ukuphazamiseka okanye iziphene ngexesha lemveliso.

- Ulawulo lobushushu: Ukugcina amaqondo obushushu afanelekileyo kuqinisekisa ukuba izixhobo azithobi kwaye iimveliso zokugqibela ziyahlangabezana nemigangatho yomgangatho.

- Die Design Complexity: Iiprofayili ezintsonkothileyo zifuna uyilo oluchanekileyo lokufa, olufuna ubungcali kunye nobunjineli obuchanekileyo.

Ubusazi? I-Aluminiyam ye-6xxx-series extrusions ithandwa kwizakhiwo zeemoto ngenxa yokuguquguquka kunye namandla. Nangona kunjalo, ukukhetha i-alloy efanelekileyo kunye nomsindo kubalulekile ukuhlangabezana neenkcukacha zepropathi enzima.

Kwizicelo ezikhethekileyo, ezifana ne-nano-compounding okanye imveliso yepolymer ephezulu, i-twin screw extruder inika ukuchaneka kunye nokuguquguquka okufunekayo ukusingatha iifomyula ezinzima. Ukukwazi ukuxuba izongezo ngokulinganayo kunye nokugcina umgangatho ongaguqukiyo kwenza kube lukhetho oluphezulu kumashishini afunayo.

Uhlahlo lwabiwo-mali kunye nezithintelo zeendleko

Uhlahlo lwabiwo-mali lunendima ebalulekileyoekugqibeni phakathi kweentlobo ze-extruder. Ngelixa i-screw extruders enye ifikeleleka ngakumbi ngaphambili, i-twin screw extruders ihlala ibonelela ngexabiso lexesha elide elingcono kwizicelo ezinzima.

| Uhlobo lobungqina | Iinkcukacha |

|---|---|

| Ukuqwalaselwa kweendleko | Iinkampani zamachiza zihlawula iipremiyamu ze-20-35% kwiiprofayili ezichanekileyo ze-thermal. |

| Imiqobo yohlahlo lwabiwo-mali | Abaphuhlisi bokongeza ukutya bakhetha iinkqubo ezihlaziyiweyo phantsi kwe-150,000 yeedola. |

| IiNdlela zeMarike | Abavelisi baseTshayina banikezela nge-60-70% yokonga iindleko kwiimodeli zaseYurophu. |

| Iindleko zizonke zobunini | Iidrives zokonga amandla zicuthe iindleko zokusebenza nge-18-22% kwiminyaka emihlanu. |

| Ulindelo lwe-ROI | IiLebhu zijolise kwii-extruders zexabiso eliphakathi ($120,000-$180,000) ukonga amandla. |

Iindleko zempahla ekrwada nazo zinefuthe kuhlahlo lwabiwo-mali. Ngokomzekelo, amaxabiso e-aluminium angenza i-60-70% yeendleko ze-extrusion zizonke. Ukulawula oku kuguquguquka, abavelisi bahlala besebenzisa izicwangciso ezifana nezivumelwano zexesha elide okanye amanyathelo okuhlaziya.

Ingcebiso: Ukuba usebenza ngohlahlo lwabiwo mali olungqingqwa, qwalasela iinkqubo ezihlaziyiweyo okanye iimodeli ezonga amandla ukunciphisa iindleko ngaphandle kokubeka esichengeni ukusebenza.

Ukwenziwa komsebenzi kunye neziphumo ezilindelekileyo

Ukulindela ukusebenza kuyahluka ngokuxhomekeke kwishishini kunye nesicelo. I-screw extruders enye ilungele imisebenzi esemgangathweni kunye neemfuno ezisezantsi zokuphuma. Nangona kunjalo, amashishini afuna ukuchaneka okuphezulu kunye nemveliso, njengokwenziwa kwezixhobo zonyango, azuza kwiubuchule obuphezulu be-twin screw extruders.

| Uphawu | Isikruru esiNye Extruder | I-Twin Screw Extruder |

|---|---|---|

| Umsebenzi | Ngaphantsi, ilungele imveliso encinci. | Ephakamileyo, ilungele imisebenzi emikhulu. |

| Ukuxuba Ukukwazi | Incinci, yanele kwimixube elula. | Igqwesileyo, iqinisekisa ukuhanjiswa okongeziweyo okufanayo. |

| Ubushushu obufanayo | Okusisiseko, kunokwahluka kwiindawo zomphanda. | Ukufana okuqinisekisiweyo, okubalulekileyo kwizicelo zonyango. |

Umzekelo, i-92% yabavelisi bezixhobo zonyango bafuna ukufana kweqondo lokushisa eliqinisekisiweyo kuzo zonke iindawo zemibhobho. Oku kuqinisekisa umgangatho wemveliso ongaguqukiyo kunye nokuthotyelwa kwemigangatho yoshishino engqongqo.

Inyani eyonwabileyo: I-twin screw extruders iyagqwesa ekuphatheni izixhobo ezingevani nobushushu njengePCL, enkosi kwiinkqubo zazo zokupholisa eziphucukileyo kunye namaxesha otshintsho olukhawulezayo.

