Isikruru umgqomo wokuvuthela ifilimu yePP/PE/LDPE/HDPE

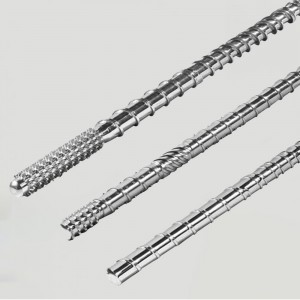

I-Screw Design: Isikrufu sefilimu evuthelweyo extrusion ngokuqhelekileyo siyilwe njenge "grooved feed" screw. Ineenqwelomoya ezinzulu kunye neegrooves ngobude bayo ukwenza lula ukunyibilika kwe-resin, ukuxuba, kunye nokuhambisa. Ubunzulu benqwelomoya kunye nepitch inokwahluka ngokuxhomekeke kwisixhobo esithile esisetyenzwayo.

Umqobo wokuxuba iCandelo: Izikrufu zefilimu ezivuthelweyo zihlala zinecandelo lokuxuba umqobo kufutshane nesiphelo sesikrufu. Eli candelo linceda ukuphucula ukuxutywa kwepolymer, ukuqinisekisa ukunyibilika okufanayo kunye nokusabalalisa izongezo.

I-High Compression Ratio: I-screw idla ngokuba ne-high compression ratio yokuphucula i-homogeneity yokunyibilika kunye nokubonelela nge-viscosity efanayo. Oku kubalulekile ekufezekiseni uzinzo oluhle lweqamza kunye nomgangatho wefilimu.

Ukwakhiwa komphanda: Umphanda ngokuqhelekileyo wenziwe ngentsimbi ekumgangatho ophezulu we-alloy kunye nonyango olufanelekileyo lobushushu ukwenzela ukuxhathisa okugqwesileyo kunye nokuqina. Imiphanda ye-nitriding okanye ye-bimetallic nayo ingasetyenziselwa ukomeleza ukuxhathisa ukunxitywa kubomi obude benkonzo.

Inkqubo yokupholisa: Imigqomo ye-Screw ye-extrusion yefilimu evuthelweyo ihlala ibonakalisa inkqubo yokupholisa ukulawula ubushushu kunye nokuthintela ukutshisa ngexesha lenkqubo yokukhupha.

Iimpawu eziKhethekileyo: Ngokuxhomekeke kwiimfuno ezithile, iimpawu ezongezelelweyo ezifana ne-melt pressure transducer okanye i-sensor yeqondo lokushisa elinyibilikayo linokufakwa kwi-screw barrel ukubonelela ngokubeka iliso kunye nokulawula amandla.

Kubalulekile ukubonisana nomenzi obekekileyo okanye umboneleli wemiphanda ukuze uqinisekise ukuba ufumana uyilo olufanelekileyo lombhobho wokuvuthela kwisicelo sakho sefilimu yePP/PE/LDPE/HDPE. Banokubonelela ngeengcebiso zeengcali ezisekelwe kwiimfuno zakho ezithile zemveliso, iimpawu zezinto eziphathekayo, kunye neemfuno ezilindelekileyo zemveliso.