Ugcino kunye Nobomi obude

Ukugcinwa kunye nokuphila ixesha elide kubalulekile xa uvavanya i-extruders. I-screw extruders enye ilula ukuyigcina ngenxa yoyilo lwazo oluthe ngqo. Lukhetho olukhulu kumashishini anobuchwephesha obulinganiselweyo.

I-twin screw extruders, ngelixa inzima ngakumbi, inikezela ngeempawu ezifana nezakhono zokuzicoca ezinciphisa ixesha lokuphumla ngexesha lokutshintsha kwezinto. Oku kubenza babe lukhetho olungcono kumashishini aneshifti zemveliso rhoqo.

Ukwandisa ubomi obude, qwalasela ezi zinto:

- Ukuntsonkotha koYilo: Uyilo olulula kulula ukulugcina kodwa lusenokungabi neempawu eziphambili.

- Ukukhetha Izinto: Izinto ezihlala ixesha elide zandisa ubomi be-extruder.

- Ukusebenza kakuhle kwamandla: Iimodeli ezineedrive ezisebenza ngamandla zinciphisa ukuguga kunye nokukrazula ixesha.

Ingcebiso yePro: Ukugcinwa rhoqo kunye nokusetyenziswa kwezinto ezikumgangatho ophezulu kunokwandisa kakhulu ubomi be-extruder yakho, ukuqinisekisa imbuyekezo engcono kutyalo-mali.

Iindleko kunye noLondolozo lweziphumo

Utyalo-mali lokuqala

Bobabini abangatshatanga kunyeamawele Scruders extruderszifuna utyalo-mali olubalulekileyo lwangaphambili. Oku kunokuba ngumqobo kumashishini amancinci naphakathi (SMEs) ajonge ukwamkela obu buchwepheshe. I-twin screw extruders, kunye noyilo lwazo oluphambili kunye nesakhono, zihlala zisiza nethegi yexabiso eliphezulu xa kuthelekiswa neenkqubo zesijija esinye. Ukongezelela, ukuntsonkotha kwaba matshini kufuna abantu abanobuchule, nto leyo eyongeza kwiindleko zokuqala.

Kumashishini asebenza kwiimarike ezingevani namaxabiso, obunye ubuchwephesha bokwandisa ngexabiso eliphantsi bunokubonakala bunomtsalane. Nangona kunjalo, ukukhetha imodeli ethembekileyo kunokunciphisa ukuhla kwexabiso kwaye kuqinisekise ixabiso elingcono lexesha elide.

ULondolozo Lwexesha elide

Ukuba ne-extruder kubandakanya okungaphezulu nje kokuthenga okokuqala. Iindleko zexesha elide zibandakanya ukugcinwa kunye neendleko zokusebenza. Ukwenziwa kweenkonzo rhoqo, kufana nokugcina isithuthi sisemgangathweni, kubalulekile ukunqanda ukuphazamiseka kwemveliso. Ukungahoywa kwesondlo kunokukhokelela ekulungiseni okubizayo kunye nexesha lokunciphisa.

- Iingqwalasela eziphambili kulondolozo:

- Ukuhlolwa okuqhelekileyo ukuchonga ukuguga.

- Ukutshintshwa kwangexesha kwamalungu ukugcina ukusebenza kakuhle.

- Ukuthambisa okufanelekileyo ukunciphisa ingxabano kunye nokwandisa ubomi.

Ukutyala imali ekugcinweni rhoqo akuqinisekisi ukusebenza ngokutyibilikayo kodwa kwandisa ixesha elide lomatshini.

Ukusebenza kakuhle kwamandla

Ukusebenza kakuhle kwamandlaidlala indima ebalulekileyo ekunciphiseni iindleko zokusebenza. Uphononongo oluthelekisa izikrufu zesikruru ezingatshatanga kunye nezimbini ziqaqambisa umahluko kusetyenziso lwamandla.

| Uhlobo lobungqina | Inkcazo |

|---|---|

| Idatha yokuSetyenziswa kwamandla | Iimodeli zamandla zibonisa ukwahluka kusetyenziso lwamandla phakathi koyilo lwe-extruder. |

| Iiparamitha zokuSebenza | Ukulungelelanisa iiparamitha ezifana nezithintelo zokufa kunempembelelo ekusebenzeni kwamandla. |

| Uthelekiso lwe-SEC | Amaxabiso aKhethekileyo okusetyenziswa kwamandla (SEC) abonisa umahluko osebenzayo. |

Ukuphucula iiparamitha zokusebenza kunokunciphisa kakhulu ukusetyenziswa kwamandla, okwenza ii-extruders zibe neendleko ezisebenzayo ngokuhamba kwexesha.

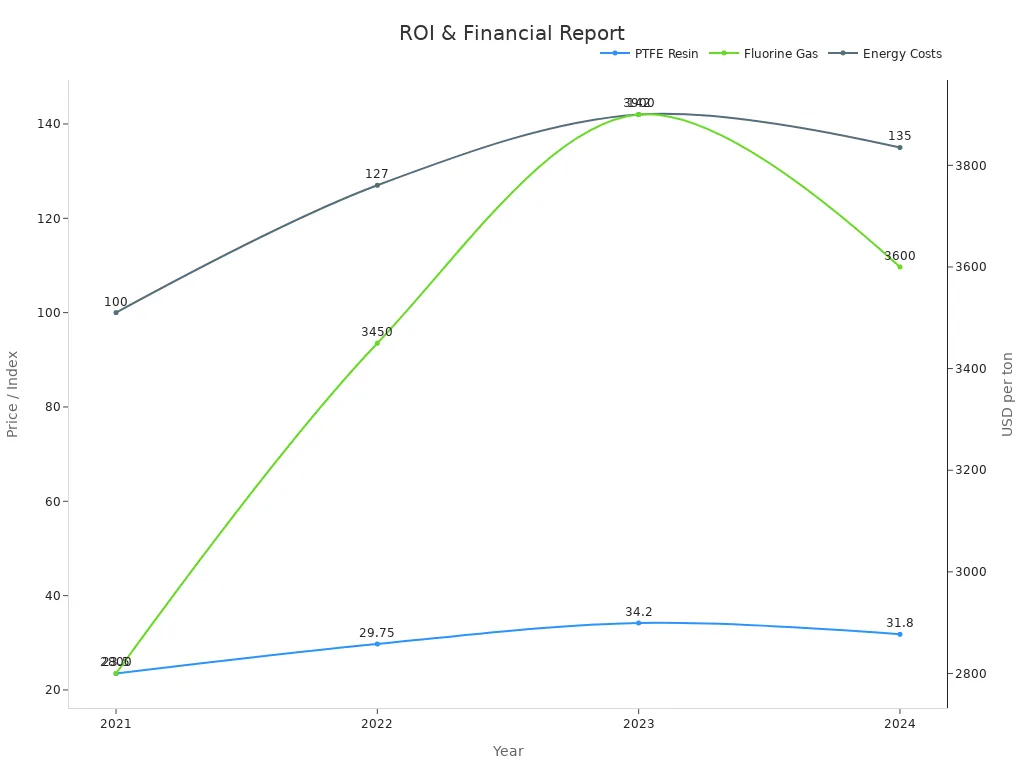

Buyela kuTyalo-mali

Imbuyekezo kutyalo-mali (i-ROI) ye-extruders ixhomekeke kwizinto ezifana nokunciphisa inkunkuma yezinto eziphathekayo, ukonga amandla, kunye nokusebenza kakuhle kwemveliso. Ukuphucula kwimodeli esebenzayo kunokunciphisa ixesha le-ROI, okwenza kube lutyalo-mali olufanelekileyo.

| Metric | Ukuphucula kwangaphambili | Emva kokuPhucula | Uphuculo |

|---|---|---|---|

| Inkunkuma yezinto eziphathekayo | 12% | 6.5% | 45.8% Ukunciphisa |

| Ukusetyenziswa kwamandla/kg | 8.7kWh | 6.2 kWh | 28.7% Ulondolozo |

| Ixesha le-ROI | 5.2 Iminyaka | 3.8 Iminyaka | 26.9% ngokukhawuleza |

Ngokugxininisa ekusebenzeni kakuhle kunye nokugcinwa rhoqo, amashishini anokufikelela kwi-ROI ngokukhawuleza kunye nokugcinwa kwexesha elide.

I-screw extruders enye isebenza kakuhle kwimisebenzi ethe tye, inika ukufikeleleka kunye nokulula. I-Twin screw extruders, kwelinye icala, igqwesa kwiinkqubo ezintsonkothileyo kunye nobuchule babo bokuxuba obuphezulu.

Ingcebiso: Soloko uthelekisa ukhetho lwakho lwe-extruder kwiimfuno zakho eziphathekayo kunye nohlahlo lwabiwo-mali. Ukugcinwa kwexesha elide kunye neendleko zokusebenza kunokuchaphazela kakhulu ukusebenza kakuhle kunye nenzuzo.

FAQ

Ngowuphi umahluko ophambili phakathi kwe-extruders enye kunye ne-twin screw?

I-screw extruders enye ilula kwaye ineendleko, ngelixaamawele Scruders extrudersnikezela ngokuxutywa okungcono kwaye uphathe izinto ezintsonkothileyo ngokufanelekileyo.

Ngawaphi amashishini axhamla kakhulu kwi-twin screw extruders?

Amashishini afana namayeza, iimoto, kunye nokulungiswa kokutya zixhomekeke kwi-twin screw extruders ngokuchaneka kwazo, ukuguquguquka, kunye nokukwazi ukuphatha imixube entsonkothileyo.

Ndingazinciphisa njani iindleko zokugcinwa kwe-extruder yam?

Ukuhlolwa rhoqo, ukutshintshwa kwenxalenye ngexesha, kunye nokuthambisa okufanelekileyo kunceda ukwandisa ubomi be-extruder yakho kunye nokunciphisa iindleko zokulondolozwa.

Ingcebiso: Ngalo lonke ixesha ulandela izikhokelo zokulondolozwa komenzi ukunqanda ixesha lokuphumla elingalindelekanga kunye nolungiso olubiza imali eninzi.

Ixesha lokuposa: Apr-30-2025